6137fcb8389968123be6279fbe1f5c76.ppt

- Количество слайдов: 107

Electricity Risk Management Seminar AIRM 17 th February 2016 Alan Kelly

Seminar Objectives Ø Ø Ø To provide an understanding of Electrical terms and the concepts of electricity To introduce Electrical Protective Devices and provide an understanding of their use To Identify the Legislation associated with Electrical Work and Electrically Operated Equipment.

Statistics Fatal Electrical Accidents In Ireland 2001– 2011 33 Fatalities In 2005 there were 5 people electrocuted – 2 of these fatalities were with Low Voltage (LV) = 50 – 1000 volts. In 2006 there were NO Electrical Fatalities in Ireland First time since 1936

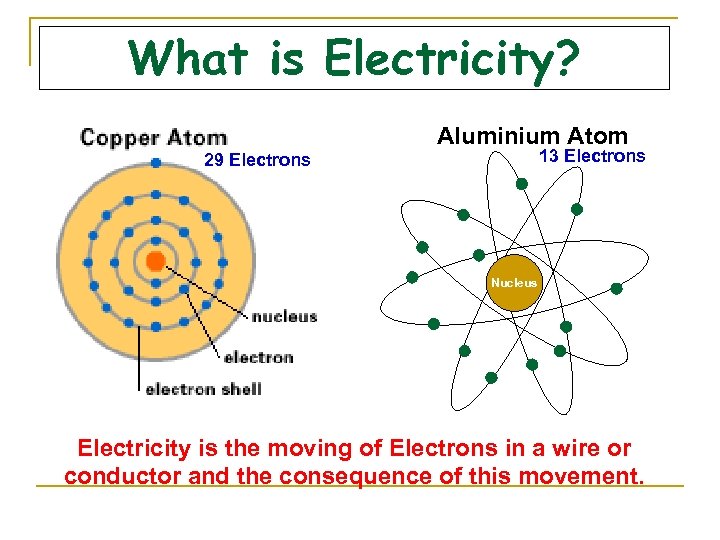

What is Electricity? SO WHAT IS IT MADE OF!!! Electricity is made up of a range of components e. g. Voltage – Current – Resistance – Power.

What is Electricity? Aluminium Atom 13 Electrons 29 Electrons Nucleus Electricity is the moving of Electrons in a wire or conductor and the consequence of this movement.

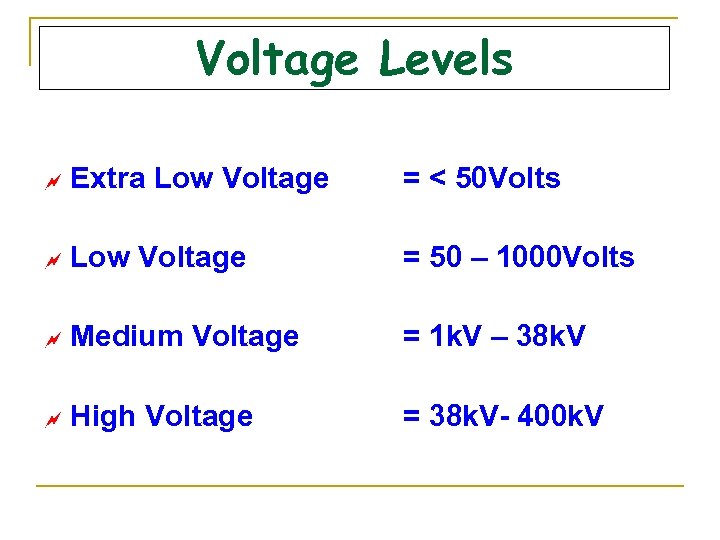

Voltage Levels ~ Extra Low Voltage = < 50 Volts ~ Low Voltage = 50 – 1000 Volts ~ Medium Voltage = 1 k. V – 38 k. V ~ High Voltage = 38 k. V- 400 k. V

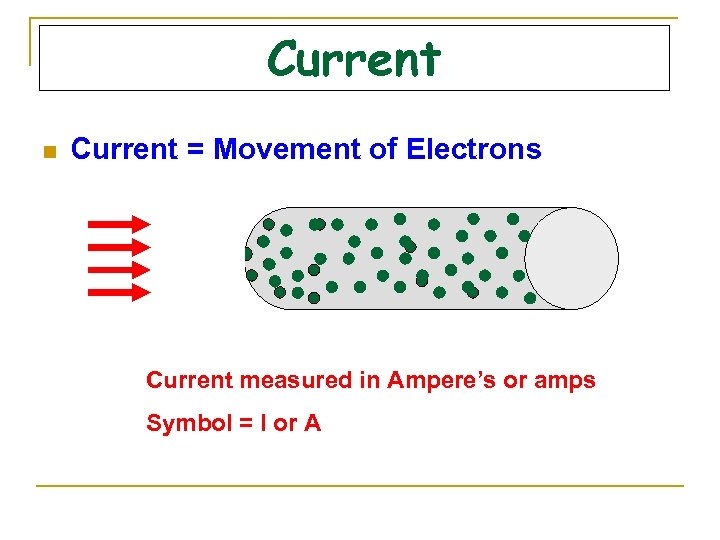

Current n Current = Movement of Electrons Current measured in Ampere’s or amps Symbol = I or A

Types of Current DIRECT CURRENT (DC) ALTERNATING CURRENT (AC)

Frequency n Frequency of a system = Number of cycles per second n In Ireland this = 50; n It is measured in Hertz (Hz) n 50 hz

Stroboscopic Effect n May cause rotating objects to appear stationary or at least moving slowly n Fluorescent lighting – Problems n Solution – Filament lighting adjacent to machine n Solution – Supply each row of lights from separate Phases

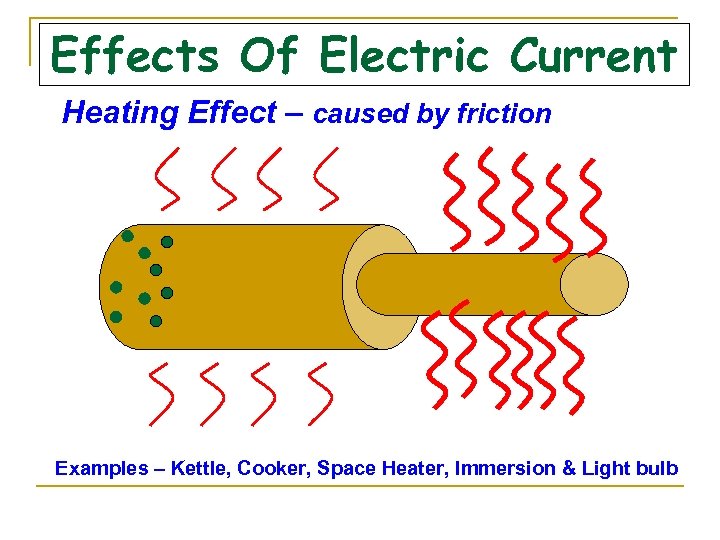

Effects Of Electric Current Heating Effect – caused by friction Examples – Kettle, Cooker, Space Heater, Immersion & Light bulb

Effects Of Electric Current Magnetic Effect Voltage Examples – Motors, Transformers, Relays, Contactors & RCD’s

