188278_633779040345551250 (1).ppt

- Количество слайдов: 49

Eastern Ontario Tower Crane Audit Presentation Presented by: Jason Gordon & Steven Mac. Donald

Presentation Overview Purpose of presentation n Terms used n How it started n Check sheet (nuts and bolts) n Audit findings n Successes, changes which occurred n Recommendations for future n

Purpose of presentation n To report to CPPAC the: – Why – How – What

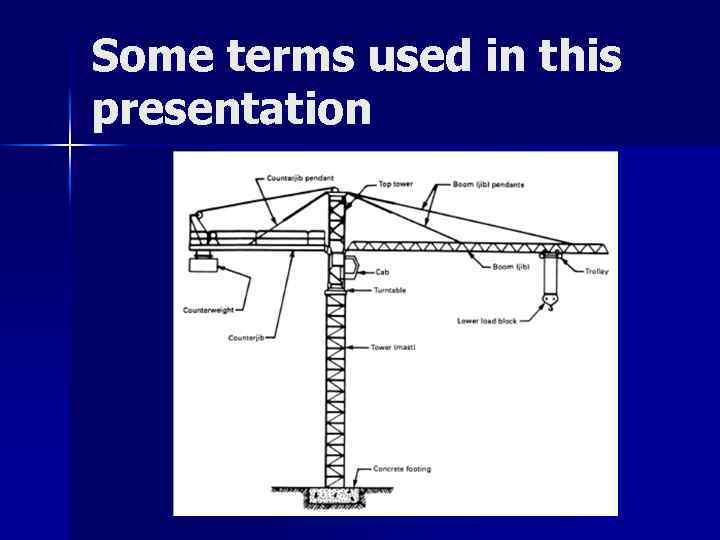

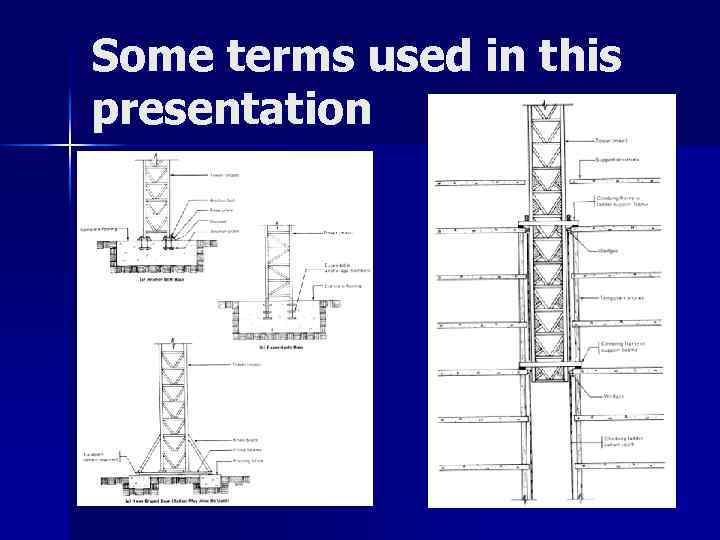

Some terms used in this presentation

Some terms used in this presentation

How it all Started… reactive to proactive Ottawa Incident: the slewing motion of a tower crane was difficult to control. n Ottawa Incident: the load of a tower crane descended uncontrolled. n Mostly control system problems. n

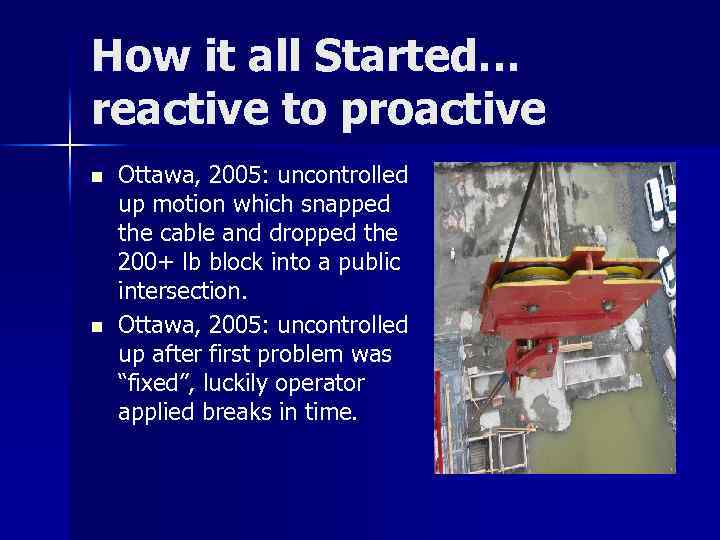

How it all Started… reactive to proactive n n Ottawa, 2005: uncontrolled up motion which snapped the cable and dropped the 200+ lb block into a public intersection. Ottawa, 2005: uncontrolled up after first problem was “fixed”, luckily operator applied breaks in time.

