ad5fcb8fcabfc58b78da314b11af0bd2.ppt

- Количество слайдов: 22

Electronic Simulation in Construction Research Team Bryan Sharp Petrofac CII Annual Conference 2001

Electronic Simulation in Construction Research Team

Team Members David Darby Makarand Hastak Bruce Kingsbury Bryan Sharp Kværner Songer University of Cincinnati Kværner Songer Petrofac LLC, Chair Randy Williams Cad. Centre Past Members Lawrence Pfeffer NIST Dustin Schwartz ABB Lummus Bob Sullivan Stone & Webster, Chair

Purpose and Objectives Purpose • Identify, analyze, and evaluate current use of interactive electronic simulation in construction. Objectives • Determine and evaluate existing technologies. • Develop procedures and recommendations on when, how, and what type of technology to use.

Definitions Electronic simulation includes: • Spatial Visualization (3 D-Static) – 3 D CAD systems and tools • Virtual Interactive Environment (3 D-Dynamic) – adds ability to manipulate objects

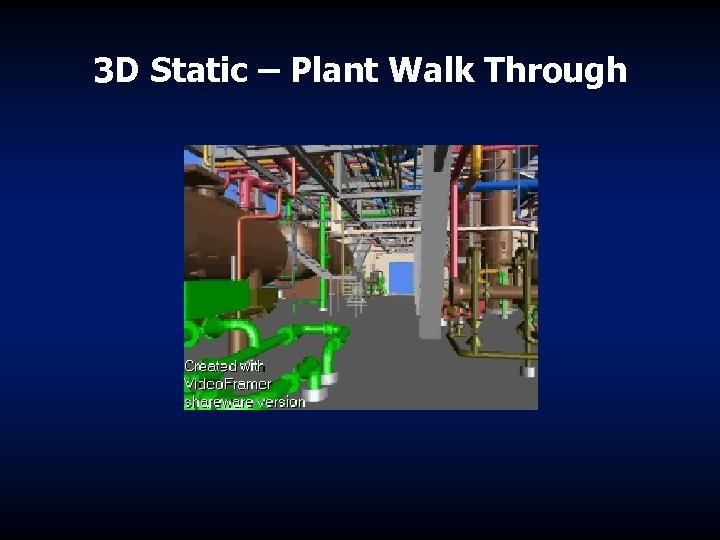

3 D Static – Plant Walk Through

Definitions Electronic simulation includes: • Spatial Visualization (3 D-Static) – 3 D CAD systems and tools • Virtual Interactive Environment (3 D-Dynamic) – adds ability to manipulate objects

