7c021140b497f48058e08c3a7502eaba.ppt

- Количество слайдов: 20

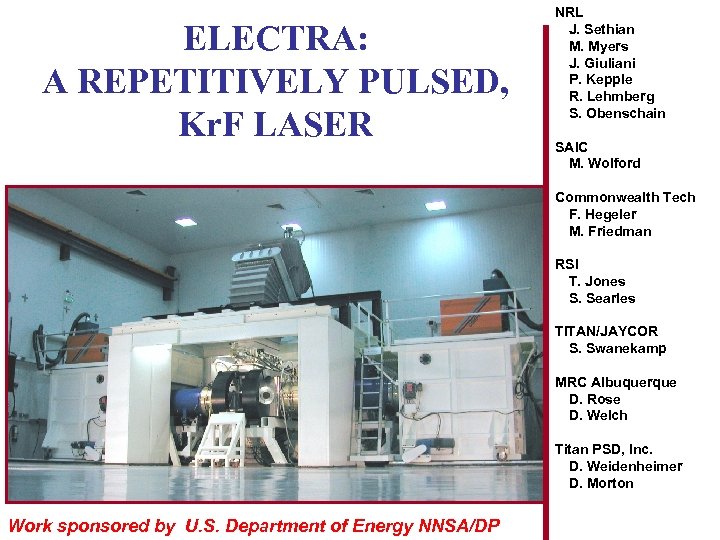

ELECTRA: A REPETITIVELY PULSED, Kr. F LASER NRL J. Sethian M. Myers J. Giuliani P. Kepple R. Lehmberg S. Obenschain SAIC M. Wolford Commonwealth Tech F. Hegeler M. Friedman RSI T. Jones S. Searles TITAN/JAYCOR S. Swanekamp MRC Albuquerque D. Rose D. Welch Titan PSD, Inc. D. Weidenheimer D. Morton Work sponsored by U. S. Department of Energy NNSA/DP

ELECTRA: A REPETITIVELY PULSED, Kr. F LASER NRL J. Sethian M. Myers J. Giuliani P. Kepple R. Lehmberg S. Obenschain SAIC M. Wolford Commonwealth Tech F. Hegeler M. Friedman RSI T. Jones S. Searles TITAN/JAYCOR S. Swanekamp MRC Albuquerque D. Rose D. Welch Titan PSD, Inc. D. Weidenheimer D. Morton Work sponsored by U. S. Department of Energy NNSA/DP

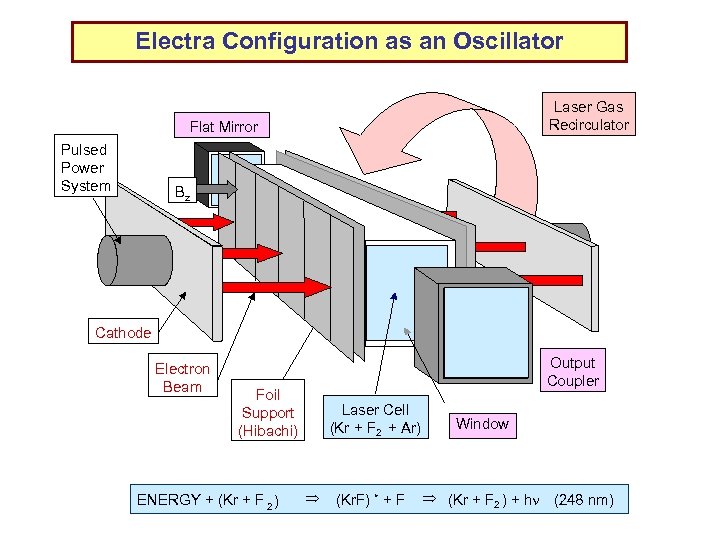

Electra Configuration as an Oscillator Laser Gas Recirculator Flat Mirror Pulsed Power System Bz Cathode Electron Beam Output Coupler Foil Support (Hibachi) ENERGY + (Kr + F 2 ) Laser Cell (Kr + F 2 + Ar) Þ (Kr. F) * + F Window Þ (Kr + F 2 ))+ hn (248 nm) +h

Electra Configuration as an Oscillator Laser Gas Recirculator Flat Mirror Pulsed Power System Bz Cathode Electron Beam Output Coupler Foil Support (Hibachi) ENERGY + (Kr + F 2 ) Laser Cell (Kr + F 2 + Ar) Þ (Kr. F) * + F Window Þ (Kr + F 2 ))+ hn (248 nm) +h

