12685c3176a93eb4f89cd6ff3543d9d2.ppt

- Количество слайдов: 89

Electronic Soft Starters for Marine & Offshore Applications LNG Off-shore 1 Passenger Ship Container (Hamburg Express) FPSO Support Vessel Navy

Electronic Soft Starters for Marine & Offshore Applications LNG Off-shore 1 Passenger Ship Container (Hamburg Express) FPSO Support Vessel Navy

About Solcon § Established in 1977, Solcon is designing, manufacturing and marketing soft starters, protection relays and control systems. § Solcon provides the world’s most comprehensive line of Low Voltage (LV) and Medium Voltage (MV) Soft Starters § 40, 000 installations since 1977 in Industrial, Marine and Offshore Applications. 2

About Solcon § Established in 1977, Solcon is designing, manufacturing and marketing soft starters, protection relays and control systems. § Solcon provides the world’s most comprehensive line of Low Voltage (LV) and Medium Voltage (MV) Soft Starters § 40, 000 installations since 1977 in Industrial, Marine and Offshore Applications. 2

About Solcon § Assembly plants in Germany, Korea, Taiwan, USA and Canada. Worldwide Service centers. § Supplying to the largest electrical contractors and shipyards, Solcon is the largest supplier of soft starters for the marine industry. TOSHIBA 3 Rolls Royce

About Solcon § Assembly plants in Germany, Korea, Taiwan, USA and Canada. Worldwide Service centers. § Supplying to the largest electrical contractors and shipyards, Solcon is the largest supplier of soft starters for the marine industry. TOSHIBA 3 Rolls Royce

Soft Starters for Marine & Offshore Applications Solcon offers the most comprehensive line of soft starters v - LV SST up to 3 MW / 1000 V v - MV SST up to 50 MW / 15 KV v We offer: v - Vast experience in Marine & Offshore Applications (see Reference List) v - Special software to reduce inrush current & voltage drop v - Heavy duty products, easy to install, friendly operation v - Marine Approvals v About 40% of our sales are to the Marine & Offshore Industries v Solcon starters are used by major marine companies in Europe & Asia v Service centers in many countries 4

Soft Starters for Marine & Offshore Applications Solcon offers the most comprehensive line of soft starters v - LV SST up to 3 MW / 1000 V v - MV SST up to 50 MW / 15 KV v We offer: v - Vast experience in Marine & Offshore Applications (see Reference List) v - Special software to reduce inrush current & voltage drop v - Heavy duty products, easy to install, friendly operation v - Marine Approvals v About 40% of our sales are to the Marine & Offshore Industries v Solcon starters are used by major marine companies in Europe & Asia v Service centers in many countries 4

M. V. Soft Starters HRVS-DN The HRVS-DN MV Soft Starters v Comprehensive line 60 -2500 A, 2300 -15000 V v Designed for generator supply (Pgen / Pmotor ≈1. 6) v Low initial current ( ≈0. 7*In) and voltage drop (<100 V @6600 V) v Advanced Motor Protection Package v Easy commissioning and maintenance, field testing with a L. V. motor v Patent pending - Wireless SCR Firing System v Patent pending – Electronic Potential Transformer (EPT) v Fiber optic control v Meets “Partial Discharge” test requirements v Friendly operation, Multi Languages LCD - English, German, French, Spanish v Communication: MODBUS, PROFIBUS and others v Chassis or cabinet type, various options are available 5

M. V. Soft Starters HRVS-DN The HRVS-DN MV Soft Starters v Comprehensive line 60 -2500 A, 2300 -15000 V v Designed for generator supply (Pgen / Pmotor ≈1. 6) v Low initial current ( ≈0. 7*In) and voltage drop (<100 V @6600 V) v Advanced Motor Protection Package v Easy commissioning and maintenance, field testing with a L. V. motor v Patent pending - Wireless SCR Firing System v Patent pending – Electronic Potential Transformer (EPT) v Fiber optic control v Meets “Partial Discharge” test requirements v Friendly operation, Multi Languages LCD - English, German, French, Spanish v Communication: MODBUS, PROFIBUS and others v Chassis or cabinet type, various options are available 5

Starting Large Motors on board ships Typical starting methods: § Direct On Line (DOL) § Star-Delta § Autotransformer (ATS) § Electronic Soft Starters § Electronic Frequency Drives (VFD) What is the optimum starting method for marine application ? 6

Starting Large Motors on board ships Typical starting methods: § Direct On Line (DOL) § Star-Delta § Autotransformer (ATS) § Electronic Soft Starters § Electronic Frequency Drives (VFD) What is the optimum starting method for marine application ? 6

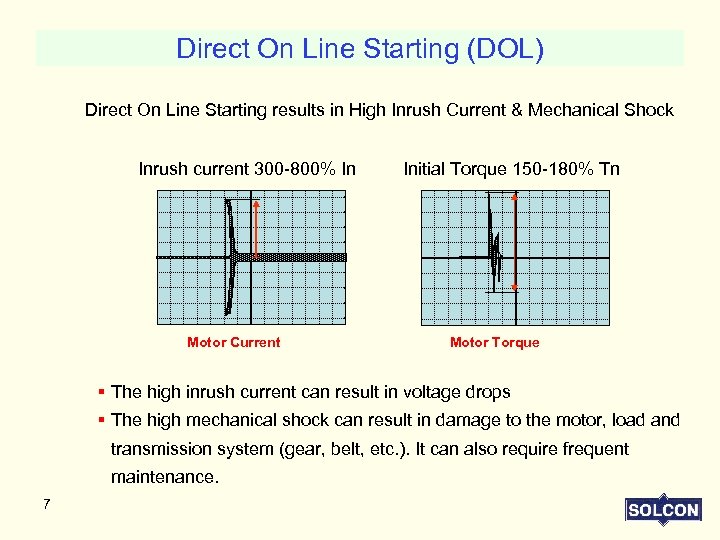

Direct On Line Starting (DOL) Direct On Line Starting results in High Inrush Current & Mechanical Shock Inrush current 300 -800% In Motor Current Initial Torque 150 -180% Tn Motor Torque § The high inrush current can result in voltage drops § The high mechanical shock can result in damage to the motor, load and transmission system (gear, belt, etc. ). It can also require frequent maintenance. 7

Direct On Line Starting (DOL) Direct On Line Starting results in High Inrush Current & Mechanical Shock Inrush current 300 -800% In Motor Current Initial Torque 150 -180% Tn Motor Torque § The high inrush current can result in voltage drops § The high mechanical shock can result in damage to the motor, load and transmission system (gear, belt, etc. ). It can also require frequent maintenance. 7

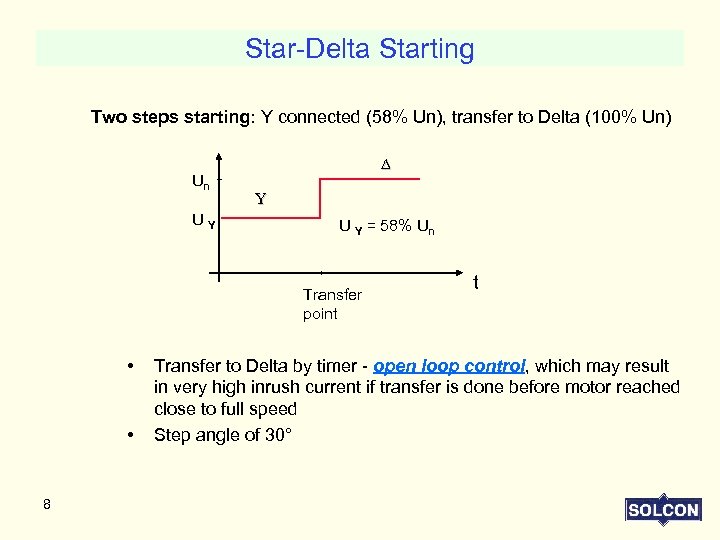

Star-Delta Starting Two steps starting: Y connected (58% Un), transfer to Delta (100% Un) Un U Y D Y U Y = 58% Un Transfer point • • 8 t Transfer to Delta by timer - open loop control, which may result in very high inrush current if transfer is done before motor reached close to full speed Step angle of 30°

Star-Delta Starting Two steps starting: Y connected (58% Un), transfer to Delta (100% Un) Un U Y D Y U Y = 58% Un Transfer point • • 8 t Transfer to Delta by timer - open loop control, which may result in very high inrush current if transfer is done before motor reached close to full speed Step angle of 30°

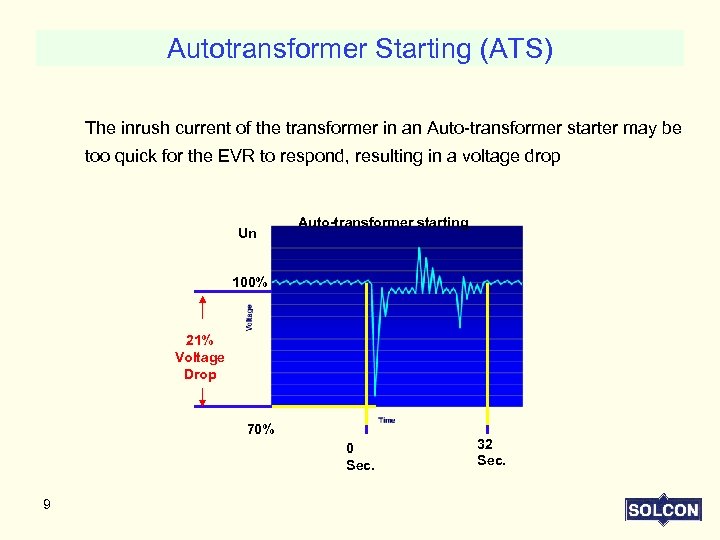

Autotransformer Starting (ATS) The inrush current of the transformer in an Auto-transformer starter may be too quick for the EVR to respond, resulting in a voltage drop Un Auto-transformer starting 100% 21% Voltage Drop 70% 0 Sec. 9 32 Sec.

Autotransformer Starting (ATS) The inrush current of the transformer in an Auto-transformer starter may be too quick for the EVR to respond, resulting in a voltage drop Un Auto-transformer starting 100% 21% Voltage Drop 70% 0 Sec. 9 32 Sec.

Reduced Voltage Starters (Soft Starters) M/V Blue Marlin, converted by HHI. Electrical Integrator: Alstom. Application: Starting 2 Thrusters (Lips) 4. 5 MW, 6. 6 KV Required: Starting from 2 (out of 3) generators 3. 2 MW each Customer considered using VFD or Soft Starters. 10

Reduced Voltage Starters (Soft Starters) M/V Blue Marlin, converted by HHI. Electrical Integrator: Alstom. Application: Starting 2 Thrusters (Lips) 4. 5 MW, 6. 6 KV Required: Starting from 2 (out of 3) generators 3. 2 MW each Customer considered using VFD or Soft Starters. 10

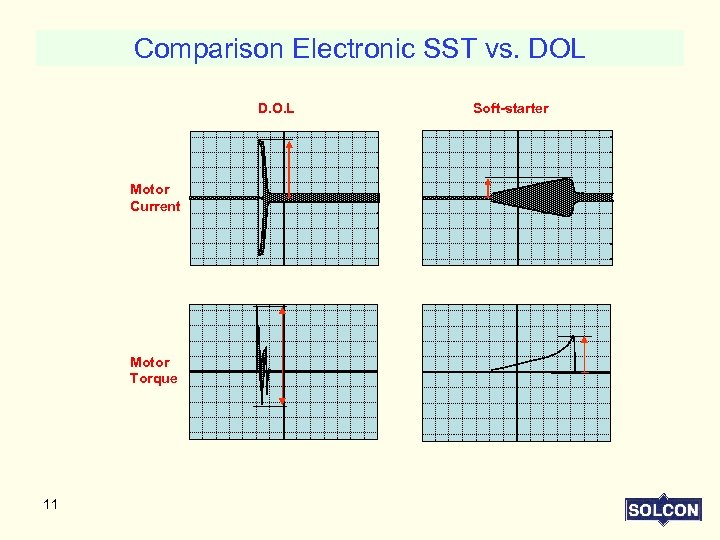

Comparison Electronic SST vs. DOL D. O. L Motor Current Motor Torque 11 Soft-starter

Comparison Electronic SST vs. DOL D. O. L Motor Current Motor Torque 11 Soft-starter

