f5c89f6474455781d3e962f622d5c01d.ppt

- Количество слайдов: 23

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A Case Study on a Rice Husk Cogeneration Power Plant Capacity Development for the Clean Development Mechanism 26 -27 March 2003 Sunway Hotel, Phnom Penh, Cambodia Mila J. Jude Cogen 3 Country Coordinator

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A Case Study on a Rice Husk Cogeneration Power Plant Capacity Development for the Clean Development Mechanism 26 -27 March 2003 Sunway Hotel, Phnom Penh, Cambodia Mila J. Jude Cogen 3 Country Coordinator

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A Case Study on a Rice Husk Cogeneration Power Plant Presentation Outline • Cogen 3 Programme • Cogeneration: How Does It Work? • Angkor Prosperous Rice Mill • Environmental and Economic Benefits • Conclusion

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A Case Study on a Rice Husk Cogeneration Power Plant Presentation Outline • Cogen 3 Programme • Cogeneration: How Does It Work? • Angkor Prosperous Rice Mill • Environmental and Economic Benefits • Conclusion

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Cogen 3 Programme • is the third phase of the European Commission (EC)-ASEAN cooperation programme • promotes the implementation of Proven, Clean and Efficient Biomass, Coal and Gas cogeneration projects by facilitating business partnerships between EU suppliers and ASEAN industries • The Full-Scale Demonstration Project (FSDP) – a grant of 15% of the cost of the equipment will be given to a project that qualifies as FSDP. An FSDP is a showcase in ASEAN aiming to convince other potential end-users to select the appropriate technology in order to replicate successes. • Country Coordinators in: Cambodia, Thailand, Malaysia, Vietnam, Philippines, Indonesia and Singapore • Cambodia Team email: cambodia@cogen 3. net

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Cogen 3 Programme • is the third phase of the European Commission (EC)-ASEAN cooperation programme • promotes the implementation of Proven, Clean and Efficient Biomass, Coal and Gas cogeneration projects by facilitating business partnerships between EU suppliers and ASEAN industries • The Full-Scale Demonstration Project (FSDP) – a grant of 15% of the cost of the equipment will be given to a project that qualifies as FSDP. An FSDP is a showcase in ASEAN aiming to convince other potential end-users to select the appropriate technology in order to replicate successes. • Country Coordinators in: Cambodia, Thailand, Malaysia, Vietnam, Philippines, Indonesia and Singapore • Cambodia Team email: cambodia@cogen 3. net

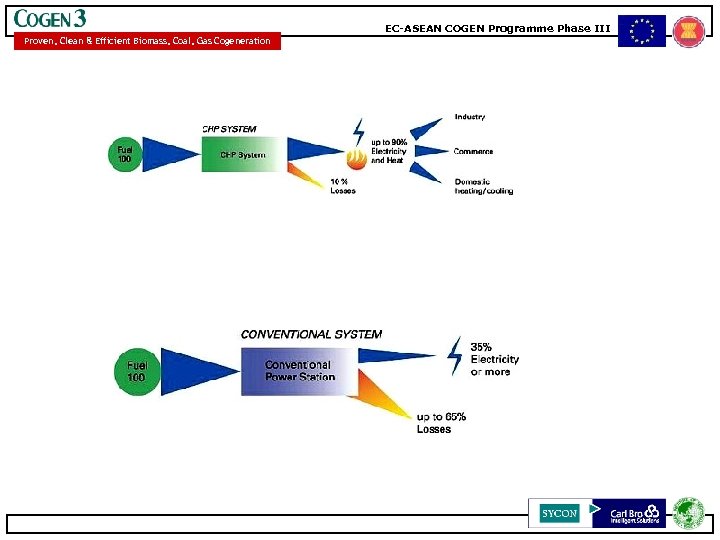

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration (Combined Heat and Power or CHP) is the simultaneous production of electricity and heat, both of which are used.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration (Combined Heat and Power or CHP) is the simultaneous production of electricity and heat, both of which are used.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration