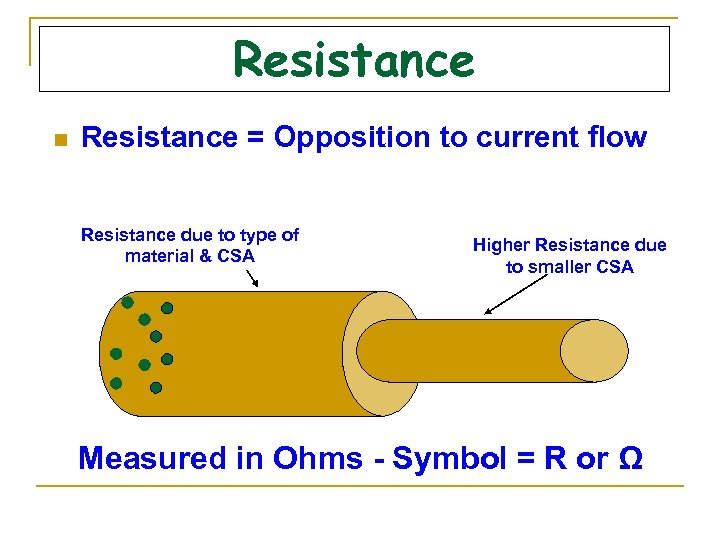

Resistance n Resistance = Opposition to current flow Resistance due to type of material & CSA Higher Resistance due to smaller CSA Measured in Ohms - Symbol = R or Ω

Power Is the rate at which Current flows at a given Resistance and Voltage Power = Voltage x Current Measured in Volt-amps / Watts e. g. 10 VA 15 k. VA /k. W

IP Rating n n IP rating of equipment refers to the electrical equipments ability to withstand the ingress of either liquids or solid bodies IP 56 ; In this example the Ingress protection offered by this equipment is given by the two numbers. The first number refers to the protection against the ingress of solid bodies. The second number refers to the protection against the ingress of liquid.

IP Rating Example of IP rating n IP 45 = Protection against normal dust and hosing and is suitable for Dairies. n IPX 4 = only protected against hosing is given

Electrical hazards associated with electrical systems and equipment include: • Electric shock • Burns sustained at the point of accidental electrical contact, or due to arcing from high voltage conductors • Fires caused by overheating or ignition of explosive atmospheres • Secondary injuries as a result of muscle spasms during shock or, for example, falling from a ladder after a mild shock.

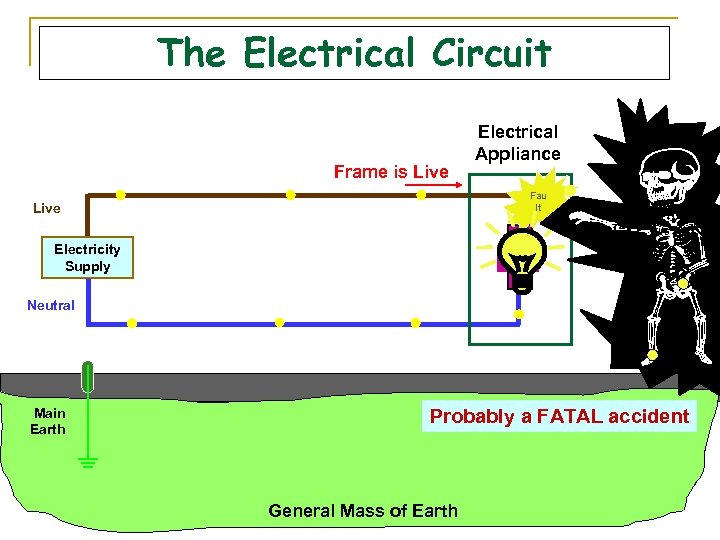

The Electrical Circuit Frame is Live Electrical Appliance Fau lt Live L O A D Electricity Supply Neutral Main Earth Probably a FATAL accident General Mass of Earth

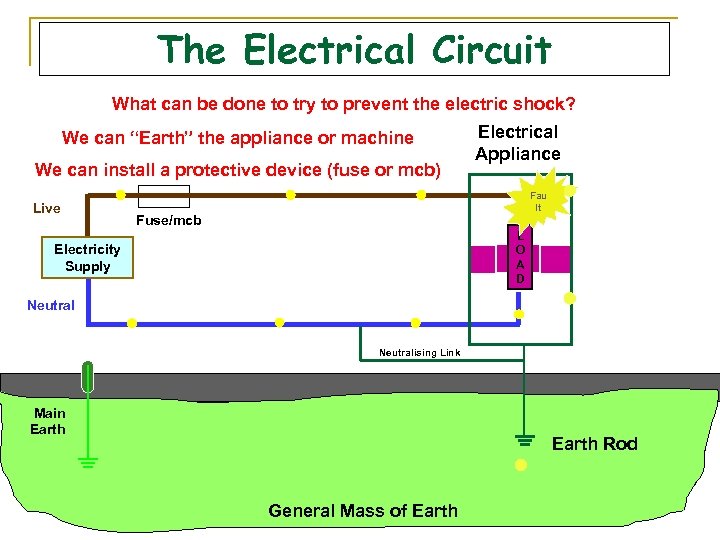

The Electrical Circuit What can be done to try to prevent the electric shock? We can “Earth” the appliance or machine We can install a protective device (fuse or mcb) Live Electrical Appliance Fau lt Fuse/mcb L O A D Electricity Supply Neutralising Link Main Earth Rod General Mass of Earth

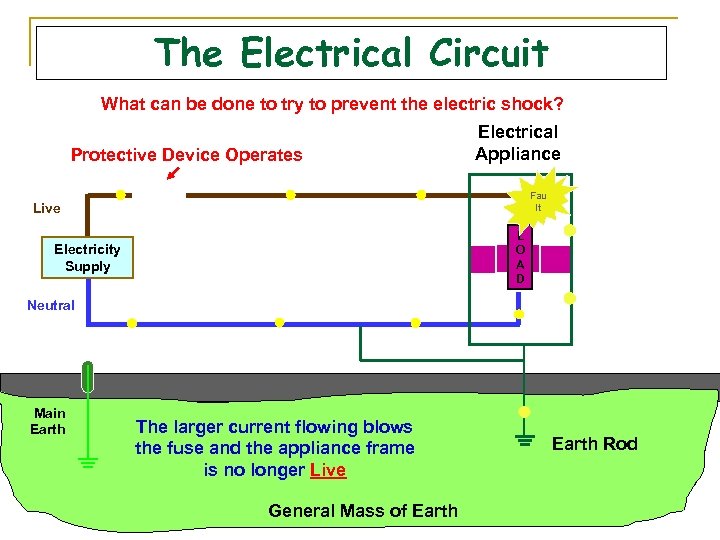

The Electrical Circuit What can be done to try to prevent the electric shock? Protective Device Operates Electrical Appliance Fau lt Live L O A D Electricity Supply Neutral Main Earth The larger current flowing blows the fuse and the appliance frame is no longer Live General Mass of Earth Rod

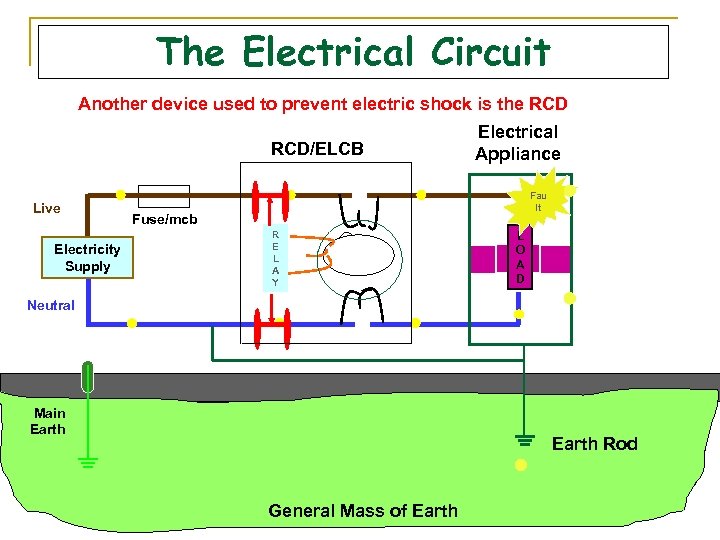

The Electrical Circuit Another device used to prevent electric shock is the RCD/ELCB Live Electricity Supply Electrical Appliance Fau lt Fuse/mcb R E L A Y L O A D Neutral Main Earth Rod General Mass of Earth

