7ecca64af9ec00148a028911f6051196.ppt

- Количество слайдов: 70

ECRx BARCODING IMPLEMENTATION Frank Goodman Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

COMMITTEE STRUCTURE Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

Barcoding Subcommittee Members Frank Goodman (Chair) n Maryann Crofoot - Alti. Med Pharmaceutical n Alicia Duval - CACDS n Ratna Jani - ECCC n Andree Soucy - Jean Coutu n Heather Smeall - Procter & Gamble n Roman Coba - Wal-Mart n Selim Toutounji - Wyeth-Ayerst n Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

Committee Mandate Build on work done by the ECR Committee, applying the concepts to Rx, OTC and cosmetics n Agree on standards for UPC and barcodes for item and case coding n Agree on target timelines for the drug channel n Suggest use of UPC number universally catalogues, price lists, tender documents, etc. n Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

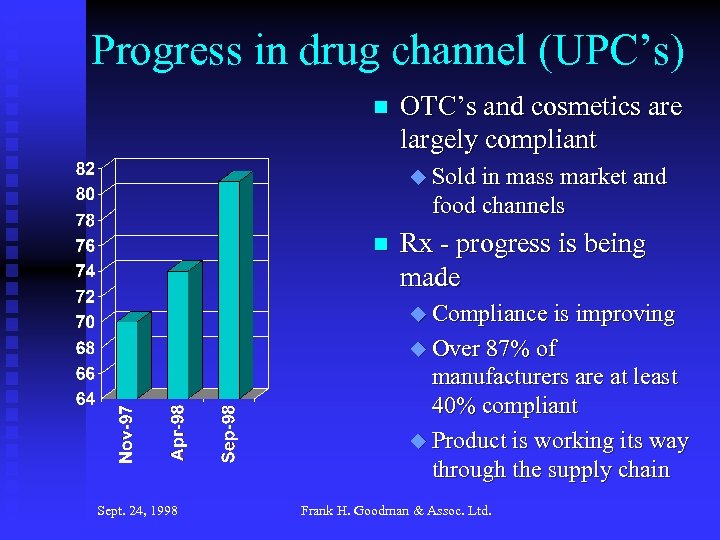

Progress in drug channel (UPC’s) n OTC’s and cosmetics are largely compliant u Sold in mass market and food channels n Rx - progress is being made u Compliance is improving u Over 87% of manufacturers are at least 40% compliant u Product is working its way through the supply chain Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

Panel Members n Ratna Jani u Director, Industry Relations and Administration u Electronic Commerce Council of Canada n Heather Smeall u Efficient Consumer Response Manager u Procter & Gamble Inc. n Bill Mc. Dowell u Director, Supply Chain Technology u Loblaw Companies Ltd. Sept. 24, 1998 Frank H. Goodman & Assoc. Ltd.

ECR Barcoding Implementation A grocery perspective Bill Mc. Dowell September 1998 10

Grocery ECR Today ECR CANADA The CEO Steering Committee was formed 5 years ago. This committee identified five Enablers that would help companies resolve inefficient business practices. • • Scan data Integrity Electronic Data Interchange (EDI) Continuous Replenishment Value Chain Analysis (VCA) and Activity-Based Costing (ABC) • Category Management 11

Grocery ECR Today Progress We at Loblaws have taken up the challenge and are moving forward. Some issues require an industry direction, and this happened in several areas. • Scan data Integrity • Item barcodes are mandatory, and new items must be certified as scannable. • Case barcodes are required and are being implemented. • UPC’s are mandatory. • Electronic Data Interchange (EDI) • The industry has adopted the VICS 4010 standard. 12

ECR in Pharmacy Progress As a result, we have achieved efficiencies in inventory management and replenishment for grocery and most Health and Beauty products. It is also true for OTC products such as generic drugs, vitamins and so on. Benefits: u u Automated ordering and inventory management Automated dated product management Simpler distribution handling processes, less labour and higher accuracy, reduced distribution costs. Reduced retail labour for receiving, handling, sales. 13

ECR in Pharmacy Implications for Pharmacy #1 Case barcodes Because of grocery industry efforts, case barcodes are becoming common, including expiry date on perishable products. Therefore: u There is an opportunity for the drug industry to gain distribution efficiencies by adopting case barcodes. u There is a similar opportunity at retail on case sales (e. g. infant formula). N. B. The largest issue here is the quality of the barcode printing. 14

ECR in Pharmacy Implications for Pharmacy #2 Unit barcodes In the grocery industry, new products are now expected to have a certificate of scanability before being listed. This means the barcode has been reviewed for clarity, contrast and dimensions. Therefore: u u Front-end scanning accuracy is 99%+. Data integrity is greatly increased while front-end labour has been reduced. 15

ECR in Pharmacy Implications for Pharmacy #3 UPC codes Every manufacturer has an internal product numbering system. Such numbers cannot be used by your customers for automated inventory management or ordering. Duplicate numbers will occur. Therefore: u As retailers move to automated inventory systems, products which are easy to handle and order will be preferred over competitive products. 16

ECR in Pharmacy Retail directions for barcodes By having UPC’s, unit and case barcodes, the retailer gains several opportunities. w w Automated systems for inventory and ordering. Efficient receiving and handling of units and cases. Dated product management. Better data for category management. 17

ECR in Pharmacy Current Challenges However, there are some issues with some prescription drug products and manufacturers. The lack of UPC’s and barcodes. The solution: u A unified Industry position u Consistent, unified industry pressure. 18

ECRx BAR CODING IMPLEMENTATION MANUFACTURER’S PERSPECTIVE PROCTER & GAMBLE Sept. 24/98

ECRx Bar Coding Implementation Costs and benefits n Usage in the supply chain n Database management and UPC set up n Challenges and opportunities n

ECRx Bar Coding Implementation Usage in the Supply Chain Standardized data management and business analysis n Category Management/Efficient Assortment n EDI Ordering and Invoicing n ASN/UCC 128 and cross docking/flow-thru n Warehouse handling; real time RF processes n