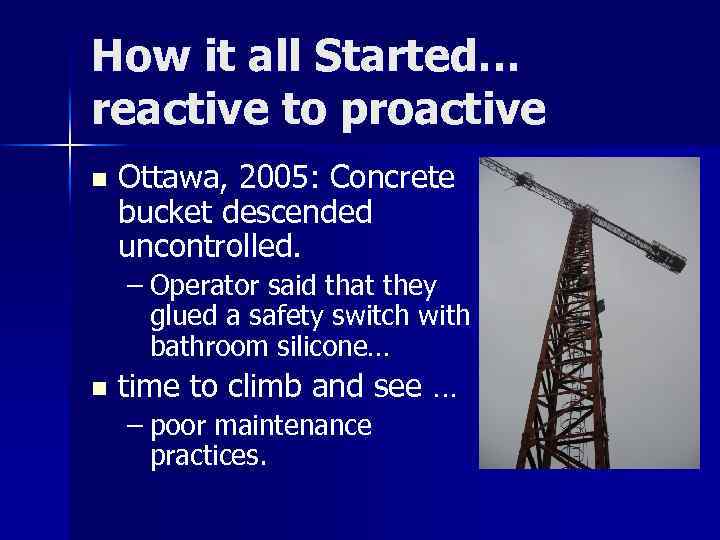

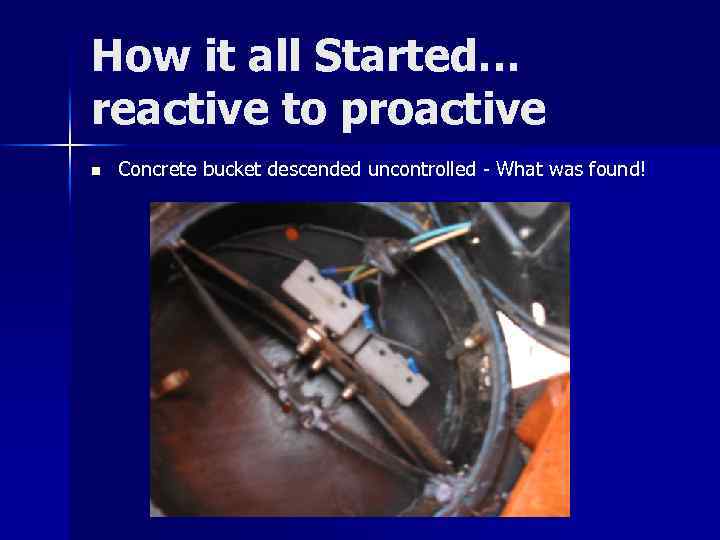

How it all Started… reactive to proactive n Ottawa, 2005: Concrete bucket descended uncontrolled. – Operator said that they glued a safety switch with bathroom silicone… n time to climb and see … – poor maintenance practices.

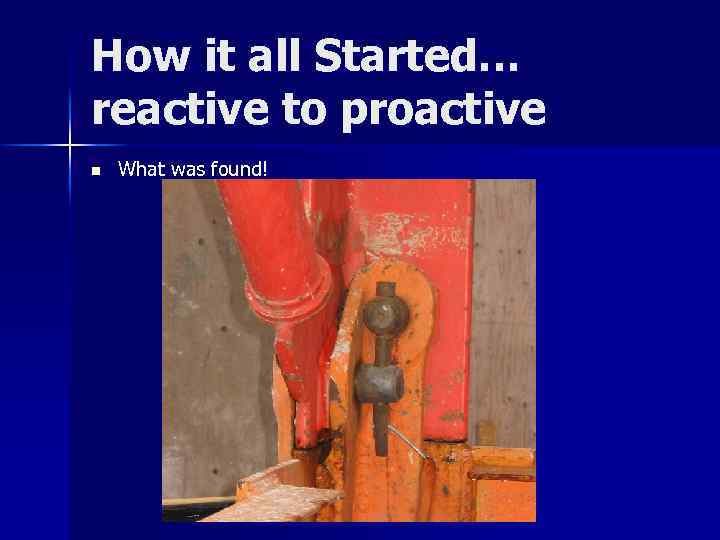

How it all Started… reactive to proactive n Concrete bucket descended uncontrolled - What was found!

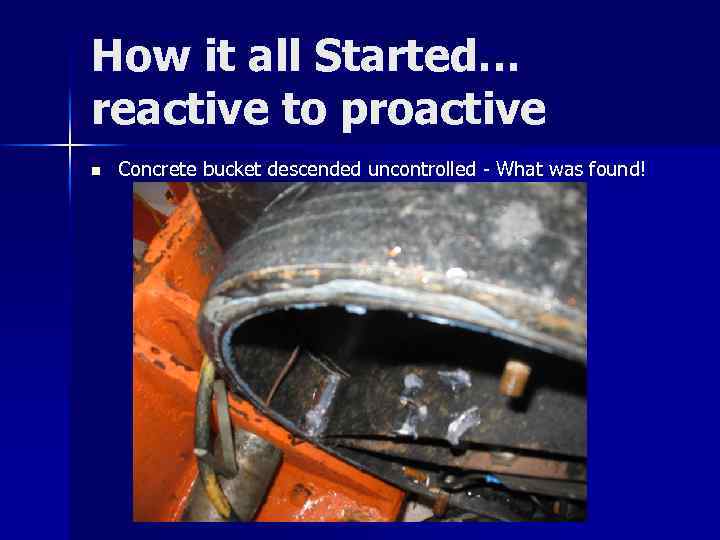

How it all Started… reactive to proactive n Concrete bucket descended uncontrolled - What was found!