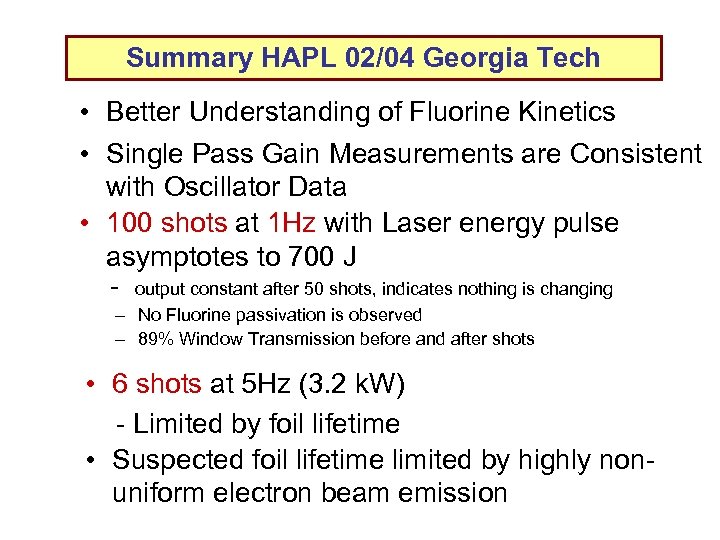

Summary HAPL 02/04 Georgia Tech • Better Understanding of Fluorine Kinetics • Single Pass Gain Measurements are Consistent with Oscillator Data • 100 shots at 1 Hz with Laser energy pulse asymptotes to 700 J - output constant after 50 shots, indicates nothing is changing – No Fluorine passivation is observed – 89% Window Transmission before and after shots • 6 shots at 5 Hz (3. 2 k. W) - Limited by foil lifetime • Suspected foil lifetime limited by highly nonuniform electron beam emission

Summary HAPL 02/04 Georgia Tech • Better Understanding of Fluorine Kinetics • Single Pass Gain Measurements are Consistent with Oscillator Data • 100 shots at 1 Hz with Laser energy pulse asymptotes to 700 J - output constant after 50 shots, indicates nothing is changing – No Fluorine passivation is observed – 89% Window Transmission before and after shots • 6 shots at 5 Hz (3. 2 k. W) - Limited by foil lifetime • Suspected foil lifetime limited by highly nonuniform electron beam emission

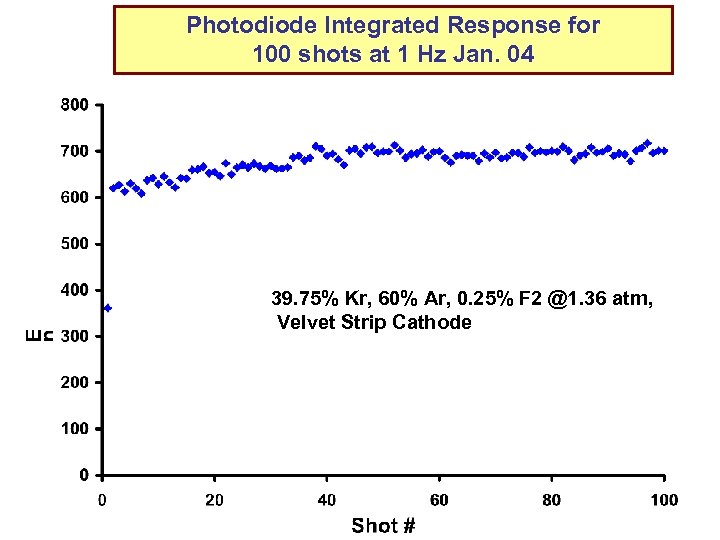

Photodiode Integrated Response for 100 shots at 1 Hz Jan. 04 39. 75% Kr, 60% Ar, 0. 25% F 2 @1. 36 atm, Velvet Strip Cathode

Photodiode Integrated Response for 100 shots at 1 Hz Jan. 04 39. 75% Kr, 60% Ar, 0. 25% F 2 @1. 36 atm, Velvet Strip Cathode

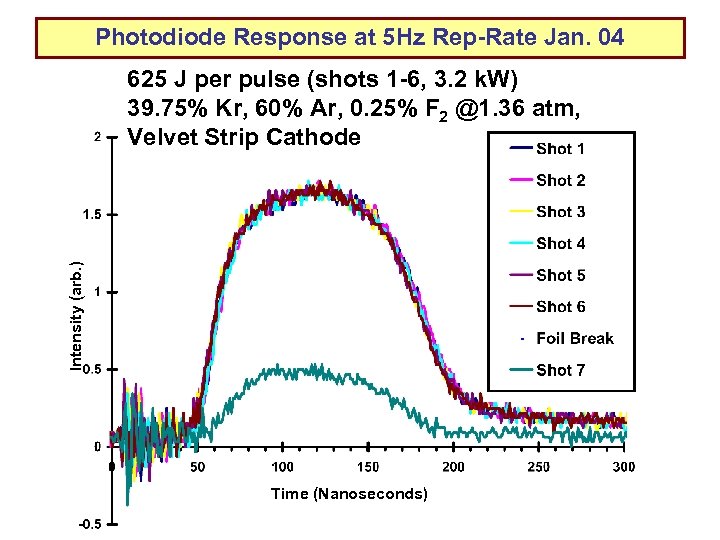

Photodiode Response at 5 Hz Rep-Rate Jan. 04 Intensity (arb. ) 625 J per pulse (shots 1 -6, 3. 2 k. W) 39. 75% Kr, 60% Ar, 0. 25% F 2 @1. 36 atm, Velvet Strip Cathode Time (Nanoseconds)