ECRx Bar Coding Implementation Costs Vendor code n Packaging artwork changes n Application of UPC, case and pallet codes n Codes administration n Validation certificates n Integration of bar code scanning capability throughout the supply chain n

ECRx Bar Coding Implementation Benefits when fully integrated Inventory accuracy improvements n Reduced inventory n Productivity improvements n Enables ASN/UCC 128 which results in reduced unloading times, reduced deductions/ refusals, internal cross dock n Leads to reduced damage levels n

ECRx Bar Coding Implementation Database Management and Set up Purchase a vendor code purchase n Assign a central administrator n Define the process for requesting and assigning UPC codes n Expand product data base to include UPC code (including vendor code) n Randomly assign codes as requested n Follow ECCC UPC guidelines n

ECRx Bar Coding Implementation Challenges and Opportunities small items n zero suppressed codes n scan accuracy n lack of use/critical mass n change management n

ECRx ~ Standards for Product Identification and Barcoding Ratna Jani Director, Industry Relations & Admin ECCC

Agenda At-A-Glance n About ECCC n Globalization of Product I. D n Standardization Issues n Future trends n Available resources

Electronic Commerce Council Mission Statement The Mission of ECCC is to take a Leadership Role in Establishing and Promoting Multi-Industry Standards for Product Identification and related Electronic Commerce Communications

ECCC’s Role in Product Identification n Accurate assignment of U. P. C. Manufacturer I. D. numbers u Maintain data base of assigned numbers n Provide education on standards to all industries u Industry Specific Workshops u Customized Sessions to meet individual needs n Developing an Electronic Product Catalogue u ECCC Net

Developing Global partnership through Global Policy Committee The UCC /EAN System Provides an Integrated Suite of Standardized Tools that Enable Effective Management of Supply Chains EN ID S • Anywhere in the World SUPPLY CHAIN MANAGEMENT DE CO • In Any Industry R BA TI CO FIC DE AT S ION • In Any Company ELECTRONIC DATA INTERCHANGE

U. P. C. standards are globally compatible and harmonized n n n Uniform Code Council (UCC) and International Article Numbering Association (EAN) establish the standards jointly Canada adopts the established standards The standards are endorsed by ISO and IEC

Standards vs Guidelines Standards are established by the American National Standards in the U. S. and adopted by the UCC and ECCC n Standards undergo a six year review process and cannot be changed. n Guidelines are established based on the business needs and within the confines of the standards. n

Inconsistencies identified in standards application Lack of understanding the standards n Ignorance to compliance factors n Poor quality compliance n Technology unable to meet the symbol quality demands n Internal resources lacked expertise n Lack of information integrity n Data unusable to monitor industry performance n

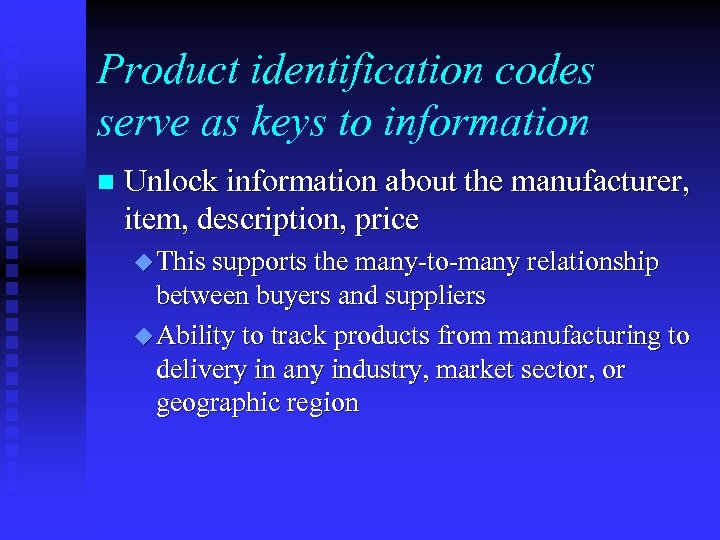

Product identification codes serve as keys to information n Unlock information about the manufacturer, item, description, price u This supports the many-to-many relationship between buyers and suppliers u Ability to track products from manufacturing to delivery in any industry, market sector, or geographic region

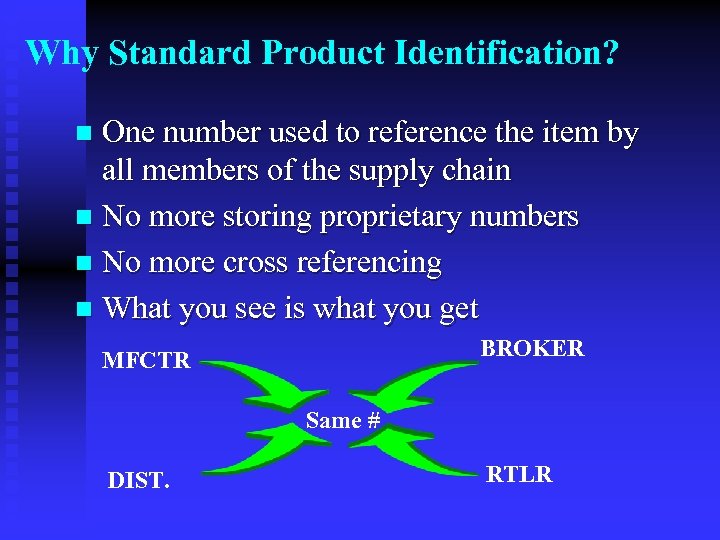

Why Standard Product Identification? One number used to reference the item by all members of the supply chain n No more storing proprietary numbers n No more cross referencing n What you see is what you get n BROKER MFCTR Same # DIST. RTLR