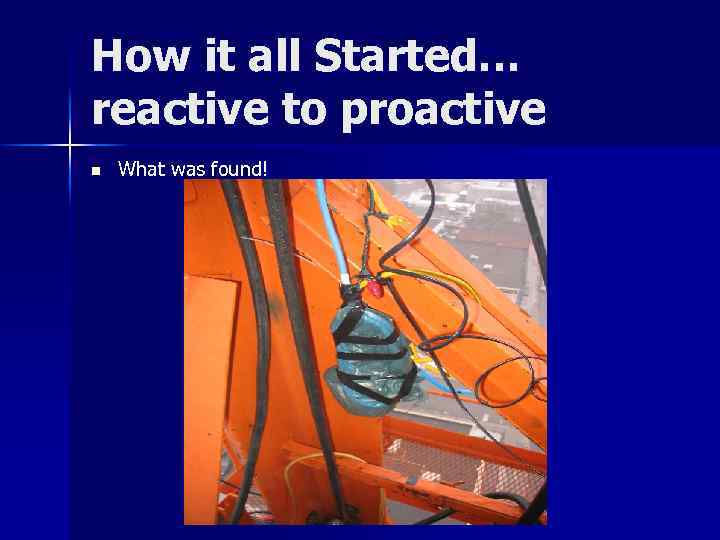

How it all Started… reactive to proactive n What was found!

How it all Started… reactive to proactive n What was found!

How it all Started… reactive to proactive n What was found!

How it all Started… More Incidents! n Ottawa: when the operator inputs down, the load goes up… the load gets stuck at the top, a loose wire is blamed.

How it all Started… reactive to proactive n Then looked for which agency inspects tower cranes and found… nobody. – Electrical Safety Authority stops at the base at the main disconnect – TSSA has determined that it is not a lifting device.

How it all Started… reactive to proactive n Is this a company specific problem or an industry wide problem? … The Eastern Ontario Tower Crane Audit is started.

Audit Format, Consistency was Key: n n Audited: – – 20 cranes 3 different cities 6 different suppliers. Issued 39 Orders – Note: Some orders involved more then one crane. Used a checklist based on CSA Z 248 -04 “Code for Tower Cranes” to ensure consistency Visual inspection only, no panels opened Many problems were common sense issues

Crane Inspection Format: n Inspection consisted of five basic stages: – Site Office Inspection (Documentation). – Between the Office and the Crane Base. – The Climb. – Meet the Operator (Cab Inspection). – Outside the Cab.

In the trailer looking for… n n n n n Drawing of Crane Base Re-bar inspection report (if applicable) Soil load bearing report (if applicable) Crane pre-installation inspection Crane post-installation inspection Wire rope certification Multiple crane operational procedure (if applicable) Elevation and plan drawings of crane on site – do the plans call for bracing the crane to the building Authorization of items which increase the windexposed area

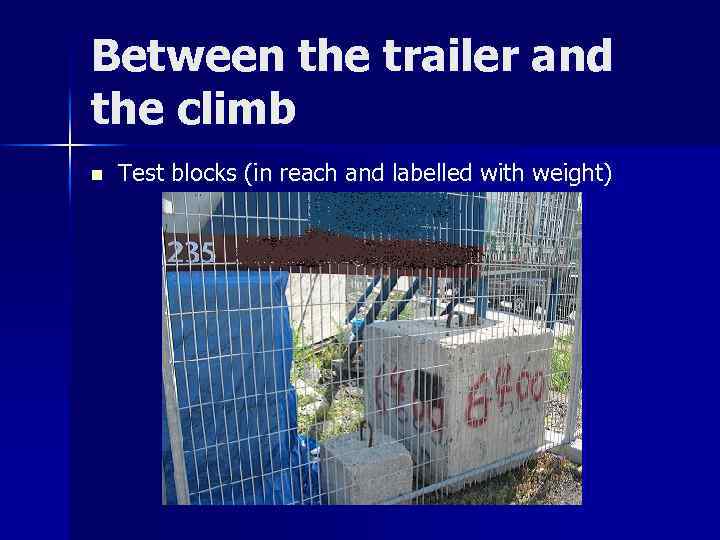

Between the trailer and the climb n Test blocks (in reach and labelled with weight)

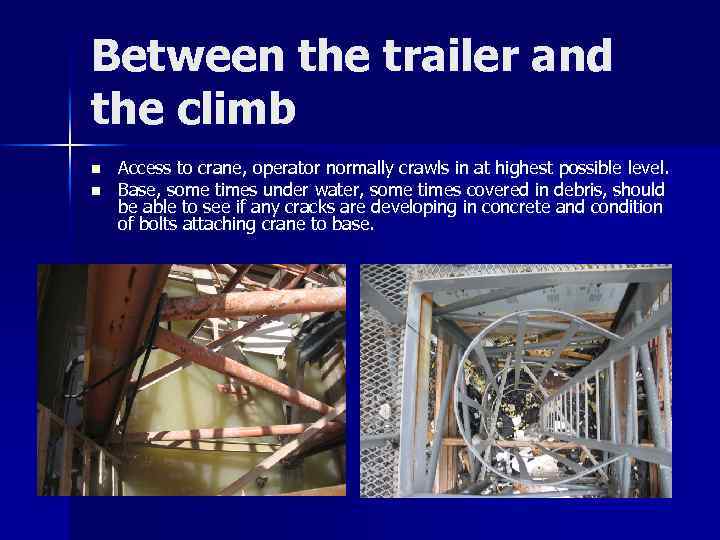

Between the trailer and the climb n n Access to crane, operator normally crawls in at highest possible level. Base, some times under water, some times covered in debris, should be able to see if any cracks are developing in concrete and condition of bolts attaching crane to base.

