f626edfc11a5426e3033845d89f13380.ppt

- Количество слайдов: 40

e-petroleumservices. com Online Field-Wide Gas-lift Optimisation Dr Alasdair S Brown Technical Manager EPS Americas Inc 1

e-petroleumservices. com Online Field-Wide Gas-lift Optimisation Dr Alasdair S Brown Technical Manager EPS Americas Inc 1

Presentation Structure e-petroleumservices. com • • Introduction Single Well vs Field Wide Online vs Offline Case Studies – Latin America – Middle East • Conclusions • Questions 2

Presentation Structure e-petroleumservices. com • • Introduction Single Well vs Field Wide Online vs Offline Case Studies – Latin America – Middle East • Conclusions • Questions 2

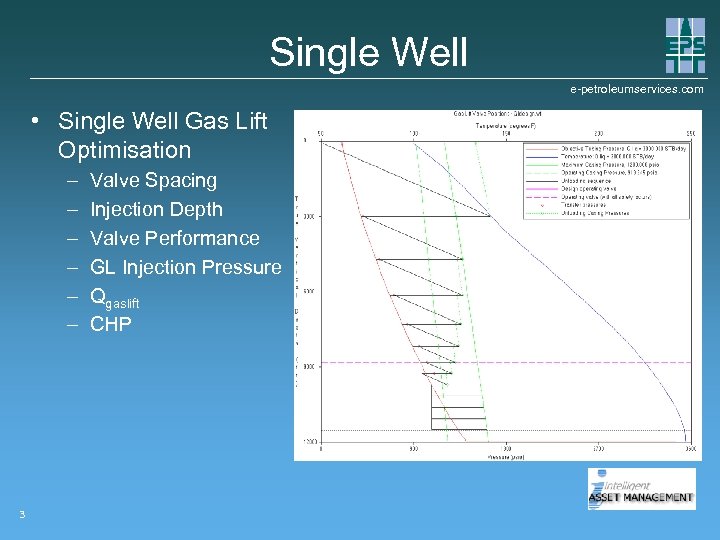

Single Well e-petroleumservices. com • Single Well Gas Lift Optimisation – – – 3 Valve Spacing Injection Depth Valve Performance GL Injection Pressure Qgaslift CHP

Single Well e-petroleumservices. com • Single Well Gas Lift Optimisation – – – 3 Valve Spacing Injection Depth Valve Performance GL Injection Pressure Qgaslift CHP

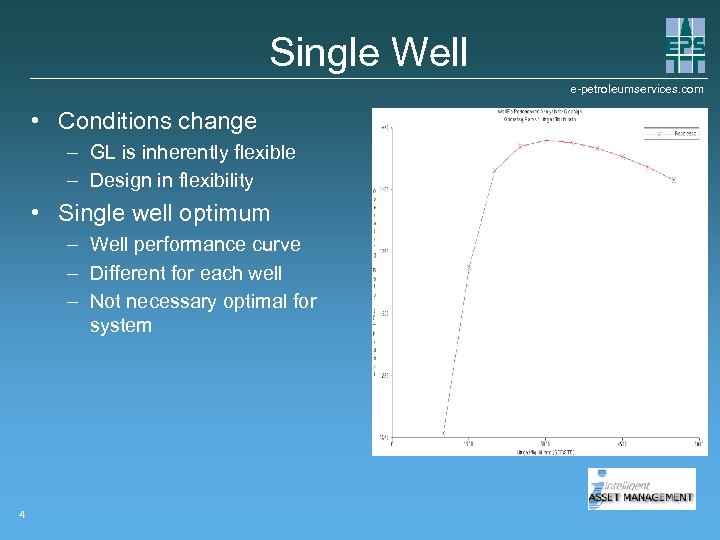

Single Well e-petroleumservices. com • Conditions change – GL is inherently flexible – Design in flexibility • Single well optimum – Well performance curve – Different for each well – Not necessary optimal for system 4

Single Well e-petroleumservices. com • Conditions change – GL is inherently flexible – Design in flexibility • Single well optimum – Well performance curve – Different for each well – Not necessary optimal for system 4

