a36d978ad996f9ab25b55eef255693cb.ppt

- Количество слайдов: 42

Easi-Sterilise Standard Operating Procedures Section 3 Sterilizing

Easi-Sterilise Standard Operating Procedures Section 3 Sterilizing

Section 3 Sterilising

Section 3 Sterilising

3. 1 Batching & Recording of a load prior to sterilisation Purpose § MUST HAVE DOCUMENTED EVIDENCE OF ALL ITEMS of a sterilising process = tracking/tracing proof § Assists in the recall of an item/load § Recording of load contents assists in compiling of statistical data on production volume

3. 1 Batching & Recording of a load prior to sterilisation Purpose § MUST HAVE DOCUMENTED EVIDENCE OF ALL ITEMS of a sterilising process = tracking/tracing proof § Assists in the recall of an item/load § Recording of load contents assists in compiling of statistical data on production volume

Warning: Do Not Store Unprocessed Items In The Sterilizer § The sterilization cycle shall be commenced immediately after loading. § Warm, moist atmosphere of the chamber can lead to— § (a) release of unprocessed items for use; § (b) contamination of packaging by condensate; § (c) an increase in bioburden on unprocessed items; and § (d) the deterioration of: § (i) chemical indicators, packaging and labelling; and § (ii) adhesive of self seal pouches, labelling and sterilizing tape.

Warning: Do Not Store Unprocessed Items In The Sterilizer § The sterilization cycle shall be commenced immediately after loading. § Warm, moist atmosphere of the chamber can lead to— § (a) release of unprocessed items for use; § (b) contamination of packaging by condensate; § (c) an increase in bioburden on unprocessed items; and § (d) the deterioration of: § (i) chemical indicators, packaging and labelling; and § (ii) adhesive of self seal pouches, labelling and sterilizing tape.

3. 2 LOADING AND RECORDING OF ITEMS FOR STEAM STERILISATION Purpose § Sterilant needs to have contact and/or penetrate all surfaces of the all items Do not: § crush items together § allow items to touch the floor, top, door or walls of the chamber § Allow enough space between each item for: § air removal, § steam penetration, § draining of condensate § drying to occur

3. 2 LOADING AND RECORDING OF ITEMS FOR STEAM STERILISATION Purpose § Sterilant needs to have contact and/or penetrate all surfaces of the all items Do not: § crush items together § allow items to touch the floor, top, door or walls of the chamber § Allow enough space between each item for: § air removal, § steam penetration, § draining of condensate § drying to occur

Loading the steriliser Light items on top shelves Heavy items on lower shelves Porous/wrapped items on upper shelf, unwrapped lower Wrapped perforated sets/kits/cassettes may be laid flat or vertically § Hollow ware must be tilted on edge in a draining position 1. to facilitate the removal of air, 2. allow steam penetration to all surfaces 3. condensation will drain from the hollow. § §

Loading the steriliser Light items on top shelves Heavy items on lower shelves Porous/wrapped items on upper shelf, unwrapped lower Wrapped perforated sets/kits/cassettes may be laid flat or vertically § Hollow ware must be tilted on edge in a draining position 1. to facilitate the removal of air, 2. allow steam penetration to all surfaces 3. condensation will drain from the hollow. § §

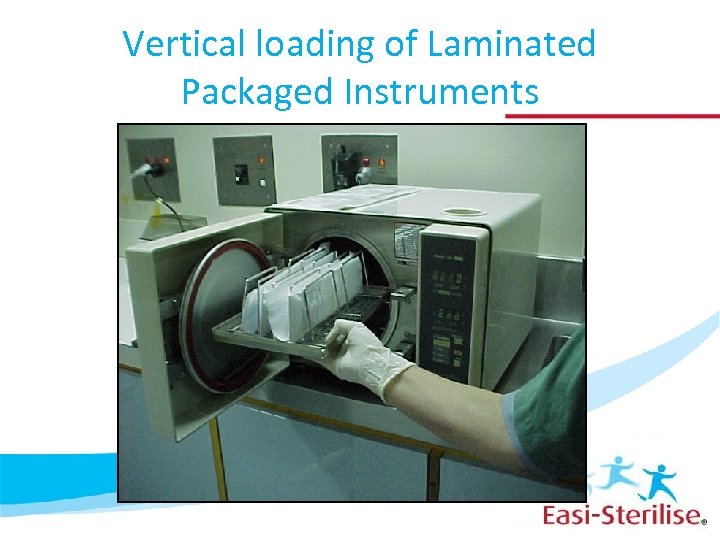

Vertical loading of Laminated Packaged Instruments

Vertical loading of Laminated Packaged Instruments

Horizontal loading of laminated pouches § Shall be placed with the paper side facing downward § Not overlapping – to allow air removal, steam penetration and condensate drainage Reference AS/NZS 4815: 2006 - 3. 4. 3. 3 Flexible packaging pg 26