Global migration to an expanded number structure Need identified to increase number capacity to fulfill rate of growth n New industry sectors coming on board n Unlimited use of application: n u Returnable asset number u Individual asset number u Location number u Service relation number

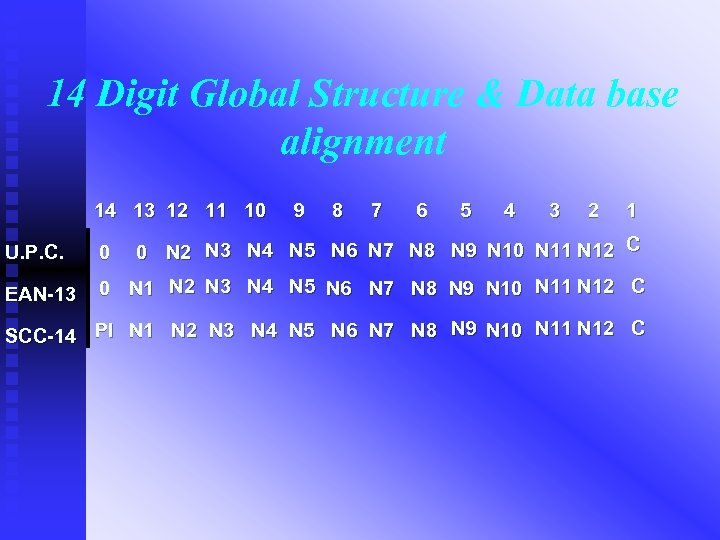

14 Digit Global Structure & Data base alignment 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 N 2 N 3 N 4 N 5 N 6 N 7 N 8 N 9 N 10 N 11 N 12 C U. P. C. 0 EAN-13 0 N 1 N 2 N 3 N 4 N 5 N 6 N 7 N 8 N 9 N 10 N 11 N 12 C SCC-14 PI N 1 N 2 N 3 N 4 N 5 N 6 N 7 N 8 N 9 N 10 N 11 N 12 C

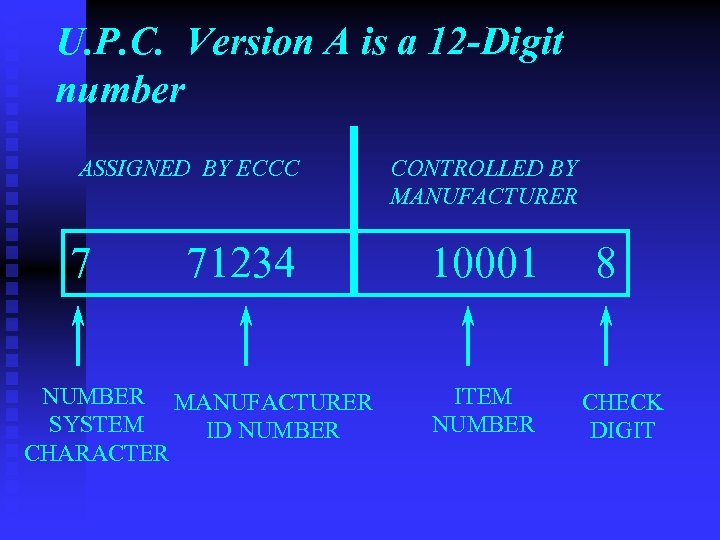

U. P. C. Version A is a 12 -Digit number ASSIGNED BY ECCC 7 71234 NUMBER MANUFACTURER SYSTEM ID NUMBER CHARACTER CONTROLLED BY MANUFACTURER 10001 ITEM NUMBER 8 CHECK DIGIT

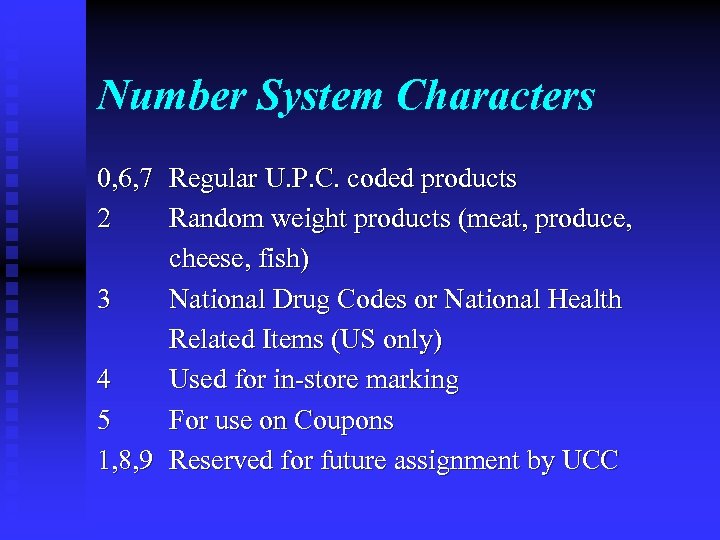

Number System Characters 0, 6, 7 Regular U. P. C. coded products 2 Random weight products (meat, produce, cheese, fish) 3 National Drug Codes or National Health Related Items (US only) 4 Used for in-store marking 5 For use on Coupons 1, 8, 9 Reserved for future assignment by UCC

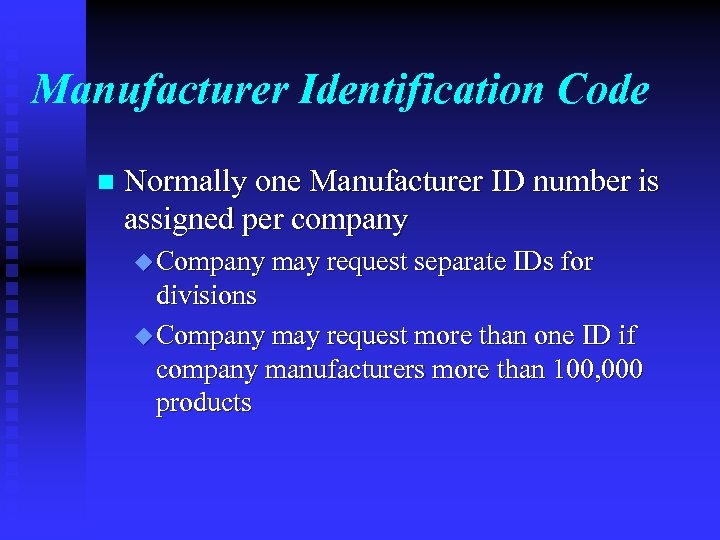

Manufacturer Identification Code n Normally one Manufacturer ID number is assigned per company u Company may request separate IDs for divisions u Company may request more than one ID if company manufacturers more than 100, 000 products