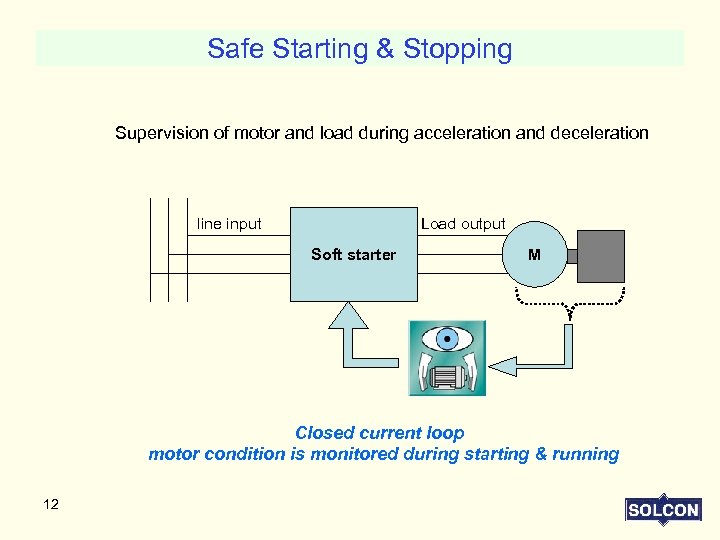

Safe Starting & Stopping Supervision of motor and load during acceleration and deceleration line input Load output Soft starter M Closed current loop motor condition is monitored during starting & running 12

Safe Starting & Stopping Supervision of motor and load during acceleration and deceleration line input Load output Soft starter M Closed current loop motor condition is monitored during starting & running 12

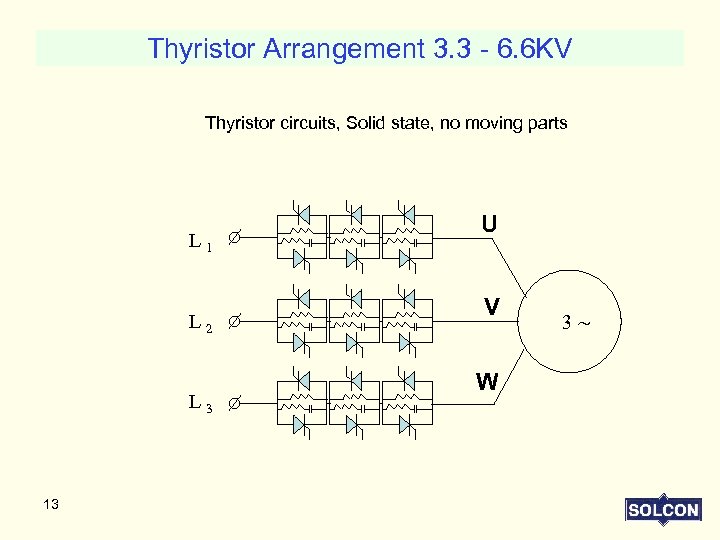

Thyristor Arrangement 3. 3 - 6. 6 KV Thyristor circuits, Solid state, no moving parts L 1 L 2 L 3 13 U V W 3~

Thyristor Arrangement 3. 3 - 6. 6 KV Thyristor circuits, Solid state, no moving parts L 1 L 2 L 3 13 U V W 3~

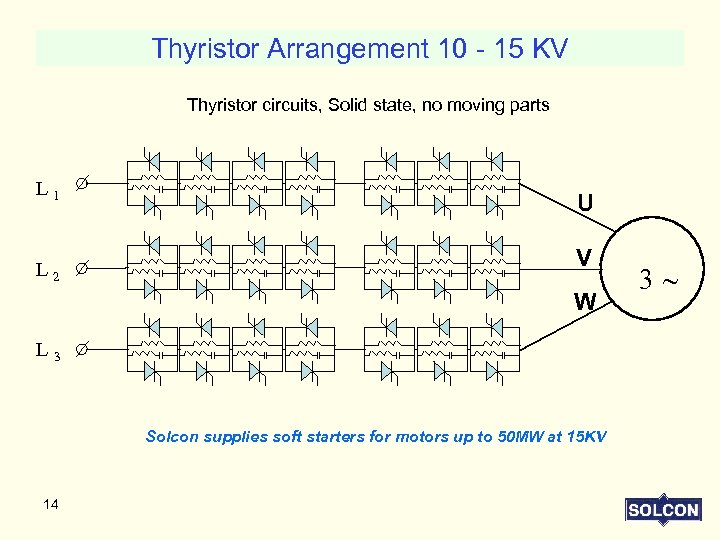

Thyristor Arrangement 10 - 15 KV Thyristor circuits, Solid state, no moving parts L 1 L 2 U V W L 3 Solcon supplies soft starters for motors up to 50 MW at 15 KV 14 3~

Thyristor Arrangement 10 - 15 KV Thyristor circuits, Solid state, no moving parts L 1 L 2 U V W L 3 Solcon supplies soft starters for motors up to 50 MW at 15 KV 14 3~

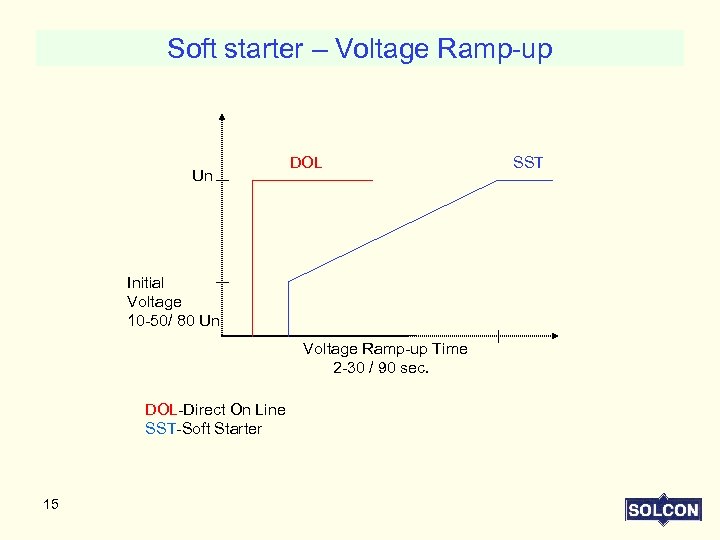

Soft starter – Voltage Ramp-up Un DOL Initial Voltage 10 -50/ 80 Un Voltage Ramp-up Time 2 -30 / 90 sec. DOL-Direct On Line SST-Soft Starter 15 SST

Soft starter – Voltage Ramp-up Un DOL Initial Voltage 10 -50/ 80 Un Voltage Ramp-up Time 2 -30 / 90 sec. DOL-Direct On Line SST-Soft Starter 15 SST

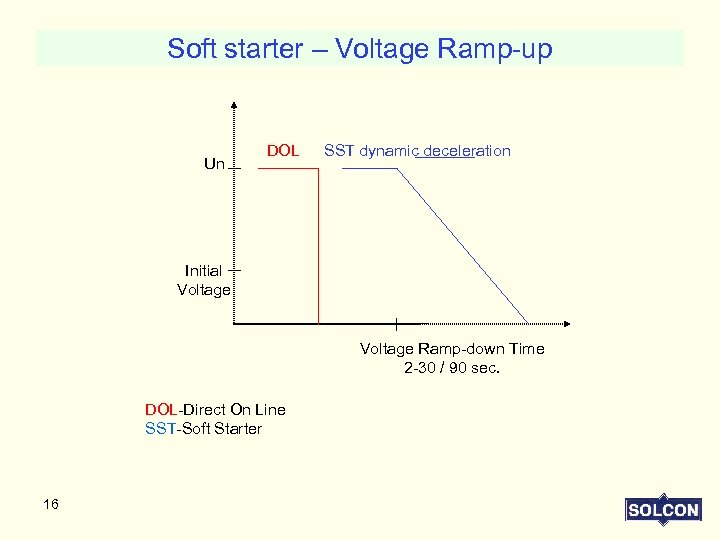

Soft starter – Voltage Ramp-up Un DOL SST dynamic deceleration Initial Voltage Ramp-down Time 2 -30 / 90 sec. DOL-Direct On Line SST-Soft Starter 16

Soft starter – Voltage Ramp-up Un DOL SST dynamic deceleration Initial Voltage Ramp-down Time 2 -30 / 90 sec. DOL-Direct On Line SST-Soft Starter 16

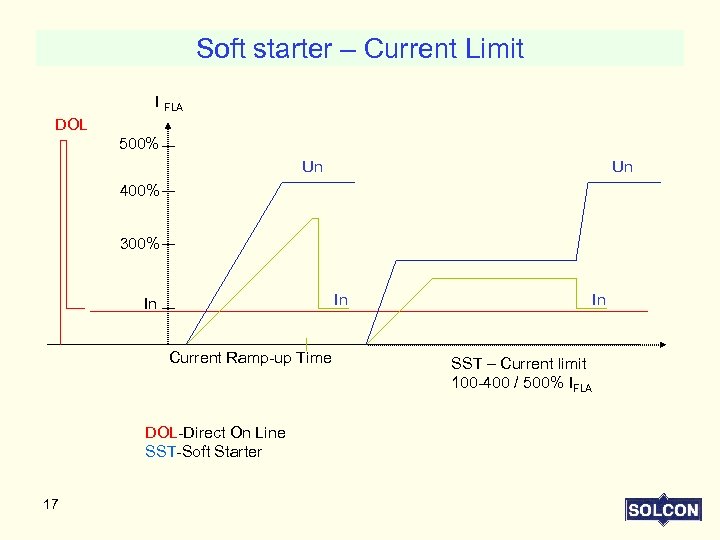

Soft starter – Current Limit I FLA DOL 500% Un Un 400% 300% In In Current Ramp-up Time DOL-Direct On Line SST-Soft Starter 17 In SST – Current limit 100 -400 / 500% IFLA

Soft starter – Current Limit I FLA DOL 500% Un Un 400% 300% In In Current Ramp-up Time DOL-Direct On Line SST-Soft Starter 17 In SST – Current limit 100 -400 / 500% IFLA

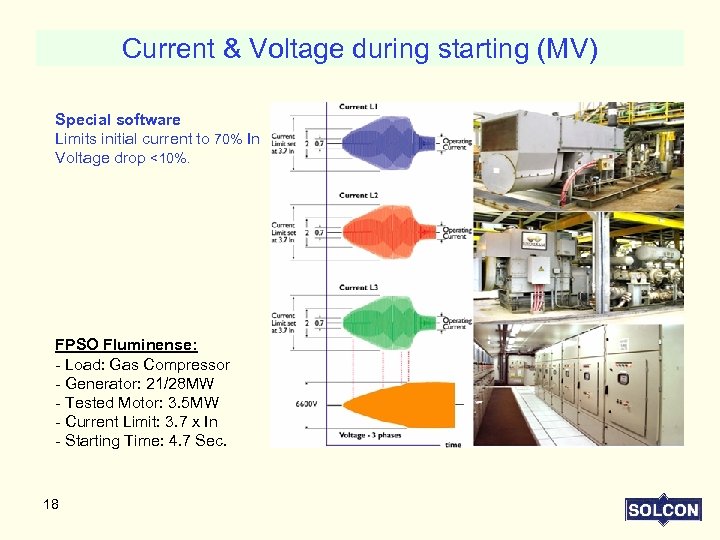

Current & Voltage during starting (MV) Special software Limits initial current to 70% In Voltage drop <10%. FPSO Fluminense: - Load: Gas Compressor - Generator: 21/28 MW - Tested Motor: 3. 5 MW - Current Limit: 3. 7 x In - Starting Time: 4. 7 Sec. 18

Current & Voltage during starting (MV) Special software Limits initial current to 70% In Voltage drop <10%. FPSO Fluminense: - Load: Gas Compressor - Generator: 21/28 MW - Tested Motor: 3. 5 MW - Current Limit: 3. 7 x In - Starting Time: 4. 7 Sec. 18

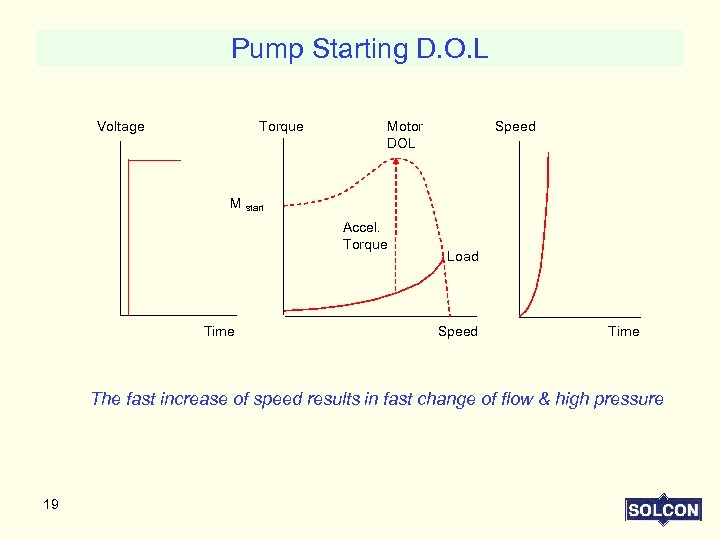

Pump Starting D. O. L Voltage Torque Motor DOL Speed M start Accel. Torque Time Load Speed Time The fast increase of speed results in fast change of flow & high pressure 19

Pump Starting D. O. L Voltage Torque Motor DOL Speed M start Accel. Torque Time Load Speed Time The fast increase of speed results in fast change of flow & high pressure 19

