fed80df8e2cc8ea178932e8ce83734f2.ppt

- Количество слайдов: 33

ECE 477 Design Review Team 5 Fall 2009 Ben Carter – Jacqui Dickerson – Ian Oliver – Dennis Lee

ECE 477 Design Review Team 5 Fall 2009 Ben Carter – Jacqui Dickerson – Ian Oliver – Dennis Lee

Outline • • • Project overview Project-specific success criteria Block diagram Component selection rationale Packaging design Schematic and theory of operation PCB layout Software design/development status Project completion timeline Questions / discussion

Outline • • • Project overview Project-specific success criteria Block diagram Component selection rationale Packaging design Schematic and theory of operation PCB layout Software design/development status Project completion timeline Questions / discussion

Project Overview • Next generation communication system for vehicles – Simple, real-time visual communication • Multi-touch input – Driver’s gestures produce an output on LEDs around the perimeter of a car • Color-coded messages – Tri-color LEDs produce blue, green, yellow, orange, and red outputs

Project Overview • Next generation communication system for vehicles – Simple, real-time visual communication • Multi-touch input – Driver’s gestures produce an output on LEDs around the perimeter of a car • Color-coded messages – Tri-color LEDs produce blue, green, yellow, orange, and red outputs

Example Gestures • 1) 2 fingers swiped right - Green LEDs in front of car slide right; signal to a pedestrian walking right that it's okay to pass 2) 3 fingers swiped up – Yellow LEDs on front of car illuminate; signal that driver in oncoming lane is entering a hazardous area 3) 5 fingers swiped down - Red LEDs in back of car blink; signal that car behind driver is tailgating/back off 4) 1 finger swiped down - Blue LEDs in back of car blink; signal to thank car behind driver for letting driver merge

Example Gestures • 1) 2 fingers swiped right - Green LEDs in front of car slide right; signal to a pedestrian walking right that it's okay to pass 2) 3 fingers swiped up – Yellow LEDs on front of car illuminate; signal that driver in oncoming lane is entering a hazardous area 3) 5 fingers swiped down - Red LEDs in back of car blink; signal that car behind driver is tailgating/back off 4) 1 finger swiped down - Blue LEDs in back of car blink; signal to thank car behind driver for letting driver merge

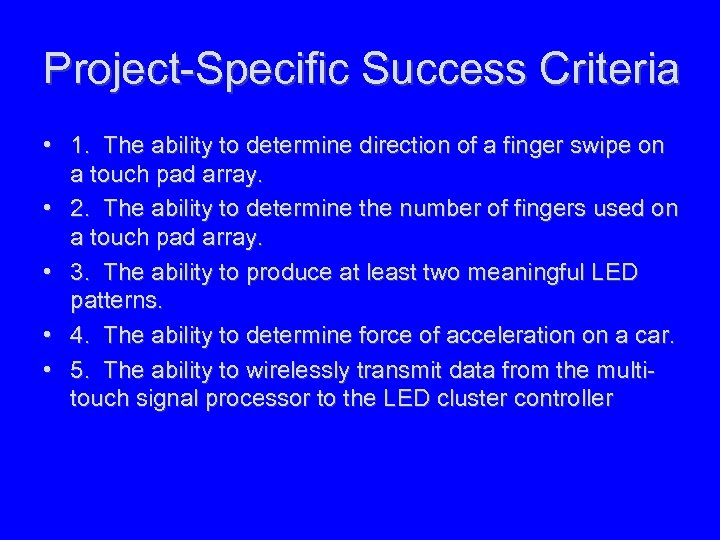

Project-Specific Success Criteria • 1. The ability to determine direction of a finger swipe on a touch pad array. • 2. The ability to determine the number of fingers used on a touch pad array. • 3. The ability to produce at least two meaningful LED patterns. • 4. The ability to determine force of acceleration on a car. • 5. The ability to wirelessly transmit data from the multitouch signal processor to the LED cluster controller

Project-Specific Success Criteria • 1. The ability to determine direction of a finger swipe on a touch pad array. • 2. The ability to determine the number of fingers used on a touch pad array. • 3. The ability to produce at least two meaningful LED patterns. • 4. The ability to determine force of acceleration on a car. • 5. The ability to wirelessly transmit data from the multitouch signal processor to the LED cluster controller

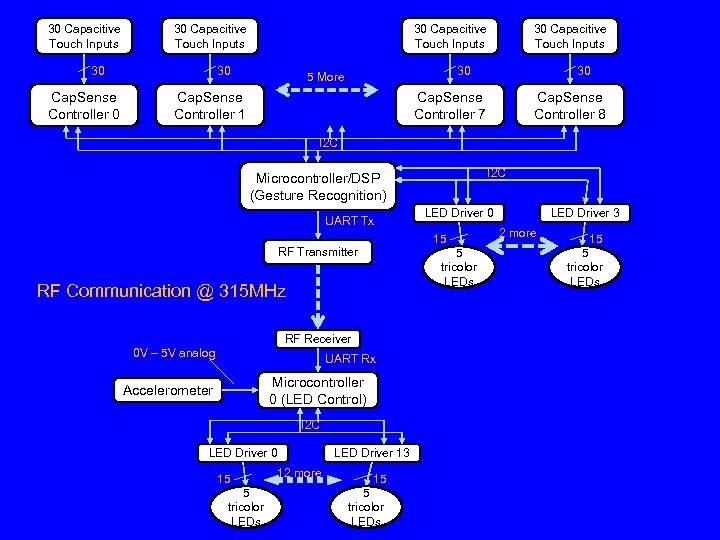

30 Capacitive Touch Inputs 30 Cap. Sense Controller 0 30 Capacitive Touch Inputs 30 5 More Cap. Sense Controller 1 30 Cap. Sense Controller 7 Cap. Sense Controller 8 I 2 C Microcontroller/DSP (Gesture Recognition) UART Tx 15 RF Transmitter 5 tricolor LEDs RF Communication @ 315 MHz RF Receiver 0 V – 5 V analog UART Rx Microcontroller 0 (LED Control) Accelerometer I 2 C LED Driver 0 15 5 tricolor LEDs 12 more LED Driver 0 LED Driver 13 15 5 tricolor LEDs LED Driver 3 2 more 15 5 tricolor LEDs