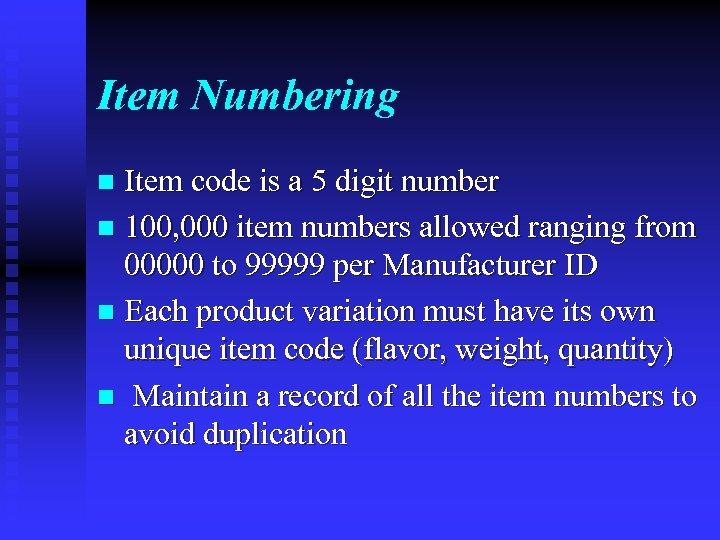

Item Numbering Item code is a 5 digit number n 100, 000 item numbers allowed ranging from 00000 to 99999 per Manufacturer ID n Each product variation must have its own unique item code (flavor, weight, quantity) n Maintain a record of all the item numbers to avoid duplication n

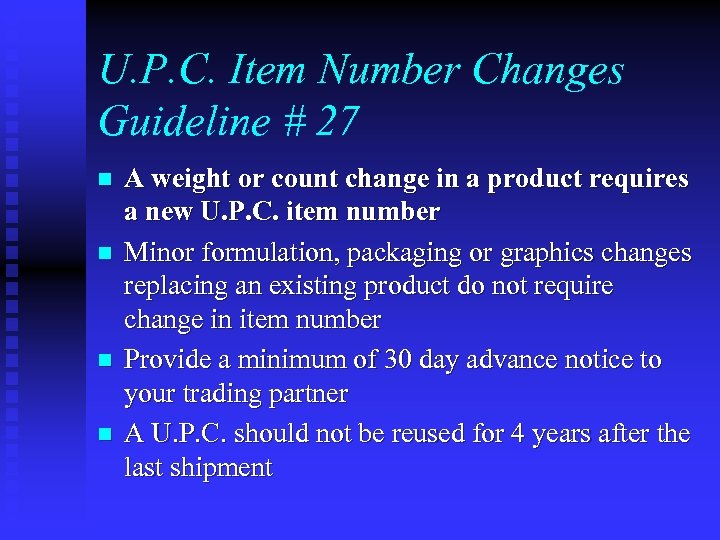

U. P. C. Item Number Changes Guideline # 27 n n A weight or count change in a product requires a new U. P. C. item number Minor formulation, packaging or graphics changes replacing an existing product do not require change in item number Provide a minimum of 30 day advance notice to your trading partner A U. P. C. should not be reused for 4 years after the last shipment

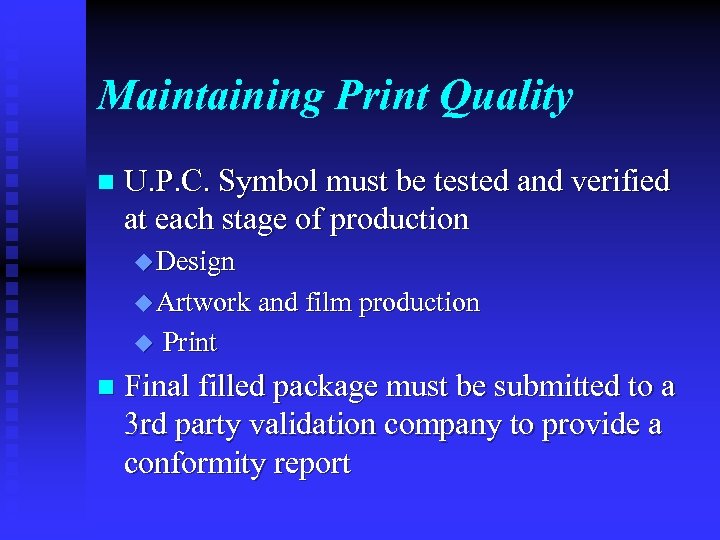

Maintaining Print Quality n U. P. C. Symbol must be tested and verified at each stage of production u Design u Artwork and film production u n Print Final filled package must be submitted to a 3 rd party validation company to provide a conformity report