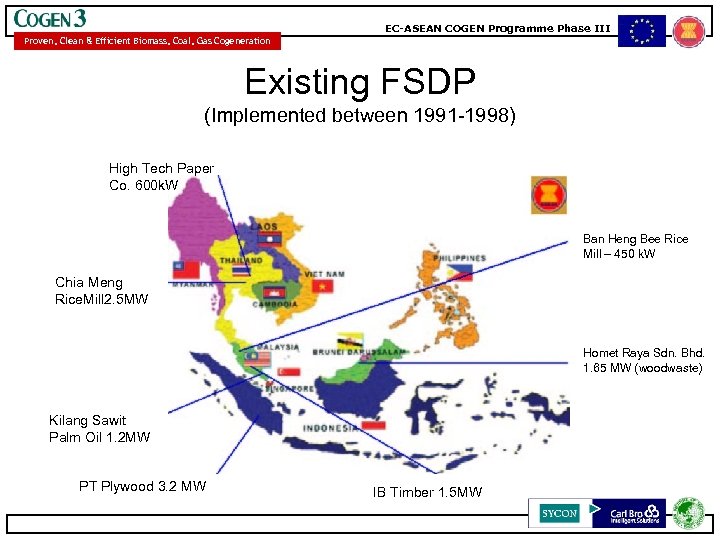

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Existing FSDP (Implemented between 1991 -1998) High Tech Paper Co. 600 k. W Ban Heng Bee Rice Mill – 450 k. W Chia Meng Rice. Mill 2. 5 MW Homet Raya Sdn. Bhd. 1. 65 MW (woodwaste) Kilang Sawit Palm Oil 1. 2 MW PT Plywood 3. 2 MW IB Timber 1. 5 MW

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Existing FSDP (Implemented between 1991 -1998) High Tech Paper Co. 600 k. W Ban Heng Bee Rice Mill – 450 k. W Chia Meng Rice. Mill 2. 5 MW Homet Raya Sdn. Bhd. 1. 65 MW (woodwaste) Kilang Sawit Palm Oil 1. 2 MW PT Plywood 3. 2 MW IB Timber 1. 5 MW

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice Mill website: www. angkorrice. com

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice Mill website: www. angkorrice. com

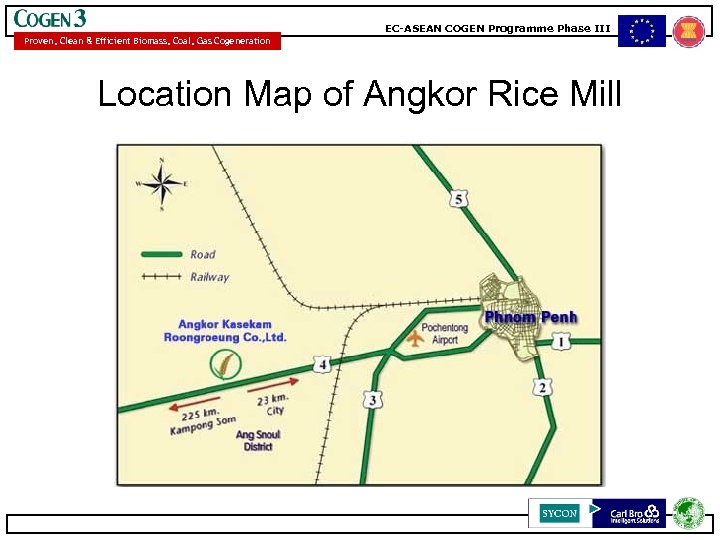

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Location Map of Angkor Rice Mill

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Location Map of Angkor Rice Mill

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice Mill

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice Mill

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration The rich, fertile soil of Central Cambodia provides optimal environment for growing Neang Malis rice

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration The rich, fertile soil of Central Cambodia provides optimal environment for growing Neang Malis rice