30 Capacitive Touch Inputs 30 Cap. Sense Controller 0 30 Capacitive Touch Inputs 30 5 More Cap. Sense Controller 1 30 Cap. Sense Controller 7 Cap. Sense Controller 8 I 2 C Microcontroller/DSP (Gesture Recognition) UART Tx 15 RF Transmitter 5 tricolor LEDs RF Communication @ 315 MHz RF Receiver 0 V – 5 V analog UART Rx Microcontroller 0 (LED Control) Accelerometer I 2 C LED Driver 0 15 5 tricolor LEDs 12 more LED Driver 0 LED Driver 13 15 5 tricolor LEDs LED Driver 3 2 more 15 5 tricolor LEDs

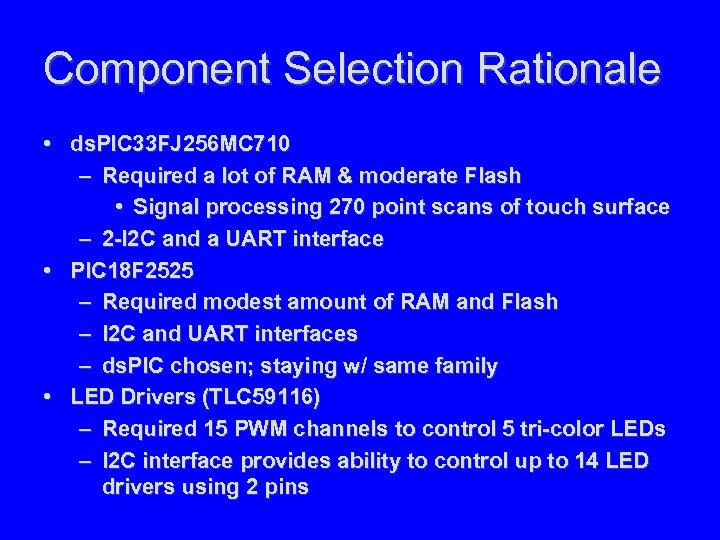

Component Selection Rationale • ds. PIC 33 FJ 256 MC 710 – Required a lot of RAM & moderate Flash • Signal processing 270 point scans of touch surface – 2 -I 2 C and a UART interface • PIC 18 F 2525 – Required modest amount of RAM and Flash – I 2 C and UART interfaces – ds. PIC chosen; staying w/ same family • LED Drivers (TLC 59116) – Required 15 PWM channels to control 5 tri-color LEDs – I 2 C interface provides ability to control up to 14 LED drivers using 2 pins

Component Selection Rationale • ds. PIC 33 FJ 256 MC 710 – Required a lot of RAM & moderate Flash • Signal processing 270 point scans of touch surface – 2 -I 2 C and a UART interface • PIC 18 F 2525 – Required modest amount of RAM and Flash – I 2 C and UART interfaces – ds. PIC chosen; staying w/ same family • LED Drivers (TLC 59116) – Required 15 PWM channels to control 5 tri-color LEDs – I 2 C interface provides ability to control up to 14 LED drivers using 2 pins

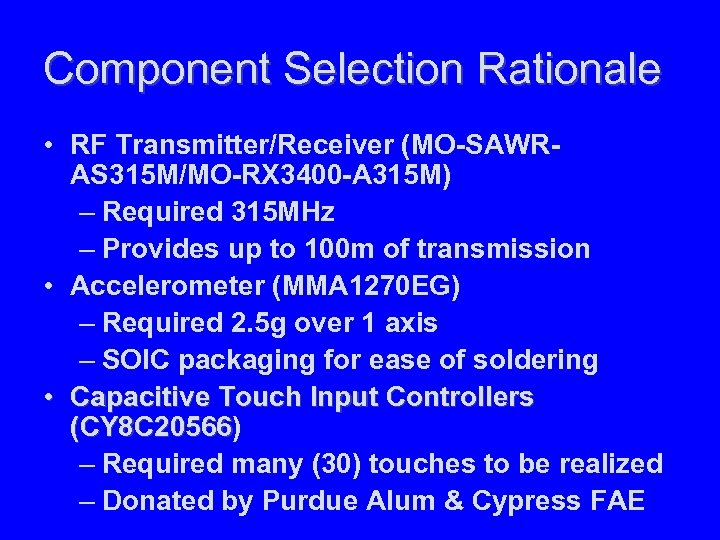

Component Selection Rationale • RF Transmitter/Receiver (MO-SAWRAS 315 M/MO-RX 3400 -A 315 M) – Required 315 MHz – Provides up to 100 m of transmission • Accelerometer (MMA 1270 EG) – Required 2. 5 g over 1 axis – SOIC packaging for ease of soldering • Capacitive Touch Input Controllers (CY 8 C 20566) (CY 8 C 20566 – Required many (30) touches to be realized – Donated by Purdue Alum & Cypress FAE