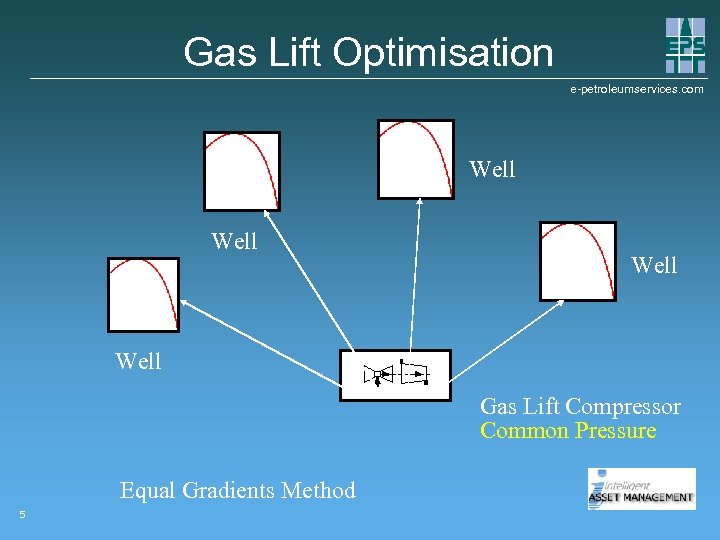

Gas Lift Optimisation e-petroleumservices. com Well Gas Lift Compressor Common Pressure Equal Gradients Method 5

Gas Lift Optimisation e-petroleumservices. com Well Gas Lift Compressor Common Pressure Equal Gradients Method 5

Field Wide Optimisation e-petroleumservices. com • Field Wide Gas Lift Optimisation – – Distribution of Gas to competing wells Pressure losses in gas lift distribution system Pressure losses in production system “Closing the Loop” • Total system modelling – including produced gas reinjection – Compressor performance – Offline/Online 6

Field Wide Optimisation e-petroleumservices. com • Field Wide Gas Lift Optimisation – – Distribution of Gas to competing wells Pressure losses in gas lift distribution system Pressure losses in production system “Closing the Loop” • Total system modelling – including produced gas reinjection – Compressor performance – Offline/Online 6

Why Online? e-petroleumservices. com • Large Number of Wells • Complex optimisation problem • Reduce cycle time – Optimisation-to-implementation – Engineer’s time concentrated on value adding tasks • Goals – Automate Process – Automate Repetitive Tasks – Optimise 7

Why Online? e-petroleumservices. com • Large Number of Wells • Complex optimisation problem • Reduce cycle time – Optimisation-to-implementation – Engineer’s time concentrated on value adding tasks • Goals – Automate Process – Automate Repetitive Tasks – Optimise 7

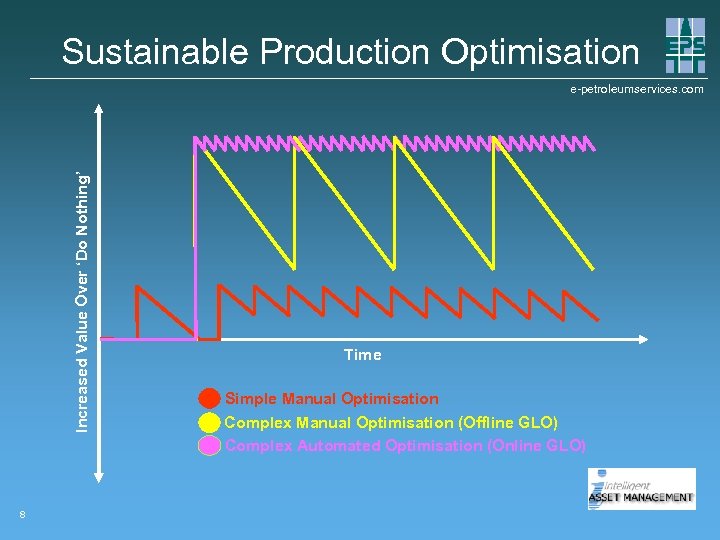

Sustainable Production Optimisation Increased Value Over ‘Do Nothing’ e-petroleumservices. com 8 Time Simple Manual Optimisation Complex Manual Optimisation (Offline GLO) Complex Automated Optimisation (Online GLO)

Sustainable Production Optimisation Increased Value Over ‘Do Nothing’ e-petroleumservices. com 8 Time Simple Manual Optimisation Complex Manual Optimisation (Offline GLO) Complex Automated Optimisation (Online GLO)