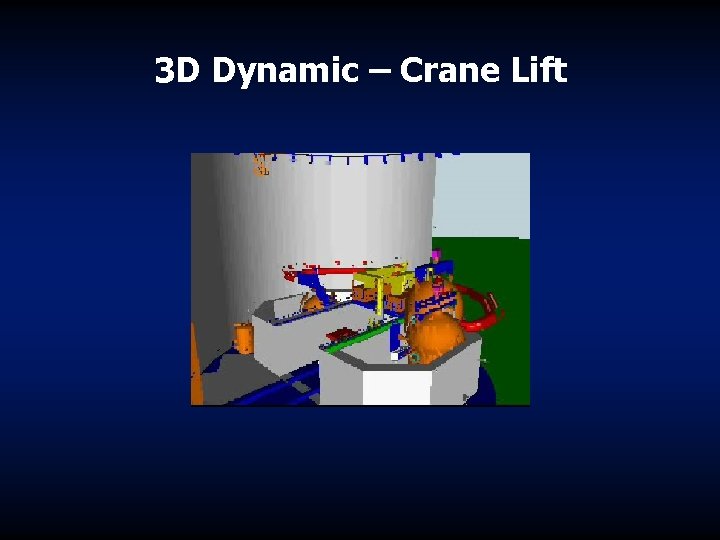

3 D Dynamic – Crane Lift

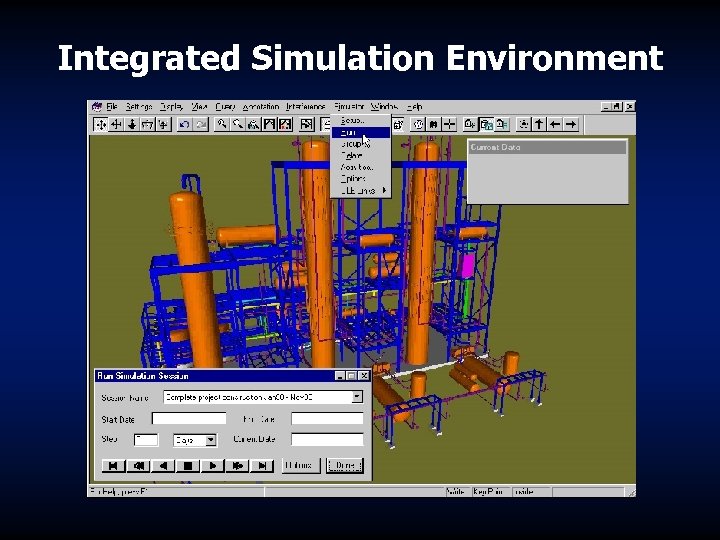

Definitions Construction Process Simulation - Mathematical models used to simulate system interactions Integrated Simulation Environment - The integration of 3 D-static, 3 Ddynamic, and mathematical simulation models into a unified framework.

Integrated Simulation Environment

Research Method/Approach • Three different surveys • Two case studies • Extensive review of literature and supplier product information • Industry conferences and trade shows

Constraints • Rapidly changing technology • “Snapshot in time”

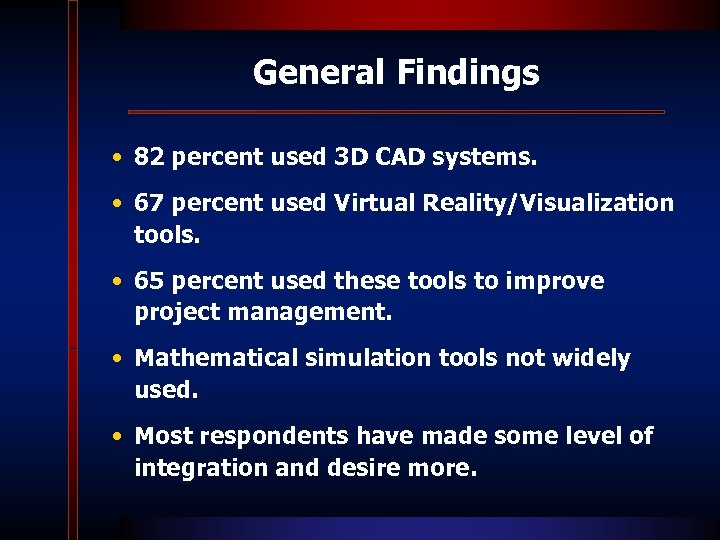

General Findings • 82 percent used 3 D CAD systems. • 67 percent used Virtual Reality/Visualization tools. • 65 percent used these tools to improve project management. • Mathematical simulation tools not widely used. • Most respondents have made some level of integration and desire more.

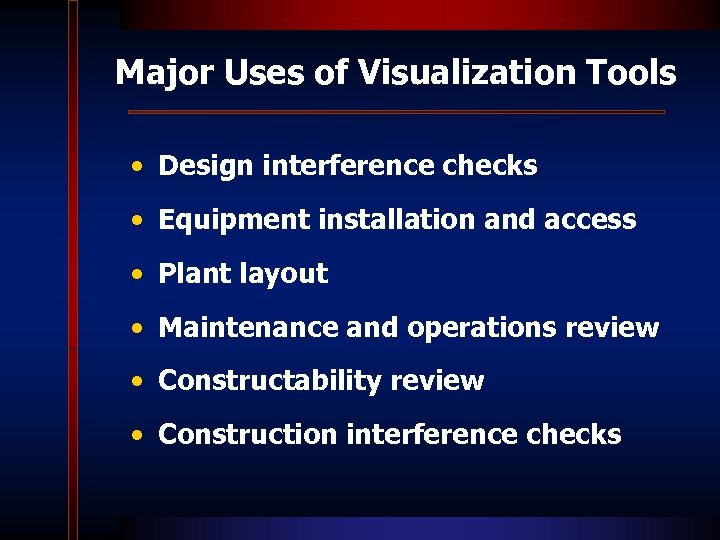

Major Uses of Visualization Tools • Design interference checks • Equipment installation and access • Plant layout • Maintenance and operations review • Constructability review • Construction interference checks