Component Selection Rationale • RF Transmitter/Receiver (MO-SAWRAS 315 M/MO-RX 3400 -A 315 M) – Required 315 MHz – Provides up to 100 m of transmission • Accelerometer (MMA 1270 EG) – Required 2. 5 g over 1 axis – SOIC packaging for ease of soldering • Capacitive Touch Input Controllers (CY 8 C 20566) (CY 8 C 20566 – Required many (30) touches to be realized – Donated by Purdue Alum & Cypress FAE

Packaging Design Constraints • Will not be demonstrating on a full size vehicle – Large RC car will house one LED Output Cluster – User Interface Module will be exterior to car, powered by an AC wall wart • Full size design would consist of several LED Output Clusters, weatherproofing, and a scheme for mounting the User Interface Module to a steering wheel

Packaging Design Constraints • Will not be demonstrating on a full size vehicle – Large RC car will house one LED Output Cluster – User Interface Module will be exterior to car, powered by an AC wall wart • Full size design would consist of several LED Output Clusters, weatherproofing, and a scheme for mounting the User Interface Module to a steering wheel

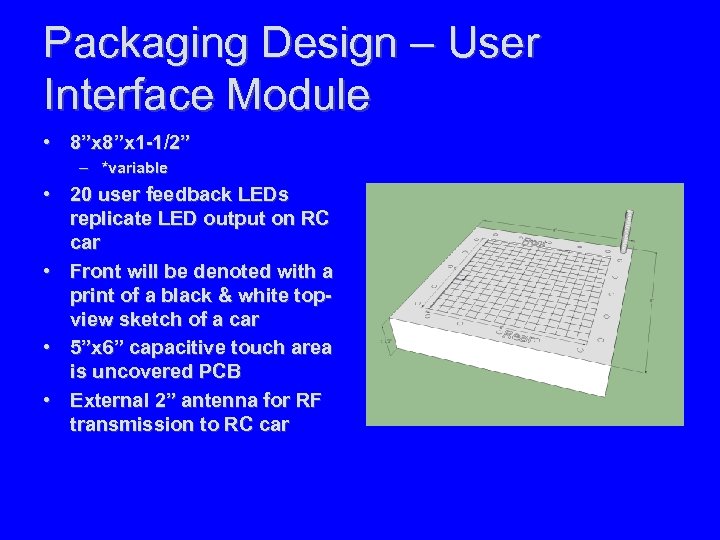

Packaging Design – User Interface Module • 8”x 1 -1/2” – *variable • 20 user feedback LEDs replicate LED output on RC car • Front will be denoted with a print of a black & white topview sketch of a car • 5”x 6” capacitive touch area is uncovered PCB • External 2” antenna for RF transmission to RC car

Packaging Design – User Interface Module • 8”x 1 -1/2” – *variable • 20 user feedback LEDs replicate LED output on RC car • Front will be denoted with a print of a black & white topview sketch of a car • 5”x 6” capacitive touch area is uncovered PCB • External 2” antenna for RF transmission to RC car

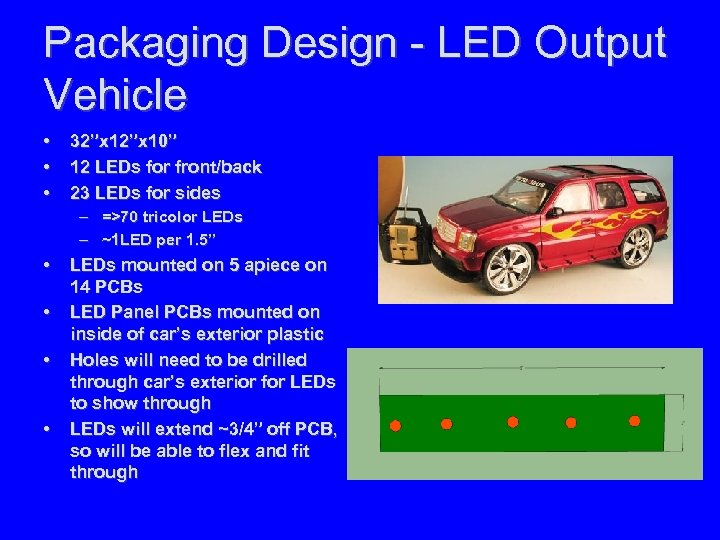

Packaging Design - LED Output Vehicle • • • 32”x 10” 12 LEDs for front/back 23 LEDs for sides – =>70 tricolor LEDs – ~1 LED per 1. 5” • • LEDs mounted on 5 apiece on 14 PCBs LED Panel PCBs mounted on inside of car’s exterior plastic Holes will need to be drilled through car’s exterior for LEDs to show through LEDs will extend ~3/4” off PCB, so will be able to flex and fit through

Packaging Design - LED Output Vehicle • • • 32”x 10” 12 LEDs for front/back 23 LEDs for sides – =>70 tricolor LEDs – ~1 LED per 1. 5” • • LEDs mounted on 5 apiece on 14 PCBs LED Panel PCBs mounted on inside of car’s exterior plastic Holes will need to be drilled through car’s exterior for LEDs to show through LEDs will extend ~3/4” off PCB, so will be able to flex and fit through

Schematic/Theory of Operation • Capacitive sensor is a pair of plates/electrodes • There is also capacitance between finger and electrodes • A sensor detects change in capacitance when finger is present

Schematic/Theory of Operation • Capacitive sensor is a pair of plates/electrodes • There is also capacitance between finger and electrodes • A sensor detects change in capacitance when finger is present