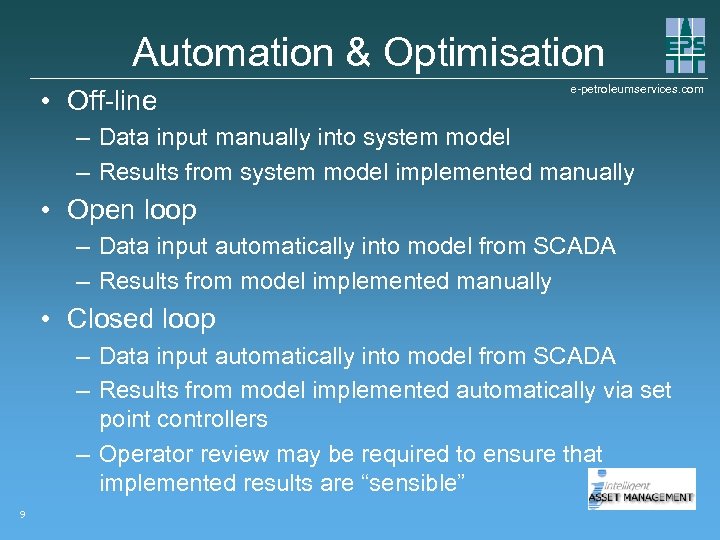

Automation & Optimisation • Off-line e-petroleumservices. com – Data input manually into system model – Results from system model implemented manually • Open loop – Data input automatically into model from SCADA – Results from model implemented manually • Closed loop – Data input automatically into model from SCADA – Results from model implemented automatically via set point controllers – Operator review may be required to ensure that implemented results are “sensible” 9

Automation & Optimisation • Off-line e-petroleumservices. com – Data input manually into system model – Results from system model implemented manually • Open loop – Data input automatically into model from SCADA – Results from model implemented manually • Closed loop – Data input automatically into model from SCADA – Results from model implemented automatically via set point controllers – Operator review may be required to ensure that implemented results are “sensible” 9

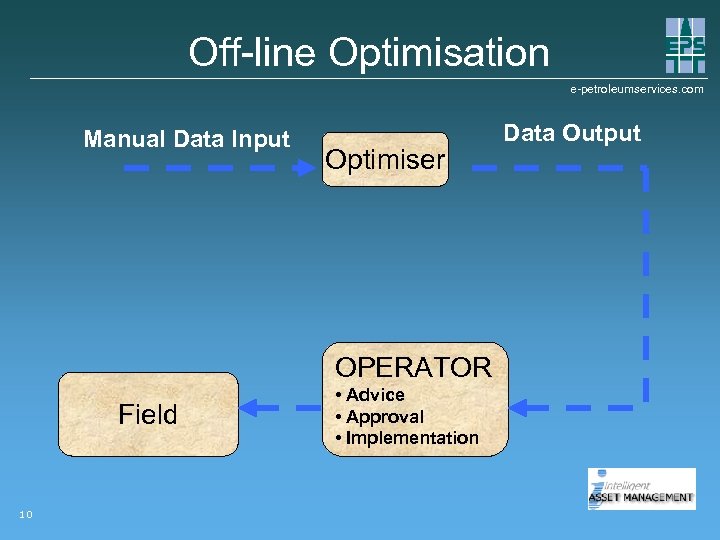

Off-line Optimisation e-petroleumservices. com Manual Data Input Optimiser OPERATOR Field 10 • Advice • Approval • Implementation Data Output

Off-line Optimisation e-petroleumservices. com Manual Data Input Optimiser OPERATOR Field 10 • Advice • Approval • Implementation Data Output

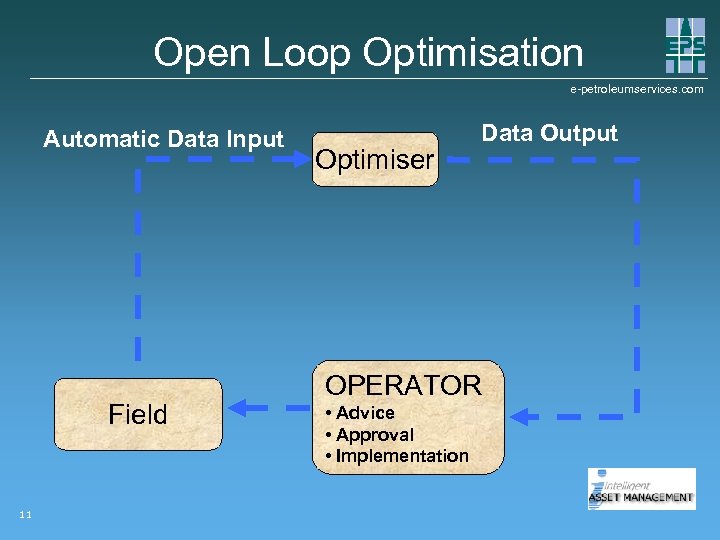

Open Loop Optimisation e-petroleumservices. com Automatic Data Input Field 11 Optimiser Data Output OPERATOR • Advice • Approval • Implementation