Horizontal loading of laminated pouches § Shall be placed with the paper side facing downward § Not overlapping – to allow air removal, steam penetration and condensate drainage Reference AS/NZS 4815: 2006 - 3. 4. 3. 3 Flexible packaging pg 26

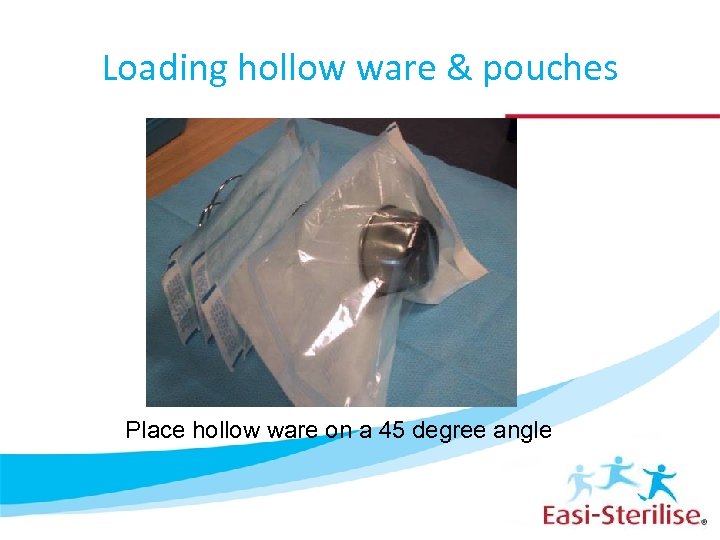

Loading hollow ware & pouches Place hollow ware on a 45 degree angle

Loading hollow ware & pouches Place hollow ware on a 45 degree angle

Loading the steriliser § All loads/cycles must have a chemical indicator to distinguish between processed and unprocessed loads § A “control” pouch containing a class 5 or 6 chemical indicator and batch label attached is included in all loads as per direction from the Chief Dental Officer, Jan 2010

Loading the steriliser § All loads/cycles must have a chemical indicator to distinguish between processed and unprocessed loads § A “control” pouch containing a class 5 or 6 chemical indicator and batch label attached is included in all loads as per direction from the Chief Dental Officer, Jan 2010

Loading of control pouch § The “control” pouch may be placed at the back of the sterilizer load on the lowest shelf (as per direction from the Chief Dental Officer, Jan 2010) or if unwrapped items are in the load, to prevent condensation dripping onto the control pouch, place the control pouch on the same shelf or above the unwrapped items

Loading of control pouch § The “control” pouch may be placed at the back of the sterilizer load on the lowest shelf (as per direction from the Chief Dental Officer, Jan 2010) or if unwrapped items are in the load, to prevent condensation dripping onto the control pouch, place the control pouch on the same shelf or above the unwrapped items

Cleaning Brushes § Reusable cleaning brushes that are unable to be disinfected in a washer disinfector are to be sterilized separately. If agreed to by the engineering department it may be possible to run this sterilizing cycle overnight. § If time does not permit, as a minimum requirement, instruments are to be cleaned and dried and left unwrapped in a dry, closed, lidded, labelled container that clearly identifies that the items are unsterile, to prevent contamination until processing can occur.

Cleaning Brushes § Reusable cleaning brushes that are unable to be disinfected in a washer disinfector are to be sterilized separately. If agreed to by the engineering department it may be possible to run this sterilizing cycle overnight. § If time does not permit, as a minimum requirement, instruments are to be cleaned and dried and left unwrapped in a dry, closed, lidded, labelled container that clearly identifies that the items are unsterile, to prevent contamination until processing can occur.

Note: § No instruments are to be sterilized overnight. § Sterilizing of any instrument (other than brushes) is not to occur in accordance with the requirements AS/NZS 4815: Sections 5 and 6.