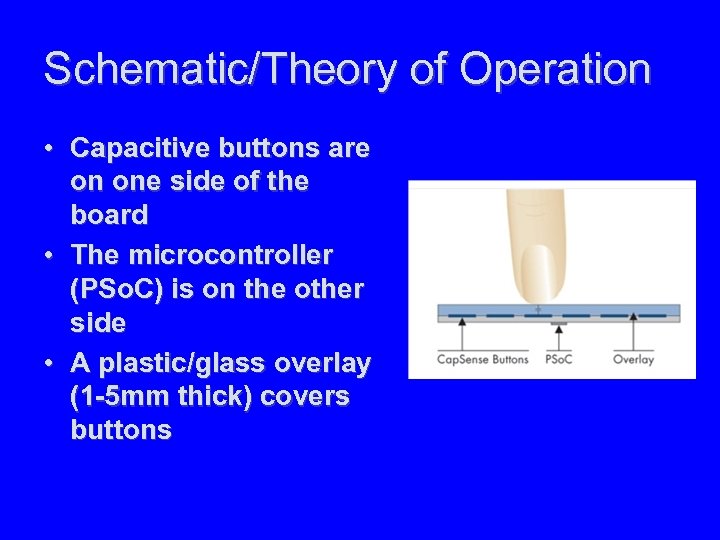

Schematic/Theory of Operation • Capacitive buttons are on one side of the board • The microcontroller (PSo. C) is on the other side • A plastic/glass overlay (1 -5 mm thick) covers buttons

Schematic/Theory of Operation • Capacitive buttons are on one side of the board • The microcontroller (PSo. C) is on the other side • A plastic/glass overlay (1 -5 mm thick) covers buttons

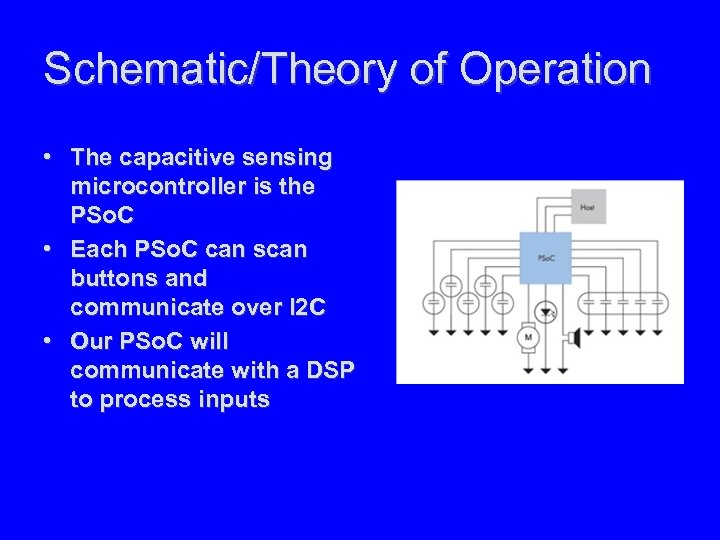

Schematic/Theory of Operation • The capacitive sensing microcontroller is the PSo. C • Each PSo. C can scan buttons and communicate over I 2 C • Our PSo. C will communicate with a DSP to process inputs

Schematic/Theory of Operation • The capacitive sensing microcontroller is the PSo. C • Each PSo. C can scan buttons and communicate over I 2 C • Our PSo. C will communicate with a DSP to process inputs

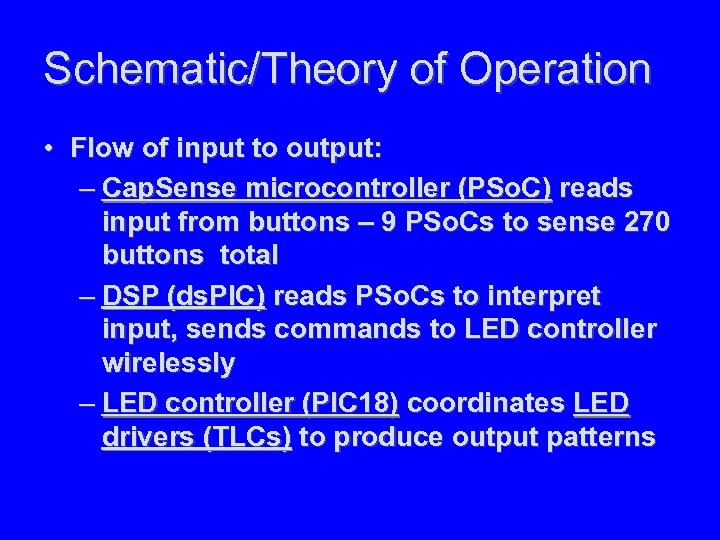

Schematic/Theory of Operation • Flow of input to output: – Cap. Sense microcontroller (PSo. C) reads input from buttons – 9 PSo. Cs to sense 270 buttons total – DSP (ds. PIC) reads PSo. Cs to interpret input, sends commands to LED controller wirelessly – LED controller (PIC 18) coordinates LED drivers (TLCs) to produce output patterns

Schematic/Theory of Operation • Flow of input to output: – Cap. Sense microcontroller (PSo. C) reads input from buttons – 9 PSo. Cs to sense 270 buttons total – DSP (ds. PIC) reads PSo. Cs to interpret input, sends commands to LED controller wirelessly – LED controller (PIC 18) coordinates LED drivers (TLCs) to produce output patterns