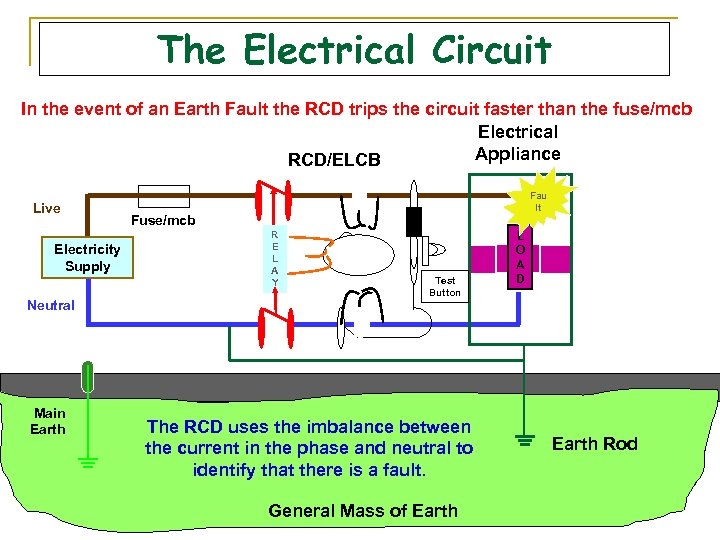

The Electrical Circuit In the event of an Earth Fault the RCD trips the circuit faster than the fuse/mcb Electrical Appliance RCD/ELCB Live Electricity Supply Neutral Main Earth Fau lt Fuse/mcb R E L A Y Test Button The RCD uses the imbalance between the current in the phase and neutral to identify that there is a fault. General Mass of Earth L O A D Earth Rod

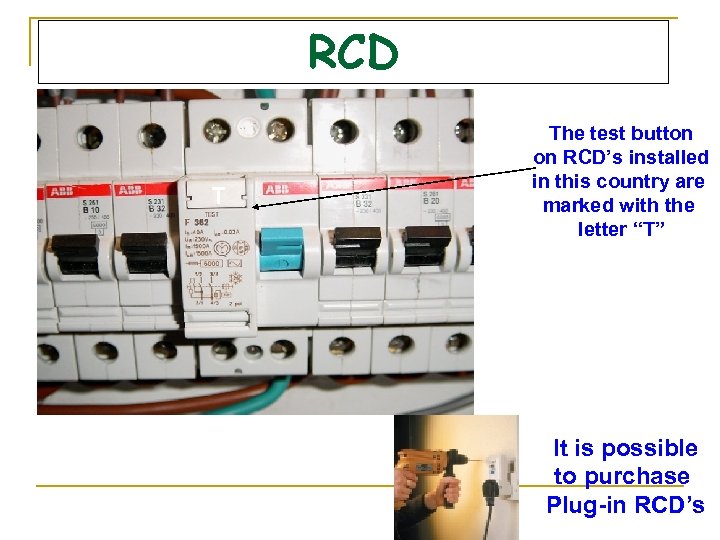

RCD T The test button on RCD’s installed in this country are marked with the letter “T” It is possible to purchase Plug-in RCD’s

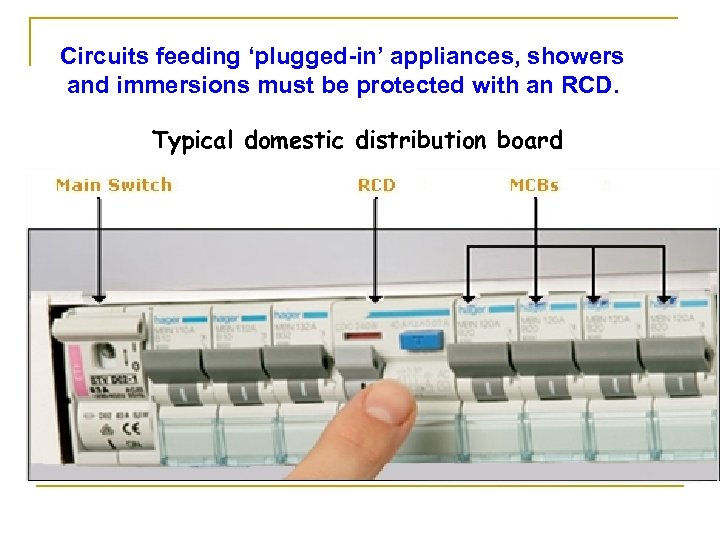

Circuits feeding ‘plugged-in’ appliances, showers and immersions must be protected with an RCD. Typical domestic distribution board

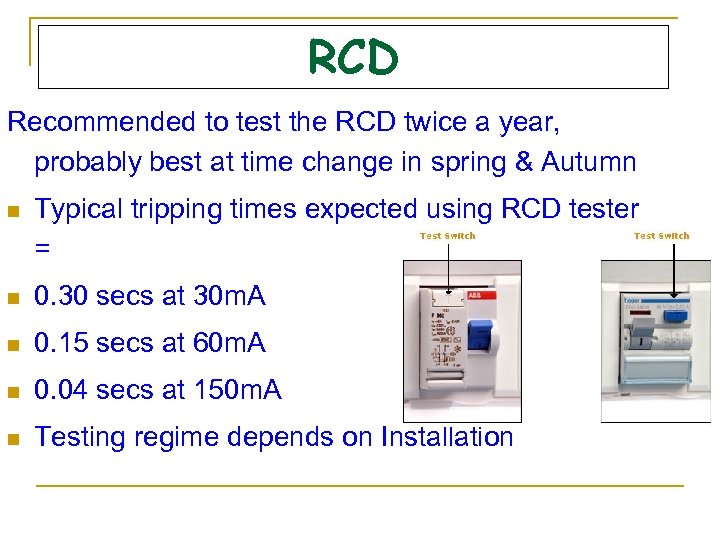

RCD Recommended to test the RCD twice a year, probably best at time change in spring & Autumn n Typical tripping times expected using RCD tester = n 0. 30 secs at 30 m. A n 0. 15 secs at 60 m. A n 0. 04 secs at 150 m. A n Testing regime depends on Installation

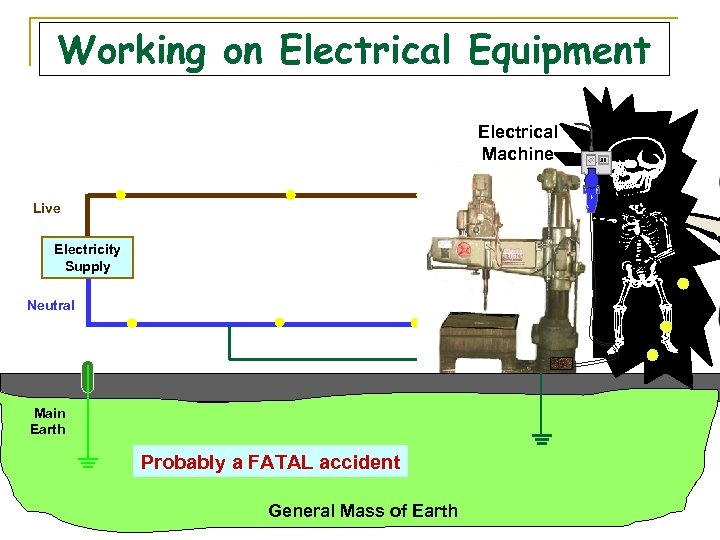

Working on Electrical Equipment Electrical Machine Live L O A D Electricity Supply Neutral Main Earth Probably a FATAL accident General Mass of Earth

Electrical Hazards ~Electric shock – electrocution Caused by simultaneous contact of two parts of the body with either: Phase (live) and Neutral (Single Phase System) Phase and another Phase (3 phase System) Phase (live) and Earth.