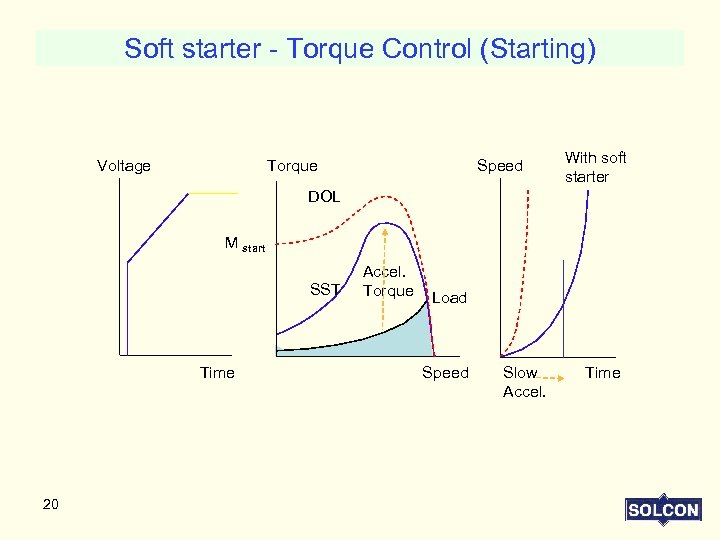

Soft starter - Torque Control (Starting) Voltage Torque Speed With soft starter DOL M start SST Time 20 Accel. Torque Load Speed Slow Accel. Time

Soft starter - Torque Control (Starting) Voltage Torque Speed With soft starter DOL M start SST Time 20 Accel. Torque Load Speed Slow Accel. Time

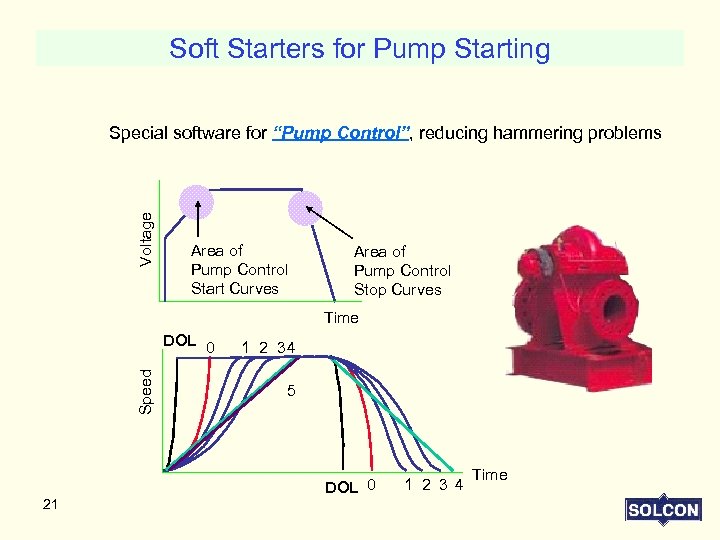

Soft Starters for Pump Starting Voltage Special software for “Pump Control”, reducing hammering problems Area of Pump Control Start Curves Area of Pump Control Stop Curves Time Speed DOL 0 21 1 2 34 5 DOL 0 1 2 3 4 Time

Soft Starters for Pump Starting Voltage Special software for “Pump Control”, reducing hammering problems Area of Pump Control Start Curves Area of Pump Control Stop Curves Time Speed DOL 0 21 1 2 34 5 DOL 0 1 2 3 4 Time

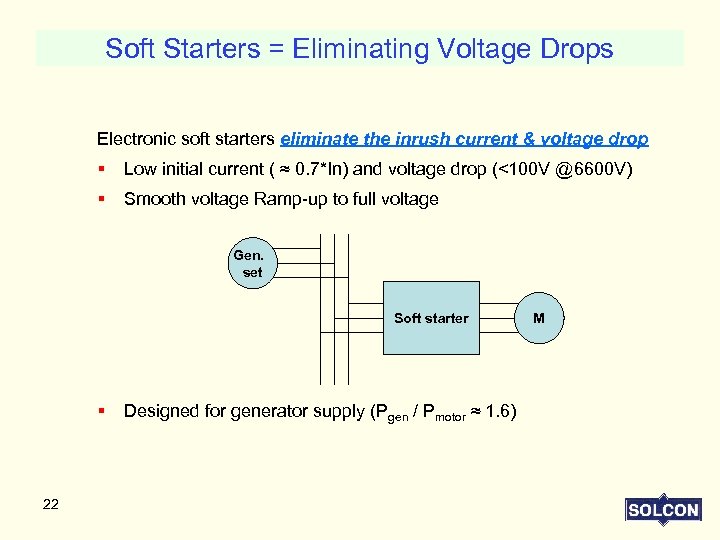

Soft Starters = Eliminating Voltage Drops Electronic soft starters eliminate the inrush current & voltage drop § Low initial current ( ≈ 0. 7*In) and voltage drop (<100 V @6600 V) § Smooth voltage Ramp-up to full voltage Gen. set § 22 Soft starter Designed for generator supply (Pgen / Pmotor ≈ 1. 6) M

Soft Starters = Eliminating Voltage Drops Electronic soft starters eliminate the inrush current & voltage drop § Low initial current ( ≈ 0. 7*In) and voltage drop (<100 V @6600 V) § Smooth voltage Ramp-up to full voltage Gen. set § 22 Soft starter Designed for generator supply (Pgen / Pmotor ≈ 1. 6) M

Soft Starters = Reduced Maintenance Electronic soft starters reduce starting torque & mechanical shock Smooth Acceleration & Deceleration (extending system’s life expectancy) 23

Soft Starters = Reduced Maintenance Electronic soft starters reduce starting torque & mechanical shock Smooth Acceleration & Deceleration (extending system’s life expectancy) 23

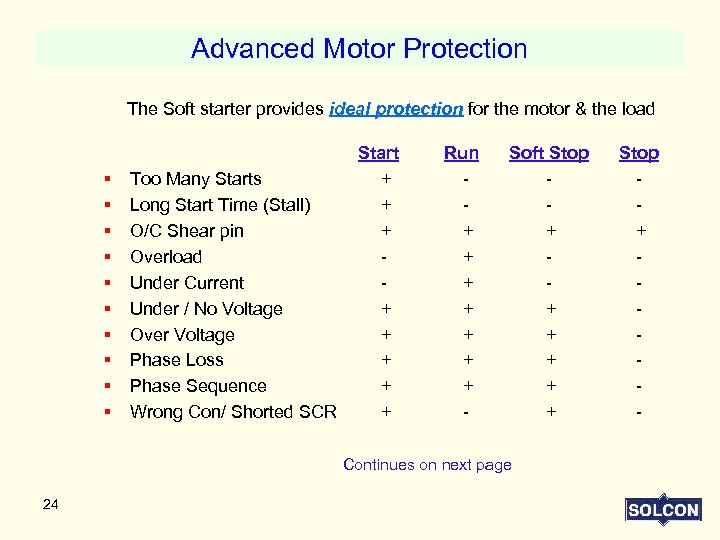

Advanced Motor Protection The Soft starter provides ideal protection for the motor & the load Start Run Soft Stop § Too Many Starts + § Long Start Time (Stall) + § O/C Shear pin + + § Overload + § Under Current + § Under / No Voltage + + + § Over Voltage + + + § Phase Loss + + + § Phase Sequence + + + § Wrong Con/ Shorted SCR + + Continues on next page 24

Advanced Motor Protection The Soft starter provides ideal protection for the motor & the load Start Run Soft Stop § Too Many Starts + § Long Start Time (Stall) + § O/C Shear pin + + § Overload + § Under Current + § Under / No Voltage + + + § Over Voltage + + + § Phase Loss + + + § Phase Sequence + + + § Wrong Con/ Shorted SCR + + Continues on next page 24

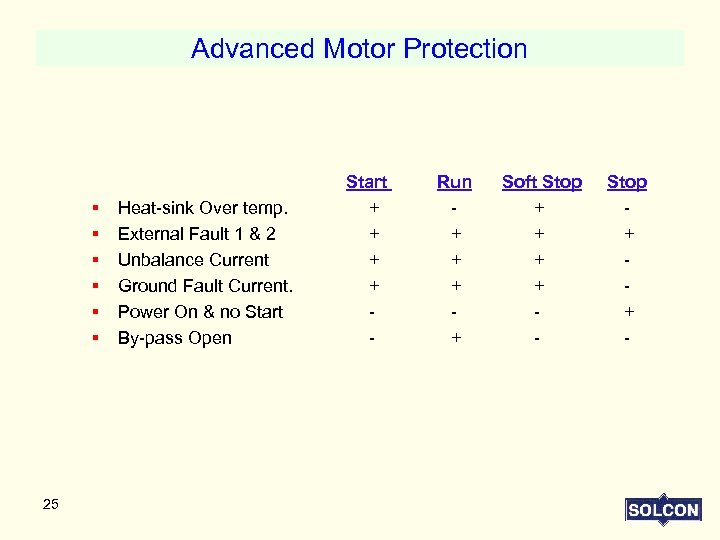

Advanced Motor Protection § Heat-sink Over temp. § External Fault 1 & 2 § Unbalance Current § Ground Fault Current. § Power On & no Start § By-pass Open 25 Start Run Soft Stop + + + + -

Advanced Motor Protection § Heat-sink Over temp. § External Fault 1 & 2 § Unbalance Current § Ground Fault Current. § Power On & no Start § By-pass Open 25 Start Run Soft Stop + + + + -

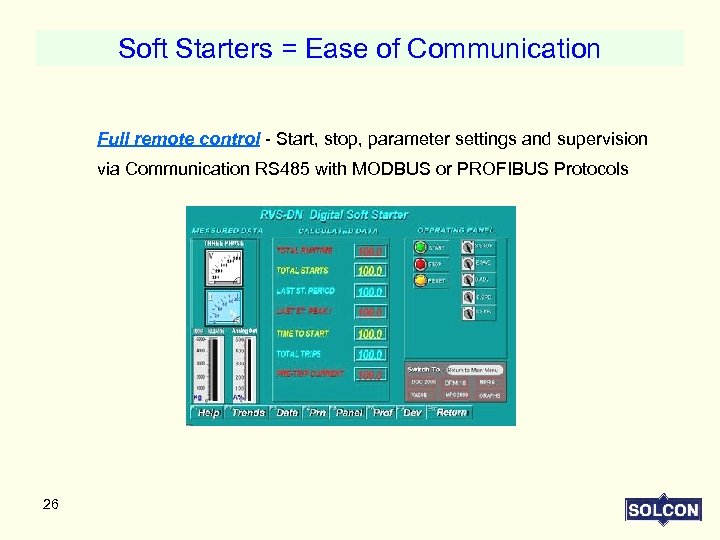

Soft Starters = Ease of Communication Full remote control - Start, stop, parameter settings and supervision via Communication RS 485 with MODBUS or PROFIBUS Protocols 26

Soft Starters = Ease of Communication Full remote control - Start, stop, parameter settings and supervision via Communication RS 485 with MODBUS or PROFIBUS Protocols 26

MV Soft Starters up to 50 MW, 15 KV 2300 - 6600 V 10 -15 KV 27

MV Soft Starters up to 50 MW, 15 KV 2300 - 6600 V 10 -15 KV 27

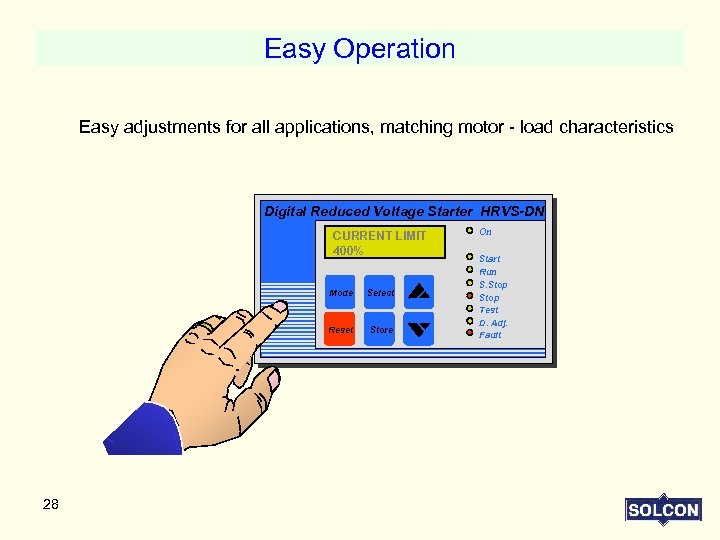

Easy Operation Easy adjustments for all applications, matching motor - load characteristics Digital Reduced Voltage Starter HRVS-DN CURRENT LIMIT 400% Mode Reset 28 Select Store On Start Run S. Stop Test D. Adj. Fault

Easy Operation Easy adjustments for all applications, matching motor - load characteristics Digital Reduced Voltage Starter HRVS-DN CURRENT LIMIT 400% Mode Reset 28 Select Store On Start Run S. Stop Test D. Adj. Fault