Photodiode Response at 5 Hz Rep-Rate Jan. 04 Intensity (arb. ) 625 J per pulse (shots 1 -6, 3. 2 k. W) 39. 75% Kr, 60% Ar, 0. 25% F 2 @1. 36 atm, Velvet Strip Cathode Time (Nanoseconds)

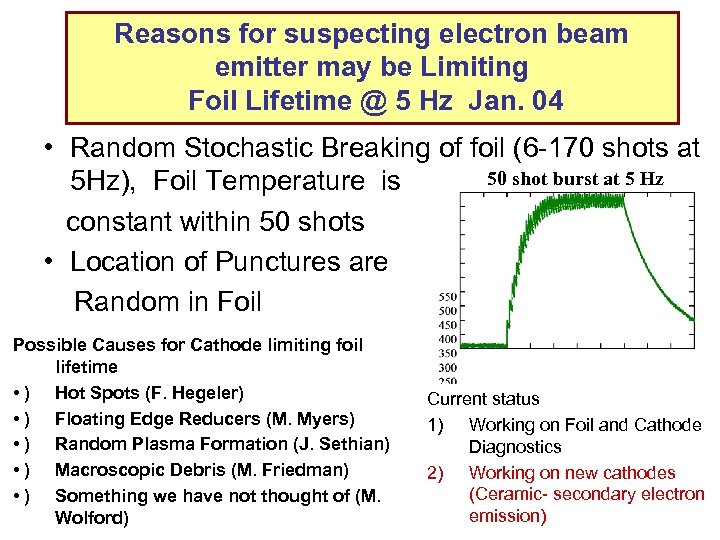

Reasons for suspecting electron beam emitter may be Limiting Foil Lifetime @ 5 Hz Jan. 04 • Random Stochastic Breaking of foil (6 -170 shots at 50 shot burst at 5 Hz 5 Hz), Foil Temperature is constant within 50 shots • Location of Punctures are Random in Foil Possible Causes for Cathode limiting foil lifetime • ) Hot Spots (F. Hegeler) • ) Floating Edge Reducers (M. Myers) • ) Random Plasma Formation (J. Sethian) • ) Macroscopic Debris (M. Friedman) • ) Something we have not thought of (M. Wolford) Current status 1) Working on Foil and Cathode Diagnostics 2) Working on new cathodes (Ceramic- secondary electron emission)

Reasons for suspecting electron beam emitter may be Limiting Foil Lifetime @ 5 Hz Jan. 04 • Random Stochastic Breaking of foil (6 -170 shots at 50 shot burst at 5 Hz 5 Hz), Foil Temperature is constant within 50 shots • Location of Punctures are Random in Foil Possible Causes for Cathode limiting foil lifetime • ) Hot Spots (F. Hegeler) • ) Floating Edge Reducers (M. Myers) • ) Random Plasma Formation (J. Sethian) • ) Macroscopic Debris (M. Friedman) • ) Something we have not thought of (M. Wolford) Current status 1) Working on Foil and Cathode Diagnostics 2) Working on new cathodes (Ceramic- secondary electron emission)

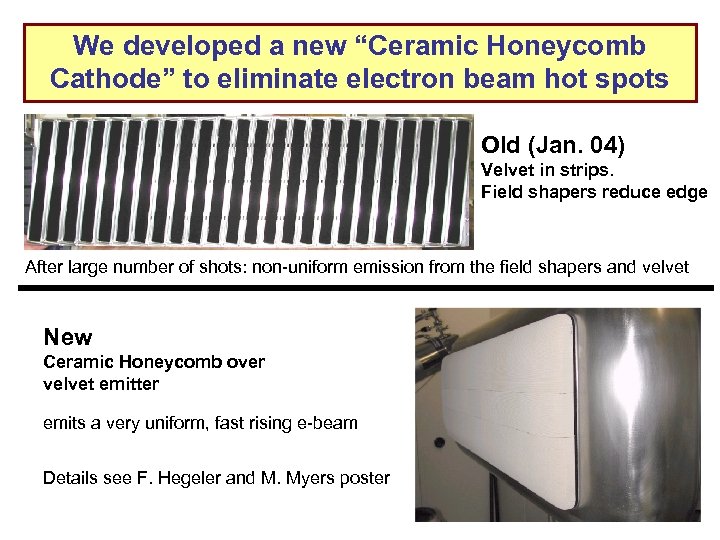

We developed a new “Ceramic Honeycomb Cathode” to eliminate electron beam hot spots Old (Jan. 04) Velvet in strips. Field shapers reduce edge After large number of shots: non-uniform emission from the field shapers and velvet New Ceramic Honeycomb over velvet emitter emits a very uniform, fast rising e-beam Details see F. Hegeler and M. Myers poster

We developed a new “Ceramic Honeycomb Cathode” to eliminate electron beam hot spots Old (Jan. 04) Velvet in strips. Field shapers reduce edge After large number of shots: non-uniform emission from the field shapers and velvet New Ceramic Honeycomb over velvet emitter emits a very uniform, fast rising e-beam Details see F. Hegeler and M. Myers poster