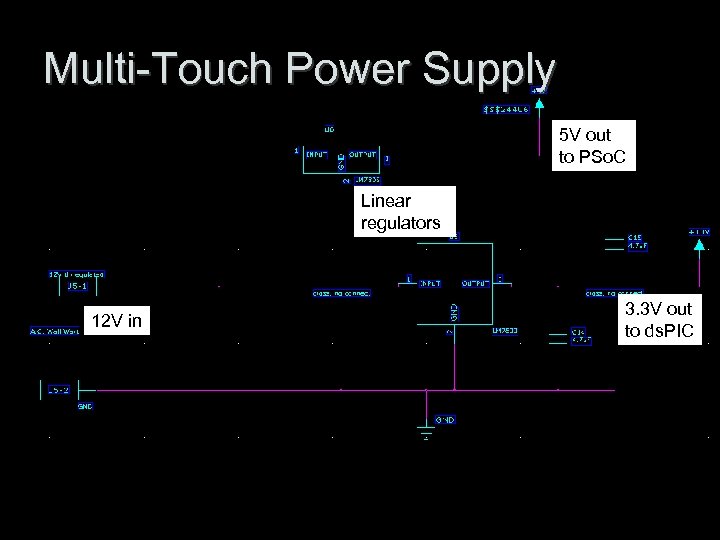

Multi-Touch Power Supply 5 V out to PSo. C Linear regulators 12 V in 3. 3 V out to ds. PIC

Multi-Touch Power Supply 5 V out to PSo. C Linear regulators 12 V in 3. 3 V out to ds. PIC

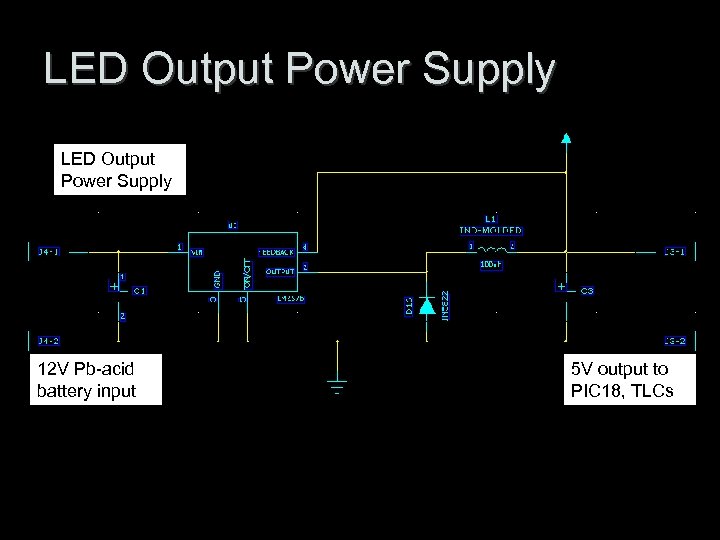

LED Output Power Supply 12 V Pb-acid battery input 5 V output to PIC 18, TLCs

LED Output Power Supply 12 V Pb-acid battery input 5 V output to PIC 18, TLCs

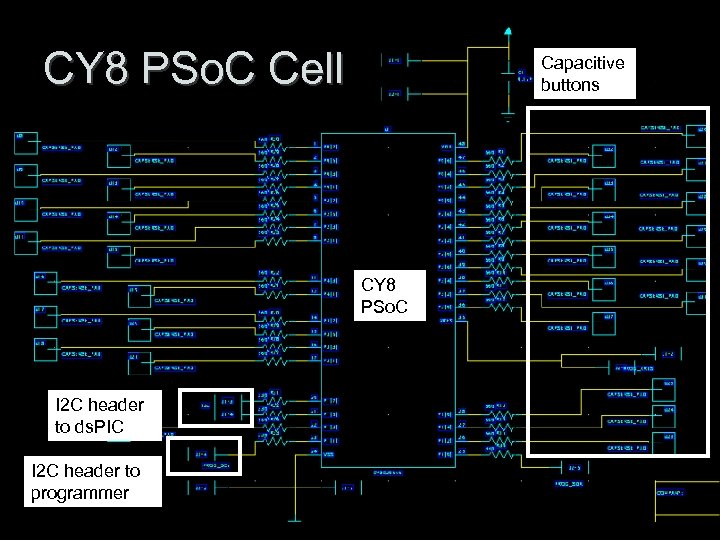

CY 8 PSo. C Cell Capacitive buttons CY 8 PSo. C I 2 C header to ds. PIC I 2 C header to programmer

CY 8 PSo. C Cell Capacitive buttons CY 8 PSo. C I 2 C header to ds. PIC I 2 C header to programmer