When To Use Soft Starters Summary: • When starting current must be reduced to avoid voltage drops, due to the low ratio between motor / Generator power. • When starting torque must be reduced (mechanical problems) • When starting complicated mechanical loads • When starting sensitive loads • When starting high inertia loads (long starting time) • For frequent starting • Preventing over pressure and hammer effect in pump applications 29

When To Use Soft Starters Summary: • When starting current must be reduced to avoid voltage drops, due to the low ratio between motor / Generator power. • When starting torque must be reduced (mechanical problems) • When starting complicated mechanical loads • When starting sensitive loads • When starting high inertia loads (long starting time) • For frequent starting • Preventing over pressure and hammer effect in pump applications 29

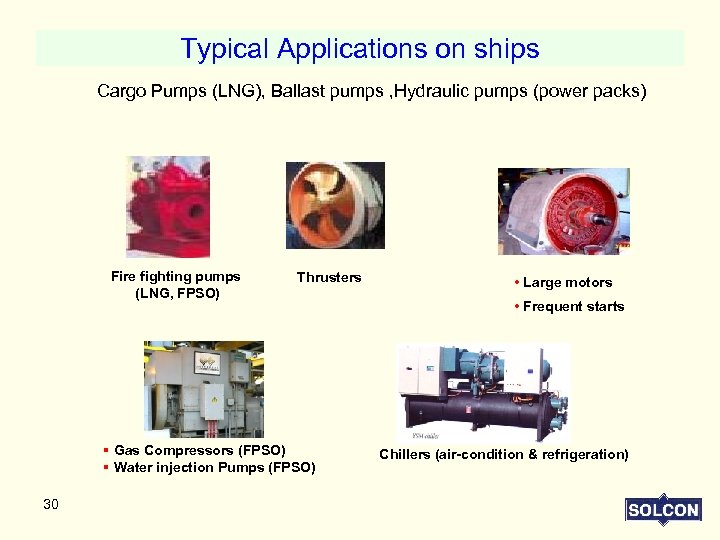

Typical Applications on ships Cargo Pumps (LNG), Ballast pumps , Hydraulic pumps (power packs) Fire fighting pumps (LNG, FPSO) Thrusters § Gas Compressors (FPSO) § Water injection Pumps (FPSO) 30 • Large motors • Frequent starts Chillers (air-condition & refrigeration)

Typical Applications on ships Cargo Pumps (LNG), Ballast pumps , Hydraulic pumps (power packs) Fire fighting pumps (LNG, FPSO) Thrusters § Gas Compressors (FPSO) § Water injection Pumps (FPSO) 30 • Large motors • Frequent starts Chillers (air-condition & refrigeration)

Solcon’s MV Soft Starters HRVS-DN § Heavy duty design for Marine & Off-shore Applications § Easy commissioning and operation, field testing with a L. V. motor § Comprehensive line 2300 -15000 V up to 50 MW § Advanced Motor Protection package § Communication: MODBUS or PROFIBUS 31

Solcon’s MV Soft Starters HRVS-DN § Heavy duty design for Marine & Off-shore Applications § Easy commissioning and operation, field testing with a L. V. motor § Comprehensive line 2300 -15000 V up to 50 MW § Advanced Motor Protection package § Communication: MODBUS or PROFIBUS 31

Solcon’s MV Soft Starters HRVS-DN § Patent pending - Wireless SCR Firing System (no wires in the power section) § Patent pending – Electronic Potential Transformer (EPT) § Fiber optic control § Meets “Partial Discharge” test requirements § Chassis or cabinet type, various options are available 32

Solcon’s MV Soft Starters HRVS-DN § Patent pending - Wireless SCR Firing System (no wires in the power section) § Patent pending – Electronic Potential Transformer (EPT) § Fiber optic control § Meets “Partial Discharge” test requirements § Chassis or cabinet type, various options are available 32

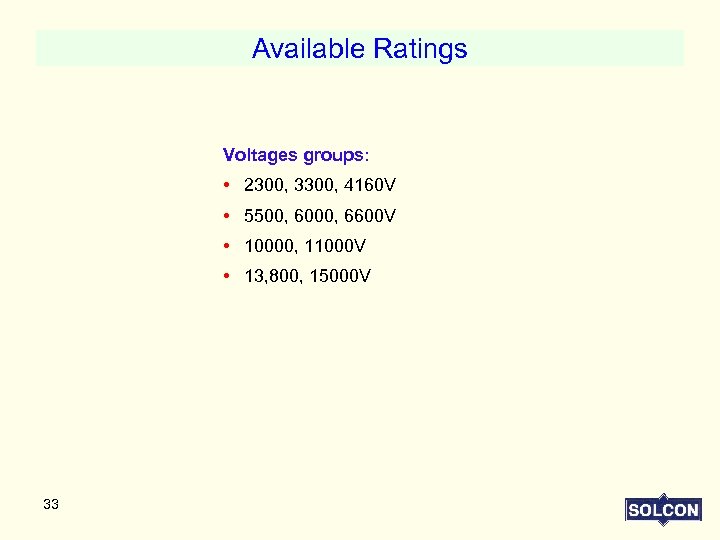

Available Ratings Voltages groups: • 2300, 3300, 4160 V • 5500, 6000, 6600 V • 10000, 11000 V • 13, 800, 15000 V 33

Available Ratings Voltages groups: • 2300, 3300, 4160 V • 5500, 6000, 6600 V • 10000, 11000 V • 13, 800, 15000 V 33

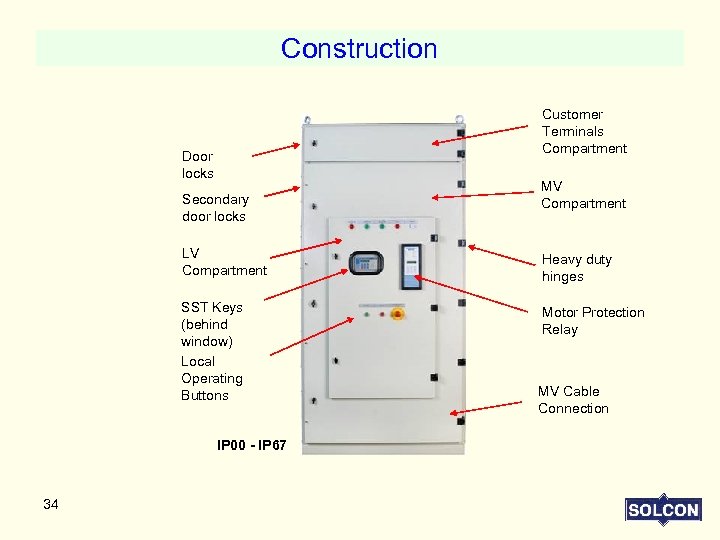

Construction Customer Terminals Compartment Door locks Secondary door locks MV Compartment LV Compartment Heavy duty hinges SST Keys (behind window) Local Operating Buttons Motor Protection Relay IP 00 - IP 67 34 MV Cable Connection

Construction Customer Terminals Compartment Door locks Secondary door locks MV Compartment LV Compartment Heavy duty hinges SST Keys (behind window) Local Operating Buttons Motor Protection Relay IP 00 - IP 67 34 MV Cable Connection

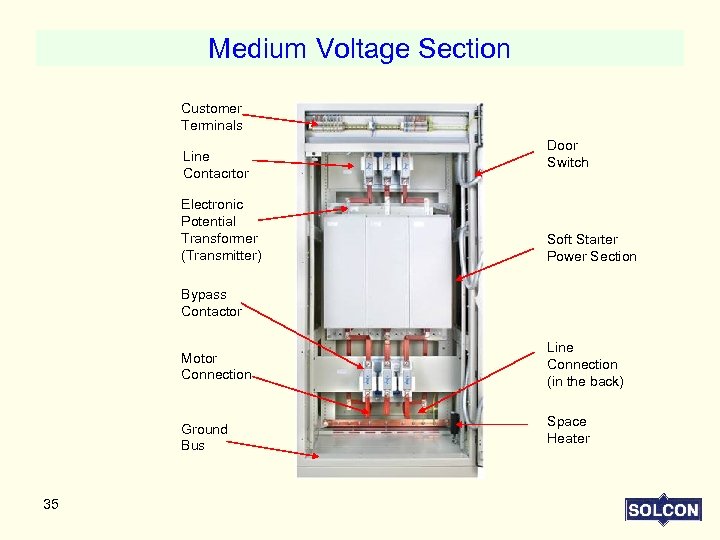

Medium Voltage Section Customer Terminals Line Contacrtor Electronic Potential Transformer (Transmitter) Door Switch Soft Starter Power Section Bypass Contactor Motor Connection Ground Bus 35 Line Connection (in the back) Space Heater

Medium Voltage Section Customer Terminals Line Contacrtor Electronic Potential Transformer (Transmitter) Door Switch Soft Starter Power Section Bypass Contactor Motor Connection Ground Bus 35 Line Connection (in the back) Space Heater

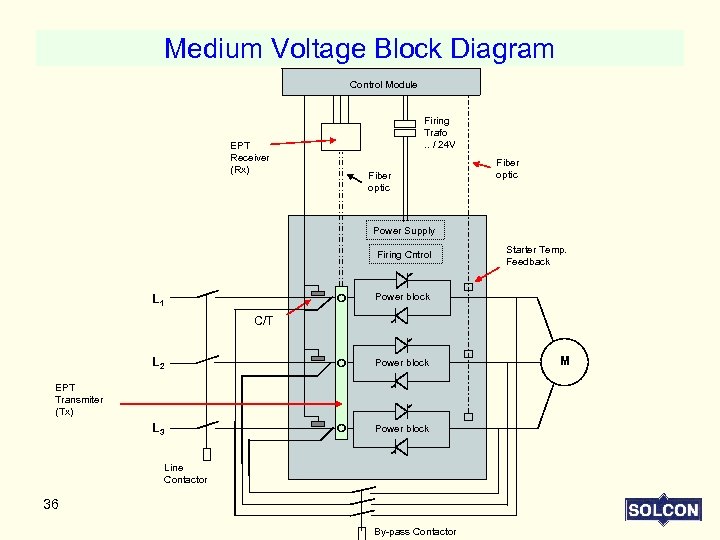

Medium Voltage Block Diagram Control Module EPT Receiver (Rx) Firing Trafo. . / 24 V Fiber optic Power Supply Firing Cntrol Starter Temp. Feedback Power block L 1 C/T L 2 Power block L 3 Power block EPT Transmiter (Tx) Line Contactor 36 By-pass Contactor M

Medium Voltage Block Diagram Control Module EPT Receiver (Rx) Firing Trafo. . / 24 V Fiber optic Power Supply Firing Cntrol Starter Temp. Feedback Power block L 1 C/T L 2 Power block L 3 Power block EPT Transmiter (Tx) Line Contactor 36 By-pass Contactor M

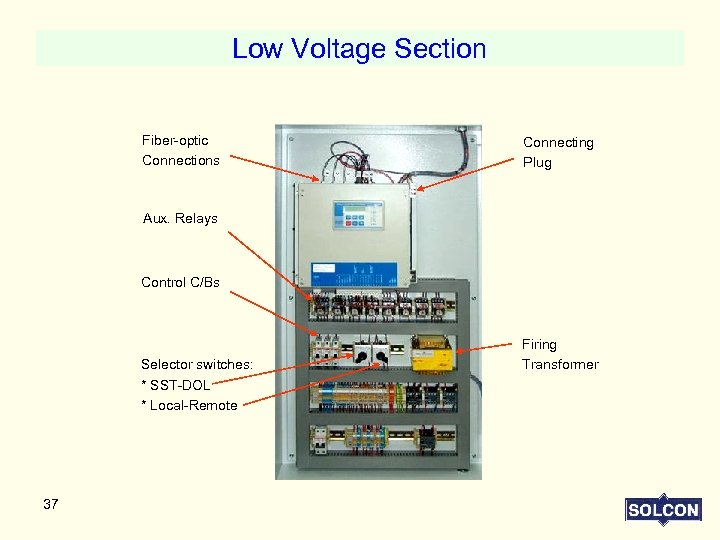

Low Voltage Section Fiber-optic Connections Connecting Plug Aux. Relays Control C/Bs Selector switches: * SST-DOL * Local-Remote 37 Firing Transformer

Low Voltage Section Fiber-optic Connections Connecting Plug Aux. Relays Control C/Bs Selector switches: * SST-DOL * Local-Remote 37 Firing Transformer