Open Loop Optimisation e-petroleumservices. com Automatic Data Input Field 11 Optimiser Data Output OPERATOR • Advice • Approval • Implementation

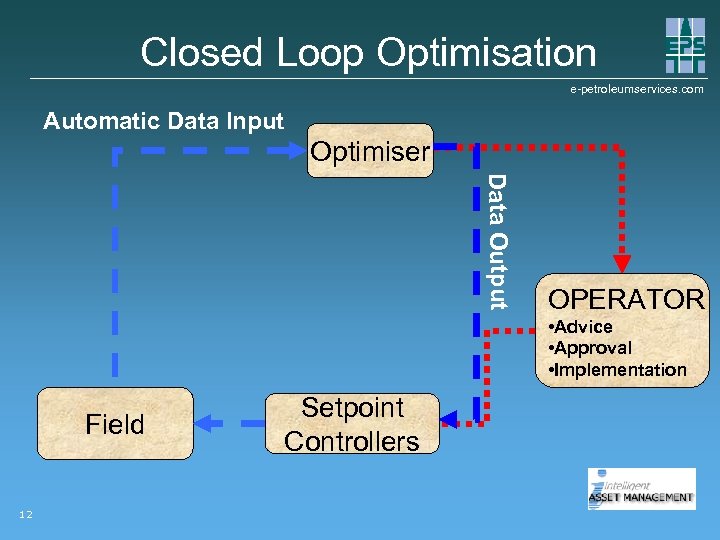

Closed Loop Optimisation e-petroleumservices. com Automatic Data Input Optimiser Data Output OPERATOR • Advice • Approval • Implementation Field 12 Setpoint Controllers

Closed Loop Optimisation e-petroleumservices. com Automatic Data Input Optimiser Data Output OPERATOR • Advice • Approval • Implementation Field 12 Setpoint Controllers

Case 1: Pd. VSA On-Line e-petroleumservices. com – SCADA data automatically loaded to give current block valve and compressor status and to constrain the optimisation to stay close to existing operating conditions – Price/cost and equipment constraint data loaded from Corporate databases – Gas injection well set-points sent directly to SCADA controllers (after production operator review as a block) – Recommended pressure control valve set-points and compressor operating conditions sent to production operators in open-loop advisory messages – Results stored in central database for access by other applications. 13

Case 1: Pd. VSA On-Line e-petroleumservices. com – SCADA data automatically loaded to give current block valve and compressor status and to constrain the optimisation to stay close to existing operating conditions – Price/cost and equipment constraint data loaded from Corporate databases – Gas injection well set-points sent directly to SCADA controllers (after production operator review as a block) – Recommended pressure control valve set-points and compressor operating conditions sent to production operators in open-loop advisory messages – Results stored in central database for access by other applications. 13

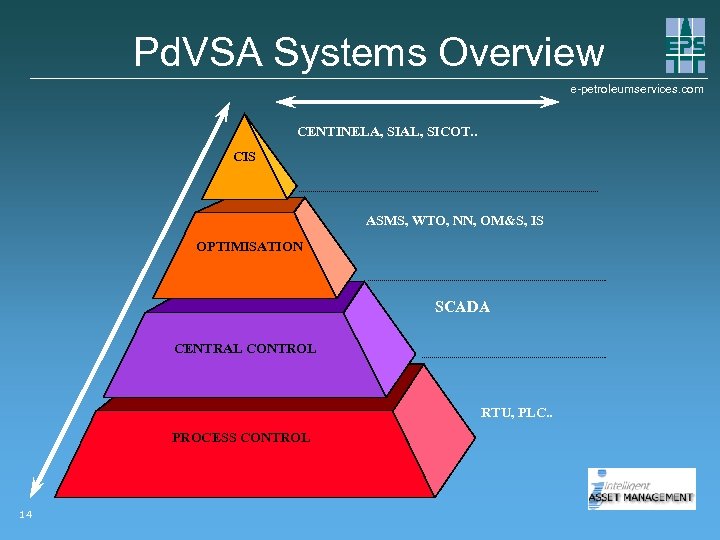

Pd. VSA Systems Overview e-petroleumservices. com CENTINELA, SIAL, SICOT. . CIS ASMS, WTO, NN, OM&S, IS OPTIMISATION SCADA CENTRAL CONTROL RTU, PLC. . PROCESS CONTROL 14