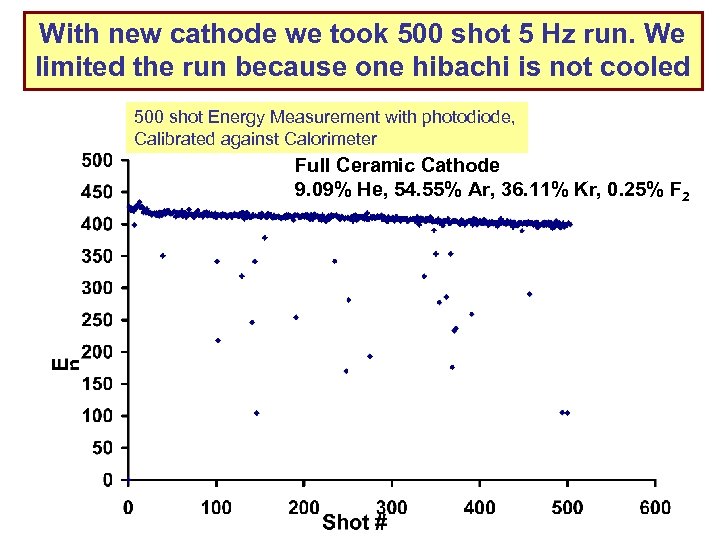

With new cathode we took 500 shot 5 Hz run. We limited the run because one hibachi is not cooled 500 shot Energy Measurement with photodiode, Calibrated against Calorimeter Full Ceramic Cathode 9. 09% He, 54. 55% Ar, 36. 11% Kr, 0. 25% F 2

With new cathode we took 500 shot 5 Hz run. We limited the run because one hibachi is not cooled 500 shot Energy Measurement with photodiode, Calibrated against Calorimeter Full Ceramic Cathode 9. 09% He, 54. 55% Ar, 36. 11% Kr, 0. 25% F 2

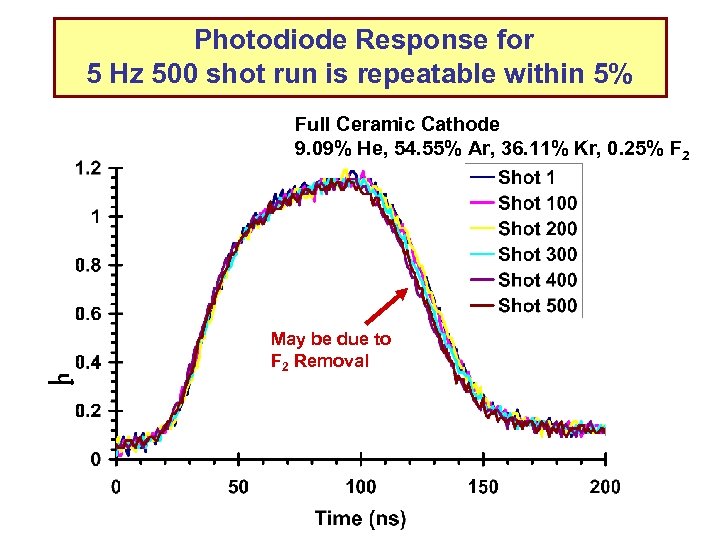

Photodiode Response for 5 Hz 500 shot run is repeatable within 5% Full Ceramic Cathode 9. 09% He, 54. 55% Ar, 36. 11% Kr, 0. 25% F 2 May be due to F 2 Removal

Photodiode Response for 5 Hz 500 shot run is repeatable within 5% Full Ceramic Cathode 9. 09% He, 54. 55% Ar, 36. 11% Kr, 0. 25% F 2 May be due to F 2 Removal

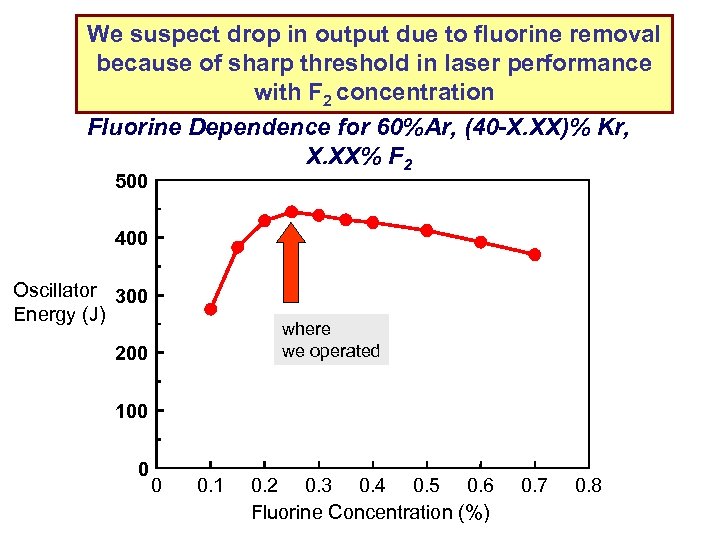

We suspect drop in output due to fluorine removal because of sharp threshold in laser performance with F 2 concentration Fluorine Dependence for 60%Ar, (40 -X. XX)% Kr, X. XX% F 2 500 400 Oscillator 300 Energy (J) where we operated 200 100 0 0 0. 1 0. 2 0. 3 0. 4 0. 5 0. 6 Fluorine Concentration (%) 0. 7 0. 8