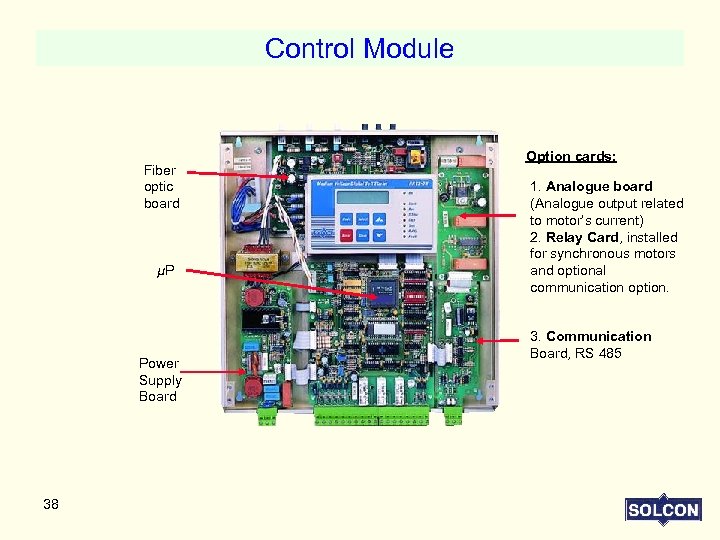

Control Module Fiber optic board µP Power Supply Board 38 Option cards: 1. Analogue board (Analogue output related to motor’s current) 2. Relay Card, installed for synchronous motors and optional communication option. 3. Communication Board, RS 485

Control Module Fiber optic board µP Power Supply Board 38 Option cards: 1. Analogue board (Analogue output related to motor’s current) 2. Relay Card, installed for synchronous motors and optional communication option. 3. Communication Board, RS 485

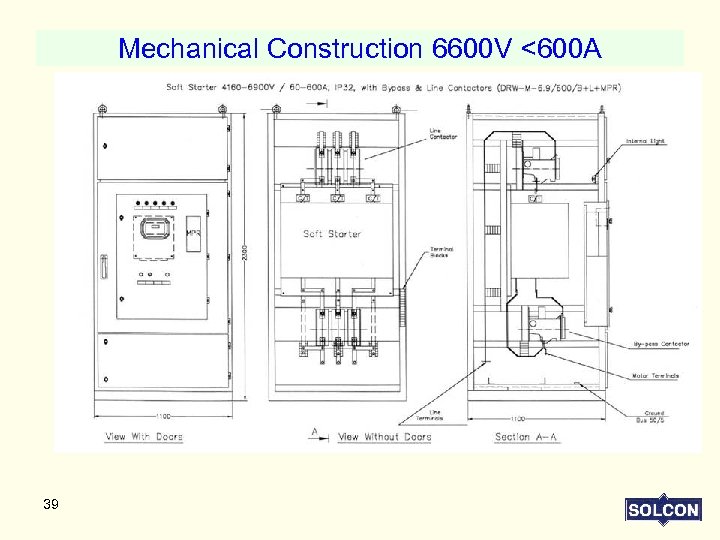

Mechanical Construction 6600 V <600 A 39

Mechanical Construction 6600 V <600 A 39

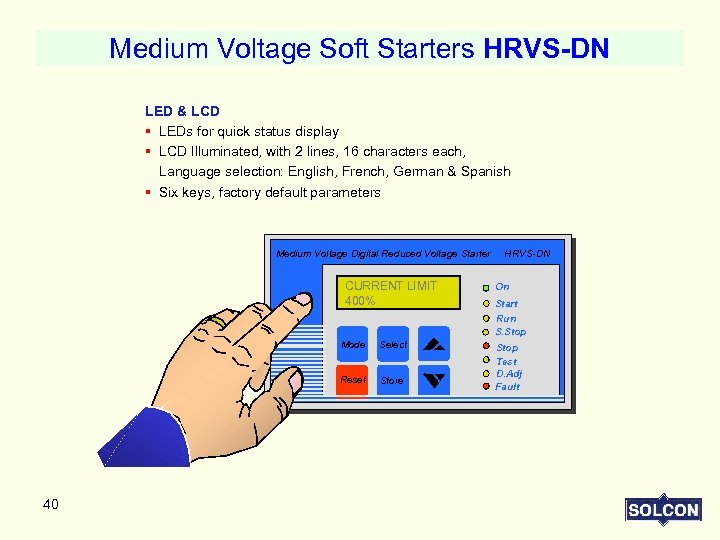

Medium Voltage Soft Starters HRVS-DN LED & LCD § LEDs for quick status display § LCD Illuminated, with 2 lines, 16 characters each, Language selection: English, French, German & Spanish § Six keys, factory default parameters Medium Voltage Digital Reduced Voltage Starter CURRENT LIMIT 400% Mode Reset 40 Select Store HRVS-DN On Start Run S. Stop Test D. Adj Fault

Medium Voltage Soft Starters HRVS-DN LED & LCD § LEDs for quick status display § LCD Illuminated, with 2 lines, 16 characters each, Language selection: English, French, German & Spanish § Six keys, factory default parameters Medium Voltage Digital Reduced Voltage Starter CURRENT LIMIT 400% Mode Reset 40 Select Store HRVS-DN On Start Run S. Stop Test D. Adj Fault

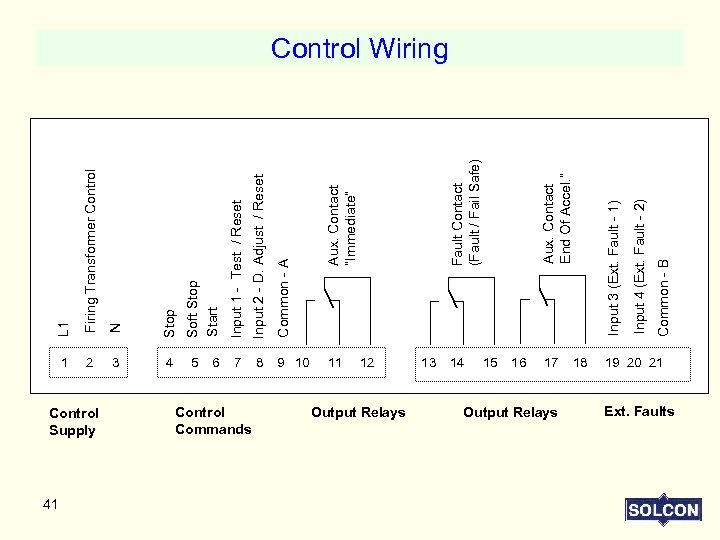

41 Control Supply Control Commands Output Relays Common - B Input 4 (Ext. Fault - 2) Input 3 (Ext. Fault - 1) Aux. Contact End Of Accel. ” Fault Contact (Fault / Fail Safe) Aux. Contact “Immediate” Common - A Input 2 - D. Adjust / Reset Input 1 - Test / Reset Soft Stop Start Stop N Firing Transformer Control L 1 Control Wiring 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Ext. Faults

41 Control Supply Control Commands Output Relays Common - B Input 4 (Ext. Fault - 2) Input 3 (Ext. Fault - 1) Aux. Contact End Of Accel. ” Fault Contact (Fault / Fail Safe) Aux. Contact “Immediate” Common - A Input 2 - D. Adjust / Reset Input 1 - Test / Reset Soft Stop Start Stop N Firing Transformer Control L 1 Control Wiring 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Ext. Faults

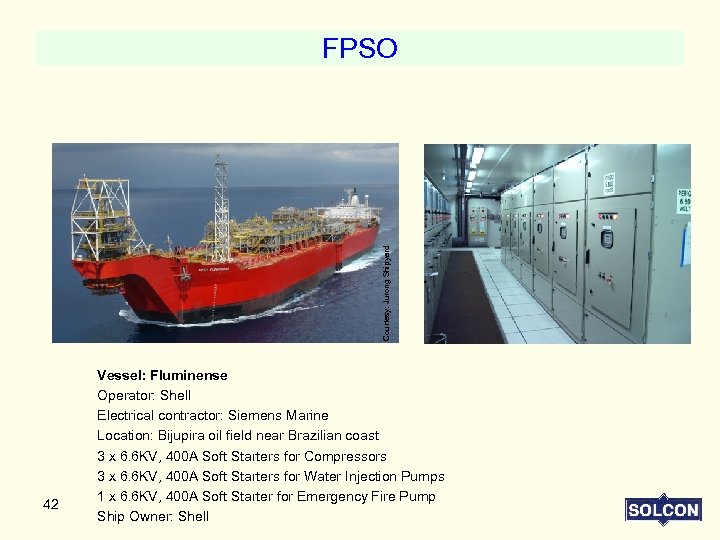

Courtesy: Jurong Shipyard FPSO 42 Vessel: Fluminense Operator: Shell Electrical contractor: Siemens Marine Location: Bijupira oil field near Brazilian coast 3 x 6. 6 KV, 400 A Soft Starters for Compressors 3 x 6. 6 KV, 400 A Soft Starters for Water Injection Pumps 1 x 6. 6 KV, 400 A Soft Starter for Emergency Fire Pump Ship Owner: Shell

Courtesy: Jurong Shipyard FPSO 42 Vessel: Fluminense Operator: Shell Electrical contractor: Siemens Marine Location: Bijupira oil field near Brazilian coast 3 x 6. 6 KV, 400 A Soft Starters for Compressors 3 x 6. 6 KV, 400 A Soft Starters for Water Injection Pumps 1 x 6. 6 KV, 400 A Soft Starter for Emergency Fire Pump Ship Owner: Shell

FPSO - Fluminense Seawater Injection Pump MV Motor Control Center 43 Gas Compressor

FPSO - Fluminense Seawater Injection Pump MV Motor Control Center 43 Gas Compressor

FPSO 44 Vessel: Modec venture 11 Customer: SANTOS (Australia) Main Contractor: MODEC (Japan) Electrical contractor: Terasaki (Japan) Shipyard: Jurong (Singapore) Soft-Starters: 3 x Water Injection Pumps (11 KV/250 A) 3 x Gas Compressors (6. 6 KV/250 A) 1 x Hot Oil Pump (6. 6 KV/140 A) Ship Owner: Modec

FPSO 44 Vessel: Modec venture 11 Customer: SANTOS (Australia) Main Contractor: MODEC (Japan) Electrical contractor: Terasaki (Japan) Shipyard: Jurong (Singapore) Soft-Starters: 3 x Water Injection Pumps (11 KV/250 A) 3 x Gas Compressors (6. 6 KV/250 A) 1 x Hot Oil Pump (6. 6 KV/140 A) Ship Owner: Modec

FPSO Vessel: Berge-helena Customer: Bergessen, Norway Soft-Starters: 3 x Water Injection Pumps (11 KV/250 A) Ship Owner: Bergessen 45

FPSO Vessel: Berge-helena Customer: Bergessen, Norway Soft-Starters: 3 x Water Injection Pumps (11 KV/250 A) Ship Owner: Bergessen 45

FPSO Vessel: “Petrojarl 1” First FPSO concept for “PGS” Electrical system: Stadt Norway (ABB) Water Injection Pump: 6600 V, 1. 8 MW Ship Owner: PGS (Petroleum Geo Services) 46

FPSO Vessel: “Petrojarl 1” First FPSO concept for “PGS” Electrical system: Stadt Norway (ABB) Water Injection Pump: 6600 V, 1. 8 MW Ship Owner: PGS (Petroleum Geo Services) 46

FPSO “Petrojarl II - Foinhaven” Electrical Contractor : Siemens Norway Water Injection Pumps (11 KV/350 A) Ship Owner: PGS (Petroleum Geo Services) 47

FPSO “Petrojarl II - Foinhaven” Electrical Contractor : Siemens Norway Water Injection Pumps (11 KV/350 A) Ship Owner: PGS (Petroleum Geo Services) 47

FPSO Vessel: Bunga Kerta Electrical contractor: Terasaki Shipyards: MISC, Malaysia Nishishiba Pumps 2 speed motor at 6. 6 KV, 35 A and 140 A 48

FPSO Vessel: Bunga Kerta Electrical contractor: Terasaki Shipyards: MISC, Malaysia Nishishiba Pumps 2 speed motor at 6. 6 KV, 35 A and 140 A 48

FPSO Main Contractor: Samsung Heavy Industries, Supplied through ABB Marine, Norway (Similar supplied to Daewoo & Hyundai shipyards through Terasaki and C&A). LNG Cargo Pumps & Compressor, 6. 6 KV, 70 A and 140 A Multi-start - 2 soft starters, each starting 5 motors Ship Owner: Woodside 49

FPSO Main Contractor: Samsung Heavy Industries, Supplied through ABB Marine, Norway (Similar supplied to Daewoo & Hyundai shipyards through Terasaki and C&A). LNG Cargo Pumps & Compressor, 6. 6 KV, 70 A and 140 A Multi-start - 2 soft starters, each starting 5 motors Ship Owner: Woodside 49

FPSO Main Contractor: SBM Monaco Application – KUITO FPSO (Angola) - Water Injection Pump ABB Motor - 6. 6 KV, 144 A, 1. 5 MW 50

FPSO Main Contractor: SBM Monaco Application – KUITO FPSO (Angola) - Water Injection Pump ABB Motor - 6. 6 KV, 144 A, 1. 5 MW 50