Effects of Electric Shock ~ Involuntary muscular contraction ~ Respiratory paralysis (Asphyxia) ~ Surface and deep tissue burns ~ Lack of Oxygen in blood, ~ Loss of consciousness ~ Ventricular fibrillation of heart (spasms) ~ Death in 3 -7 minutes if no intervention (CPR).

Effects of Electric Shock depend on: ~ Level of Voltage ~ Duration of shock ~ Body Resistance ~ Insulating material (e. g. shoes, gloves) ~ Path of current ~ Person’s health (e. g. heart condition) ~ Age.

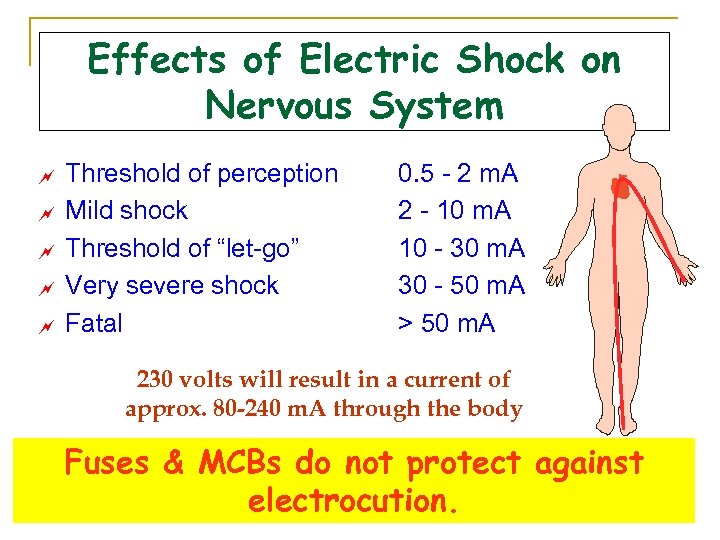

Effects of Electric Shock on Nervous System ~ ~ ~ Threshold of perception Mild shock Threshold of “let-go” Very severe shock Fatal 0. 5 - 2 m. A 2 - 10 m. A 10 - 30 m. A 30 - 50 m. A > 50 m. A 230 volts will result in a current of approx. 80 -240 m. A through the body Fuses & MCBs do not protect against electrocution.

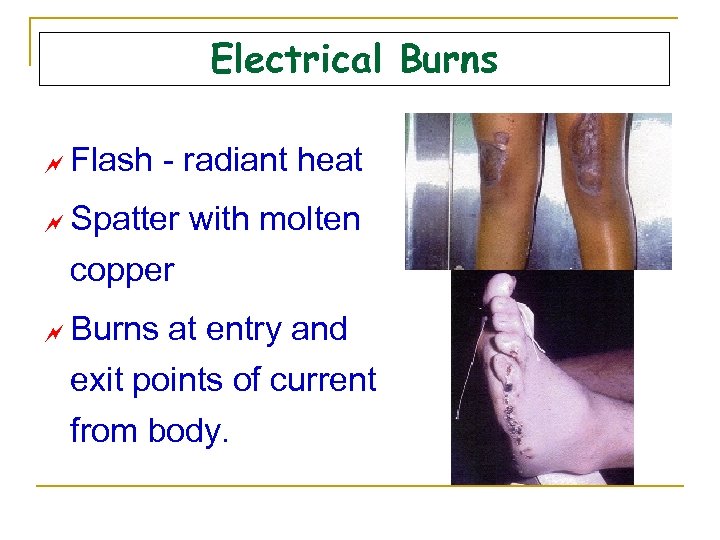

Electrical Burns ~ Flash - radiant heat ~ Spatter with molten copper ~ Burns at entry and exit points of current from body.

Protection Against Electric Shock ~ Proper Earthing and Bonding ~ Use of Earth Leakage Circuit Breaker (RCD) ~ Safe System of Work (Lockout/Tagout) ~ Use of Insulated Gloves, ~ Use of Insulated Footwear or Insulated Mat ~ Use of Double Insulated Work Equipment ~ Regular Inspection & Testing of Installation and Equipment

Electrical Device Safety 1. Properly fitted plug tops 2. Plug tops should have the correct fuse 3. Routine Safety Testing 4. Do not place fluids on top of electrical devices 5. Do not plug in equipment when you have wet hands 6. Report all faults 7. Report all frayed cables, broken plugs or any plugs that feel warm.

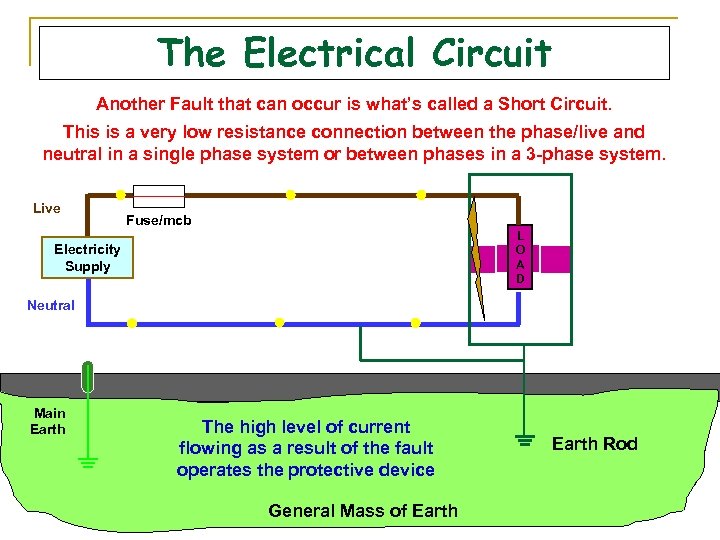

The Electrical Circuit Another Fault that can occur is what’s called a Short Circuit. This is a very low resistance connection between the phase/live and neutral in a single phase system or between phases in a 3 -phase system. Live Fuse/mcb L O A D Electricity Supply Neutral Main Earth The high level of current flowing as a result of the fault operates the protective device General Mass of Earth Rod

Electrical Hazards n Short Circuit Explosive effect of discharge. Fire. Pressure Wave Shrapnel Sound

Protection Against Short Circuit ~ Use of Proper Circuit Protection. ~ Use of Insulated Tools ~ Adequate information about the risks ~ Use of Full Face Visor & Helmet, ~ Use of appropriate Arc Resistive Overalls ~ Use of suitable barriers & screens ~ Accompaniment by second person ~ Effective control of work area

LEGISLATION ~ The SHAWW (General Application) Regs, 2007 (S. I. 299 ) Part III – Electricity. ~ The SHAWW (General Application) Regs, (Amendment), 2007 (S. I. 732) ~ The National Rules for Electrical Installations. Code of Practice produced by the Electro. Technical Council of Ireland (ETCI).

Electrical Standards ~ ~ The Electro-Technical Council of Ireland (ETCI), is the National body responsible for the harmonisation of standards in the electro-technical field, in collaboration with the National Standards Authority of Ireland (NSAI). ETCI is the Irish Member of the International Electro-technical Commission (IEC) and the European Committee for Electro-Technical Standardisation (CENELEC)

Statutory requirements – SI 299 of 2007 n Part 3 of the General Application Regulations 2007 requires precautions to be taken against the risk of death or personal injury and to prevent danger so far as is reasonably practicable from electricity used in work activities.

