5a114c79c1968d77f630158ab214c7a8.ppt

- Количество слайдов: 25

EKO SAVE - PURGE COMPOUNDS FOR PURE RESULTS March 2008 www. eko-plastic. com

EKO SAVE - PURGE COMPOUNDS FOR PURE RESULTS March 2008 www. eko-plastic. com

EKO Plastic Improvements • EKO is the leading purging company in Israel since 1999. Located in kibbutz Bet Keshet near the sea of Galilee. We develop and Manufacture the EKO SAVE ™ purging Technology to supply solutions to the varied technologies of the Plastic industry. • Eko save™ technology is exporting to: Italy, Norway, Sweden, Holland, Canada, usa, India, Taiwan and more

EKO Plastic Improvements • EKO is the leading purging company in Israel since 1999. Located in kibbutz Bet Keshet near the sea of Galilee. We develop and Manufacture the EKO SAVE ™ purging Technology to supply solutions to the varied technologies of the Plastic industry. • Eko save™ technology is exporting to: Italy, Norway, Sweden, Holland, Canada, usa, India, Taiwan and more

marketing recommended model 1. 2. 3. Excellent working knowledge of Eko products. Being conversant with Purging Technologies and Processing instructions. Being at ease with EKO's web site model “Calculate Your Saving”. Implementing of “training” and emphasizing the need for a systematical use of cleaning in order to save money. q “Training” is the best marketing tool to achieve “systematical-use” and benefits for all. 5. Invest more time on potential clients that are already aware of their need for the Purging Technology. 4. 6. Direct relationship to the relevant contact people; plant , production, purchase & maintenance managers.

marketing recommended model 1. 2. 3. Excellent working knowledge of Eko products. Being conversant with Purging Technologies and Processing instructions. Being at ease with EKO's web site model “Calculate Your Saving”. Implementing of “training” and emphasizing the need for a systematical use of cleaning in order to save money. q “Training” is the best marketing tool to achieve “systematical-use” and benefits for all. 5. Invest more time on potential clients that are already aware of their need for the Purging Technology. 4. 6. Direct relationship to the relevant contact people; plant , production, purchase & maintenance managers.

… marketing recommended model 7. To support and guide by giving samples and attending trials for those who show interest or with potentially big customers. 8. Systematic regular visits to clients. 9. Keeping a regular stock of Eko Save products for 2 month of consumption. q Availability of Eko Save products in stock is vital for marketing success. It is very Easy to lose a client (that has just became aware of his need for Eko Save products) because of a late supply. 10. Setting a Minimum quantity per order( we recommend- 200 Kg) even if it means that it’s more than one months consumption for a client.

… marketing recommended model 7. To support and guide by giving samples and attending trials for those who show interest or with potentially big customers. 8. Systematic regular visits to clients. 9. Keeping a regular stock of Eko Save products for 2 month of consumption. q Availability of Eko Save products in stock is vital for marketing success. It is very Easy to lose a client (that has just became aware of his need for Eko Save products) because of a late supply. 10. Setting a Minimum quantity per order( we recommend- 200 Kg) even if it means that it’s more than one months consumption for a client.

6 implementation steps 1. Testing Eko Save to show it’s contribution for money saving. It is recommended to compare it to the competitors materials focused on: “Best Price For Performance”. 2. Training operators and management to work correctly & systematically. with Eko Save products & to follow the processing instructions completely. 3. Setting a list of rules. When clients should use Eko Save and how much to use in each case (quantity tables) 4. Working with the clients on availability of Eko Save products to the operators. It is recommended to use a “quantities marked buckets”. 5. A consistent checking system over achievements and irregular problems that are an outcome of the use of Eko Save and transferring these results into graphs. 6. Nominating a responsible operator/manager to be in charge of the subject for a period of the first 3 months at least.

6 implementation steps 1. Testing Eko Save to show it’s contribution for money saving. It is recommended to compare it to the competitors materials focused on: “Best Price For Performance”. 2. Training operators and management to work correctly & systematically. with Eko Save products & to follow the processing instructions completely. 3. Setting a list of rules. When clients should use Eko Save and how much to use in each case (quantity tables) 4. Working with the clients on availability of Eko Save products to the operators. It is recommended to use a “quantities marked buckets”. 5. A consistent checking system over achievements and irregular problems that are an outcome of the use of Eko Save and transferring these results into graphs. 6. Nominating a responsible operator/manager to be in charge of the subject for a period of the first 3 months at least.