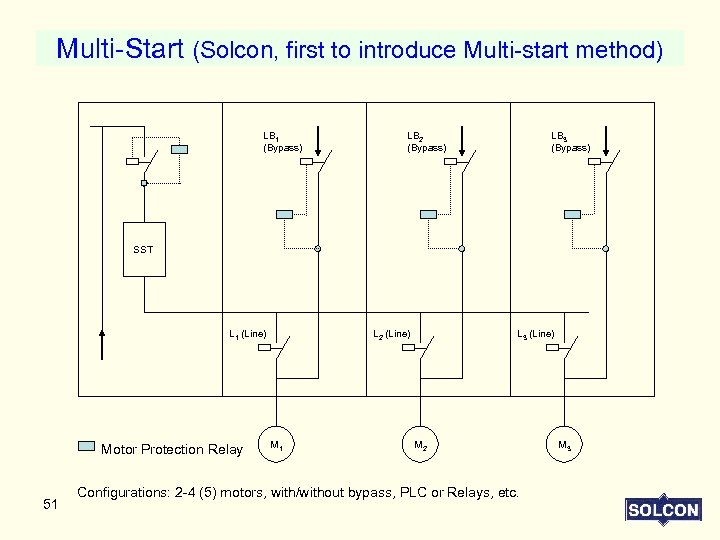

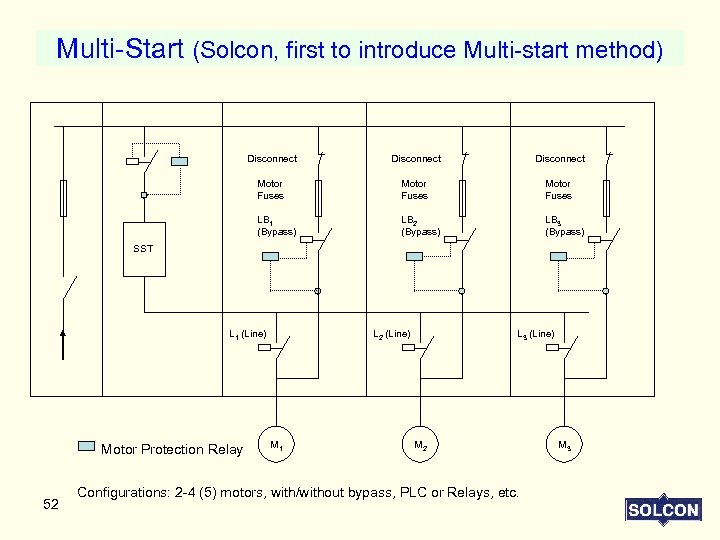

Multi-Start (Solcon, first to introduce Multi-start method) LB 1 (Bypass) LB 2 (Bypass) LB 3 (Bypass) SST L 1 (Line) Motor Protection Relay 51 L 2 (Line) M 1 L 3 (Line) M 2 Configurations: 2 -4 (5) motors, with/without bypass, PLC or Relays, etc. M 3

Multi-Start (Solcon, first to introduce Multi-start method) LB 1 (Bypass) LB 2 (Bypass) LB 3 (Bypass) SST L 1 (Line) Motor Protection Relay 51 L 2 (Line) M 1 L 3 (Line) M 2 Configurations: 2 -4 (5) motors, with/without bypass, PLC or Relays, etc. M 3

Multi-Start (Solcon, first to introduce Multi-start method) Disconnect Motor Fuses LB 1 (Bypass) LB 2 (Bypass) LB 3 (Bypass) SST L 1 (Line) Motor Protection Relay 52 L 2 (Line) M 1 L 3 (Line) M 2 Configurations: 2 -4 (5) motors, with/without bypass, PLC or Relays, etc. M 3

Multi-Start (Solcon, first to introduce Multi-start method) Disconnect Motor Fuses LB 1 (Bypass) LB 2 (Bypass) LB 3 (Bypass) SST L 1 (Line) Motor Protection Relay 52 L 2 (Line) M 1 L 3 (Line) M 2 Configurations: 2 -4 (5) motors, with/without bypass, PLC or Relays, etc. M 3

Support Vessels M/S Blue Marlin WARTSILA / LIPS extendable thruster Electrical Contractor: HHI 2 x 6600 V, 4. 5 MW Retractable Thruster Ship Owner: Dockwise Shipping B. V. , Netherlands 53

Support Vessels M/S Blue Marlin WARTSILA / LIPS extendable thruster Electrical Contractor: HHI 2 x 6600 V, 4. 5 MW Retractable Thruster Ship Owner: Dockwise Shipping B. V. , Netherlands 53

1500 Offshore Platform 90 54 0 900 ‘Helder A” Platform, North Sea, six MV SST are installed and operating Customer: UNOCAL 76 (United Oil of California) Special requirements: Dual voltage at 2. 3 & 3. 3 KV and Max. cabinet height - 1. 5 meter Platform Owner: Shell (Previously UNOCAL 76)

1500 Offshore Platform 90 54 0 900 ‘Helder A” Platform, North Sea, six MV SST are installed and operating Customer: UNOCAL 76 (United Oil of California) Special requirements: Dual voltage at 2. 3 & 3. 3 KV and Max. cabinet height - 1. 5 meter Platform Owner: Shell (Previously UNOCAL 76)

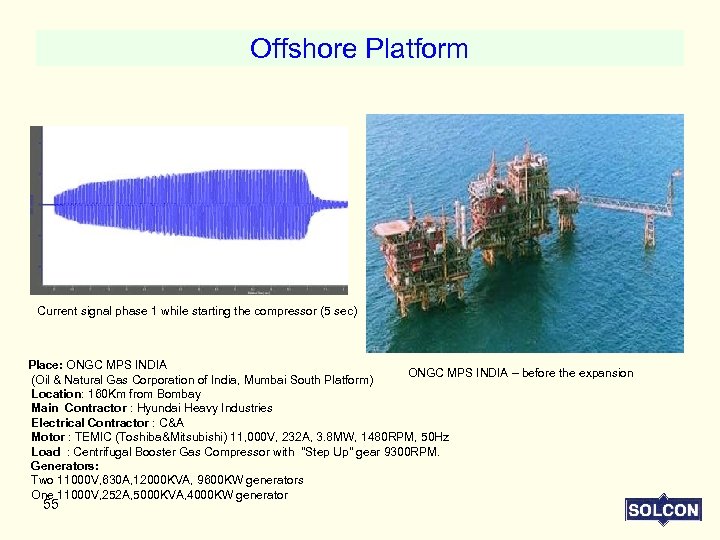

Offshore Platform Current signal phase 1 while starting the compressor (5 sec) Place: ONGC MPS INDIA – before the expansion (Oil & Natural Gas Corporation of India, Mumbai South Platform) Location: 160 Km from Bombay Main Contractor : Hyundai Heavy Industries Electrical Contractor : C&A Motor : TEMIC (Toshiba&Mitsubishi) 11, 000 V, 232 A, 3. 8 MW, 1480 RPM, 50 Hz Load : Centrifugal Booster Gas Compressor with "Step Up" gear 9300 RPM. Generators: Two 11000 V, 630 A, 12000 KVA, 9600 KW generators One 11000 V, 252 A, 5000 KVA, 4000 KW generator 55

Offshore Platform Current signal phase 1 while starting the compressor (5 sec) Place: ONGC MPS INDIA – before the expansion (Oil & Natural Gas Corporation of India, Mumbai South Platform) Location: 160 Km from Bombay Main Contractor : Hyundai Heavy Industries Electrical Contractor : C&A Motor : TEMIC (Toshiba&Mitsubishi) 11, 000 V, 232 A, 3. 8 MW, 1480 RPM, 50 Hz Load : Centrifugal Booster Gas Compressor with "Step Up" gear 9300 RPM. Generators: Two 11000 V, 630 A, 12000 KVA, 9600 KW generators One 11000 V, 252 A, 5000 KVA, 4000 KW generator 55

Dredger Ship - picture shown for reference only Main Contractor – A Dutch Shipyard Electrical Contractor - Siemens Holland 2 x HRVS-DN 6600 V, 300 A (Dredge Pumps) Ship Owner: IADC Penta-Ocean Construction Co. , Ltd 56

Dredger Ship - picture shown for reference only Main Contractor – A Dutch Shipyard Electrical Contractor - Siemens Holland 2 x HRVS-DN 6600 V, 300 A (Dredge Pumps) Ship Owner: IADC Penta-Ocean Construction Co. , Ltd 56

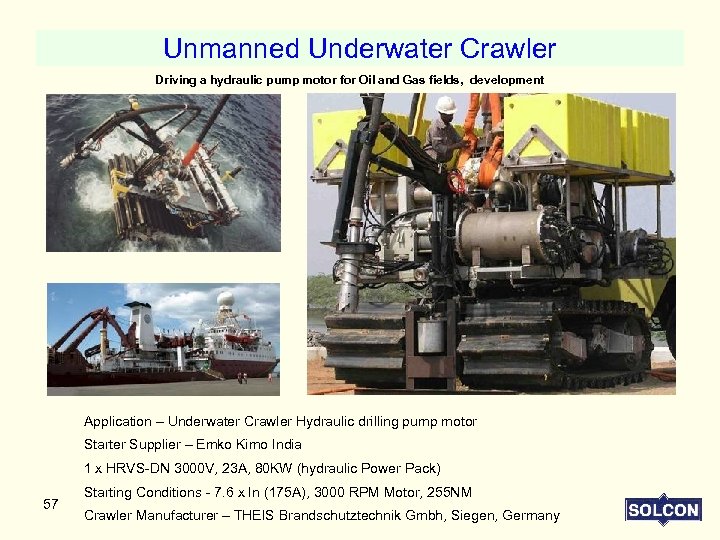

Unmanned Underwater Crawler Driving a hydraulic pump motor for Oil and Gas fields, development Application – Underwater Crawler Hydraulic drilling pump motor Starter Supplier – Emko Kimo India 1 x HRVS-DN 3000 V, 23 A, 80 KW (hydraulic Power Pack) 57 Starting Conditions - 7. 6 x In (175 A), 3000 RPM Motor, 255 NM Crawler Manufacturer – THEIS Brandschutztechnik Gmbh, Siegen, Germany

Unmanned Underwater Crawler Driving a hydraulic pump motor for Oil and Gas fields, development Application – Underwater Crawler Hydraulic drilling pump motor Starter Supplier – Emko Kimo India 1 x HRVS-DN 3000 V, 23 A, 80 KW (hydraulic Power Pack) 57 Starting Conditions - 7. 6 x In (175 A), 3000 RPM Motor, 255 NM Crawler Manufacturer – THEIS Brandschutztechnik Gmbh, Siegen, Germany

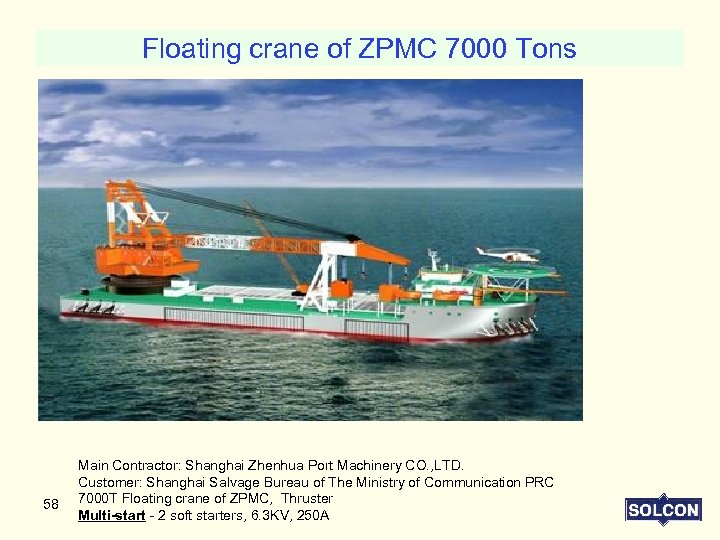

Floating crane of ZPMC 7000 Tons 58 Main Contractor: Shanghai Zhenhua Port Machinery CO. , LTD. Customer: Shanghai Salvage Bureau of The Ministry of Communication PRC 7000 T Floating crane of ZPMC, Thruster Multi-start - 2 soft starters, 6. 3 KV, 250 A

Floating crane of ZPMC 7000 Tons 58 Main Contractor: Shanghai Zhenhua Port Machinery CO. , LTD. Customer: Shanghai Salvage Bureau of The Ministry of Communication PRC 7000 T Floating crane of ZPMC, Thruster Multi-start - 2 soft starters, 6. 3 KV, 250 A