Note: § No instruments are to be sterilized overnight. § Sterilizing of any instrument (other than brushes) is not to occur in accordance with the requirements AS/NZS 4815: Sections 5 and 6.

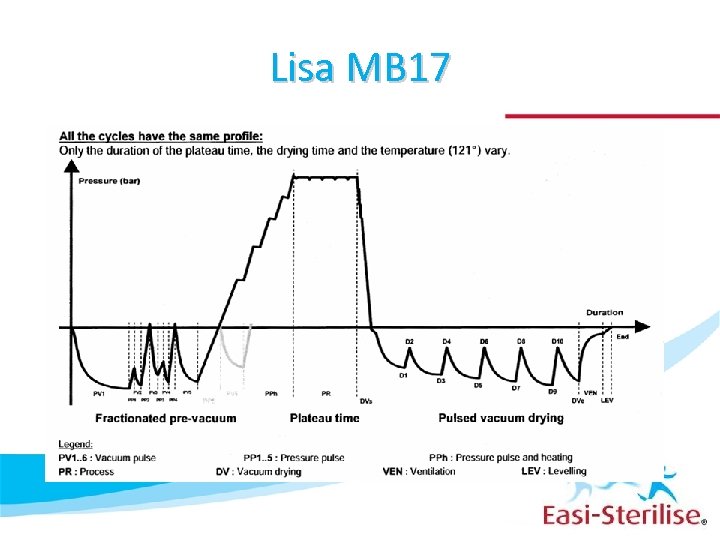

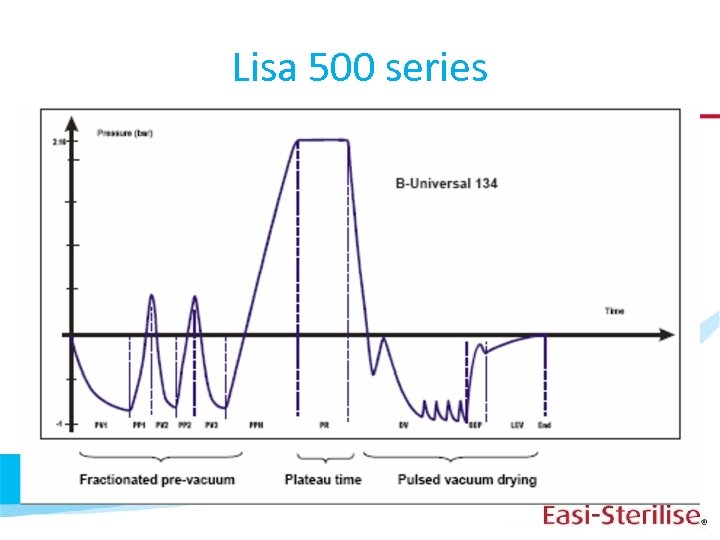

The Sterilisation Cycle § Air removal stage & steam generation & temperature § pre vacuum x 1 or x 3 or x 6 vacuums § downward displacement § Holding/sterilisation - time at temperature § Drying – exhaust steam § May have a post –vacuum drying stage

The Sterilisation Cycle § Air removal stage & steam generation & temperature § pre vacuum x 1 or x 3 or x 6 vacuums § downward displacement § Holding/sterilisation - time at temperature § Drying – exhaust steam § May have a post –vacuum drying stage

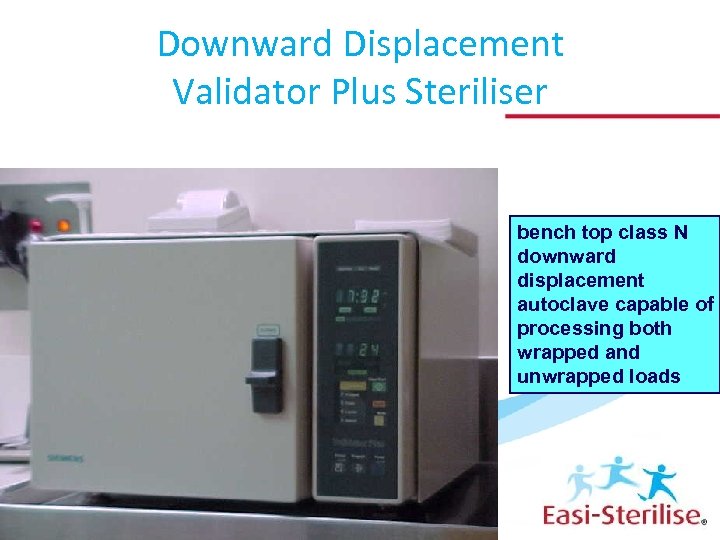

Downward Displacement Validator Plus Steriliser. bench top class N downward displacement autoclave capable of processing both wrapped and unwrapped loads