Pd. VSA Systems Overview e-petroleumservices. com CENTINELA, SIAL, SICOT. . CIS ASMS, WTO, NN, OM&S, IS OPTIMISATION SCADA CENTRAL CONTROL RTU, PLC. . PROCESS CONTROL 14

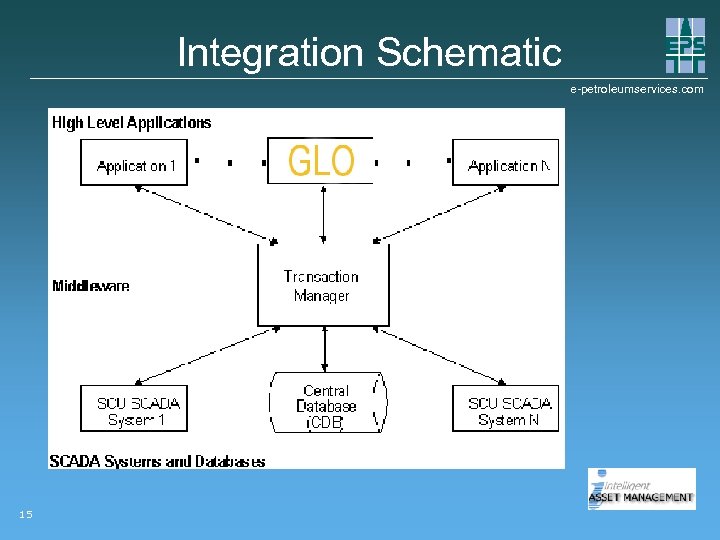

Integration Schematic e-petroleumservices. com 15

Integration Schematic e-petroleumservices. com 15

System Architecture e-petroleumservices. com 16

System Architecture e-petroleumservices. com 16

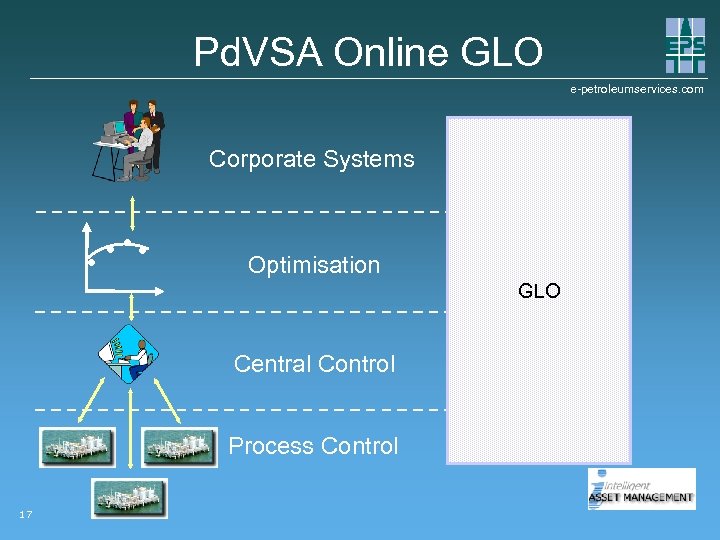

Pd. VSA Online GLO e-petroleumservices. com Corporate Systems Optimisation GLO Central Control Process Control 17

Pd. VSA Online GLO e-petroleumservices. com Corporate Systems Optimisation GLO Central Control Process Control 17

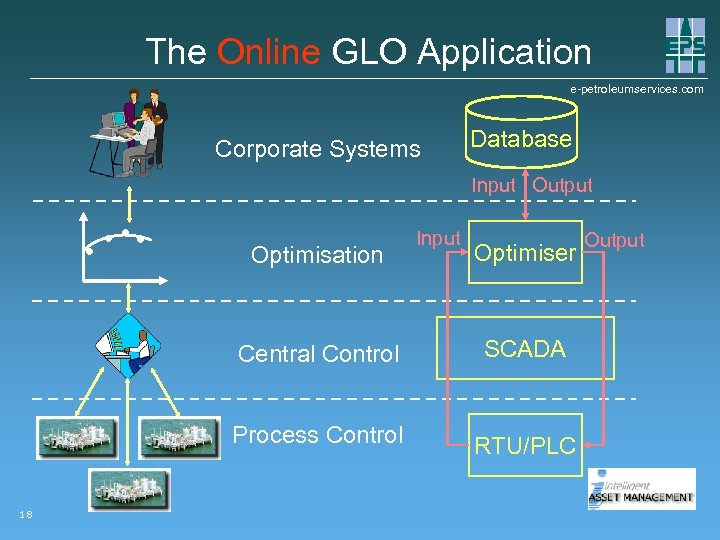

The Online GLO Application e-petroleumservices. com Corporate Systems Database Input Output Optimisation Input Optimiser Central Control Process Control 18 SCADA RTU/PLC Output