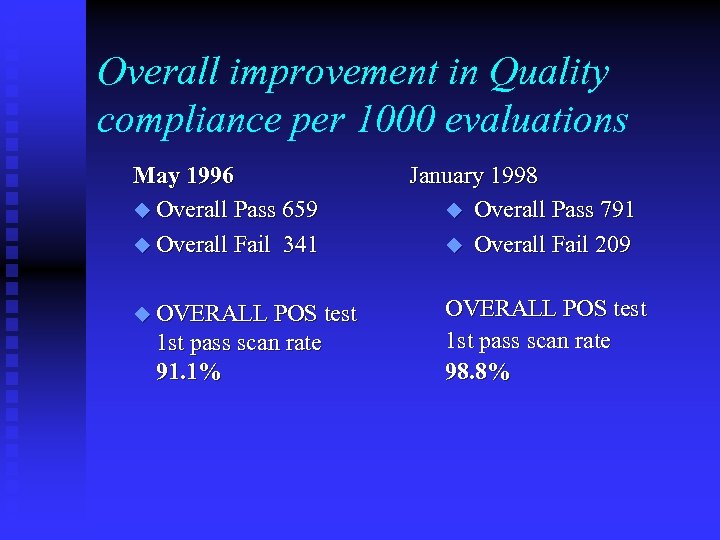

Overall improvement in Quality compliance per 1000 evaluations May 1996 u Overall Pass 659 u Overall Fail 341 u OVERALL POS test 1 st pass scan rate 91. 1% January 1998 u Overall Pass 791 u Overall Fail 209 OVERALL POS test 1 st pass scan rate 98. 8%

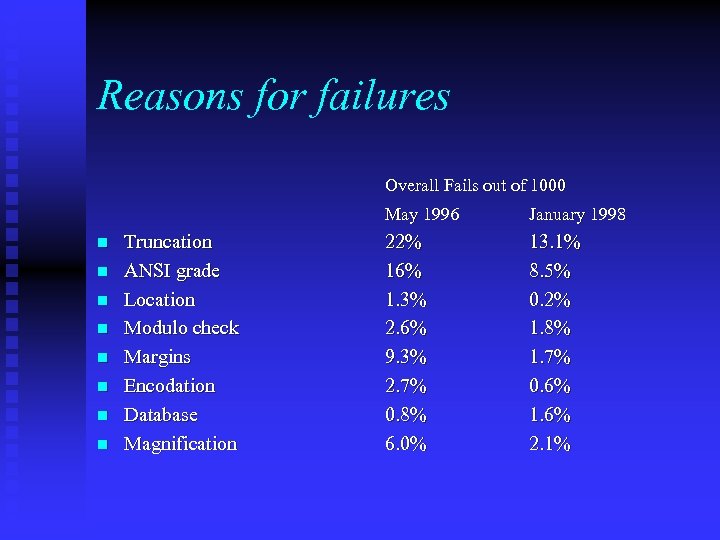

Reasons for failures Overall Fails out of 1000 May 1996 n n n n Truncation ANSI grade Location Modulo check Margins Encodation Database Magnification January 1998 22% 16% 1. 3% 2. 6% 9. 3% 2. 7% 0. 8% 6. 0% 13. 1% 8. 5% 0. 2% 1. 8% 1. 7% 0. 6% 1. 6% 2. 1%