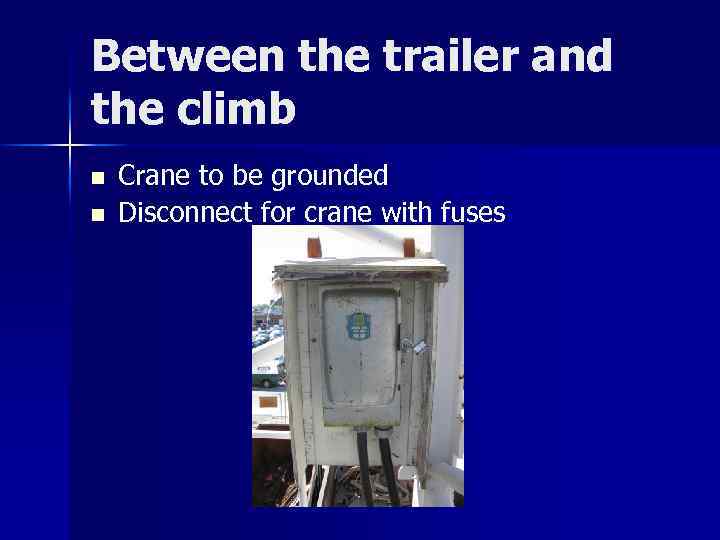

Between the trailer and the climb n n Crane to be grounded Disconnect for crane with fuses

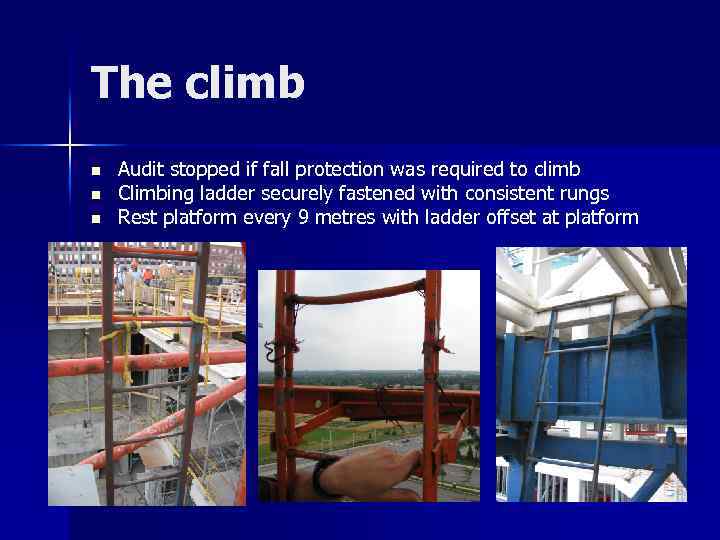

The climb n n n Audit stopped if fall protection was required to climb Climbing ladder securely fastened with consistent rungs Rest platform every 9 metres with ladder offset at platform

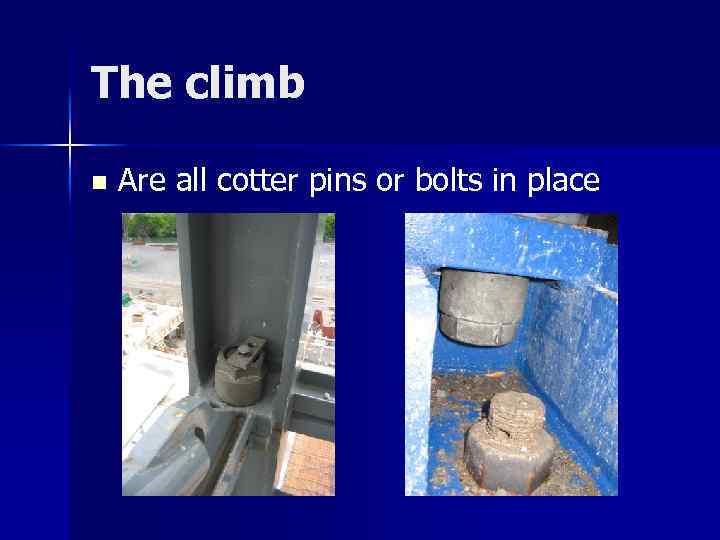

The climb n Are all cotter pins or bolts in place

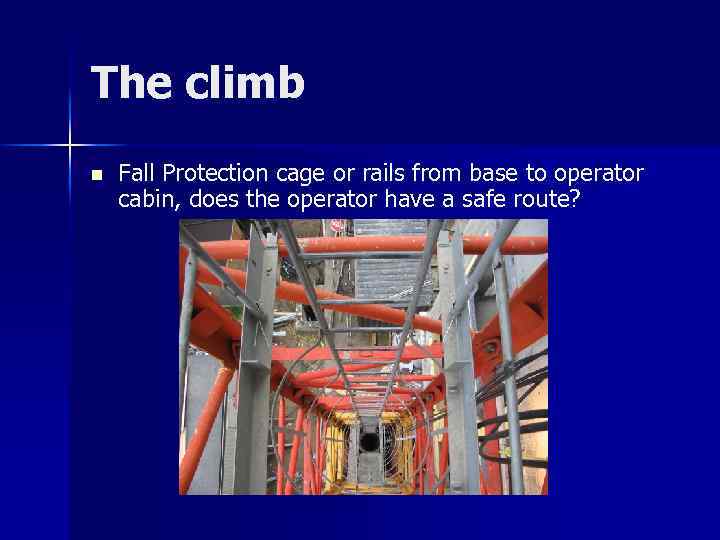

The climb n Fall Protection cage or rails from base to operator cabin, does the operator have a safe route?