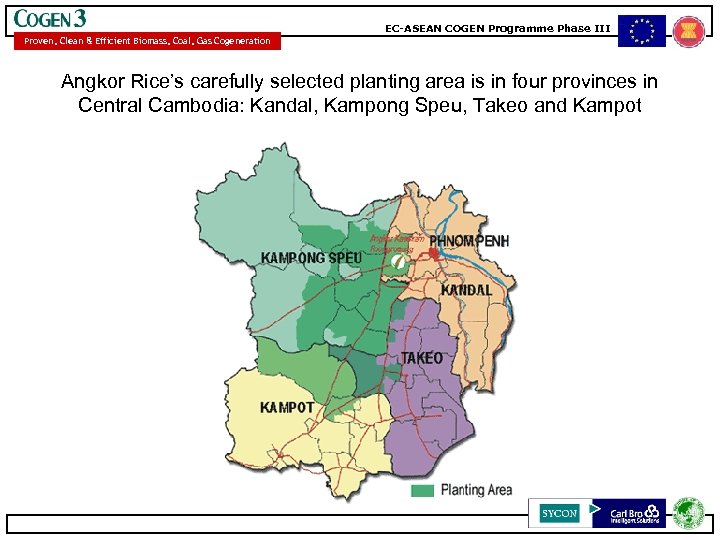

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice’s carefully selected planting area is in four provinces in Central Cambodia: Kandal, Kampong Speu, Takeo and Kampot

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Angkor Rice’s carefully selected planting area is in four provinces in Central Cambodia: Kandal, Kampong Speu, Takeo and Kampot

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A farmer transplanting seedlings

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration A farmer transplanting seedlings

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration The region’s (central Cambodia) naturally fertile and sandy soil enables farmers to grow Angkor Rice’s premium-quality Neang Malis rice in a traditional way without chemicals.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration The region’s (central Cambodia) naturally fertile and sandy soil enables farmers to grow Angkor Rice’s premium-quality Neang Malis rice in a traditional way without chemicals.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration More than 25, 000 families are Angkor Rice’s members and growing Neang Malis rice. There are no middlemen. Angkor Rice sets a high standard. The Agriculture Division distributes high quality seeds and instructs the farmers in planting rice.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration More than 25, 000 families are Angkor Rice’s members and growing Neang Malis rice. There are no middlemen. Angkor Rice sets a high standard. The Agriculture Division distributes high quality seeds and instructs the farmers in planting rice.

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Products of Angkor Rice: 100% Neang Malis

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Products of Angkor Rice: 100% Neang Malis

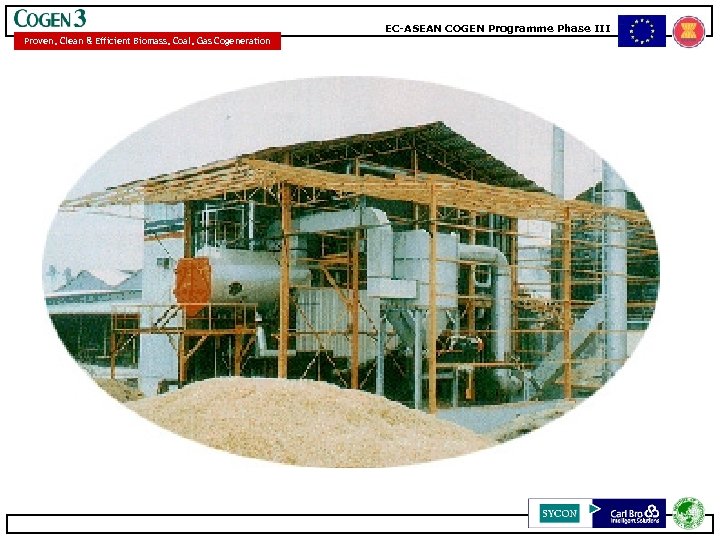

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill • Steam turbine system with 1 MW electric capacity • Present capacity of the mill is 10 tons/hour. Proposed expansion of another 10 tons/hour • Rice husk will be used as fuel • Two scenarios: – steam has no value – steam has value equal to 50% of the cost for steam generation in a boiler using fuel oil • Excess Electricity exported to other customers • Utilization of heat for drying