We suspect drop in output due to fluorine removal because of sharp threshold in laser performance with F 2 concentration Fluorine Dependence for 60%Ar, (40 -X. XX)% Kr, X. XX% F 2 500 400 Oscillator 300 Energy (J) where we operated 200 100 0 0 0. 1 0. 2 0. 3 0. 4 0. 5 0. 6 Fluorine Concentration (%) 0. 7 0. 8

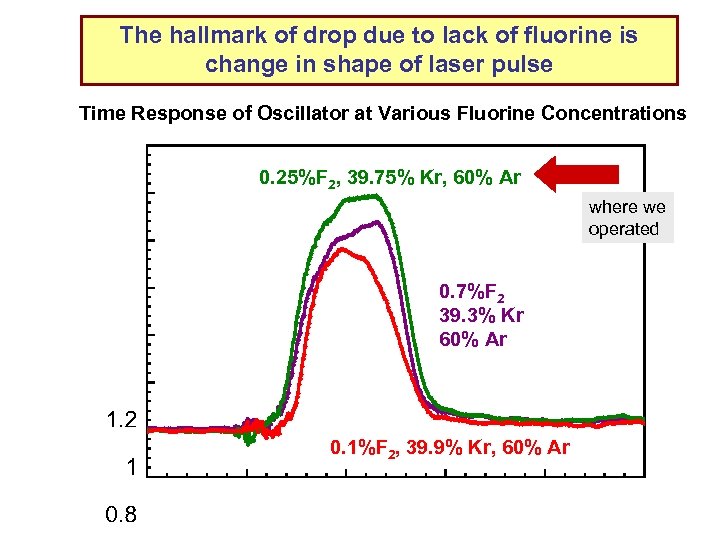

The hallmark of drop due to lack of fluorine is change in shape of laser pulse Time Response of Oscillator at Various Fluorine Concentrations 0. 25%F 2, 39. 75% Kr, 60% Ar where we operated 0. 7%F 2 39. 3% Kr 60% Ar 0. 1%F 2, 39. 9% Kr, 60% Ar

The hallmark of drop due to lack of fluorine is change in shape of laser pulse Time Response of Oscillator at Various Fluorine Concentrations 0. 25%F 2, 39. 75% Kr, 60% Ar where we operated 0. 7%F 2 39. 3% Kr 60% Ar 0. 1%F 2, 39. 9% Kr, 60% Ar

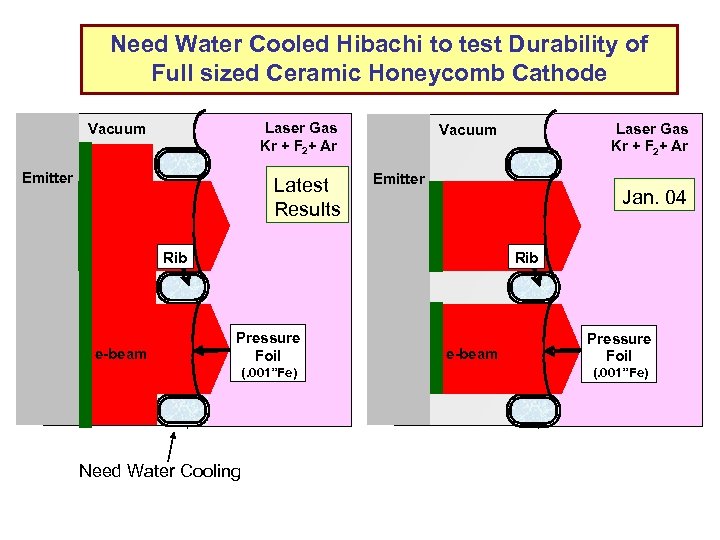

Need Water Cooled Hibachi to test Durability of Full sized Ceramic Honeycomb Cathode Laser Gas Kr + F 2+ Ar Vacuum Emitter Latest Results Emitter Jan. 04 Rib e-beam Laser Gas Kr + F 2+ Ar Vacuum Rib Pressure Foil (. 001”Fe) (. 002”Ti) Need Water Cooling e-beam Pressure Foil (. 001”Fe) (. 002”Ti)

Need Water Cooled Hibachi to test Durability of Full sized Ceramic Honeycomb Cathode Laser Gas Kr + F 2+ Ar Vacuum Emitter Latest Results Emitter Jan. 04 Rib e-beam Laser Gas Kr + F 2+ Ar Vacuum Rib Pressure Foil (. 001”Fe) (. 002”Ti) Need Water Cooling e-beam Pressure Foil (. 001”Fe) (. 002”Ti)

Electra has fired 7715 single sided shots continuously into 22 psi of Ar gas using the water cooled hibachi and 1 mil Stainless Steel Foil The run was terminated due to a problem with the cathode…not the hibachi

Electra has fired 7715 single sided shots continuously into 22 psi of Ar gas using the water cooled hibachi and 1 mil Stainless Steel Foil The run was terminated due to a problem with the cathode…not the hibachi