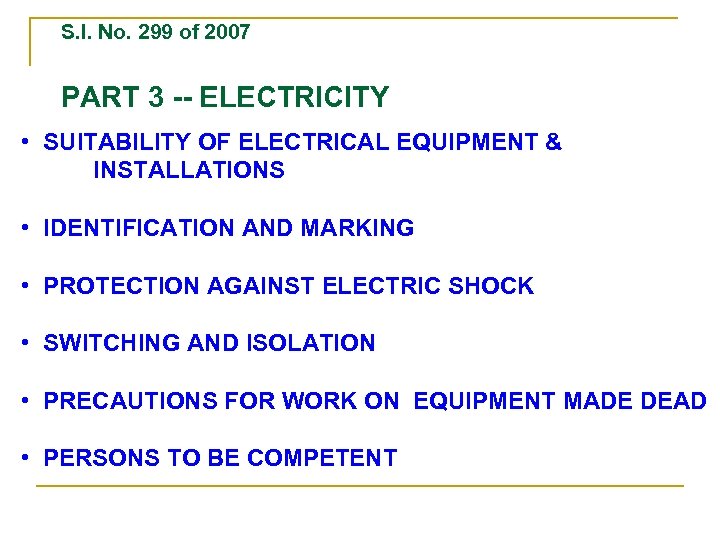

S. I. No. 299 of 2007 PART 3 -- ELECTRICITY • SUITABILITY OF ELECTRICAL EQUIPMENT & INSTALLATIONS • IDENTIFICATION AND MARKING • PROTECTION AGAINST ELECTRIC SHOCK • SWITCHING AND ISOLATION • PRECAUTIONS FOR WORK ON EQUIPMENT MADE DEAD • PERSONS TO BE COMPETENT

Isolation The Disconnection and Separation of electrical equipment from every source of electrical energy in such a way that the disconnection and separation is secure. n

Earthing n Means the connection of the exposed conductive parts of an installation to the conductive mass of the earth

Regulation 75: Application of Part 3 2) This Part does not apply to— (a) any electrical equipment or electrical installation used exclusively for electrical testing or research purposes, or (b) medical electrical equipment, but persons using equipment referred to in subparagraph (b) shall ensure that the equipment or installation is constructed, installed, maintained, protected and used, with adequate precautions being taken, so as to prevent danger.

Statutory requirements – SI 299 of 2007 Regulation 76: n An Employer shall ensure that. All electrical equipment and electrical installations are – a) b) c) d) e) f) Designed Constructed Installed Maintained Protected, and Used so as to prevent danger.

Statutory requirements – SI 299 of 2007 Regulation 78: An employer shall ensure that – a) All electrical equipment is suitably identified where necessary to prevent danger, b) All electrical equipment, other than cables & overhead lines, displays the makers name together with all ratings necessary to show that it is suitable for the purpose for which it is used, and c) All electrical circuits are suitably identified at their source to allow those circuits to be safely and securely de-energised and isolated

Statutory requirements – SI 299 of 2007 Regulation 79: An employer shall ensure that all live parts which may cause danger – a) Are suitably covered with insulating material and so protected as to prevent danger Or b) Are the subject of precautions taken to prevent danger, including, where appropriate, the live parts being suitably placed to prevent danger.

n Regulation 81: (1) An employer shall ensure that – (a) a circuit supplying portable equipment or a socket outlet intended to supply portable equipment, including any circuit supplied by an electrical generator, and in which is used alternating current at a voltage(i) exceeding 125 volts and (ii) not exceeding 1000 volts, is protected by one or more RCD’s having a tripping current not exceeding 30 m. A’s operating within such a period of time so as to provide the necessary protection to prevent danger to any person coming into direct or indirect contact with any live part of the circuit.

Regulation 81: (b) (c) portable equipment is maintained in a manner fit for safe use. portable equipment which is(i) exposed to conditions causing deterioration liable to result in danger, and (ii) supplied at a voltage exceeding 125 V AC is – - Visually checked by the user before use, and -Periodically inspected by a competent Person, appropriate to the nature, location and use of the equipment.

Regulation 81: (2) An employer shall ensure, where appropriate, that a competent person— (a) tests any portable equipment described in paragraph (1)(c)(i) and (ii), and (b) certifies whether or not the portable equipment (including any cables and plugs) was, on the day of test, as far as could reasonably be ascertained, safe and without risk to persons coming into direct or indirect contact with any live part of the equipment.

Regulation 81: (3) If the certificate of the competent person referred to in paragraph (2) indicates that the portable equipment tested was not, on the day of the test, safe and without risk, as described in that paragraph, the employer shall ensure that the equipment is not used until it is made safe and certified as such in compliance with paragraph (2).

Regulation 81: (4) An employer shall ensure that – (a) Portable equipment, other than portable (i) (iii) transformers and portable Generators, supplied at a voltage exceeding 125 V ac is not used in – Construction work, External quarrying activities, or Damp or confined locations Unless its rating exceeds 2 k. VA

Statutory requirements – SI 299 of 2007 Regulation 81: (b) Portable hand lamps supplied at a voltage exceeding 25 volts ac or 50 V dc is not used in – (i) Construction work, (ii) External quarrying activities, or (iii) Damp or confined locations, and

Regulation 81: (c) Where a transformer or engine driven generator is used to supply electricity to portable equipment at a voltage greater than 25 volts, but not exceeding 125 volts AC, the neutral (star) point of the secondary windings of three-phase transformers and generators, or the midpoint of the secondary windings of single-phase transformers and generators, shall be connected to earth and in the case of transformers these shall be of the double wound isolating type.

n n Portable transformers supplied at a voltage exceeding 125 volts AC come within the application of Regulation 81(1) and a maximum cable length of two metres should be used on the high voltage or supply side. Where an extension lead is required, this should be used on the low voltage or secondary side of the transformer and it should be suitable for the environment in which it is used.

Statutory requirements – SI 299 of 2007 n Regulation 86 : An employer shall ensure that(a) Work activity, including the operation, use and maintenance of electrical equipment or electrical installations, is carried out in a manner that prevents danger. (b) Before work is carried out on live electrical equipment the equipment is, where appropriate , made dead so as to prevent danger.

Statutory requirements – SI 299 of 2007 Regulation 86 : (c) Adequate precautions are taken to prevent danger arising from(i) Electrical equipment which has been made dead becoming live while work is carried out on or near that equipment, and (ii) Any electrical equipment inadvertently becoming live,

Statutory requirements – SI 299 of 2007 (d) Where it is necessary for work to be carried out on or near any live part, other than one suitably covered with insulating material so as to prevent danger, of electrical equipment, a person is not engaged in work activity unless- (i) it is unreasonable in the circumstances for it to be dead; (ii) it is reasonable in the circumstances for such a person to be at work on or near it while it is live, and (iii) suitable precautions are taken to prevent danger, including, where necessary, the provision of protective equipment.

Statutory requirements – SI 299 of 2007 Regulation 87: An employer shall ensure that(a) Adequate working space, adequate means of access and egress and adequate lighting are provided at all electrical equipment …. . and b) Emergency lighting is fitted in all switchrooms in order to give an adequate degree of lighting in the event of a loss of electrical supply.