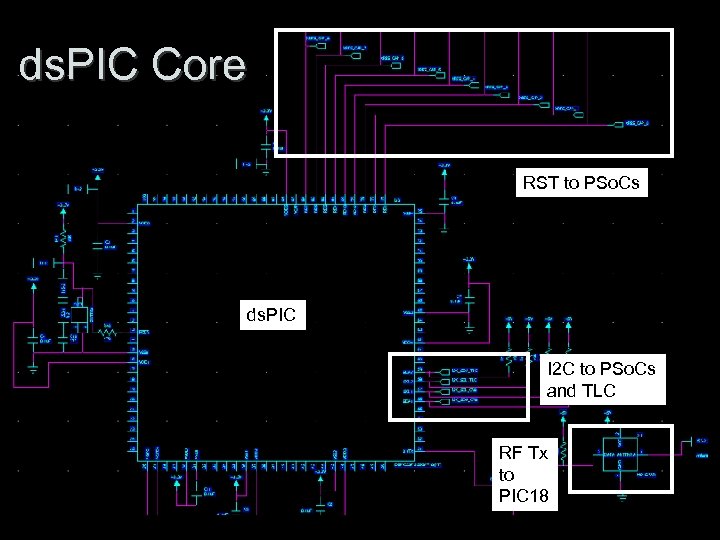

ds. PIC Core RST to PSo. Cs ds. PIC I 2 C to PSo. Cs and TLC RF Tx to PIC 18

ds. PIC Core RST to PSo. Cs ds. PIC I 2 C to PSo. Cs and TLC RF Tx to PIC 18

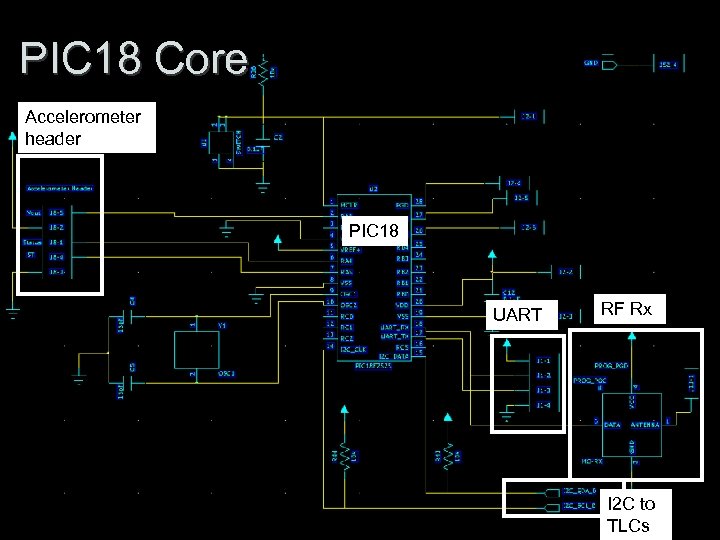

PIC 18 Core Accelerometer header PIC 18 UART RF Rx I 2 C to TLCs

PIC 18 Core Accelerometer header PIC 18 UART RF Rx I 2 C to TLCs

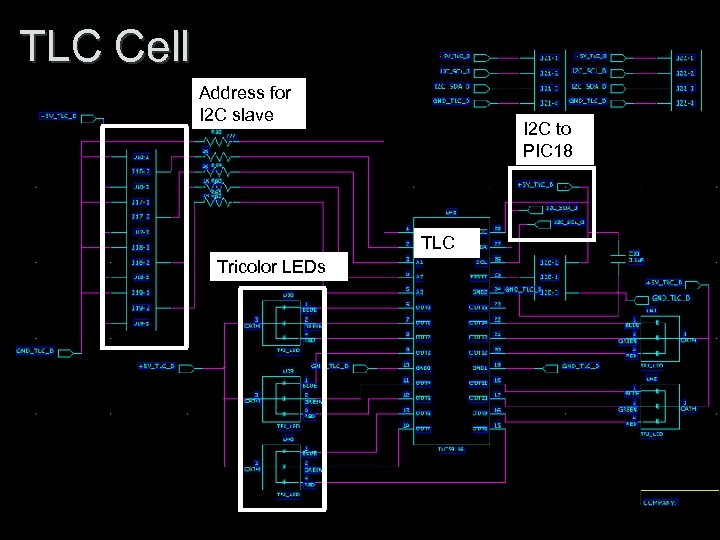

TLC Cell Address for I 2 C slave I 2 C to PIC 18 TLC Tricolor LEDs

TLC Cell Address for I 2 C slave I 2 C to PIC 18 TLC Tricolor LEDs

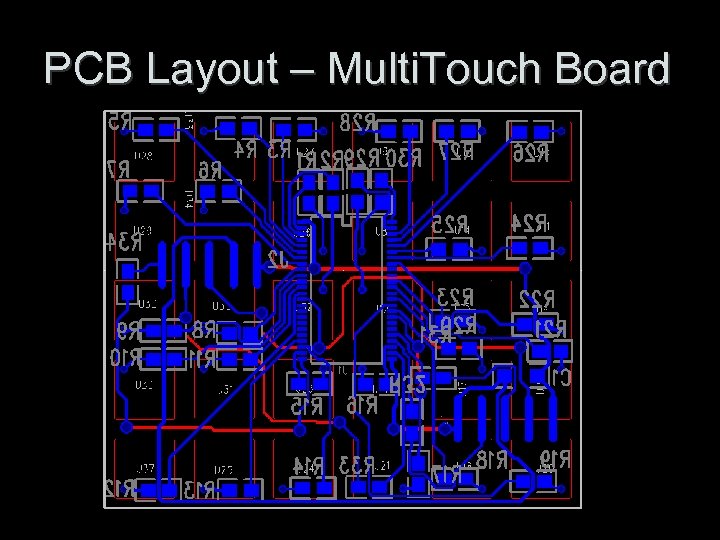

PCB Layout – Multi. Touch Board • Main Components – 1 Cypress PSOC chip and 30 Cap. Sense Pads • Other Components – 34 Resistors, 2 Headers, 1 Capacitor, and 1 OR gate • 5” x 6” Section of the larger User Interface Board • Via on each Cap. Sense pad made routing very difficult

PCB Layout – Multi. Touch Board • Main Components – 1 Cypress PSOC chip and 30 Cap. Sense Pads • Other Components – 34 Resistors, 2 Headers, 1 Capacitor, and 1 OR gate • 5” x 6” Section of the larger User Interface Board • Via on each Cap. Sense pad made routing very difficult