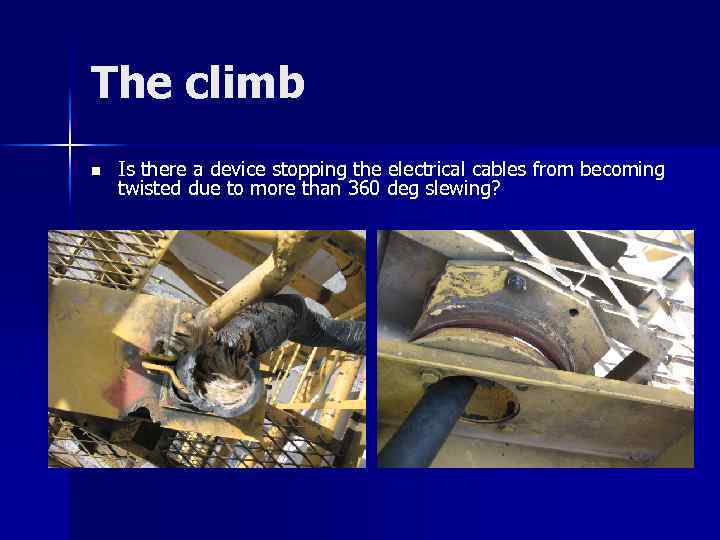

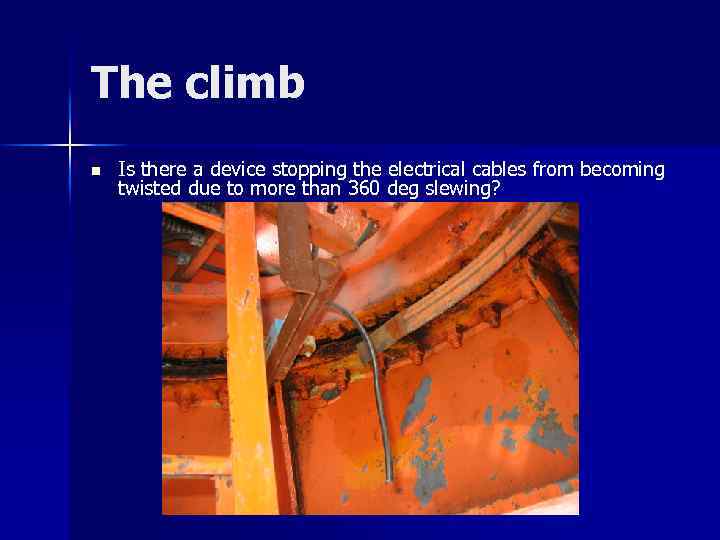

The climb n Is there a device stopping the electrical cables from becoming twisted due to more than 360 deg slewing?

The climb n Is there a device stopping the electrical cables from becoming twisted due to more than 360 deg slewing?

Meeting the operator Normally very happy to see inspectors n No information on operators was recorded n Asked Operator not to operate crane during audit (about 20 minutes) n

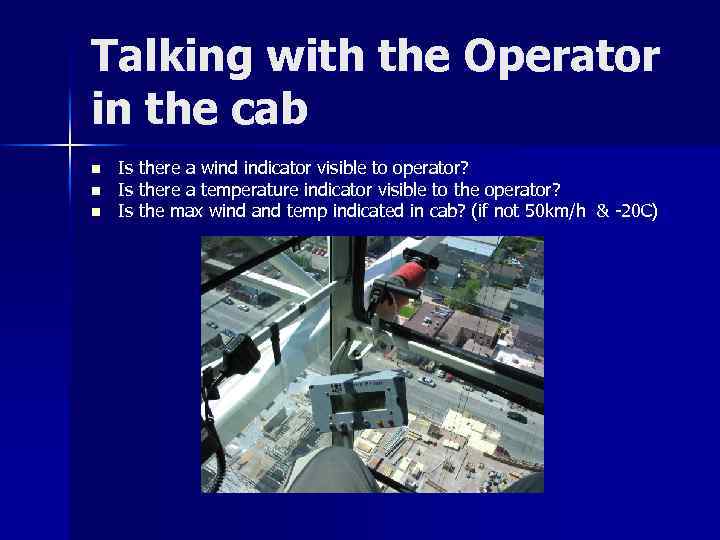

Talking with the Operator in the cab n n n Is there a wind indicator visible to operator? Is there a temperature indicator visible to the operator? Is the max wind and temp indicated in cab? (if not 50 km/h & -20 C)

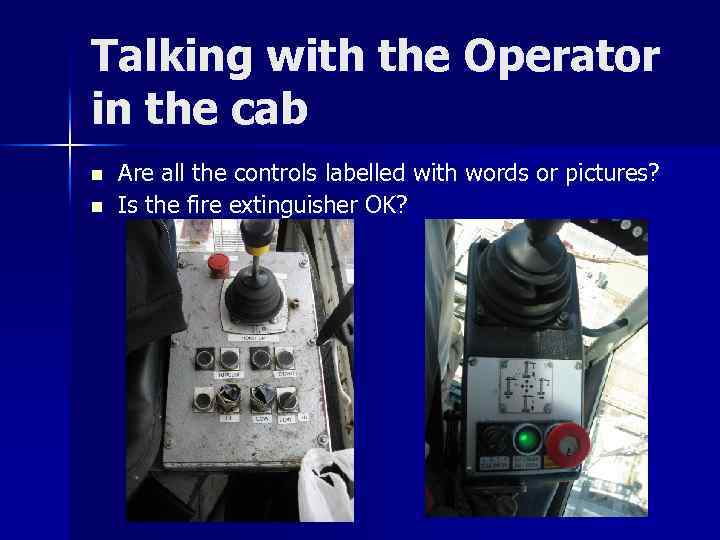

Talking with the Operator in the cab n n Are all the controls labelled with words or pictures? Is the fire extinguisher OK?