Statutory requirements – SI 299 of 2007 Regulation 88: An employer shall ensure that no person is engaged in any work activity to which this part relates where technical knowledge and experience is necessary to prevent danger unless that person is competent or is under such degree of supervision as is appropriate, having regard to the nature of the work

Regulation 89: An employer shall ensure that— (a) a new electrical installation and a major alteration of, or extension to, an existing electrical installation is, after completion, inspected and tested by a competent person and a report of the test is completed verifying that the relevant requirements of this Part have been complied with, n

n Regulation 89 (b) an existing electrical installation is tested by a competent person in an appropriate manner — (i) from time to time where required having regard to the nature, location and use of the installation, or (ii) if an inspector so requires and a report of the test is completed by the competent person carrying out the test,

Statutory requirements – SI 299 of 2007 Regulation 91: (2) An employer shall ensure that only an authorised person or a person acting with his or her consent, or under his or her supervision, can enter any part of a substation or switchroom in which there may be danger

Electrical Safety It is an employer’s duty to provide staff with Safe Systems of Work It is absolutely essential that they have safe work methods and procedures in place to ensure the safety of all who work on electrical equipment or installations:

Electrical Safety When it comes to Electrical Work there are only two scenario’s: ~ Working on Equipment ‘Dead’ ~ Working on Equipment ‘Live’ There is no in between Therefore a Safe Operating Procedure is required for both.

Working on Equipment ‘Dead’ It is always preferable to work on ‘dead’ equipment or installations (SI 299). Any Procedure for making Electrical Equipment ‘Dead’ e. g. Lockout/Tagout Procedure should be based on the 5 golden rules: 1 Disconnect from the power supply 2 Prevent re-connection (lock-off) 3 Check for absence of voltage 4 Earth and short circuit (if appropriate) 5 Protect from adjacent live parts

Lockout and Tagout Procedure based on 5 Golden Rules PURPOSE ~ To comply with Health and Safety legislation ~ To protect employees from any unintended release of potentially hazardous energy while setting up, adjusting, repairing, servicing, maintaining or installing equipment or machinery.

Lockout and Tagout When to use: Lockout and Tagout must be used where the unexpected energising, start up or release of stored energy could occur and cause injury. Who should use: All personnel authorised to implement a Lockout and Tagout system. Personnel trained in the identification of energy sources, location and operation of isolating equipment and utilisation of Lockout and Tagout devices.

Lockout and Tagout What is Lockout: The placement of a Lockout Device on an energy isolation device to ensure that the isolation device and the system it controls cannot be accidentally or inadvertently operated. What is Tagout: The placement of a Tagout Device on an energy isolation device to indicate that the isolation device and the system being controlled should not be operated until the Tagout Device is removed.

Lockout and Tagout Lockout devices must: ~ Be approved type and robust enough for the environment in which they will be used. ~ Only be removed by the person who applied them. ~ Only have one available key in the possession of the approved person

Lockout and Tagout devices must: ~ Be securely attached with a self locking device ~ Be able to withstand the environmental conditions ~ Only be removed by the person who applied them. ~ Be prominently displayed and identify the person who attached the Tagout device

Electrical Contractor Management ~ ~ ~ ~ ~ Valid Public Liability Insurance Contractor Safety Statement Contractor Job Method Statement Risk Assessment Site Induction Permit to Work – Lockout Permit Competent workers (with Safe Pass) Suitable Safety Equipment & PPE Suitable (certified & tested) Instruments

Working on Equipment ‘Live’ Electrical equipment or installations are deemed to be ‘Live’ if they are not ‘Dead’ i. e. switched off, locked off and verified that it is off. Live Working should be the exception and only carried out when it is unreasonable for the electricity supply to be switched off and suitable precautions are taken to minimise the risks.

Live Working Precautions ~ ~ ~ The use of people who are properly trained and competent to work safely on live equipment. The provision of adequate information to the person carrying out the work about the live parts involved and the likely risks. The use of suitable tools including insulated tools, equipment and protective clothing. The use of suitable insulated barriers or screens. The use of suitable instruments and test probes. Accompaniment by another person if their presence could contribute significantly to ensuring that danger is prevented.

Personal Protective Equipment (PPE) Arc Flash Protection Overalls These overalls are designed to protect the body from burn injuries resulting from electrical short circuit. EN 61482 Electrical Insulated Gloves These gauntlet type latex gloves should comply with the international standard EN 60903. They should be stamped with the live working symbol along with Class 0 to indicate they will insulate up to 1000 volts. Before use each glove should be visually examined and inflated to check for damage and punctures. Any glove that fails the tests must be cut up and scrapped immediately. Live Working Symbol = Electrical Insulated Mat The insulated mat provides effective means of improving protection against second point of contact. It should be stamped with the live working symbol and the level of voltage to which it will insulate. Electrical Insulated Boots The insulated boots should comply with the international standard EN 50321. They should be indelibly stamped on the inside of each boot with the live working symbol, the level of voltage to which they will insulate and the month and year of manufacture. The boots must be checked for cuts, punctures or worn soles before use.

Personal Protective Equipment (PPE) Face and Eye Protection A full face visor complying with the international standard EN 166 must be worn where there is a risk of face or eye damage from electrical short circuits. Insulated Shrouding is designed for temporary protection against accidental contact during work. It should be stamped with the live working symbol and indicate the level of voltage to which it will insulate.

Personal Protective Equipment (PPE) Test Instruments All test instruments used on Live electrical equipment Must be fully insulated to a minimum voltage level of 1000 volts. They should comply with the international standard EN 61243 Test Instrument Leads and Probes Test equipment connecting leads and probes should be sufficiently protected to prevent accidental contact when being applied to and removed from live parts e. g. maximum of 3 mm exposed metal tip of probe.

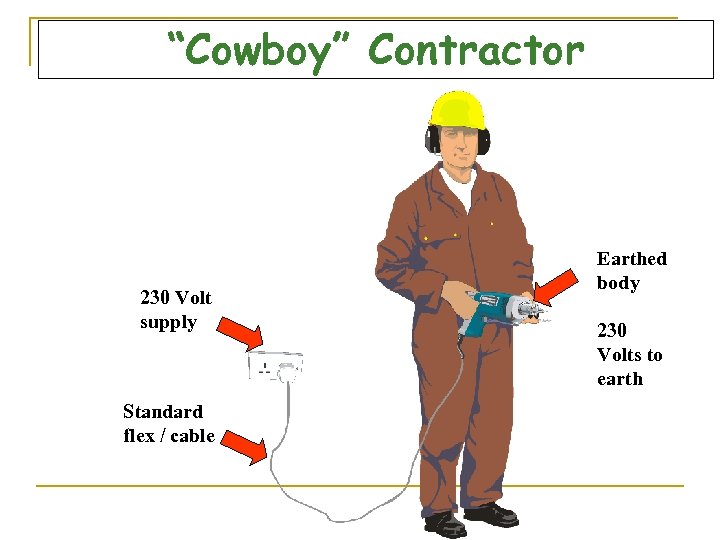

“Cowboy” Contractor 230 Volt supply Standard flex / cable Earthed body 230 Volts to earth