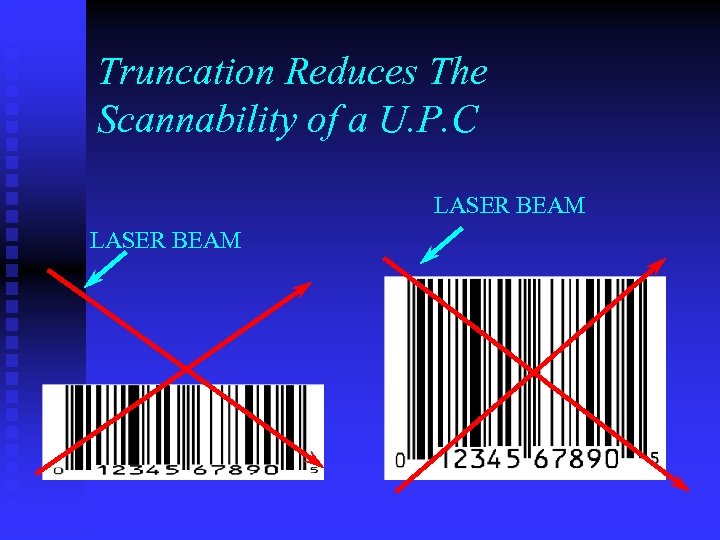

Truncation Reduces The Scannability of a U. P. C LASER BEAM

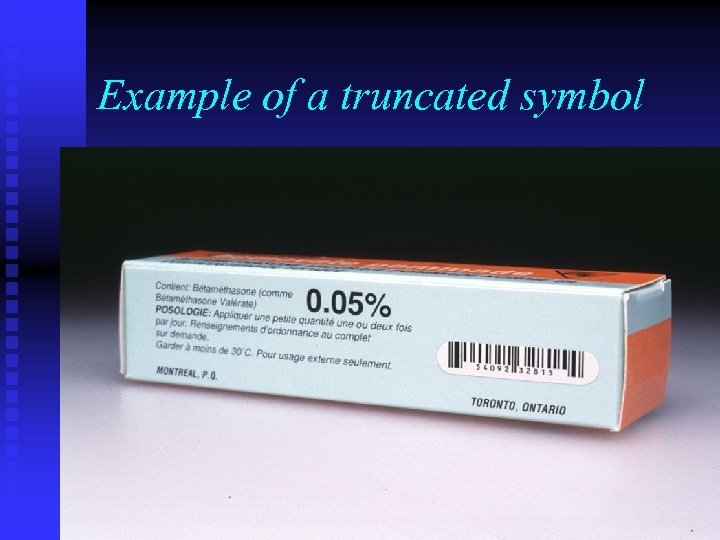

Example of a truncated symbol

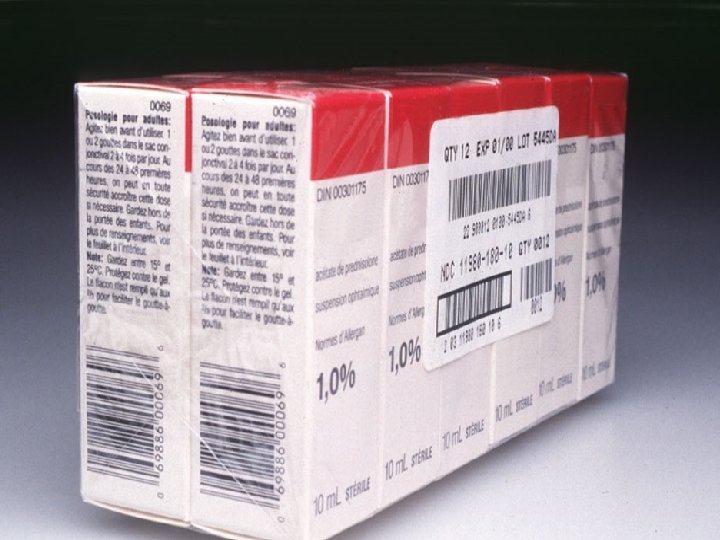

Truncation is prohibited except for small items n Small packaging exemptions apply to: Products that contain too much regulatory requirements u Products that do not have a panel for an 80% full height symbol u Uniquely shaped products u

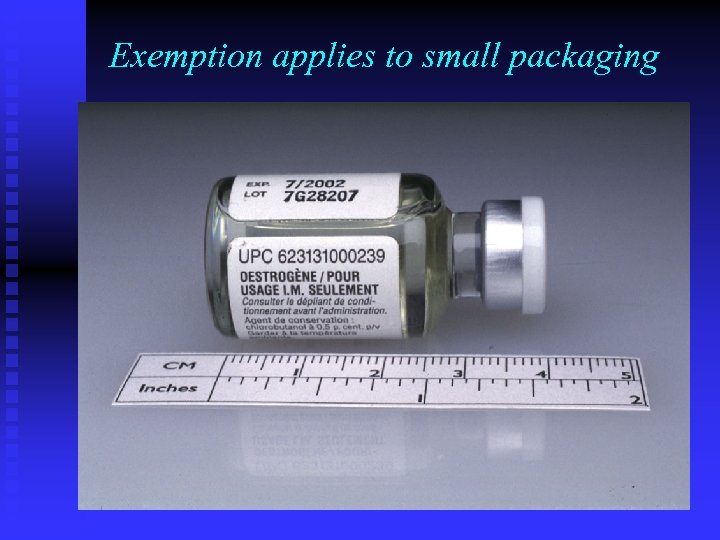

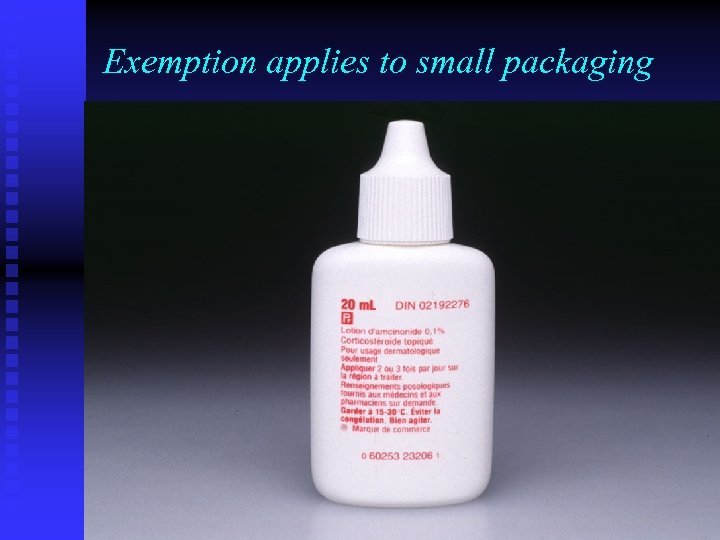

Exemption applies to small packaging

Exemption applies to small packaging

Exemption applies to small packaging

U. P. C. symbol quality plays a significant role in item management n Goal is to maintain a 99% accuracy scan rate. n Scan rate allows the monitoring of product movement and category management n Validate the U. P. C. Symbol for quality compliance