PCB Layout – Multi. Touch Board

PCB Layout – Multi. Touch Board

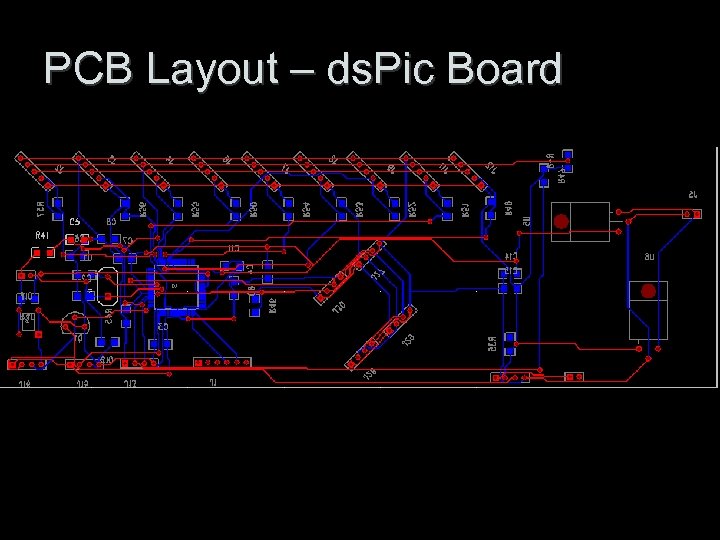

PCB Layout – ds. Pic Board • Main Components – ds. PIC, RF Transmitter, Power Supply • Other Components – 10 Capacitors, 16 Resistors, 1 Switch, and 17 Headers • 2” x 7” section of the larger User Interface Board • Lots of space allowed for large heat sink and ease of routing

PCB Layout – ds. Pic Board • Main Components – ds. PIC, RF Transmitter, Power Supply • Other Components – 10 Capacitors, 16 Resistors, 1 Switch, and 17 Headers • 2” x 7” section of the larger User Interface Board • Lots of space allowed for large heat sink and ease of routing

PCB Layout – ds. Pic Board

PCB Layout – ds. Pic Board

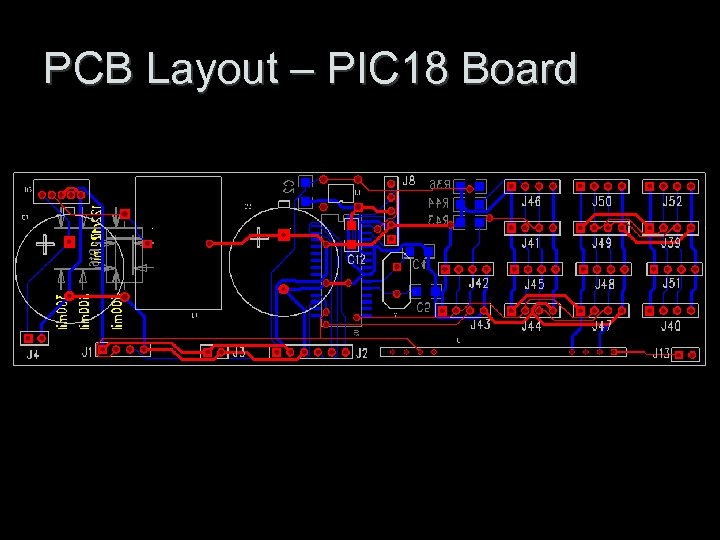

PCB Layout – PIC 18 Board • Main Components – PIC 18, RF Receiver, Power Supply • Other Components – Switch, 18 Headers, 3 Resistors, 4 Capacitors, 1 Inductor, and 1 Diode • 1. 4” x 5” • Plenty of space allowed for easy routing and the ability to actually minimize the area of the board

PCB Layout – PIC 18 Board • Main Components – PIC 18, RF Receiver, Power Supply • Other Components – Switch, 18 Headers, 3 Resistors, 4 Capacitors, 1 Inductor, and 1 Diode • 1. 4” x 5” • Plenty of space allowed for easy routing and the ability to actually minimize the area of the board

PCB Layout – PIC 18 Board

PCB Layout – PIC 18 Board

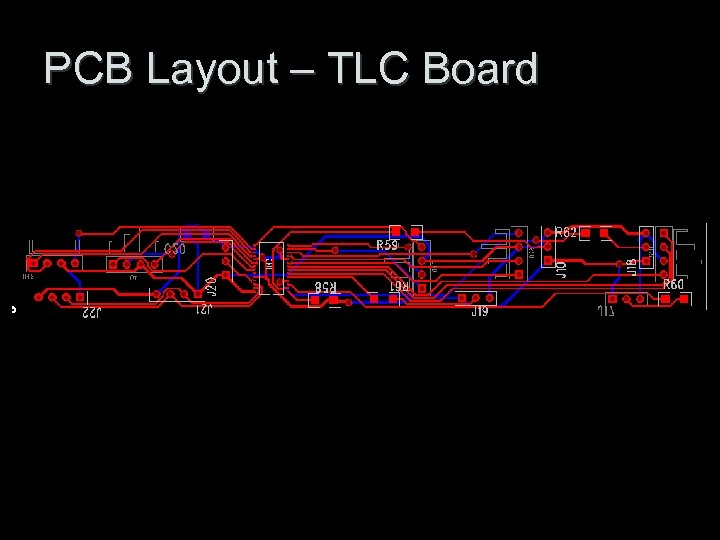

PCB Layout – TLC Board • Main Components – 5 LEDs and a single TLC driver chip • Other Components – 5 Resistors, 5 Headers, 1 Capacitor • 0. 5” x 5” • Tight space required careful routing

PCB Layout – TLC Board • Main Components – 5 LEDs and a single TLC driver chip • Other Components – 5 Resistors, 5 Headers, 1 Capacitor • 0. 5” x 5” • Tight space required careful routing