Downward Displacement Validator Plus Steriliser. bench top class N downward displacement autoclave capable of processing both wrapped and unwrapped loads

Small Pre vacuum

Small Pre vacuum

Lisa MB 17

Lisa MB 17

Lisa 500 series

Lisa 500 series

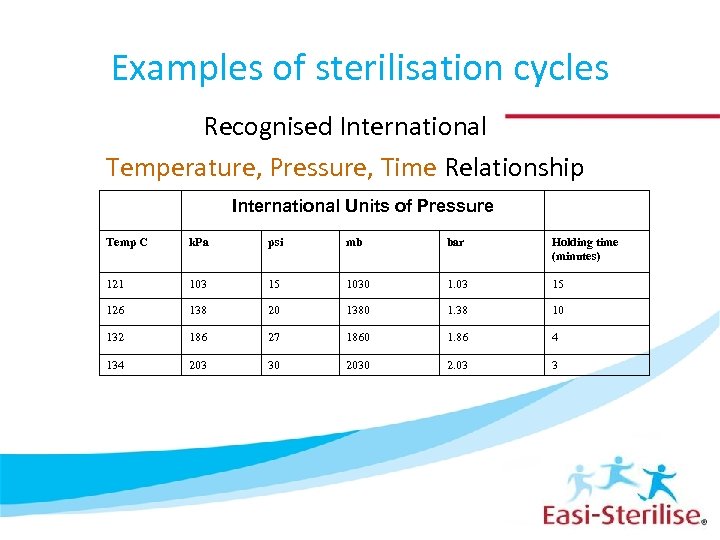

Examples of sterilisation cycles Recognised International Temperature, Pressure, Time Relationship International Units of Pressure Temp C k. Pa psi mb bar Holding time (minutes) 121 103 15 1030 1. 03 15 126 138 20 1380 1. 38 10 132 186 27 1860 1. 86 4 134 203 30 2030 2. 03 3

Examples of sterilisation cycles Recognised International Temperature, Pressure, Time Relationship International Units of Pressure Temp C k. Pa psi mb bar Holding time (minutes) 121 103 15 1030 1. 03 15 126 138 20 1380 1. 38 10 132 186 27 1860 1. 86 4 134 203 30 2030 2. 03 3