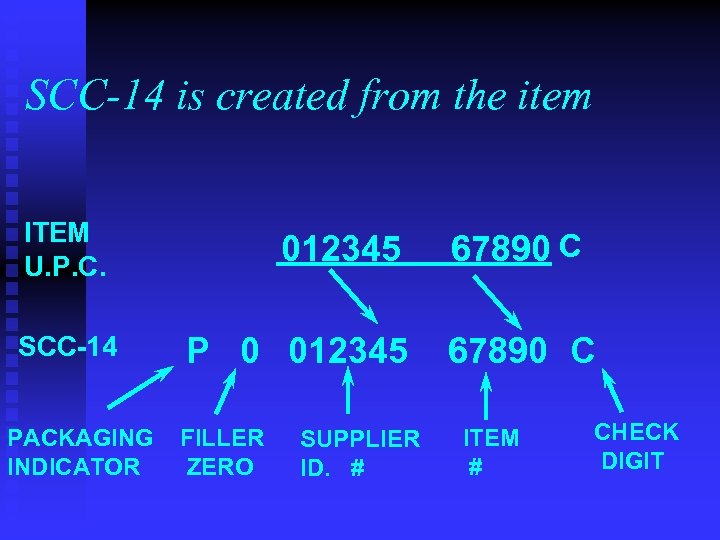

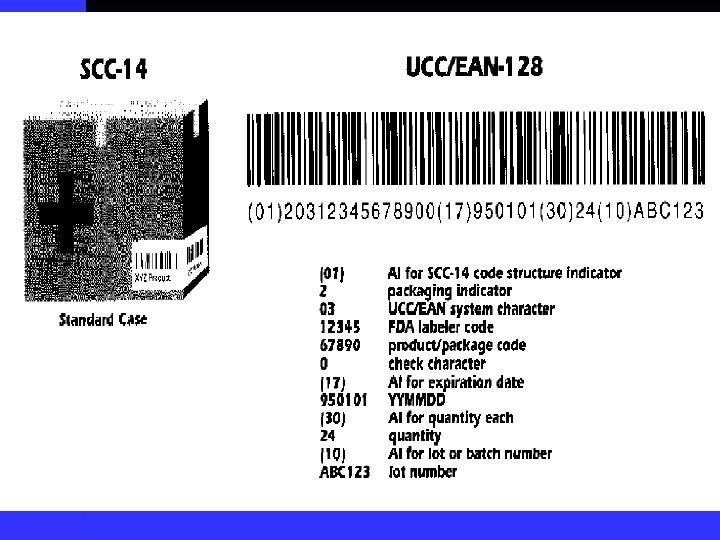

SCC-14 is created from the item ITEM U. P. C. SCC-14 PACKAGING INDICATOR 012345 P 0 012345 FILLER ZERO SUPPLIER ID. # 67890 C ITEM # CHECK DIGIT

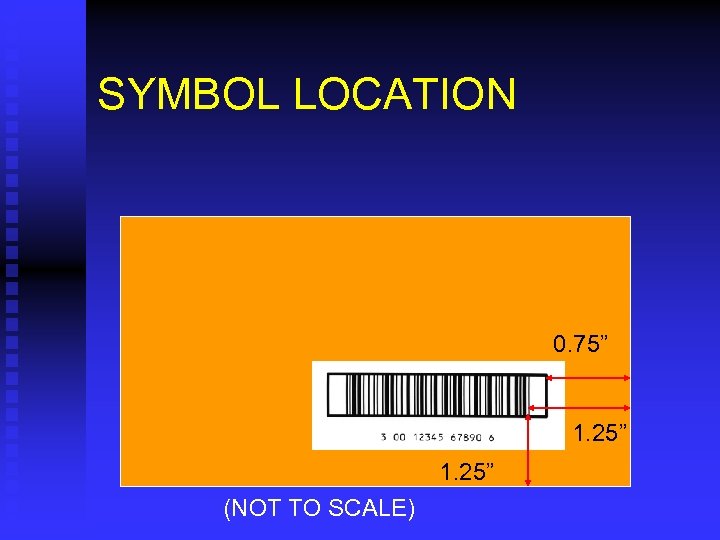

SYMBOL LOCATION 0. 75” 1. 25” (NOT TO SCALE)