FAQ FREQUENT ASKED QUESTIONS What is Purging? Let’s begin by reviewing the reasons for purging. By definition, purging is to 'undergo or cause evacuation. ' For plastic processors, purging is an essential part of the cleaning process. Done properly, purging should: v Effectively displace the resident resin. v Eliminate the resident resin in dead spots or negative flow areas. v Remove heat sensitive resins, additives and pigments which are susceptible to degradation. v Eliminate black specks produced by carbon build-up

FAQ FREQUENT ASKED QUESTIONS What is Purging? Let’s begin by reviewing the reasons for purging. By definition, purging is to 'undergo or cause evacuation. ' For plastic processors, purging is an essential part of the cleaning process. Done properly, purging should: v Effectively displace the resident resin. v Eliminate the resident resin in dead spots or negative flow areas. v Remove heat sensitive resins, additives and pigments which are susceptible to degradation. v Eliminate black specks produced by carbon build-up

FAQ – WHEN SHOULD YOU PURGE? This question comes up often and there are three common reasons for purging: 1. Changeover: the changeover between jobs, since purging will remove previous colors, resins and carbon build-up that will contaminate future production 2. Shutdown and Startup: are sources of degradation caused by excessive heat exposure to the resin 3. Routine Preventive Maintenance: purging can help extend the operating life of plastic processing machinery. 4. There is no necessity to purge between easy colors on short production runs.

FAQ – WHEN SHOULD YOU PURGE? This question comes up often and there are three common reasons for purging: 1. Changeover: the changeover between jobs, since purging will remove previous colors, resins and carbon build-up that will contaminate future production 2. Shutdown and Startup: are sources of degradation caused by excessive heat exposure to the resin 3. Routine Preventive Maintenance: purging can help extend the operating life of plastic processing machinery. 4. There is no necessity to purge between easy colors on short production runs.

What is the basic way of using EKO-SAVE purging products? FAQ - The full procedures of use - in each technology- are in the EKO web-sight & should be read & understood before usage. The basic way of using is: 1. 2. 3. 4. 5. To use EKO SAVE purge in a continuous cleaning routine when changing colors & materials & not as a method for dealing putting out fires. Clean the color dozer, hoper & throat well, raise the temperatures at the end of the cylinder, die & head by 20 c. Empty all the remaining materiel from the cylinder & fill the machine with EKO SAVE (1. 5 volume of the cylinder + die + head). Let the EKO SAVE purge stand in the machine for 10 minutes, check to see that the material is slowly flowing out of the die or mould. Push out the EKO SAVE purge at alternating between 20 -50% of working speeds. If the machine is still not clean return to stage number 3.

What is the basic way of using EKO-SAVE purging products? FAQ - The full procedures of use - in each technology- are in the EKO web-sight & should be read & understood before usage. The basic way of using is: 1. 2. 3. 4. 5. To use EKO SAVE purge in a continuous cleaning routine when changing colors & materials & not as a method for dealing putting out fires. Clean the color dozer, hoper & throat well, raise the temperatures at the end of the cylinder, die & head by 20 c. Empty all the remaining materiel from the cylinder & fill the machine with EKO SAVE (1. 5 volume of the cylinder + die + head). Let the EKO SAVE purge stand in the machine for 10 minutes, check to see that the material is slowly flowing out of the die or mould. Push out the EKO SAVE purge at alternating between 20 -50% of working speeds. If the machine is still not clean return to stage number 3.

What are the big problems in Extrusion cleaning? FAQ – The most problematic areas for cleaning are: flat dies, blow molding heads, blow film dies & adaptors. Certain materials & colors may also be problematic but with the correct resin & following the Eko purge instruction you can resolve all these problems.

What are the big problems in Extrusion cleaning? FAQ – The most problematic areas for cleaning are: flat dies, blow molding heads, blow film dies & adaptors. Certain materials & colors may also be problematic but with the correct resin & following the Eko purge instruction you can resolve all these problems.

What are the big problems of purging in Injection Molding? FAQ – The problematic areas are usually the end of the screw, the nozzle & the hot runner. Problematic materials & colors can be a course for problems; example a machine which works with a number of different polymer resins can course degraded polymer which will be the course of burnt degraded resin. The correct EKO-purge with the instructions will solve these problems.

What are the big problems of purging in Injection Molding? FAQ – The problematic areas are usually the end of the screw, the nozzle & the hot runner. Problematic materials & colors can be a course for problems; example a machine which works with a number of different polymer resins can course degraded polymer which will be the course of burnt degraded resin. The correct EKO-purge with the instructions will solve these problems.

FAQ – How long can I leave "Eko Save" in the barrel? • We recommend you follow the purging procedures, but extended residence time will not harm the equipment, or decrease the effectiveness of EKO SAVE.