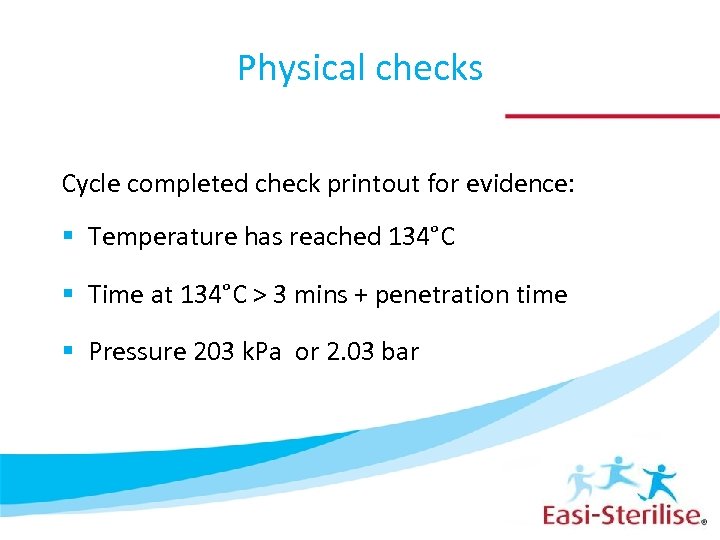

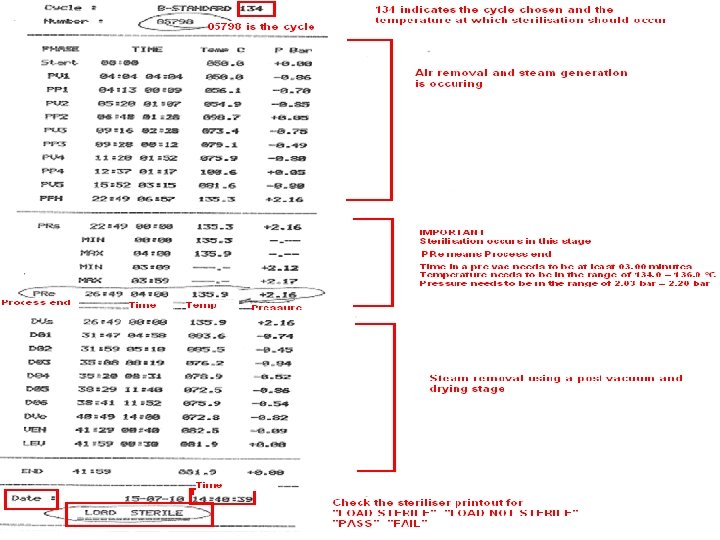

Physical checks Cycle completed check printout for evidence: § Temperature has reached 134°C § Time at 134°C > 3 mins + penetration time § Pressure 203 k. Pa or 2. 03 bar

Physical checks Cycle completed check printout for evidence: § Temperature has reached 134°C § Time at 134°C > 3 mins + penetration time § Pressure 203 k. Pa or 2. 03 bar

stand alone printer Other types? In built printer

stand alone printer Other types? In built printer

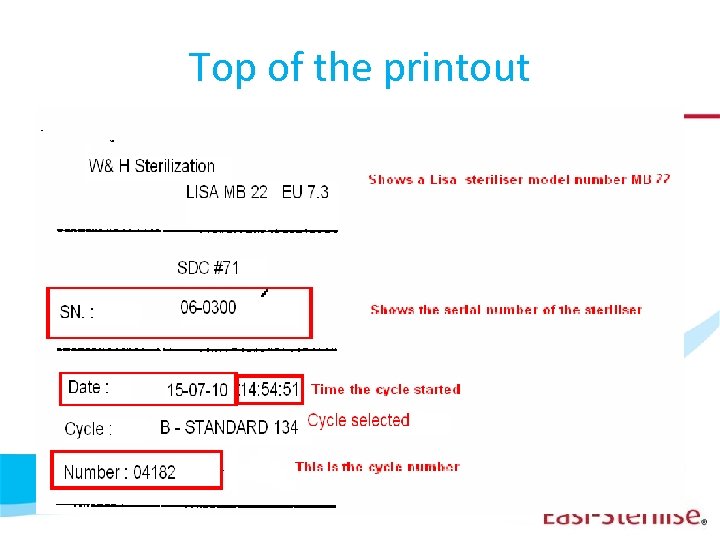

Top of the printout

Top of the printout

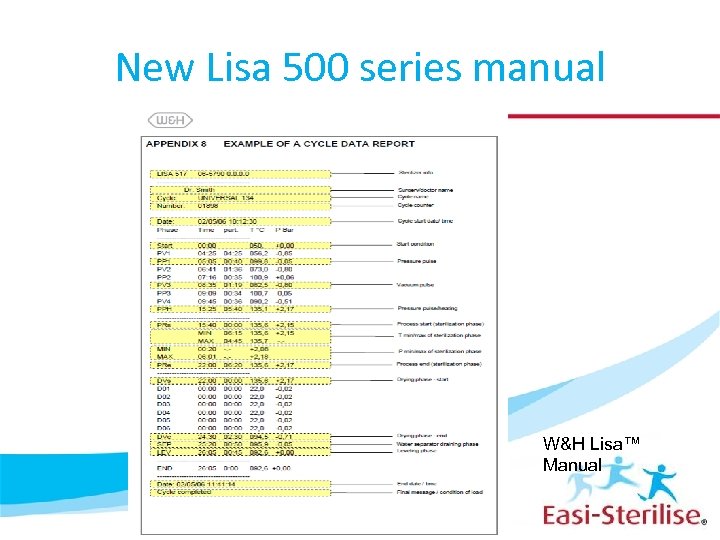

New Lisa 500 series manual W&H Lisa™ Manual

New Lisa 500 series manual W&H Lisa™ Manual

3. 3 Releasing & Unloading a Sterilised Load § To ensure that the staff unloading the steriliser check that sterilisation has occurred in accordance with the validated process and authorises the release of the load