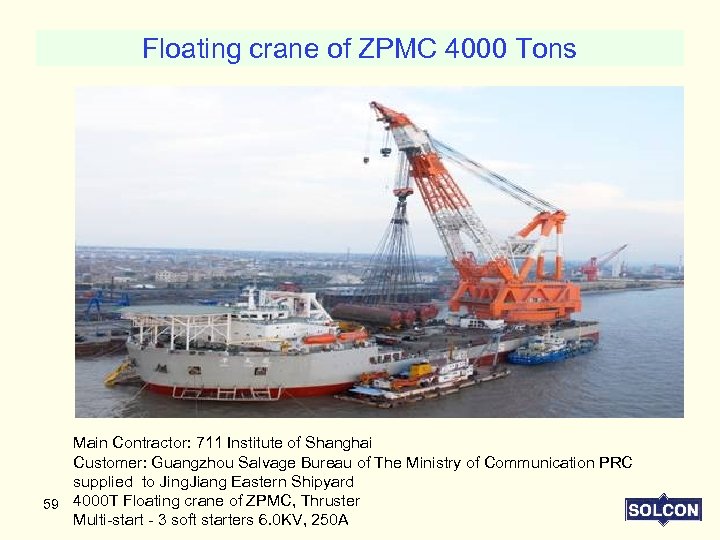

Floating crane of ZPMC 4000 Tons Main Contractor: 711 Institute of Shanghai Customer: Guangzhou Salvage Bureau of The Ministry of Communication PRC supplied to Jing. Jiang Eastern Shipyard 59 4000 T Floating crane of ZPMC, Thruster Multi-start - 3 soft starters 6. 0 KV, 250 A

Floating crane of ZPMC 4000 Tons Main Contractor: 711 Institute of Shanghai Customer: Guangzhou Salvage Bureau of The Ministry of Communication PRC supplied to Jing. Jiang Eastern Shipyard 59 4000 T Floating crane of ZPMC, Thruster Multi-start - 3 soft starters 6. 0 KV, 250 A

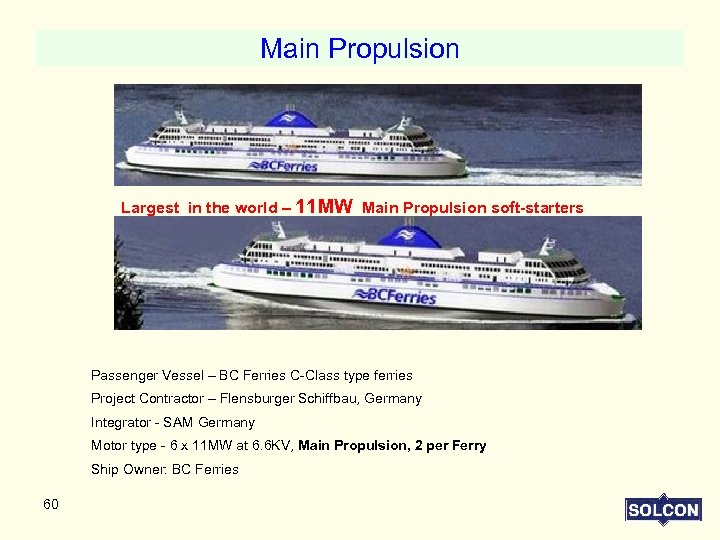

Main Propulsion Largest in the world – 11 MW Main Propulsion soft-starters Passenger Vessel – BC Ferries C-Class type ferries Project Contractor – Flensburger Schiffbau, Germany Integrator - SAM Germany Motor type - 6 x 11 MW at 6. 6 KV, Main Propulsion, 2 per Ferry Ship Owner: BC Ferries 60

Main Propulsion Largest in the world – 11 MW Main Propulsion soft-starters Passenger Vessel – BC Ferries C-Class type ferries Project Contractor – Flensburger Schiffbau, Germany Integrator - SAM Germany Motor type - 6 x 11 MW at 6. 6 KV, Main Propulsion, 2 per Ferry Ship Owner: BC Ferries 60

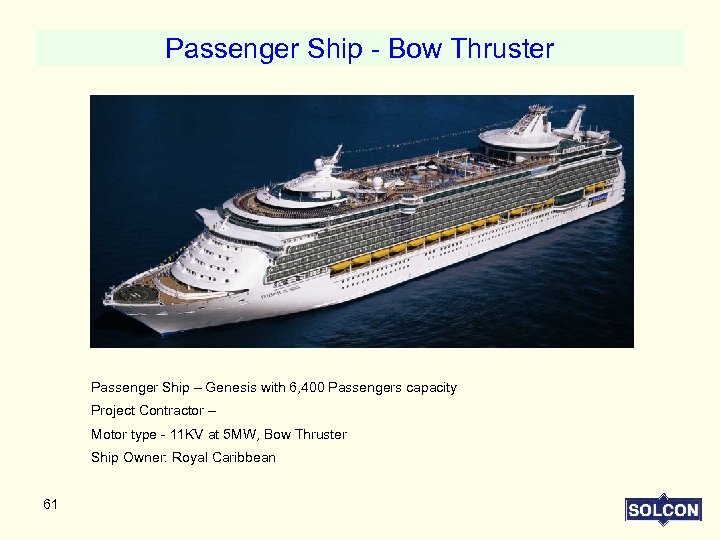

Passenger Ship - Bow Thruster Passenger Ship – Genesis with 6, 400 Passengers capacity Project Contractor – Motor type - 11 KV at 5 MW, Bow Thruster Ship Owner: Royal Caribbean 61

Passenger Ship - Bow Thruster Passenger Ship – Genesis with 6, 400 Passengers capacity Project Contractor – Motor type - 11 KV at 5 MW, Bow Thruster Ship Owner: Royal Caribbean 61

LV Soft Starters up to 3 MW, 1000 V 8 -72 A 85 -170 A 210 -390 A 460 -820 A 1100 -1800 A 2150 -3000 A 62

LV Soft Starters up to 3 MW, 1000 V 8 -72 A 85 -170 A 210 -390 A 460 -820 A 1100 -1800 A 2150 -3000 A 62

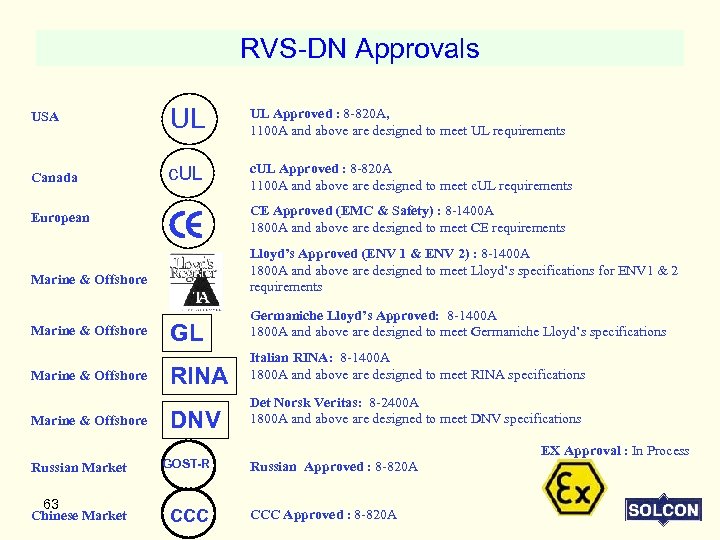

RVS-DN Approvals USA UL UL Approved : 8 -820 A, 1100 A and above are designed to meet UL requirements Canada c. UL Approved : 8 -820 A 1100 A and above are designed to meet c. UL requirements CE Approved (EMC & Safety) : 8 -1400 A 1800 A and above are designed to meet CE requirements European Lloyd’s Approved (ENV 1 & ENV 2) : 8 -1400 A 1800 A and above are designed to meet Lloyd’s specifications for ENV 1 & 2 requirements Marine & Offshore GL RINA DNV Russian Market GOST-R 63 Chinese Market CCC Germaniche Lloyd’s Approved: 8 -1400 A 1800 A and above are designed to meet Germaniche Lloyd’s specifications Italian RINA: 8 -1400 A 1800 A and above are designed to meet RINA specifications Det Norsk Veritas: 8 -2400 A 1800 A and above are designed to meet DNV specifications EX Approval : In Process Russian Approved : 8 -820 A CCC Approved : 8 -820 A

RVS-DN Approvals USA UL UL Approved : 8 -820 A, 1100 A and above are designed to meet UL requirements Canada c. UL Approved : 8 -820 A 1100 A and above are designed to meet c. UL requirements CE Approved (EMC & Safety) : 8 -1400 A 1800 A and above are designed to meet CE requirements European Lloyd’s Approved (ENV 1 & ENV 2) : 8 -1400 A 1800 A and above are designed to meet Lloyd’s specifications for ENV 1 & 2 requirements Marine & Offshore GL RINA DNV Russian Market GOST-R 63 Chinese Market CCC Germaniche Lloyd’s Approved: 8 -1400 A 1800 A and above are designed to meet Germaniche Lloyd’s specifications Italian RINA: 8 -1400 A 1800 A and above are designed to meet RINA specifications Det Norsk Veritas: 8 -2400 A 1800 A and above are designed to meet DNV specifications EX Approval : In Process Russian Approved : 8 -820 A CCC Approved : 8 -820 A

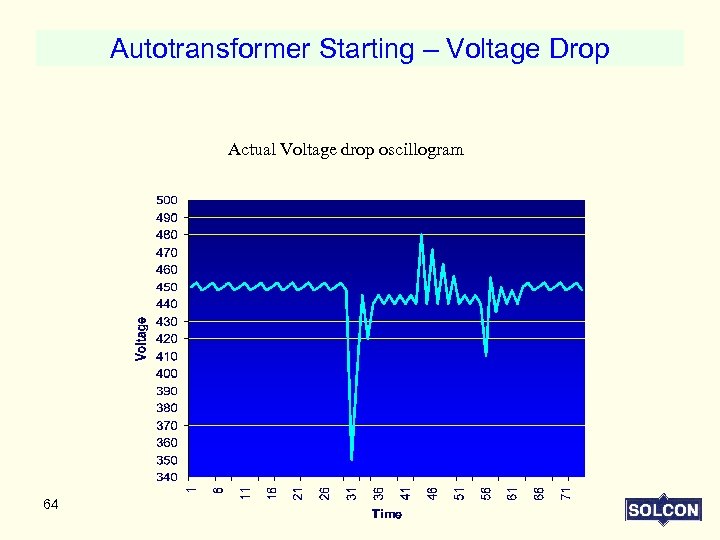

Autotransformer Starting – Voltage Drop Actual Voltage drop oscillogram 64

Autotransformer Starting – Voltage Drop Actual Voltage drop oscillogram 64

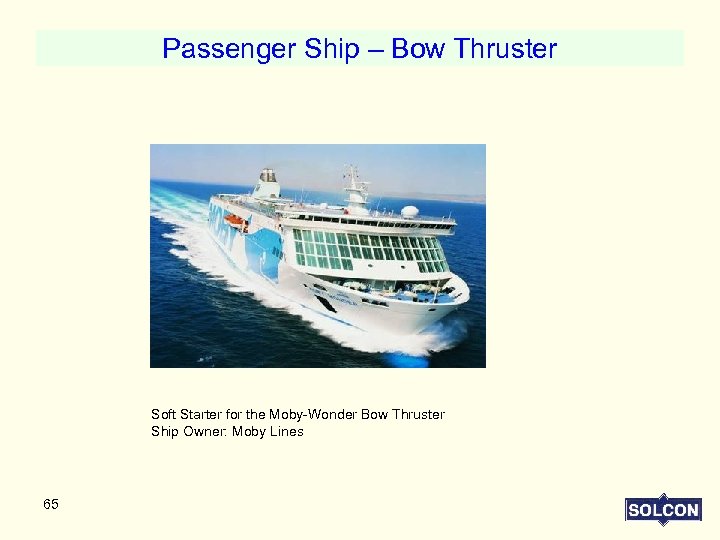

Passenger Ship – Bow Thruster Soft Starter for the Moby-Wonder Bow Thruster Ship Owner: Moby Lines 65

Passenger Ship – Bow Thruster Soft Starter for the Moby-Wonder Bow Thruster Ship Owner: Moby Lines 65

Passenger Ship - Refrigeration Compressors Passenger Ship – Cilja Lines, 20 different installations Project Contractor - York Sweden Electrical Contractor - Electromontage Motor type - 450 KW Chillers Ship Owner: Cilja Lines 66

Passenger Ship - Refrigeration Compressors Passenger Ship – Cilja Lines, 20 different installations Project Contractor - York Sweden Electrical Contractor - Electromontage Motor type - 450 KW Chillers Ship Owner: Cilja Lines 66

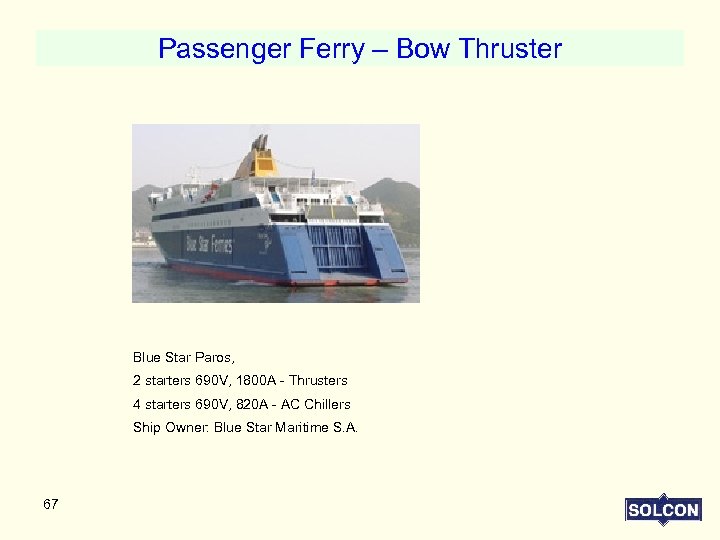

Passenger Ferry – Bow Thruster Blue Star Paros, 2 starters 690 V, 1800 A - Thrusters 4 starters 690 V, 820 A - AC Chillers Ship Owner: Blue Star Maritime S. A. 67