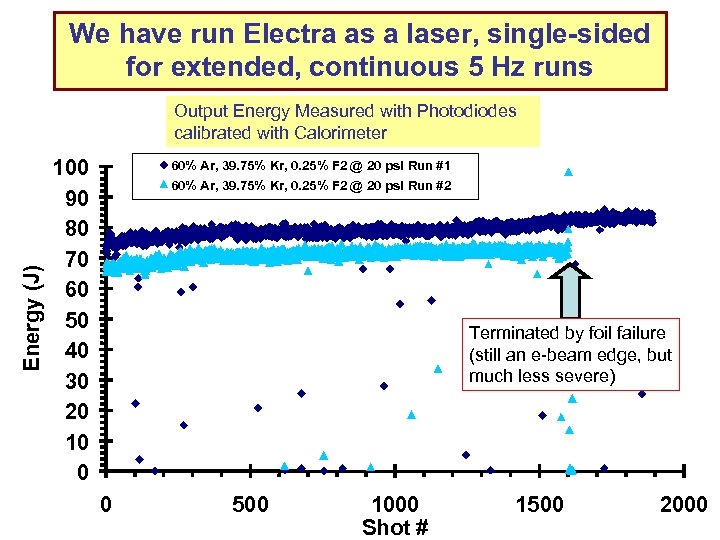

We have run Electra as a laser, single-sided for extended, continuous 5 Hz runs Energy (J) Output Energy Measured with Photodiodes calibrated with Calorimeter 100 90 80 70 60 50 40 30 20 10 0 60% Ar, 39. 75% Kr, 0. 25% F 2 @ 20 psi Run #1 60% Ar, 39. 75% Kr, 0. 25% F 2 @ 20 psi Run #2 Terminated by foil failure (still an e-beam edge, but much less severe) 0 500 1000 Shot # 1500 2000

We have run Electra as a laser, single-sided for extended, continuous 5 Hz runs Energy (J) Output Energy Measured with Photodiodes calibrated with Calorimeter 100 90 80 70 60 50 40 30 20 10 0 60% Ar, 39. 75% Kr, 0. 25% F 2 @ 20 psi Run #1 60% Ar, 39. 75% Kr, 0. 25% F 2 @ 20 psi Run #2 Terminated by foil failure (still an e-beam edge, but much less severe) 0 500 1000 Shot # 1500 2000

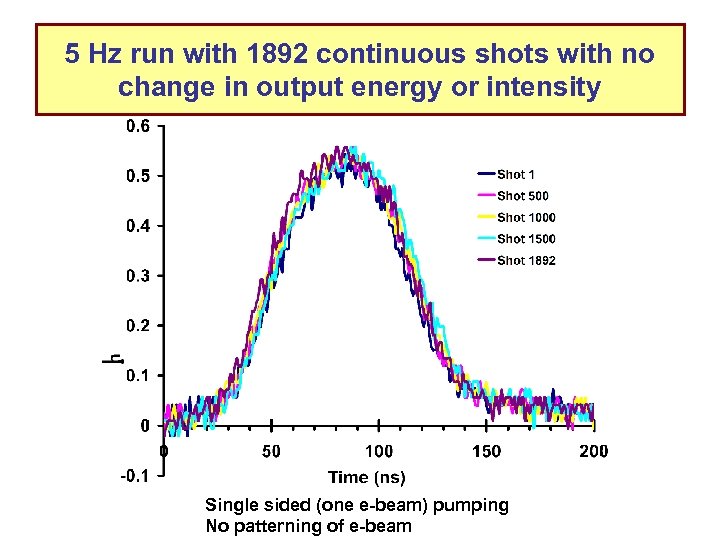

5 Hz run with 1892 continuous shots with no change in output energy or intensity Single sided (one e-beam) pumping No patterning of e-beam

5 Hz run with 1892 continuous shots with no change in output energy or intensity Single sided (one e-beam) pumping No patterning of e-beam

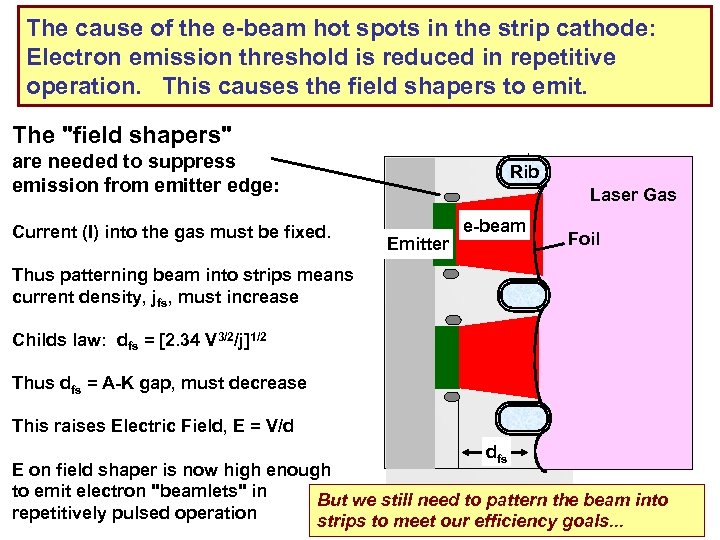

The cause of the e-beam hot spots in the strip cathode: Electron emission threshold is reduced in repetitive operation. This causes the field shapers to emit. The "field shapers" are needed to suppress emission from emitter edge: Current (I) into the gas must be fixed. Rib Laser Gas Emitter e-beam Foil Thus patterning beam into strips means current density, jfs, must increase Childs law: dfs = [2. 34 V 3/2/j]1/2 Thus dfs = A-K gap, must decrease This raises Electric Field, E = V/d dfs E on field shaper is now high enough to emit electron "beamlets" in But we still need to pattern the beam into repetitively pulsed operation strips to meet our efficiency goals. . .