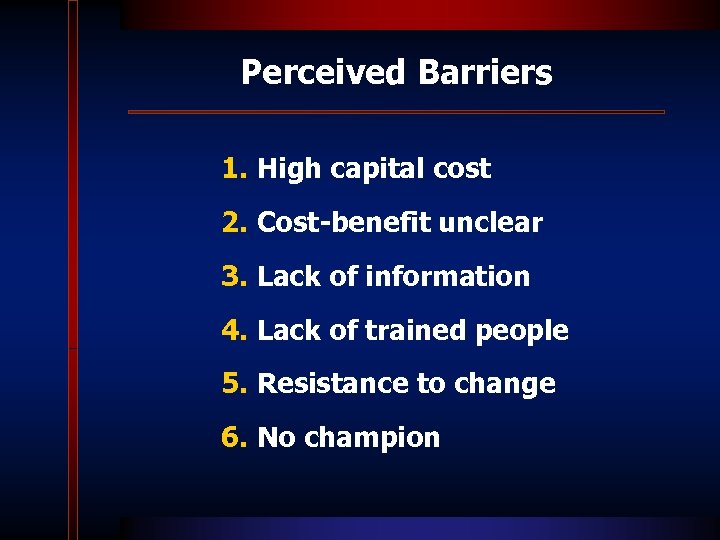

Perceived Barriers 1. High capital cost 2. Cost-benefit unclear 3. Lack of information 4. Lack of trained people 5. Resistance to change 6. No champion

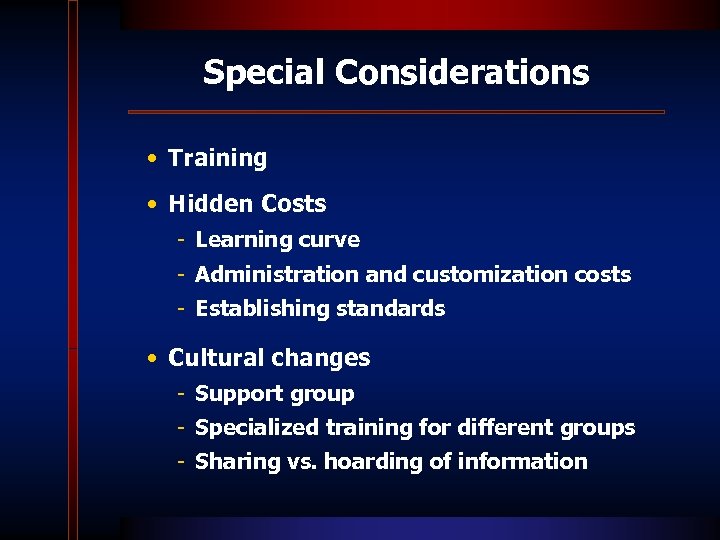

Special Considerations • Training • Hidden Costs - Learning curve - Administration and customization costs - Establishing standards • Cultural changes - Support group - Specialized training for different groups - Sharing vs. hoarding of information

Perceived Benefits 1. Constructability benefits 2. Reduction in rework 3. Client satisfaction 4. Improvement in quality 5. Project management benefits

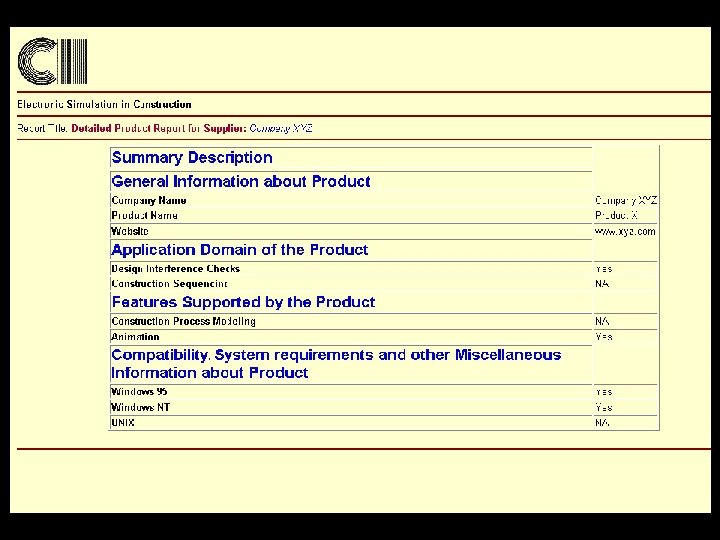

Tool — Decision Aid • Emerging Technologies Web site http: //www. new-technologies. org/ECT/ • Web-enabled database - Module 1 – Is ESIC right for you? - Module 2 • Specify desired applications, features • Identify suitable products

Conclusions • ESIC is a rapidly evolving technology. • Research latest technology for best fit. • ESIC adds value (92 percent believe). • Significant benefits - reduction in costs - reduction in schedule - reduction in rework • Benefits outweigh barriers.

Recommendations • Analyze current and future needs. • Research current technology. • Training! • Use the tools. - ESIC Implementation Guidelines - Supplier Criteria Review Checklist - Decision Aid

Future of Industry: Through the Crystal Ball • Integration (FIATECH) • Web-enabled • Data-centric • VRML, XML • Hand-held computers

ad5fcb8fcabfc58b78da314b11af0bd2.ppt