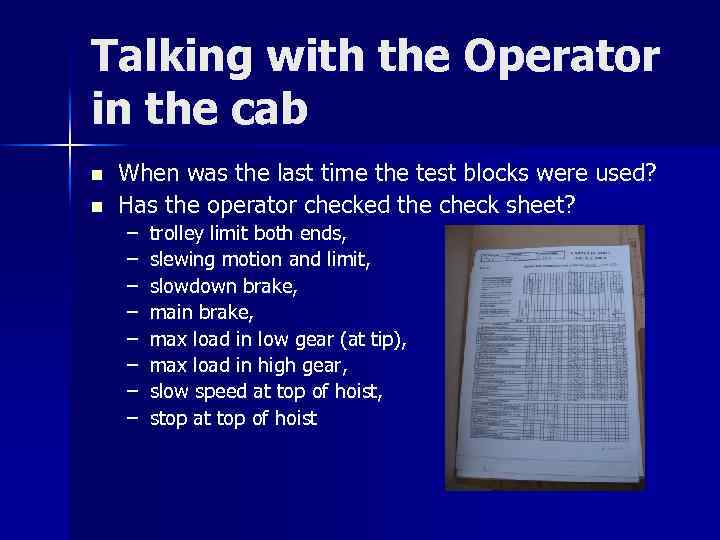

Talking with the Operator in the cab n n When was the last time the test blocks were used? Has the operator checked the check sheet? – – – – trolley limit both ends, slewing motion and limit, slowdown brake, main brake, max load in low gear (at tip), max load in high gear, slow speed at top of hoist, stop at top of hoist

Outside the cab. n Can the weather vane mechanism be activated from the cab?

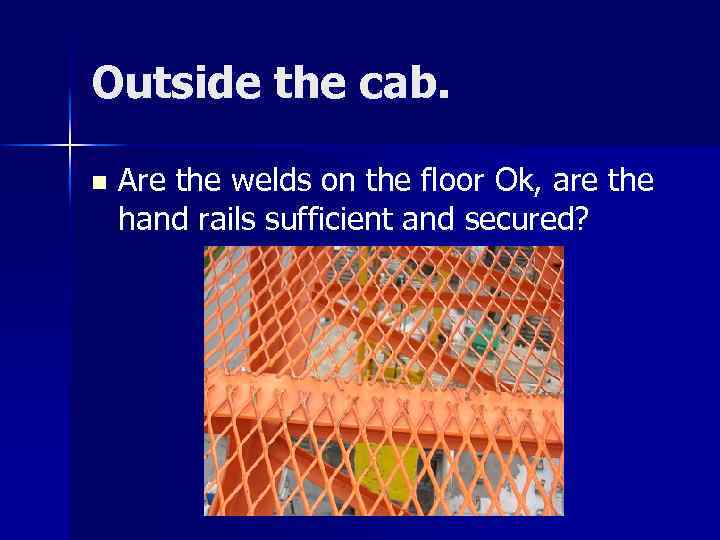

Outside the cab. n Are the welds on the floor Ok, are the hand rails sufficient and secured?

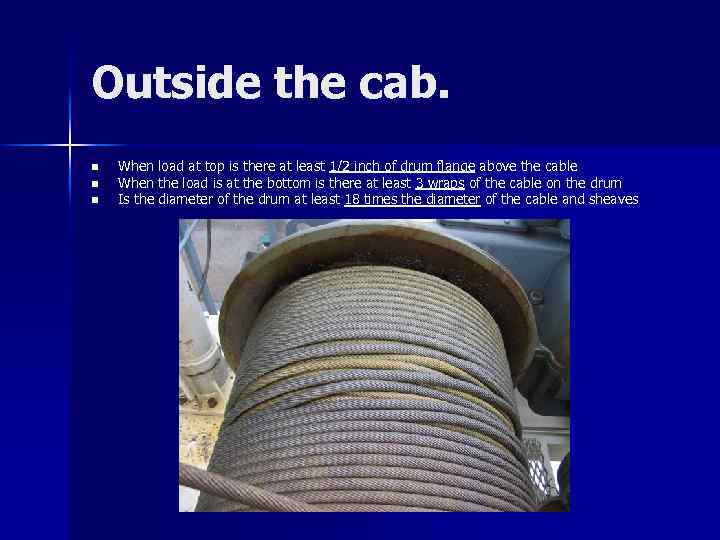

Outside the cab. n n n When load at top is there at least 1/2 inch of drum flange above the cable When the load is at the bottom is there at least 3 wraps of the cable on the drum Is the diameter of the drum at least 18 times the diameter of the cable and sheaves