3. 3 Releasing & Unloading a Sterilised Load § To ensure that the staff unloading the steriliser check that sterilisation has occurred in accordance with the validated process and authorises the release of the load

3. 3 Releasing & Unloading a Sterilised Load § Immediately cycle has completed § Printout confirms sterilisation parameters are met - sign Remove load - Visually check § Chemical indicators have changed colour correctly § No visible wet packs & packs intact § Check items unloaded correspond with load documentation § Check and record results of process challenge devices (if used) on sterilizing log chart § Check and record results of biological indicator (if used) on sterilizing log chart

3. 3 Releasing & Unloading a Sterilised Load § Immediately cycle has completed § Printout confirms sterilisation parameters are met - sign Remove load - Visually check § Chemical indicators have changed colour correctly § No visible wet packs & packs intact § Check items unloaded correspond with load documentation § Check and record results of process challenge devices (if used) on sterilizing log chart § Check and record results of biological indicator (if used) on sterilizing log chart

3. 3 Releasing & Unloading a Sterilised Load § Only in exceptional circumstances (such as involved in providing direct patient care) would a delay to removing a completed sterilization load, be considered acceptable and no more than 30 minutes from when the cycle has finished.

3. 3 Releasing & Unloading a Sterilised Load § Only in exceptional circumstances (such as involved in providing direct patient care) would a delay to removing a completed sterilization load, be considered acceptable and no more than 30 minutes from when the cycle has finished.

3. 3 Releasing & Unloading a Sterilised Load Document in steriliser record/log Sign the sterilizer cycle printout and attach Document time of release Signature or identification of person releasing the load Ensure the items unloaded correspond with load documentation § Attach the “control” pouch batch label § Attach the control class 5 chemical indicator § Immediately notify the supervisor if not met. § §

3. 3 Releasing & Unloading a Sterilised Load Document in steriliser record/log Sign the sterilizer cycle printout and attach Document time of release Signature or identification of person releasing the load Ensure the items unloaded correspond with load documentation § Attach the “control” pouch batch label § Attach the control class 5 chemical indicator § Immediately notify the supervisor if not met. § §