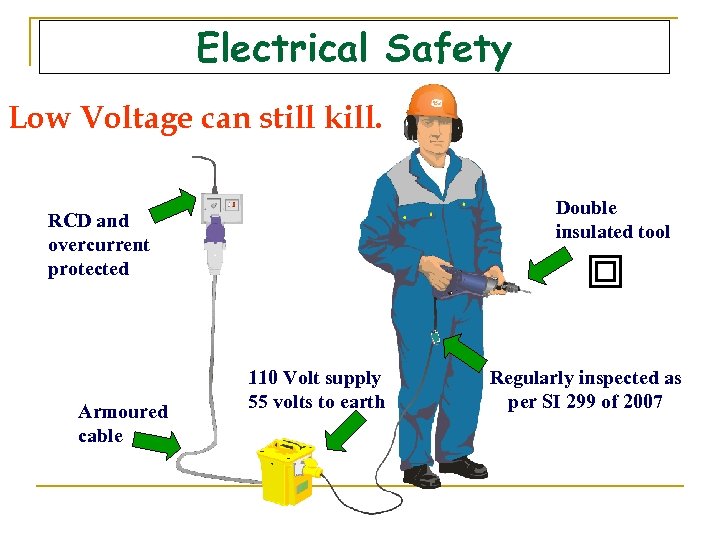

Electrical Safety Low Voltage can still kill. Double insulated tool RCD and overcurrent protected Armoured cable 110 Volt supply 55 volts to earth Regularly inspected as per SI 299 of 2007

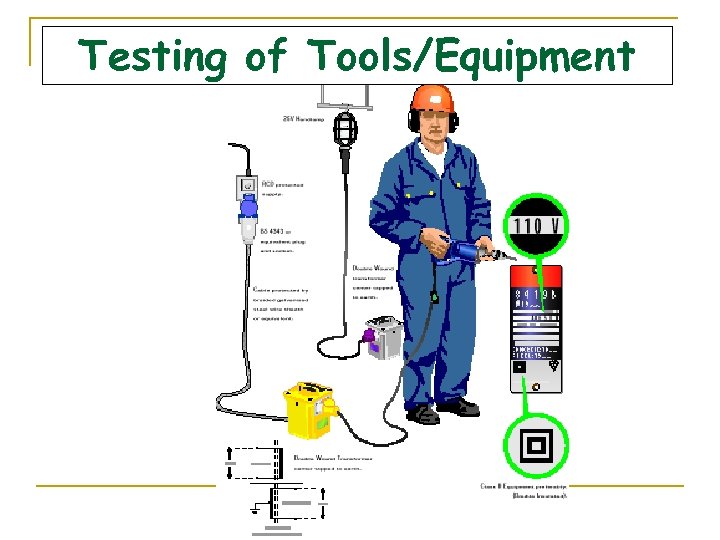

Testing of Tools/Equipment

Portable Appliance Testing USE OF WORK EQUIPMENT It is the duty of every employer to ensure that in the case of work equipment which is exposed to conditions causing deterioration liable to result in a danger to safety or health, that periodic inspections and, where appropriate, testing is carried out. The results of inspections should be kept for 5 years from date of inspection.

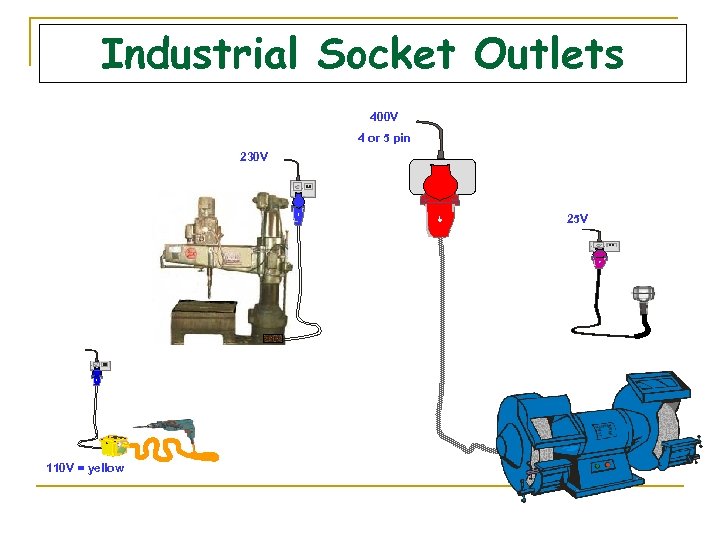

Industrial Socket Outlets 400 V 4 or 5 pin 230 V 25 V 110 V = yellow

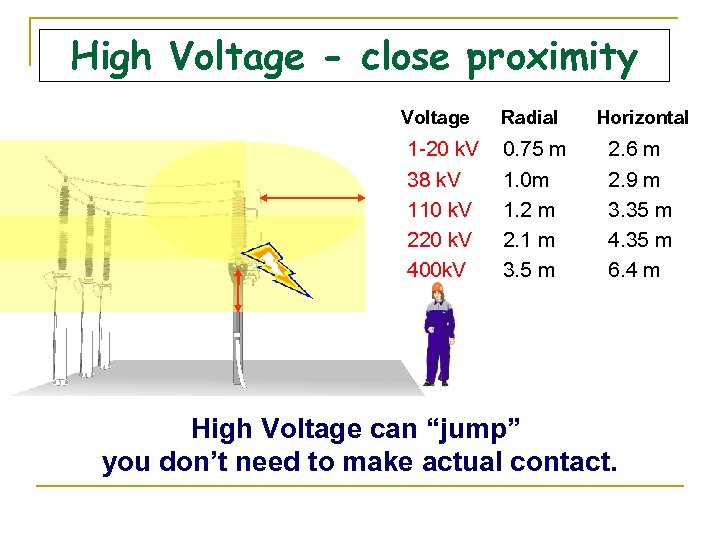

High Voltage - close proximity Voltage 1 -20 k. V 38 k. V 110 k. V 220 k. V 400 k. V Radial Horizontal 0. 75 m 1. 0 m 1. 2 m 2. 1 m 3. 5 m 2. 6 m 2. 9 m 3. 35 m 4. 35 m 6. 4 m High Voltage can “jump” you don’t need to make actual contact.

ELECTRICAL SAFETY-High Voltage ~ Access to HV Apparatus must be restricted to authorised personnel only ~ Doors & gates to rooms, cubicles and compounds: q q Must be kept locked to prevent entry by unauthorised personnel, and, Key must be controlled.

Working beneath a Live Line ~ Where work is to be carried out close to a live line, ESB Networks insist on the line being switched out for the duration of such work. ~ In some situations work will be allowed but only after detailed consultation and with the understanding that strict safety precautions will be employed. ~ In addition to all previously mentioned precautions a barrier of timber or an earthed steel net will be erected under the supervision of ESB at a height also determined by ESB.

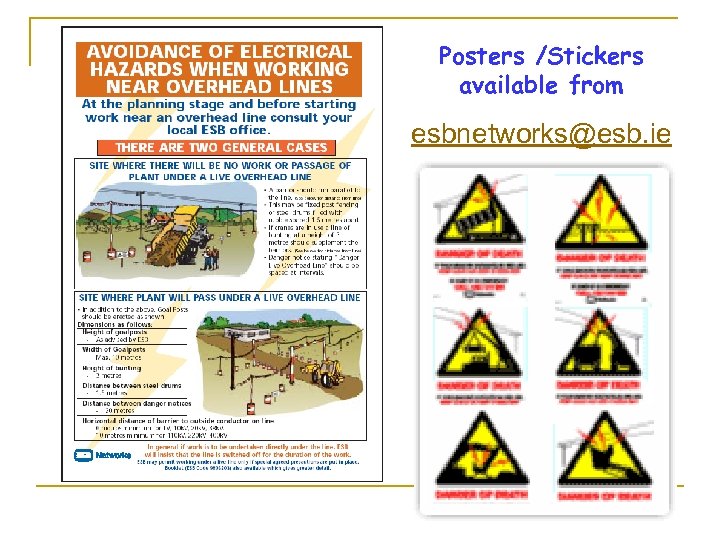

Working in Proximity to Overhead Lines ~ Sites where there will be no work or passage of plant under a live line require barriers to prevent close approach. ~ Sites where plant will pass under a live line require defined passageways under the line to be made. ~ Sites where work will be done beneath a live line require further precautions in addition to the provision of barriers and passageways.