The cause of the e-beam hot spots in the strip cathode: Electron emission threshold is reduced in repetitive operation. This causes the field shapers to emit. The "field shapers" are needed to suppress emission from emitter edge: Current (I) into the gas must be fixed. Rib Laser Gas Emitter e-beam Foil Thus patterning beam into strips means current density, jfs, must increase Childs law: dfs = [2. 34 V 3/2/j]1/2 Thus dfs = A-K gap, must decrease This raises Electric Field, E = V/d dfs E on field shaper is now high enough to emit electron "beamlets" in But we still need to pattern the beam into repetitively pulsed operation strips to meet our efficiency goals. . .

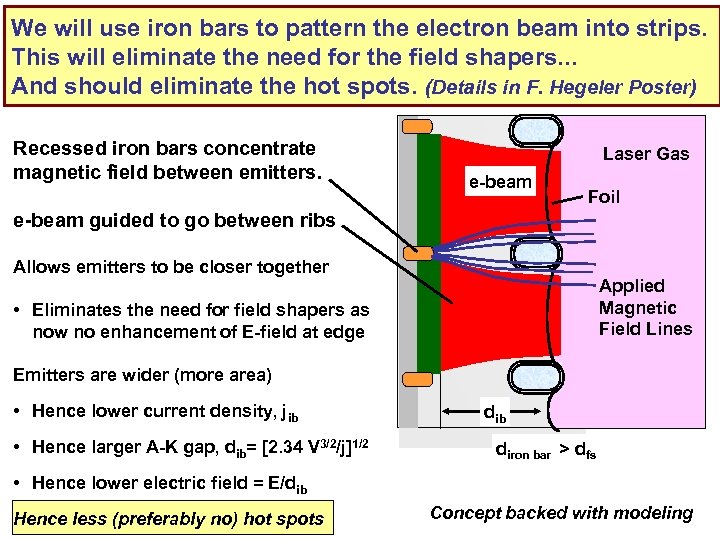

We will use iron bars to pattern the electron beam into strips. This will eliminate the need for the field shapers. . . And should eliminate the hot spots. (Details in F. Hegeler Poster) Recessed iron bars concentrate magnetic field between emitters. Laser Gas e-beam Foil e-beam guided to go between ribs Allows emitters to be closer together Applied Magnetic Field Lines • Eliminates the need for field shapers as now no enhancement of E-field at edge Emitters are wider (more area) • Hence lower current density, jib • Hence larger A-K gap, dib= [2. 34 V 3/2/j]1/2 dib diron bar > dfs • Hence lower electric field = E/dib Hence less (preferably no) hot spots Concept backed with modeling

We will use iron bars to pattern the electron beam into strips. This will eliminate the need for the field shapers. . . And should eliminate the hot spots. (Details in F. Hegeler Poster) Recessed iron bars concentrate magnetic field between emitters. Laser Gas e-beam Foil e-beam guided to go between ribs Allows emitters to be closer together Applied Magnetic Field Lines • Eliminates the need for field shapers as now no enhancement of E-field at edge Emitters are wider (more area) • Hence lower current density, jib • Hence larger A-K gap, dib= [2. 34 V 3/2/j]1/2 dib diron bar > dfs • Hence lower electric field = E/dib Hence less (preferably no) hot spots Concept backed with modeling

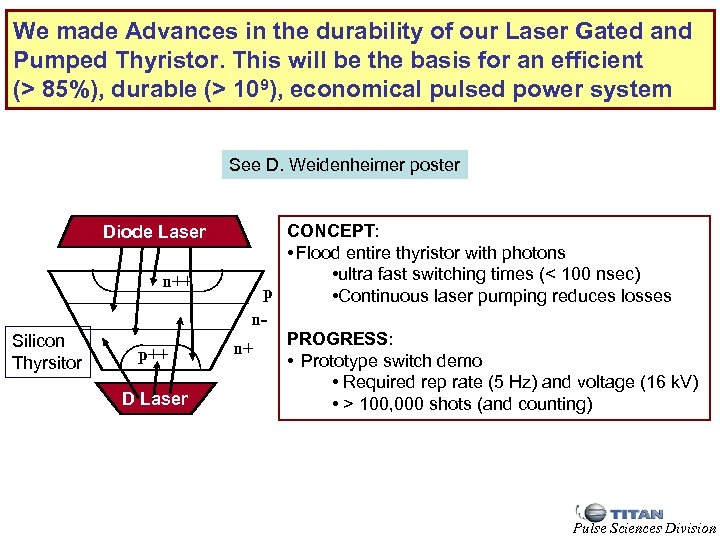

We made Advances in the durability of our Laser Gated and Pumped Thyristor. This will be the basis for an efficient (> 85%), durable (> 109), economical pulsed power system See D. Weidenheimer poster Diode Laser n++ Silicon Thyrsitor p++ D Laser CONCEPT: • Flood entire thyristor with photons • ultra fast switching times (< 100 nsec) p • Continuous laser pumping reduces losses n. PROGRESS: n+ • Prototype switch demo • Required rep rate (5 Hz) and voltage (16 k. V) • > 100, 000 shots (and counting) Pulse Sciences Division