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill • Steam turbine system with 1 MW electric capacity • Present capacity of the mill is 10 tons/hour. Proposed expansion of another 10 tons/hour • Rice husk will be used as fuel • Two scenarios: – steam has no value – steam has value equal to 50% of the cost for steam generation in a boiler using fuel oil • Excess Electricity exported to other customers • Utilization of heat for drying

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill Scenario: Steam has no value • • • Total Investment Cost including contingency: 1. 5 million euro Net Present Value: 3. 1257 million euro IRR: 49. 7% Discounted Payback Time: 2. 3 years Cogeneration Project Lifetime: 20 years

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill Scenario: Steam has no value • • • Total Investment Cost including contingency: 1. 5 million euro Net Present Value: 3. 1257 million euro IRR: 49. 7% Discounted Payback Time: 2. 3 years Cogeneration Project Lifetime: 20 years

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill Scenario: Steam has value equal to 50% of fuel oil cost • • • Total Investment Cost including contingency: 1. 5 million euro Net Present Value: 4. 659 million euro IRR: 64. 4% Discounted Payback Time: 1. 6 years Cogeneration Project Lifetime: 20 years

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Proposed Rice Husk-Fired Cogeneration Power Plant Angkor Rice Mill Scenario: Steam has value equal to 50% of fuel oil cost • • • Total Investment Cost including contingency: 1. 5 million euro Net Present Value: 4. 659 million euro IRR: 64. 4% Discounted Payback Time: 1. 6 years Cogeneration Project Lifetime: 20 years

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Cogen 3 Pre-evaluation and Recommendations • Project seems feasible • Further investigations are recommended, concerning: – detailed design (electricity capacity of steam turbine, utilization of capacity) – necessary investment – real value of steam (benefits of drying using steam) – necessary investment in drying process – necessary investment in electricity distribution grid – all issues, (especially government regulations) related to selling of electricity to other parties • Requires a full feasibility study and investigation

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Cogen 3 Pre-evaluation and Recommendations • Project seems feasible • Further investigations are recommended, concerning: – detailed design (electricity capacity of steam turbine, utilization of capacity) – necessary investment – real value of steam (benefits of drying using steam) – necessary investment in drying process – necessary investment in electricity distribution grid – all issues, (especially government regulations) related to selling of electricity to other parties • Requires a full feasibility study and investigation

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Benefits of the Rice-Husk Cogeneration Power Plant Environmental Benefits • Less pollution • Uses rice husk, which is considered an agricultural waste Economic Benefits • Savings (electricity production) • Income generating (selling excess electricity, ash sales) • Generates job • Saves on fuel, no foreign currency needed

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Benefits of the Rice-Husk Cogeneration Power Plant Environmental Benefits • Less pollution • Uses rice husk, which is considered an agricultural waste Economic Benefits • Savings (electricity production) • Income generating (selling excess electricity, ash sales) • Generates job • Saves on fuel, no foreign currency needed

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Opportunities in Cambodia Biomass – opportunities in rice mill, rubber processing plants, palm oil refinery Gas – gas supply in Cambodia is in the exploratory stage. If gas is available, there will be opportunities in Buildings (hotels, restaurants, hospitals, schools, offices, supermarkets, etc. ) and Industries (cement, pharmaceuticals, garments)

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration Opportunities in Cambodia Biomass – opportunities in rice mill, rubber processing plants, palm oil refinery Gas – gas supply in Cambodia is in the exploratory stage. If gas is available, there will be opportunities in Buildings (hotels, restaurants, hospitals, schools, offices, supermarkets, etc. ) and Industries (cement, pharmaceuticals, garments)

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration For more information, please visit COGEN 3 Website at: http: //www. cogen 3. net Thank You !

EC-ASEAN COGEN Programme Phase III Proven, Clean & Efficient Biomass, Coal, Gas Cogeneration For more information, please visit COGEN 3 Website at: http: //www. cogen 3. net Thank You !