PCB Layout – TLC Board

PCB Layout – TLC Board

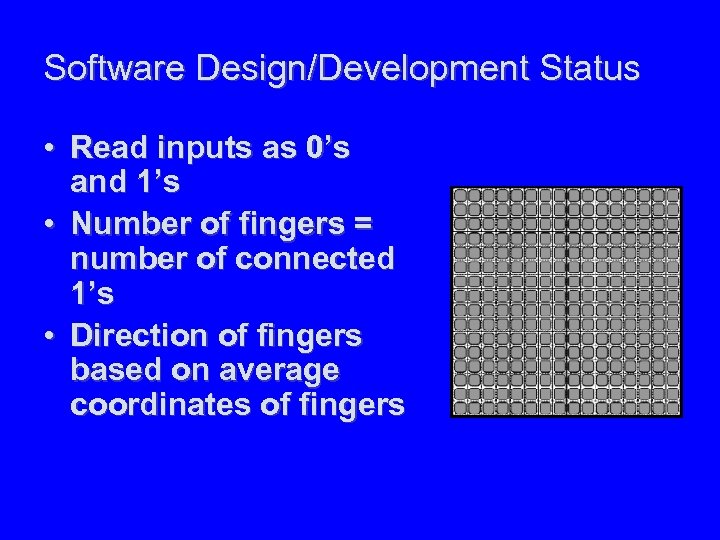

Software Design/Development Status • Read inputs as 0’s and 1’s • Number of fingers = number of connected 1’s • Direction of fingers based on average coordinates of fingers

Software Design/Development Status • Read inputs as 0’s and 1’s • Number of fingers = number of connected 1’s • Direction of fingers based on average coordinates of fingers

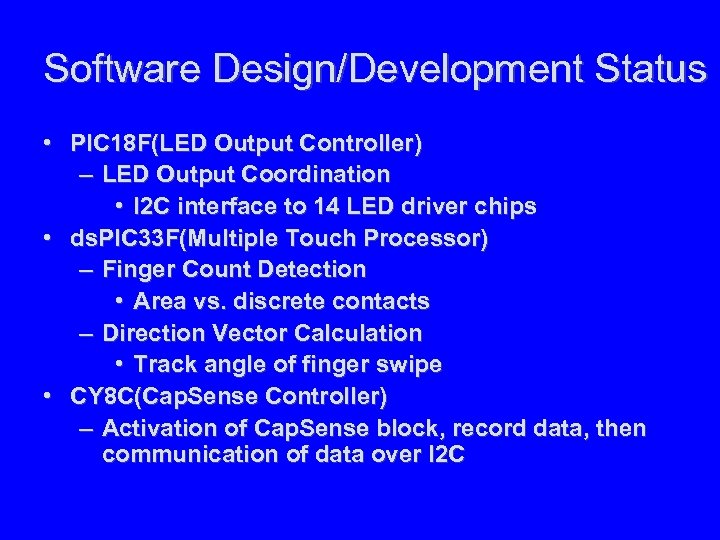

Software Design/Development Status • PIC 18 F(LED Output Controller) – LED Output Coordination • I 2 C interface to 14 LED driver chips • ds. PIC 33 F(Multiple Touch Processor) – Finger Count Detection • Area vs. discrete contacts – Direction Vector Calculation • Track angle of finger swipe • CY 8 C(Cap. Sense Controller) – Activation of Cap. Sense block, record data, then communication of data over I 2 C

Software Design/Development Status • PIC 18 F(LED Output Controller) – LED Output Coordination • I 2 C interface to 14 LED driver chips • ds. PIC 33 F(Multiple Touch Processor) – Finger Count Detection • Area vs. discrete contacts – Direction Vector Calculation • Track angle of finger swipe • CY 8 C(Cap. Sense Controller) – Activation of Cap. Sense block, record data, then communication of data over I 2 C

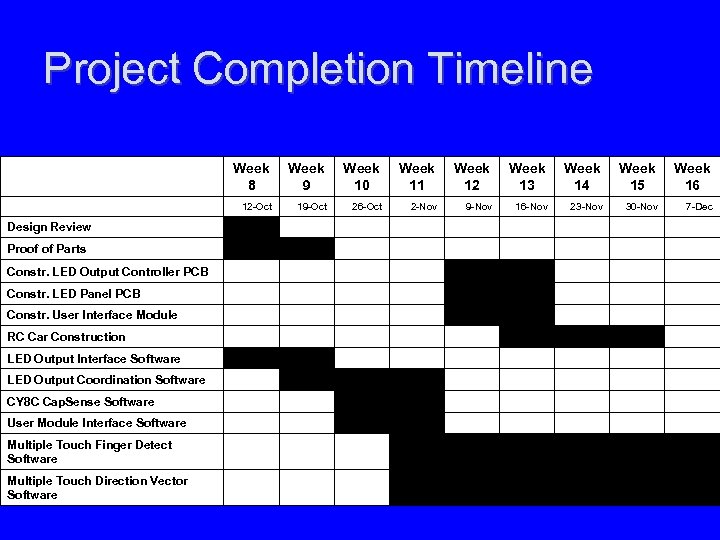

Project Completion Timeline Week 8 Week 9 Week 10 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 12 -Oct 19 -Oct 26 -Oct 2 -Nov 9 -Nov 16 -Nov 23 -Nov 30 -Nov 7 -Dec Design Review Proof of Parts Constr. LED Output Controller PCB Constr. LED Panel PCB Constr. User Interface Module RC Car Construction LED Output Interface Software LED Output Coordination Software CY 8 C Cap. Sense Software User Module Interface Software Multiple Touch Finger Detect Software Multiple Touch Direction Vector Software

Project Completion Timeline Week 8 Week 9 Week 10 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 12 -Oct 19 -Oct 26 -Oct 2 -Nov 9 -Nov 16 -Nov 23 -Nov 30 -Nov 7 -Dec Design Review Proof of Parts Constr. LED Output Controller PCB Constr. LED Panel PCB Constr. User Interface Module RC Car Construction LED Output Interface Software LED Output Coordination Software CY 8 C Cap. Sense Software User Module Interface Software Multiple Touch Finger Detect Software Multiple Touch Direction Vector Software

Questions / Discussion

Questions / Discussion