Passenger Ferry – Bow Thruster Blue Star Paros, 2 starters 690 V, 1800 A - Thrusters 4 starters 690 V, 820 A - AC Chillers Ship Owner: Blue Star Maritime S. A. 67

Container Carrier M/S Hamburg Express Ballast pumps 9 x 580 A RVS-DN starters, 440 V Ship Owner: Hapag Lloyd 68

Container Carrier M/S Hamburg Express Ballast pumps 9 x 580 A RVS-DN starters, 440 V Ship Owner: Hapag Lloyd 68

Seismic Research Vessels BGP-Pioneer Bow Thruster at 0. 5 MW / 440 V Ship Owner: TGS 69

Seismic Research Vessels BGP-Pioneer Bow Thruster at 0. 5 MW / 440 V Ship Owner: TGS 69

Support Vessels MV Lochnagar Ulstein for Petro Bras Croatian Shipyard Bow Thruster at 1. 8 MW / 690 V 70

Support Vessels MV Lochnagar Ulstein for Petro Bras Croatian Shipyard Bow Thruster at 1. 8 MW / 690 V 70

Buoy Tanker Platform & Storage Ship Name - Navion Hispania Ship Type - Buoy tanker platform with storage tank for loading and offloading Application - bow Thruster 690 V, 2400 A Electrical Contractor - Aker Norway 71 Power section in the rear part Control module in the front part

Buoy Tanker Platform & Storage Ship Name - Navion Hispania Ship Type - Buoy tanker platform with storage tank for loading and offloading Application - bow Thruster 690 V, 2400 A Electrical Contractor - Aker Norway 71 Power section in the rear part Control module in the front part

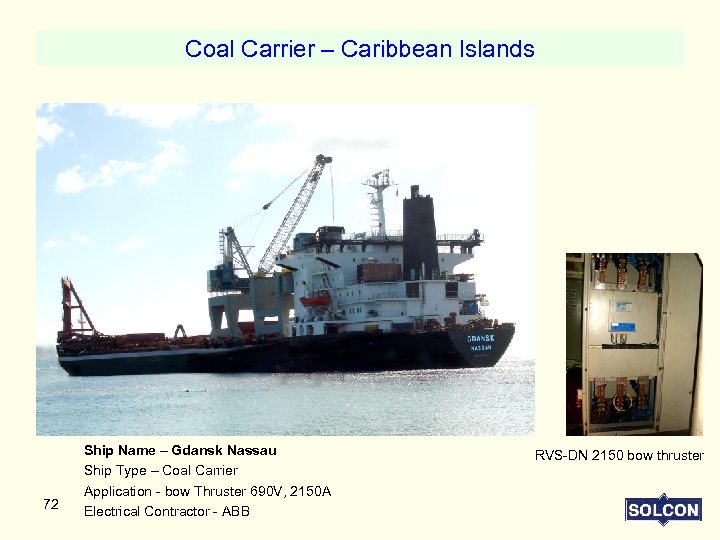

Coal Carrier – Caribbean Islands 72 Ship Name – Gdansk Nassau Ship Type – Coal Carrier Application - bow Thruster 690 V, 2150 A Electrical Contractor - ABB RVS-DN 2150 bow thruster

Coal Carrier – Caribbean Islands 72 Ship Name – Gdansk Nassau Ship Type – Coal Carrier Application - bow Thruster 690 V, 2150 A Electrical Contractor - ABB RVS-DN 2150 bow thruster

Support Vessels Vessel Name - MV Botnica Main Contractor – Aker Finnyards Sub Contractor – Ulstein Norway Motor type - 4 x Hydraulic Power Packs, each 450 KW (for crane) 73

Support Vessels Vessel Name - MV Botnica Main Contractor – Aker Finnyards Sub Contractor – Ulstein Norway Motor type - 4 x Hydraulic Power Packs, each 450 KW (for crane) 73

Support Vessels MV Northern Eagle Sabroe Refrigeration Compressors, 440 V, 220 KW 74

Support Vessels MV Northern Eagle Sabroe Refrigeration Compressors, 440 V, 220 KW 74

Support Vessels MS Syklus Hydraulic Stern Thrusters 220 KW 75

Support Vessels MS Syklus Hydraulic Stern Thrusters 220 KW 75

Private Yachts MS Leinebris Ulstein Bow Thruster 110 KW 76

Private Yachts MS Leinebris Ulstein Bow Thruster 110 KW 76

Three Italian LNG Carriers WMO shipyard (Jotland - Denmark) 3 Vessels at 3 x 220 KW LNG Pumps per vessel 77

Three Italian LNG Carriers WMO shipyard (Jotland - Denmark) 3 Vessels at 3 x 220 KW LNG Pumps per vessel 77

Seismic Research – Main Propulsion CGG FOHN Shipyard: La-Spezia (Italy) Schottel 360° Azimuth Main Propulsion 2 x 1. 1 MW 78

Seismic Research – Main Propulsion CGG FOHN Shipyard: La-Spezia (Italy) Schottel 360° Azimuth Main Propulsion 2 x 1. 1 MW 78

Offshore Platform Pemex (Petroleum of Mexico) Pol-Chuc platform, Dos-Bocas 6 water injection pumps 480 V, 300 HP Platform Owner: PEMEX 79

Offshore Platform Pemex (Petroleum of Mexico) Pol-Chuc platform, Dos-Bocas 6 water injection pumps 480 V, 300 HP Platform Owner: PEMEX 79

AKAL-J Mexico 6 x Crude oil and Gas pumps (480 V/390 A) 80

AKAL-J Mexico 6 x Crude oil and Gas pumps (480 V/390 A) 80

Oil & Gas Pemex (Petroleum of Mexico) Abkatun-A platform, Dos-Bocas location, 3 air-compressors 480, 200 HP Platform Owner: PEMEX 81

Oil & Gas Pemex (Petroleum of Mexico) Abkatun-A platform, Dos-Bocas location, 3 air-compressors 480, 200 HP Platform Owner: PEMEX 81

Unmanned Underwater ROV (Remote Operated Vehicle) 1 x RVS-DX Driving a hydraulic power pack for the “Explorer 4” robotic arm 82

Unmanned Underwater ROV (Remote Operated Vehicle) 1 x RVS-DX Driving a hydraulic power pack for the “Explorer 4” robotic arm 82

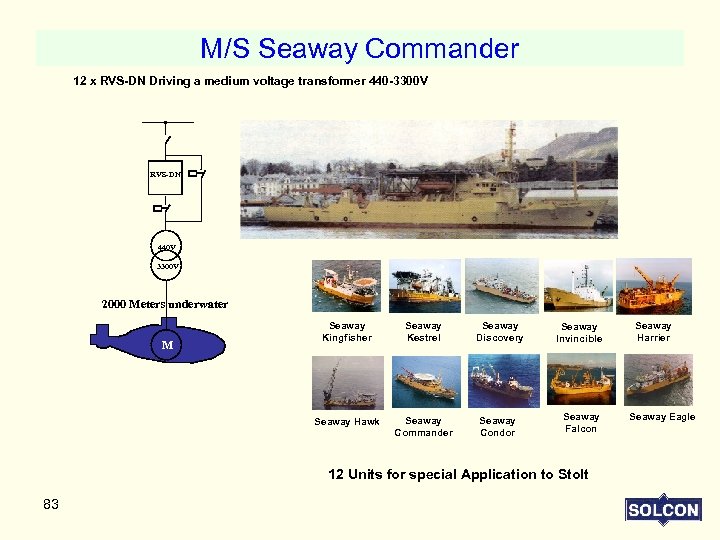

M/S Seaway Commander 12 x RVS-DN Driving a medium voltage transformer 440 -3300 V RVS-DN 440 V 3300 V 2000 Meters underwater M 83 Seaway Kingfisher Seaway Kestrel Seaway Discovery Seaway Invincible Seaway Hawk Falcon Commander Condor 12 Units for special Application to Stolt Seaway Harrier Seaway Eagle

M/S Seaway Commander 12 x RVS-DN Driving a medium voltage transformer 440 -3300 V RVS-DN 440 V 3300 V 2000 Meters underwater M 83 Seaway Kingfisher Seaway Kestrel Seaway Discovery Seaway Invincible Seaway Hawk Falcon Commander Condor 12 Units for special Application to Stolt Seaway Harrier Seaway Eagle

Naval Application Italian Aircraft Carrier “Cavour” All auxiliary motors of the gas turbines Shock tested for 100 G 84

Naval Application Italian Aircraft Carrier “Cavour” All auxiliary motors of the gas turbines Shock tested for 100 G 84

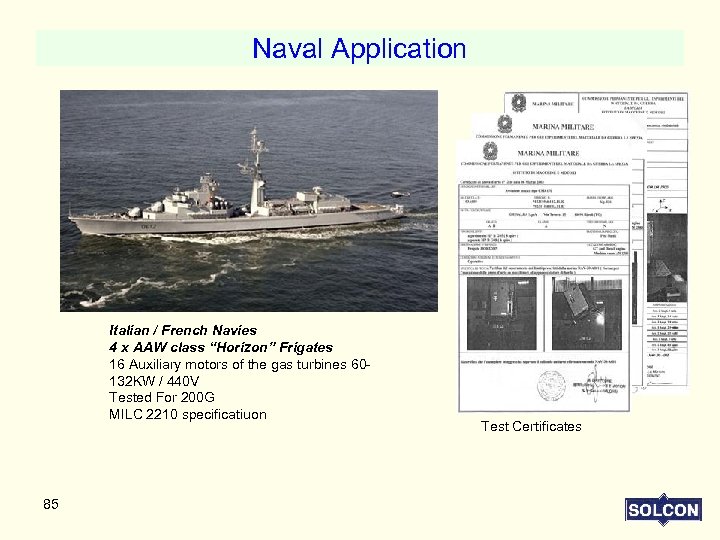

Naval Application Italian / French Navies 4 x AAW class “Horizon” Frigates 16 Auxiliary motors of the gas turbines 60132 KW / 440 V Tested For 200 G MILC 2210 specificatiuon 85 Test Certificates

Naval Application Italian / French Navies 4 x AAW class “Horizon” Frigates 16 Auxiliary motors of the gas turbines 60132 KW / 440 V Tested For 200 G MILC 2210 specificatiuon 85 Test Certificates

SEM-N for Naval Applications MIL-Spec tests included: - Temperature cycle - Mechanical shock - Vibration - Humidity & condensation - Salt mist 86

SEM-N for Naval Applications MIL-Spec tests included: - Temperature cycle - Mechanical shock - Vibration - Humidity & condensation - Salt mist 86

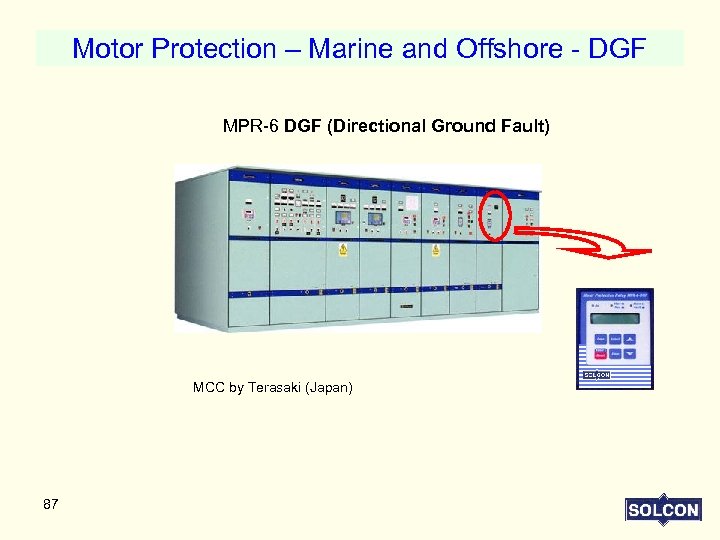

Motor Protection – Marine and Offshore - DGF MPR-6 DGF (Directional Ground Fault) MCC by Terasaki (Japan) 87

Motor Protection – Marine and Offshore - DGF MPR-6 DGF (Directional Ground Fault) MCC by Terasaki (Japan) 87

Motor Protection – Marine and Offshore LNG FINIMA – 8 Protection Relays 88

Motor Protection – Marine and Offshore LNG FINIMA – 8 Protection Relays 88

Thank you 89

Thank you 89