FAQ – How long can I leave "Eko Save" in the barrel? • We recommend you follow the purging procedures, but extended residence time will not harm the equipment, or decrease the effectiveness of EKO SAVE.

FAQ – Is EKO SAVE safe for people? • Yes. All active ingredients are completely non-toxic and have been approved by the Food and Drug Administration (FDA) for use in food.

FAQ – Is EKO SAVE safe for people? • Yes. All active ingredients are completely non-toxic and have been approved by the Food and Drug Administration (FDA) for use in food.

FAQ – Does EKO SAVE have a shelf life? • EKO SAVE shelf life is similar to any plastic resin.

FAQ – Does EKO SAVE have a shelf life? • EKO SAVE shelf life is similar to any plastic resin.

FAQ -Do I have to raise or lower temperatures to make EKO SAVE work better? • It is advisable to raise the temperatures in problematic areas.

FAQ -Do I have to raise or lower temperatures to make EKO SAVE work better? • It is advisable to raise the temperatures in problematic areas.

FAQ – Is EKO SAVE safe for hot runner systems? • Yes. Our products can be processed through gates & hot runners. It is advisable to clean with the mould open or to inject small quantities (up to 50%) into the closed mold.

FAQ – Is EKO SAVE safe for hot runner systems? • Yes. Our products can be processed through gates & hot runners. It is advisable to clean with the mould open or to inject small quantities (up to 50%) into the closed mold.

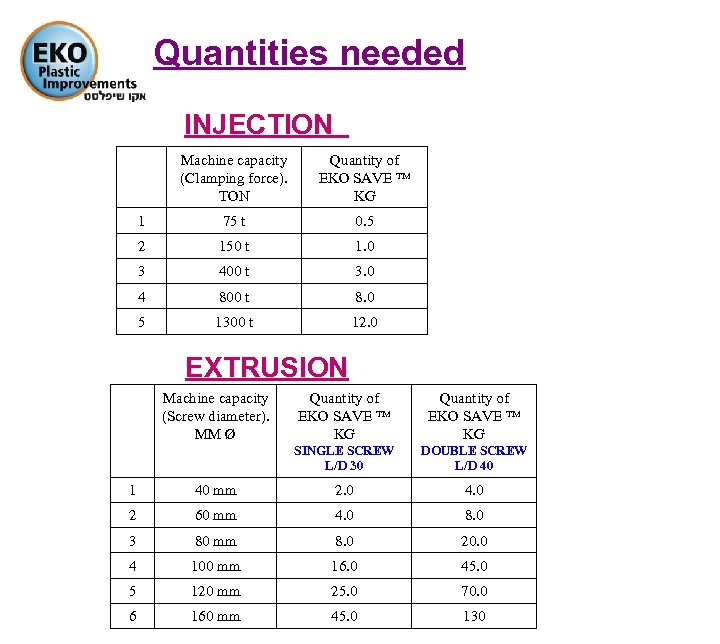

FAQ – How much EKO SAVE is required to clean an Injection Molding Machine or Extruders? EKO –PLASTICS recommends 1½ volume times of the cylinder capacity to clean the cylinder and screw. If the machine has not been purged for a long time or is old it is probable that you will need to purge with twice to three times the cylinder capacity. • In the case of blow molding heads and blow film dies we recommend enough material to fill cylinder, die and head 1. 5 volume times. • See Quantities table below.

FAQ – How much EKO SAVE is required to clean an Injection Molding Machine or Extruders? EKO –PLASTICS recommends 1½ volume times of the cylinder capacity to clean the cylinder and screw. If the machine has not been purged for a long time or is old it is probable that you will need to purge with twice to three times the cylinder capacity. • In the case of blow molding heads and blow film dies we recommend enough material to fill cylinder, die and head 1. 5 volume times. • See Quantities table below.

Quantities needed INJECTION Machine capacity (Clamping force). TON Quantity of EKO SAVE ™ KG 1 75 t 0. 5 2 150 t 1. 0 3 400 t 3. 0 4 800 t 8. 0 5 1300 t 12. 0 EXTRUSION Machine capacity (Screw diameter). MM Ø Quantity of EKO SAVE ™ KG SINGLE SCREW L/D 30 DOUBLE SCREW L/D 40 1 40 mm 2. 0 4. 0 2 60 mm 4. 0 8. 0 3 80 mm 8. 0 20. 0 4 100 mm 16. 0 45. 0 5 120 mm 25. 0 70. 0 6 160 mm 45. 0 130