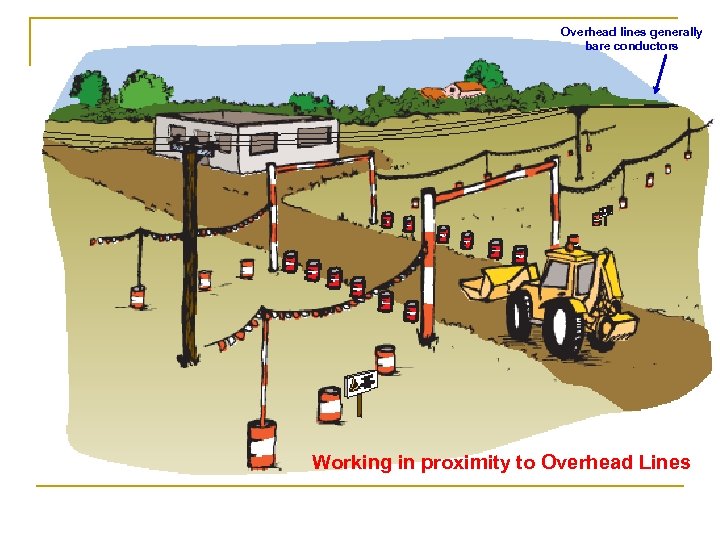

Passage beneath a Live Line ~ Contractor should erect wooden or nonconducting material goal posts at the entrance to the passage on each side of the line. ~ The goal posts should be in line with the protection barrier. ~ The passageway should be as narrow as possible, not exceed 10 metres and should be fenced or have steel drums on either side.

Overhead lines generally bare conductors Working in proximity to Overhead Lines

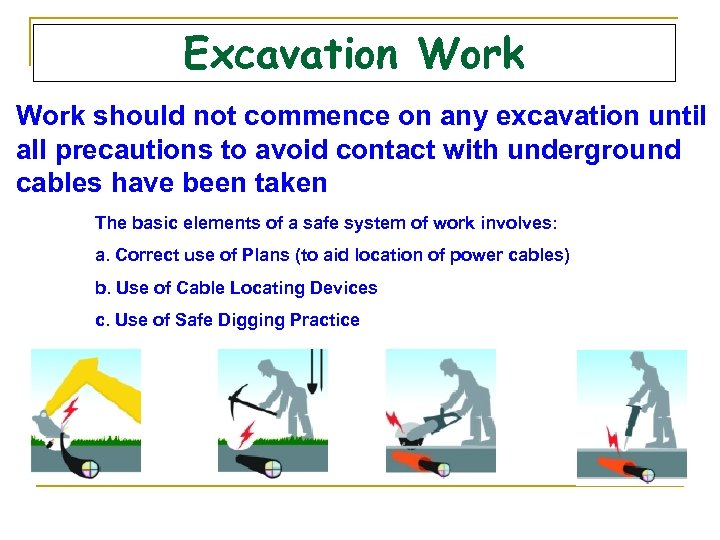

Excavation Work should not commence on any excavation until all precautions to avoid contact with underground cables have been taken The basic elements of a safe system of work involves: a. Correct use of Plans (to aid location of power cables) b. Use of Cable Locating Devices c. Use of Safe Digging Practice

Farms n Farm buildings have special safety requirements for electrical installations and equipment. n Farm working conditions and hazards place much heavier demands on electrical equipment. Special wiring rules for farm buildings must be followed to avoid the risk of accidents. n Domestic equipment is not suitable for use in farm buildings. n A comprehensive booklet 'Farm Well Farm Safely' is available that gives detailed advice on using electricity safely in and around the farm.

New Installations If you are having a new house wired or having existing wiring renewed or extended you should get an ETCI Completion Certificate from your electrical contractor. This certificate is your contractor's statement that the installation complies with the National Wiring Rules. This certificate will also be required before a new supply can be connected.

esbnetworks@esb. ie

Communicating Electrical Safety to your Staff n Motivate and encourage staff to be conscious of electrical safety. n Ensure staff are familiar with the Company safety statement and are aware of their obligations. n Ensure staff know the location of emergency switches and isolating devices. n Train staff in the safe use of electrical equipment. n Train staff in First Aid and CPR in the event of an electric shock accident. n Provide staff with appropriate personal protective equipment ( PPE ) and ensure they are trained in its use and maintenance.

Safety Procedures n Put procedures in place to ensure the safety of staff, the electrical installation and the equipment connected to it. n Maintain an up to date record of the electrical installation and update the safety statement where necessary. n Restrict access to areas where electrical installation work is being carried out.

Safety Procedures n Keep work locations clean and tidy especially those where electrical equipment is being worked on. n Keep clear all access routes to emergency switches and distribution boards. n Ensure that portable electrical tools and equipment are low voltage - supplied via suitable transformers. n Identify the location and routes of underground cables, including ESB cables, before any site construction work or excavation work is commenced. n Consult the proper authorities, including ESB Networks before any construction work is commenced in the vicinity of overhead wires, lines or cables.

Your Electrical Installation n n It must comply with the Electro Technical Council of Ireland (ETCI) wiring regulations. Restrict the operation of, and work on, to those competent and qualified to do so. Employ only competent contractors. Ensure that all circuit breakers, fuses, isolators and switches are labelled and cross-referenced to the circuits they control. Hazardous areas, such as explosive, highly flammable and wet locations require special electrical fittings.

Switch-rooms n Keep securely closed and locked. n Restrict access to authorised personnel. n Must be adequately lit and ventilated. n Access routes must be kept free and clear at all times - never use as storage space.

Distribution boards and Fuse boards n Keep doors and covers securely closed. n Access must be kept free and clear at all times.

Appointed Person n Assign somebody to be in charge of the Electrical Installation “Controller” or “Authorised Person” n Allow No Work to take place on the Electrical Installation unless this person has given permission & the work is carried out under a Permit n Fault Switching - Same Permission applies

Posters /Stickers available from esbnetworks@esb. ie

Sources of Further Information n CENELEC (European Committee for Electrotechnical Standardisation), 35 Rue de Stassartstraat, B-1050 Brussels, n International Electrotechnical Commission (IEC), 3 Rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland n The Irish Standards Catalogue published by the National Standards Authority of Ireland (NSAI) may be purchased from: NSAI, Glasnevin, Dublin 9 n I. S. 370: 2007, Colour Code for Buried Plastics Piping

Sources of Further Information Electro-Technical Council of Ireland Ltd (ETCI), ETCI Offices, Unit H 12, Centrepoint Business Park, Oak Road, Dublin 12 n n n n ET 101: National Rules for Electrical Installations, 4 th edition 2008 ET 105: National Rules for Electrical Installations in Potentially Explosive Atmospheres, 2 nd edition ET 106: National Rules for Electrical Installations in Medically Used Rooms ET 202: Guide to the Selection of Electrical Apparatus for Use in Potentially Explosive Atmospheres ET 206: Good Practice Guide on the Management of Electrical Safety at Work ET 209: A Recommended Maintenance & Inspection Routine for Electrical Installations in Potentially Explosive Atmospheres ET 210: Code of Practice for the Selection and Installation of Low Voltage Generators

Sources of Further Information n European Communities (Electrical Equipment for Use in Explosive Atmospheres) Regulations 1999 (S. I. No. 83 of 1999) Building Regulations Technical Guidance Document B: Fire Safety, published by the Department of the Environment, Heritage and Local Government HSA Code of Practice for Avoiding Danger from Underground Services,

To report an emergency, please phone ESB at 1850 372 999

6137fcb8389968123be6279fbe1f5c76.ppt