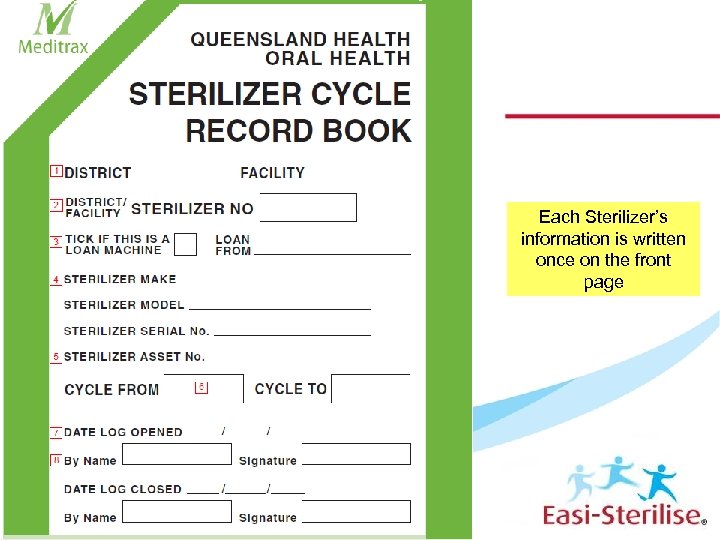

Each Sterilizer’s information is written once on the front page

Each Sterilizer’s information is written once on the front page

Found on CHRISP Oral Health website

Found on CHRISP Oral Health website

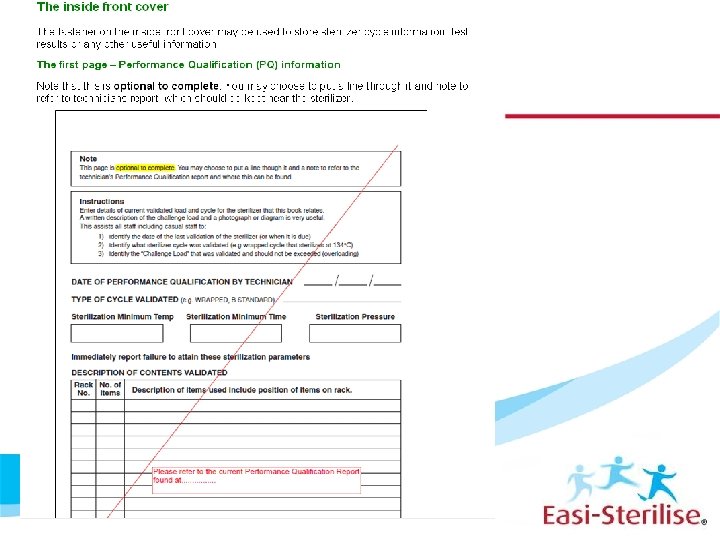

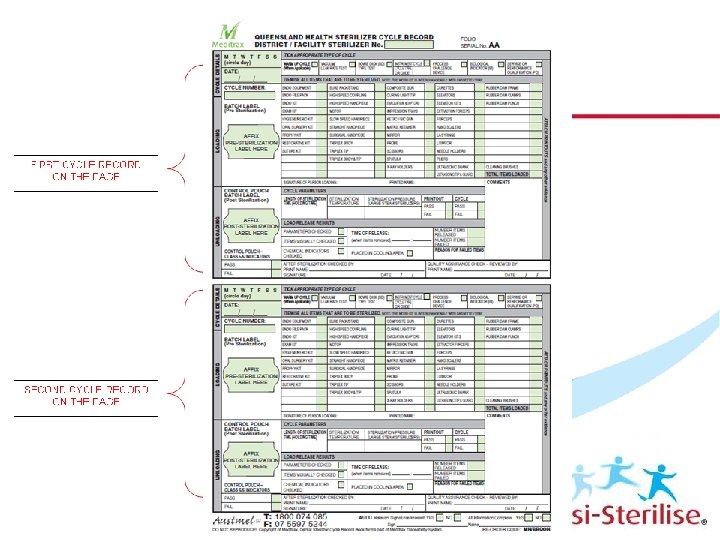

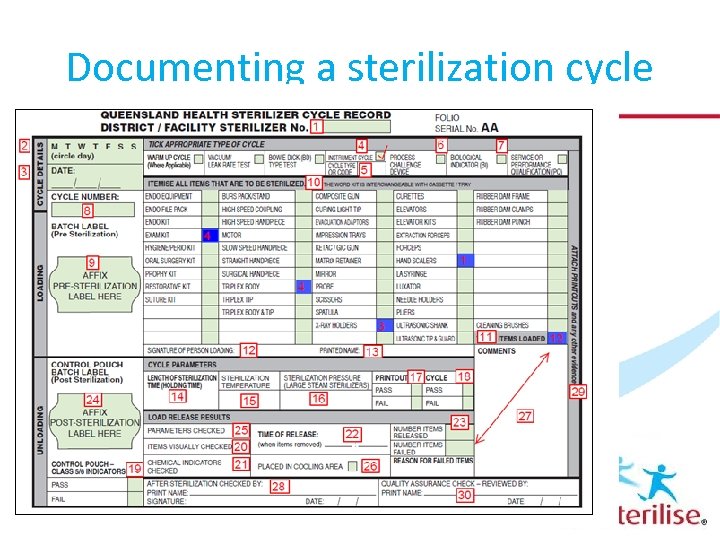

Documenting a sterilization cycle

Documenting a sterilization cycle

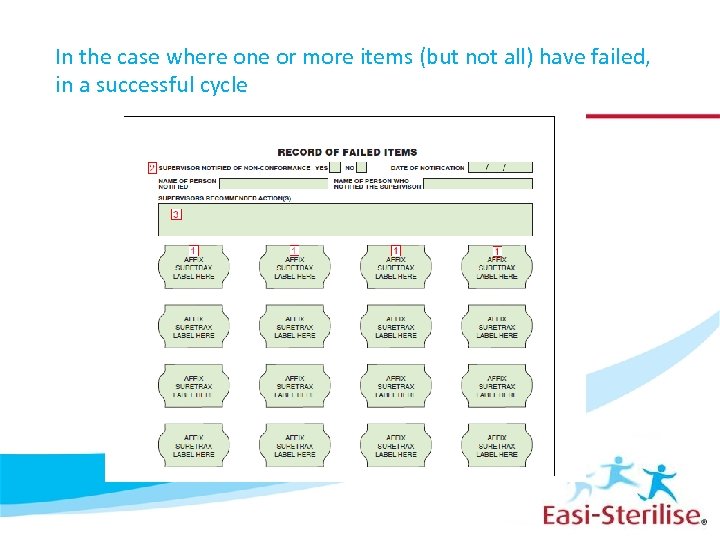

In the case where one or more items (but not all) have failed, in a successful cycle