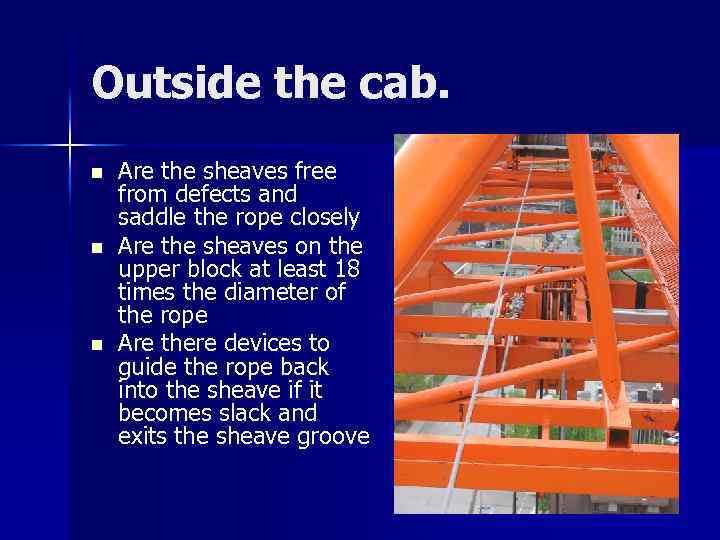

Outside the cab. n n n Are the sheaves free from defects and saddle the rope closely Are the sheaves on the upper block at least 18 times the diameter of the rope Are there devices to guide the rope back into the sheave if it becomes slack and exits the sheave groove

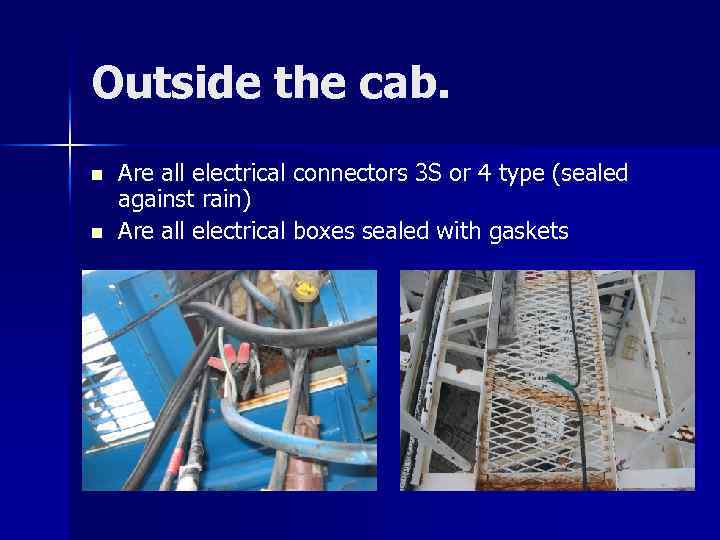

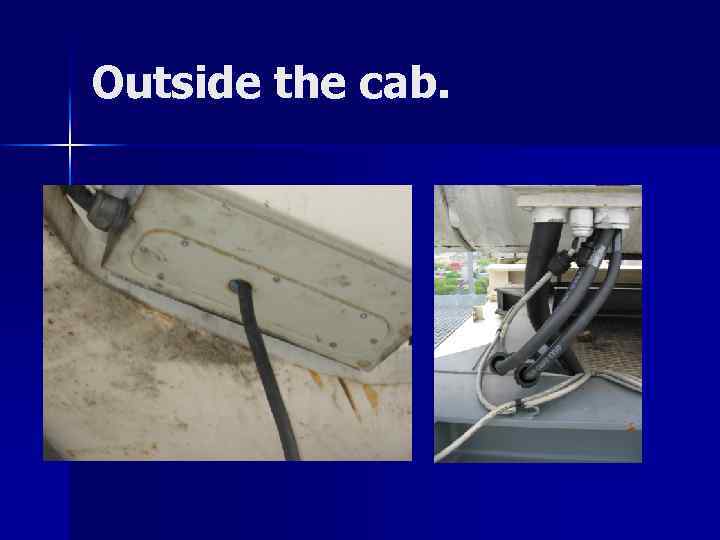

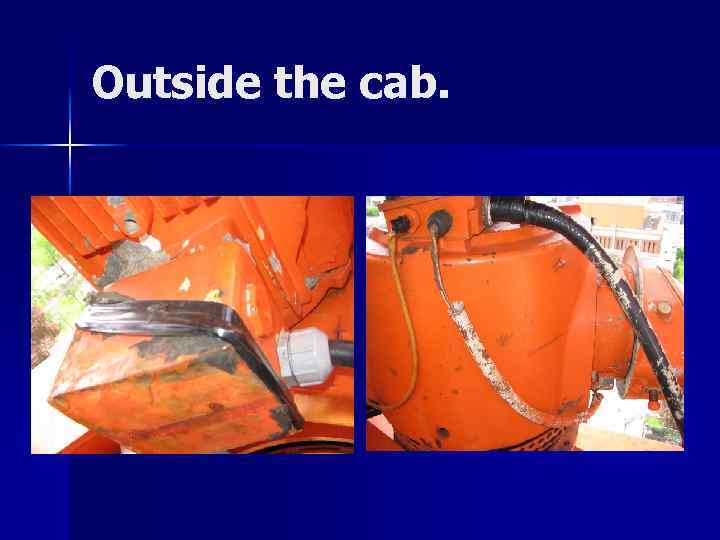

Outside the cab. n n Are all electrical connectors 3 S or 4 type (sealed against rain) Are all electrical boxes sealed with gaskets

Outside the cab.

Outside the cab.