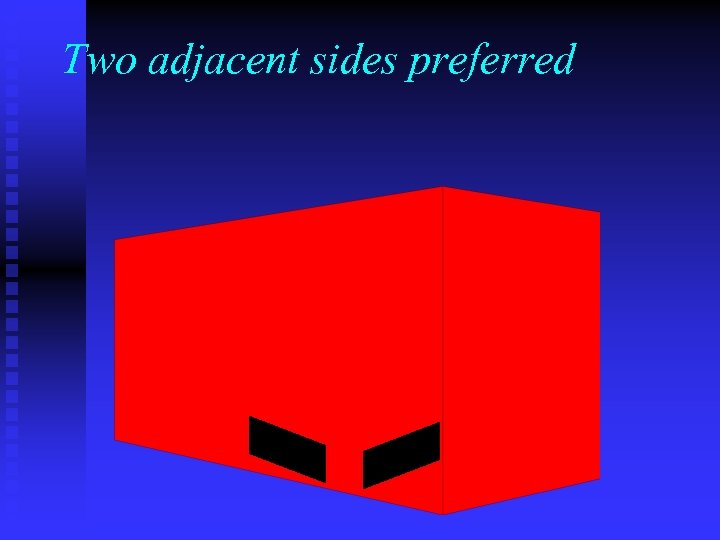

Two adjacent sides preferred

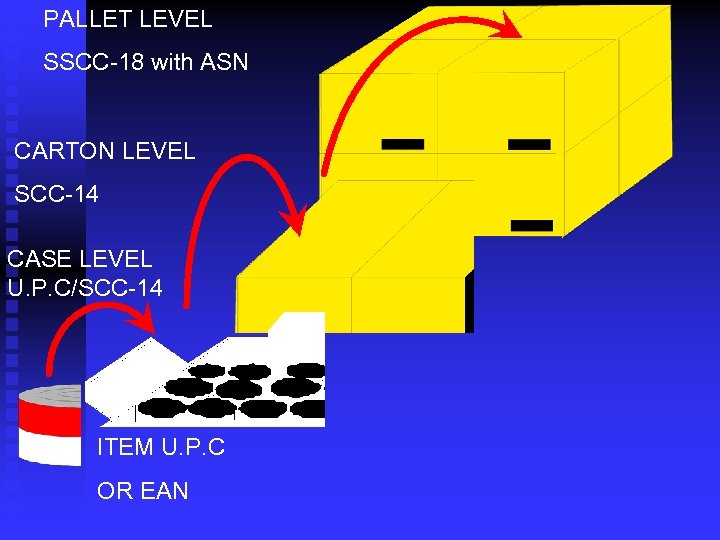

PALLET LEVEL SSCC-18 with ASN CARTON LEVEL SCC-14 CASE LEVEL U. P. C/SCC-14 ITEM U. P. C OR EAN

Macro view of Industry Trends and Impact

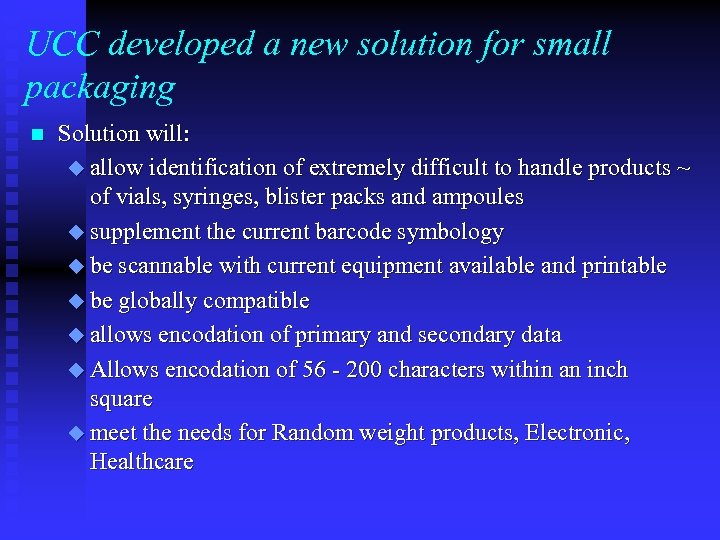

UCC developed a new solution for small packaging n Solution will: u allow identification of extremely difficult to handle products ~ of vials, syringes, blister packs and ampoules u supplement the current barcode symbology u be scannable with current equipment available and printable u be globally compatible u allows encodation of primary and secondary data u Allows encodation of 56 - 200 characters within an inch square u meet the needs for Random weight products, Electronic, Healthcare

New terms for the solutions are… n The Reduced Space Symbol (RSS) n The Composite Symbol

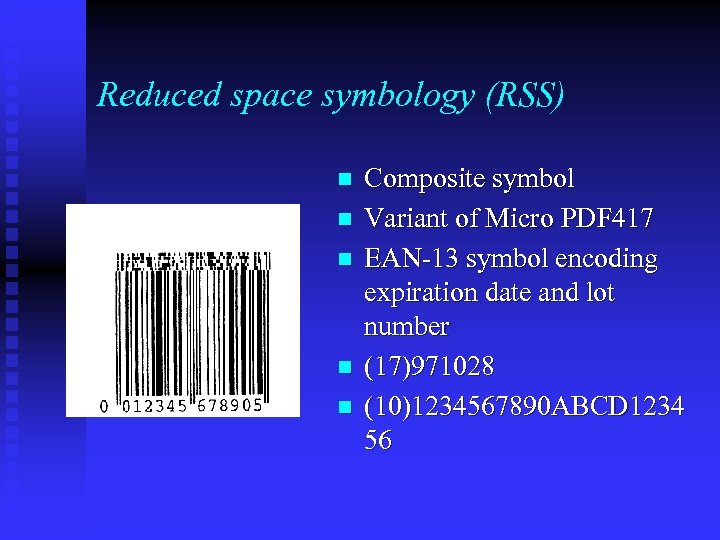

Reduced space symbology (RSS) n n n Composite symbol Variant of Micro PDF 417 EAN-13 symbol encoding expiration date and lot number (17)971028 (10)1234567890 ABCD 1234 56

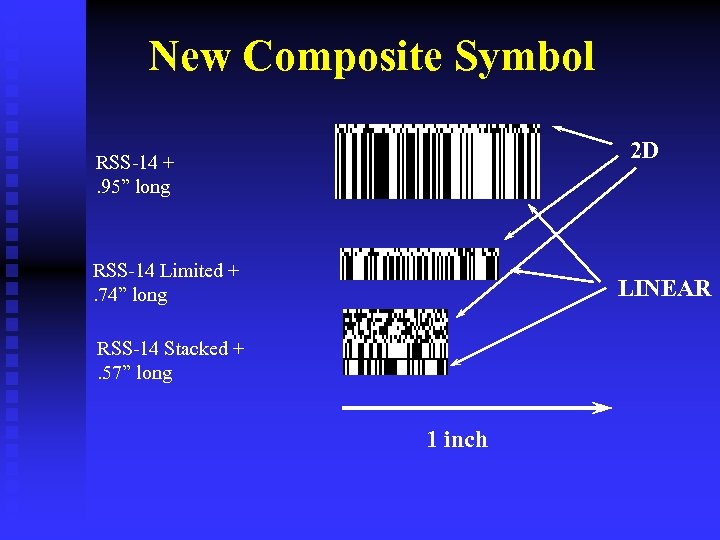

New Composite Symbol 2 D RSS-14 +. 95” long RSS-14 Limited +. 74” long LINEAR RSS-14 Stacked +. 57” long 1 inch

Small item marking solution

Keeping abreast on trends: n Standards manuals u U. P. C. Implementation guideline u Application standards for shipping containers n Through ECCC knowledge network u EDI and Product ID Standards u Education Programs u Industry Supply Chain Updates u UCC/EAN Activities

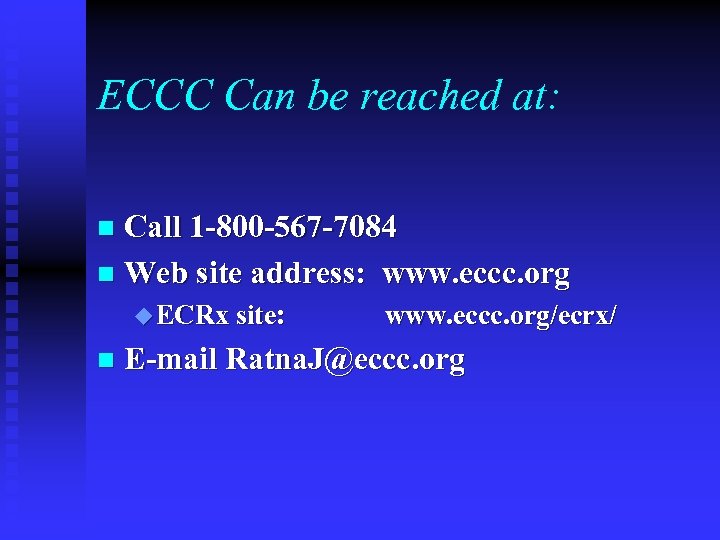

ECCC Can be reached at: Call 1 -800 -567 -7084 n Web site address: www. eccc. org n u ECRx site: n www. eccc. org/ecrx/ E-mail Ratna. J@eccc. org

7ecca64af9ec00148a028911f6051196.ppt