In the case where one or more items (but not all) have failed, in a successful cycle

3. 3 Releasing & Unloading a Sterilised Load § Considerations for unwrapped items/load – written procedures for appropriate handling to minimise cross contamination § Handling § Transfer or transportation § Storage

3. 3 Releasing & Unloading a Sterilised Load § Considerations for unwrapped items/load – written procedures for appropriate handling to minimise cross contamination § Handling § Transfer or transportation § Storage

Cooling items § Away from high activity areas § Do not use forced cooling by fans or air con. § Do not place on solid surfaces, as condensation from vapour (still within the pack) can result. § Items dropped on the floor, placed on a dirty surface, compressed, torn, have broken seals, or are wet, are considered non-sterile and shall be reprocessed.

Cooling items § Away from high activity areas § Do not use forced cooling by fans or air con. § Do not place on solid surfaces, as condensation from vapour (still within the pack) can result. § Items dropped on the floor, placed on a dirty surface, compressed, torn, have broken seals, or are wet, are considered non-sterile and shall be reprocessed.

Following cooling § Where plastic dust covers are used, the item shall be cooled before being placed in the dust cover § Plastic dust covers – new, clean, intact, sealed. § If dust covers are used for the purpose of storage, they shall be labelled ‘Dust cover only’.

Following cooling § Where plastic dust covers are used, the item shall be cooled before being placed in the dust cover § Plastic dust covers – new, clean, intact, sealed. § If dust covers are used for the purpose of storage, they shall be labelled ‘Dust cover only’.

The key pieces of legislation relating to recordkeeping are § § Public Records Act 2002 Public Services Act 1996 Electronic Transactions (Qld) Act 2001 Evidence Act 1977 § See also QH clinical records retention and disposal schedule § http: //paweb. sth. health. qld. gov. au/sqrm/hims/recor ds/documents/disposal_retention_sched. pdf

The key pieces of legislation relating to recordkeeping are § § Public Records Act 2002 Public Services Act 1996 Electronic Transactions (Qld) Act 2001 Evidence Act 1977 § See also QH clinical records retention and disposal schedule § http: //paweb. sth. health. qld. gov. au/sqrm/hims/recor ds/documents/disposal_retention_sched. pdf

3. 4 Managing a failed sterilizer cycle and load Common Reasons for failed cycles § § § Wet items Packaging not in tack Chemical indicator colour change Sterilising parameters Steriliser printout (illegible, run out of paper) Power outages

3. 4 Managing a failed sterilizer cycle and load Common Reasons for failed cycles § § § Wet items Packaging not in tack Chemical indicator colour change Sterilising parameters Steriliser printout (illegible, run out of paper) Power outages

3. 4 Managing a failed sterilizer cycle and load Items must be: § Unwrap § Re-wash if the item has become wet, was dropped on the floor or in contact with other contaminants § Rewrapped § Reloaded § Resterilised § manufacturer’s instructions provide troubleshooting (rectification) procedures, undertake a sterilisation cycle with an empty chamber with a class 5 or 6 chemical indicator

3. 4 Managing a failed sterilizer cycle and load Items must be: § Unwrap § Re-wash if the item has become wet, was dropped on the floor or in contact with other contaminants § Rewrapped § Reloaded § Resterilised § manufacturer’s instructions provide troubleshooting (rectification) procedures, undertake a sterilisation cycle with an empty chamber with a class 5 or 6 chemical indicator

3. 4 Managing a failed sterilizer cycle and load Documenting the failed load: § The sterilizer print out must be fixed to the log sheet with ‘FAILED LOAD” written clearly across the print out in permanent ink in a blank area § The steriliser log/record must indicate that the load was identified as failed § If the steriliser requires maintenance, place an out of order sign on the steriliser and inform management and maintenance immediately

3. 4 Managing a failed sterilizer cycle and load Documenting the failed load: § The sterilizer print out must be fixed to the log sheet with ‘FAILED LOAD” written clearly across the print out in permanent ink in a blank area § The steriliser log/record must indicate that the load was identified as failed § If the steriliser requires maintenance, place an out of order sign on the steriliser and inform management and maintenance immediately