Quantities needed INJECTION Machine capacity (Clamping force). TON Quantity of EKO SAVE ™ KG 1 75 t 0. 5 2 150 t 1. 0 3 400 t 3. 0 4 800 t 8. 0 5 1300 t 12. 0 EXTRUSION Machine capacity (Screw diameter). MM Ø Quantity of EKO SAVE ™ KG SINGLE SCREW L/D 30 DOUBLE SCREW L/D 40 1 40 mm 2. 0 4. 0 2 60 mm 4. 0 8. 0 3 80 mm 8. 0 20. 0 4 100 mm 16. 0 45. 0 5 120 mm 25. 0 70. 0 6 160 mm 45. 0 130

FAQ – Can you shut down Extruders & Injection Machines on EKO SAVE? • It is recommended by us to shut down your machinery with EKO SAVE purging compound, this process will eliminate and remove all loosened and degraded colorants, additives, and plastics that may be stuck in your machine.

FAQ – Can you shut down Extruders & Injection Machines on EKO SAVE? • It is recommended by us to shut down your machinery with EKO SAVE purging compound, this process will eliminate and remove all loosened and degraded colorants, additives, and plastics that may be stuck in your machine.

FAQ – What are the different purging materials & how do they work? There are basically two types of purging materials: 1. A Chemical Purge which breaks down the plastic at its molecular level there by lowering its viscosity making it very easy to expel from your machine. 2. A Mechanical Purge which is based on a resin with a low M. F. I & additives that push & scrap the resin & dirt out of the machine. 3. Purging materials are divided into liquid purge additives, ready purge mixes & compounds. 4. EKO-SAVE products are in the manly compounds.

FAQ – What are the different purging materials & how do they work? There are basically two types of purging materials: 1. A Chemical Purge which breaks down the plastic at its molecular level there by lowering its viscosity making it very easy to expel from your machine. 2. A Mechanical Purge which is based on a resin with a low M. F. I & additives that push & scrap the resin & dirt out of the machine. 3. Purging materials are divided into liquid purge additives, ready purge mixes & compounds. 4. EKO-SAVE products are in the manly compounds.

FAQ – How do you overcome difficult pigments & burnt degraded resin? • Ensure that you work with the purging instructions fully. • Raising the working temperatures in difficult areas such as blow molding heads, adaptors, flat die extruders & hot runners. • Leaving in the Eko purge for recommended length of time. • Repeat the cleaning process twice in succession.

FAQ – How do you overcome difficult pigments & burnt degraded resin? • Ensure that you work with the purging instructions fully. • Raising the working temperatures in difficult areas such as blow molding heads, adaptors, flat die extruders & hot runners. • Leaving in the Eko purge for recommended length of time. • Repeat the cleaning process twice in succession.

FAQ – Can you reuse the EKO- SAVE purge materials? • You should not reuse any purge because you are putting material which is contaminated back into the machine also the level of the cleaning concentrates whether chemical or physical have been substantially reduced.

FAQ – Can you reuse the EKO- SAVE purge materials? • You should not reuse any purge because you are putting material which is contaminated back into the machine also the level of the cleaning concentrates whether chemical or physical have been substantially reduced.

EKO SAVE CHARACTERISTICS q. The compounds are high quality Polyolefin's with low Melt Flow Indexes. q. Containing Minerals that absorbs humidity, changes viscosity, cleaning agents and Blowing agents that produce pressure inside the Screw , Barrel, Die and Mould. q. Heat stabilized, they can be used for transition between materials with large temperature variances , also for shutting down and starting up the machinery. q. Purges easily out of the machine.

EKO SAVE CHARACTERISTICS q. The compounds are high quality Polyolefin's with low Melt Flow Indexes. q. Containing Minerals that absorbs humidity, changes viscosity, cleaning agents and Blowing agents that produce pressure inside the Screw , Barrel, Die and Mould. q. Heat stabilized, they can be used for transition between materials with large temperature variances , also for shutting down and starting up the machinery. q. Purges easily out of the machine.

KO SAVE CHARACTERISTICS q. A molecular structure that enables easy and convenient cleaning of Hot Runners and Manifolds of Injection molding machines, accumulator heads of Blow Molding machines and different types of difficult purging problems. q Non abrasive, non toxic, non Acidic , doesn’t contain Glass Fibers. q Guarantees safety for the operator and equipment. q FDA (food) Approval. q Working temperature ranges of 140 c-380 c.

KO SAVE CHARACTERISTICS q. A molecular structure that enables easy and convenient cleaning of Hot Runners and Manifolds of Injection molding machines, accumulator heads of Blow Molding machines and different types of difficult purging problems. q Non abrasive, non toxic, non Acidic , doesn’t contain Glass Fibers. q Guarantees safety for the operator and equipment. q FDA (food) Approval. q Working temperature ranges of 140 c-380 c.

Good Luck

Good Luck