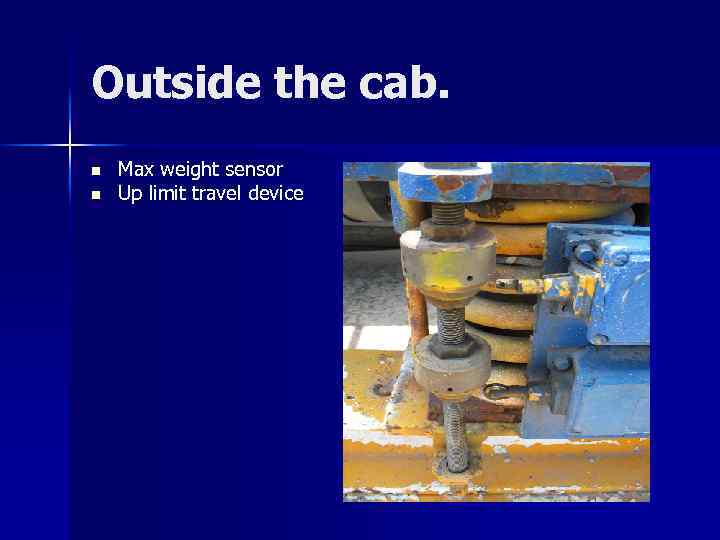

Outside the cab. n n Max weight sensor Up limit travel device

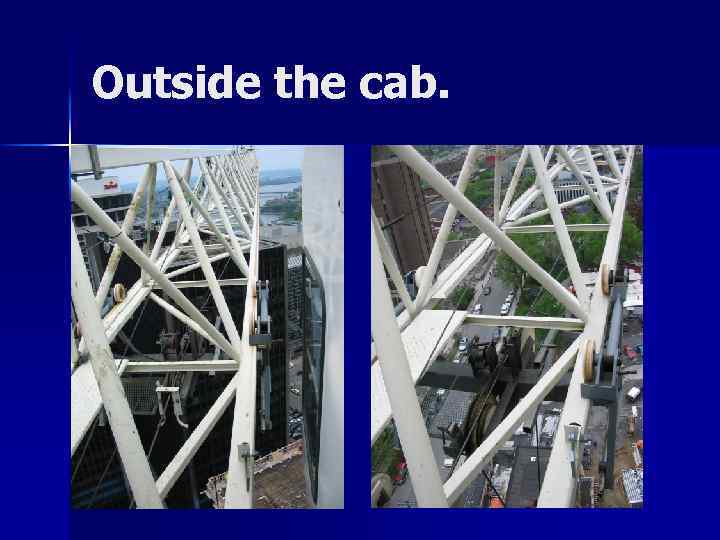

Outside the cab.

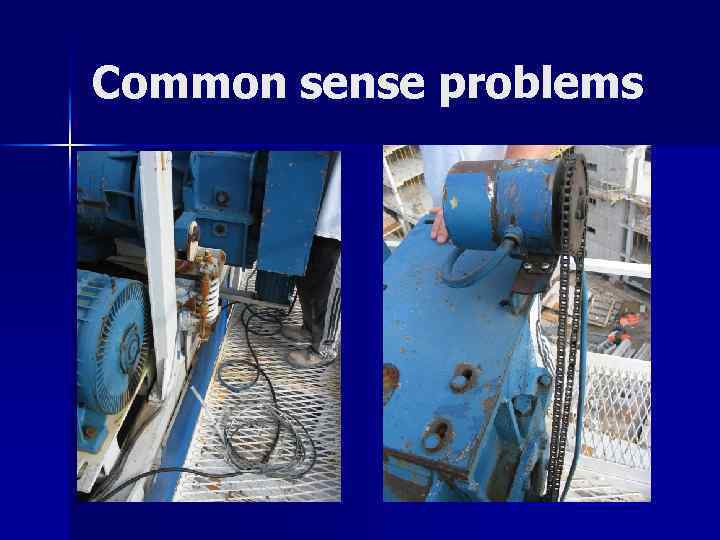

Common sense problems

Common sense problems

Common sense problems

Some of the Orders n n A 25(2)(h) order can be used to address the CSA Standard (for items which have no Regulation) with text as follows: The following precautions shall be taken to protect the safety of all workers on the project: Electrical Connectors missing or inadequate for their use Connections shall be suitable for exterior use including at Electrical Box terminations. Wind Speed Indicator & Temperature indicator shall be visible to the operator. Maximum Wind Speed and Minimum Operating Temperature shall be posted in the cab.

Some of the Orders n n n Fire Extinguishers are missing or not Charged. Guarding - Guard around chain and sprockets for hoist upper-limit control mechanism is missing - not to Manufacturers Specification. Slewing Brake Not to Manufactures Specifications. Windshield Wiper is not functional. A Procedure shall be developed for operating more then one crane on the project.

What the Audit found: n The condition of the tower crane : n Depends on… – the age of the crane. n n n Does not depend on… – – who owns the crane. the city the company is from. Most of the problems are in the control system and not the structure. Regulation 213/91 covers many Structural Issues but lacks in other areas.

Success Stories! Changes that occurred: n n Pre-start check sheet documentation implemented Improper Electrical Connections were originally found on all cranes; now found on less than 1/3. Operator log books had all boxes checked; now only the tests done are checked. Compliance with climbing (rest platforms larger)

Recommendations to MOL from the Audit § MOL should inspect a crane a couple of n n weeks after installation MOL Inspectors to enforce preventative maintenance by asking for a report of the reason for every malfunction of a tower crane and the corrective action taken. MOL should implement consistent province wide Tower Crane Inspections.

Thank you for your time. n Do you have any questions n The END. n

188278_633779040345551250 (1).ppt