We made Advances in the durability of our Laser Gated and Pumped Thyristor. This will be the basis for an efficient (> 85%), durable (> 109), economical pulsed power system See D. Weidenheimer poster Diode Laser n++ Silicon Thyrsitor p++ D Laser CONCEPT: • Flood entire thyristor with photons • ultra fast switching times (< 100 nsec) p • Continuous laser pumping reduces losses n. PROGRESS: n+ • Prototype switch demo • Required rep rate (5 Hz) and voltage (16 k. V) • > 100, 000 shots (and counting) Pulse Sciences Division

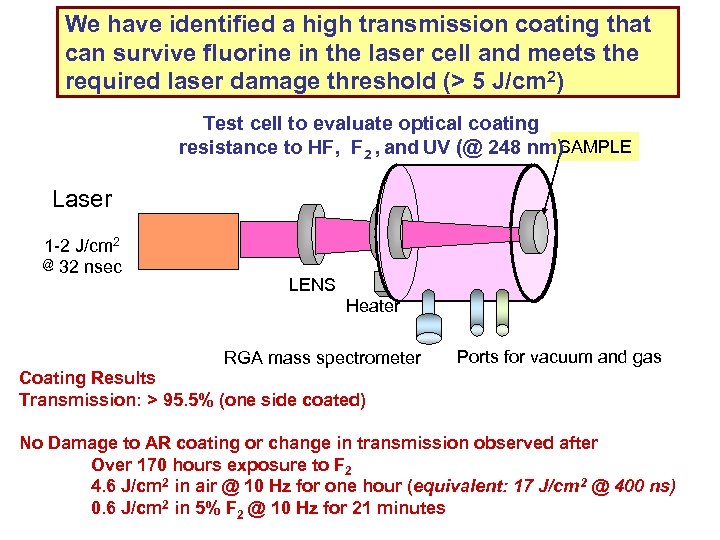

We have identified a high transmission coating that can survive fluorine in the laser cell and meets the required laser damage threshold (> 5 J/cm 2) Test cell to evaluate optical coating SAMPLE resistance to HF, F 2 , and UV (@ 248 nm) Laser 1 -2 J/cm 2 @ 32 nsec LENS Heater RGA mass spectrometer Ports for vacuum and gas Coating Results Transmission: > 95. 5% (one side coated) No Damage to AR coating or change in transmission observed after Over 170 hours exposure to F 2 4. 6 J/cm 2 in air @ 10 Hz for one hour (equivalent: 17 J/cm 2 @ 400 ns) 0. 6 J/cm 2 in 5% F 2 @ 10 Hz for 21 minutes

We have identified a high transmission coating that can survive fluorine in the laser cell and meets the required laser damage threshold (> 5 J/cm 2) Test cell to evaluate optical coating SAMPLE resistance to HF, F 2 , and UV (@ 248 nm) Laser 1 -2 J/cm 2 @ 32 nsec LENS Heater RGA mass spectrometer Ports for vacuum and gas Coating Results Transmission: > 95. 5% (one side coated) No Damage to AR coating or change in transmission observed after Over 170 hours exposure to F 2 4. 6 J/cm 2 in air @ 10 Hz for one hour (equivalent: 17 J/cm 2 @ 400 ns) 0. 6 J/cm 2 in 5% F 2 @ 10 Hz for 21 minutes

Summary Increased foil lifetime by improving e-beam uniformity with new "ceramic honeycomb" cathode: 5 Hz run extended from 5 shots to 500 shots Limited by lack of cooling in one hibachi 3700 shots @ 5 Hz in two runs laser output consistent Limitation still seems to be e-beam "hot spots" We will continue development of new cathode: (F. Hegeler poster) Eliminate hot spots pattern into strips Extended lifetime of solid state pulsed power switch (Weidenheimer poster) Identified high transmission, uv and fluorine resistant window coating

Summary Increased foil lifetime by improving e-beam uniformity with new "ceramic honeycomb" cathode: 5 Hz run extended from 5 shots to 500 shots Limited by lack of cooling in one hibachi 3700 shots @ 5 Hz in two runs laser output consistent Limitation still seems to be e-beam "hot spots" We will continue development of new cathode: (F. Hegeler poster) Eliminate hot spots pattern into strips Extended lifetime of solid state pulsed power switch (Weidenheimer poster) Identified high transmission, uv and fluorine resistant window coating