The Online GLO Application e-petroleumservices. com Corporate Systems Database Input Output Optimisation Input Optimiser Central Control Process Control 18 SCADA RTU/PLC Output

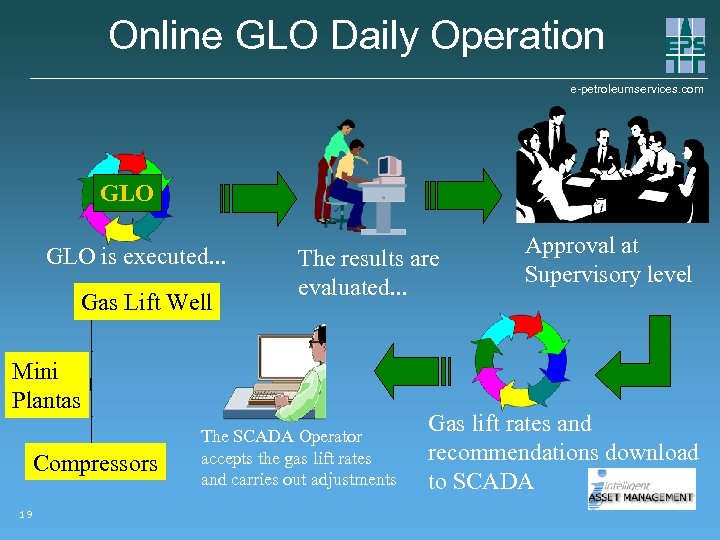

Online GLO Daily Operation e-petroleumservices. com GLO is executed. . . Gas Lift Well The results are evaluated. . . Mini Plantas Compressors 19 The SCADA Operator accepts the gas lift rates and carries out adjustments Approval at Supervisory level Gas lift rates and recommendations download to SCADA

Online GLO Daily Operation e-petroleumservices. com GLO is executed. . . Gas Lift Well The results are evaluated. . . Mini Plantas Compressors 19 The SCADA Operator accepts the gas lift rates and carries out adjustments Approval at Supervisory level Gas lift rates and recommendations download to SCADA

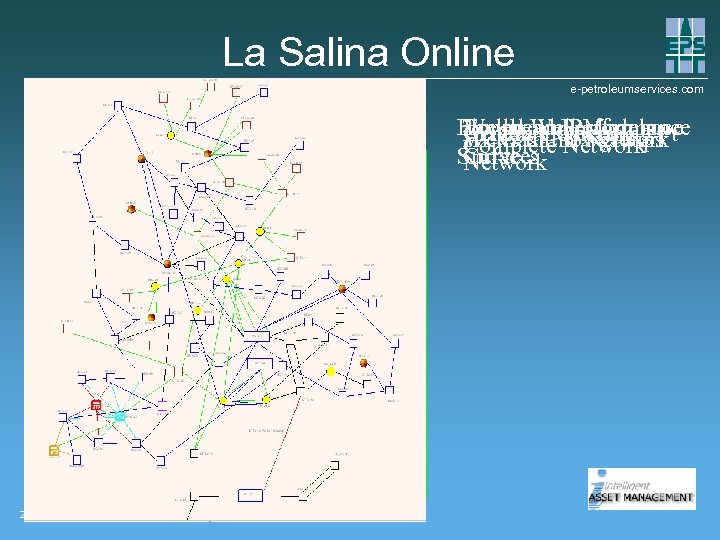

La Salina Online e-petroleumservices. com Flowgroup. Performance Wellhead. Operating Tunedin. Gathering Pt Performance LP Gas. Well Models Generate. Flowgroups HP Gas Network Wells Lift Network Complete Surfaces Curve Network 22

La Salina Online e-petroleumservices. com Flowgroup. Performance Wellhead. Operating Tunedin. Gathering Pt Performance LP Gas. Well Models Generate. Flowgroups HP Gas Network Wells Lift Network Complete Surfaces Curve Network 22

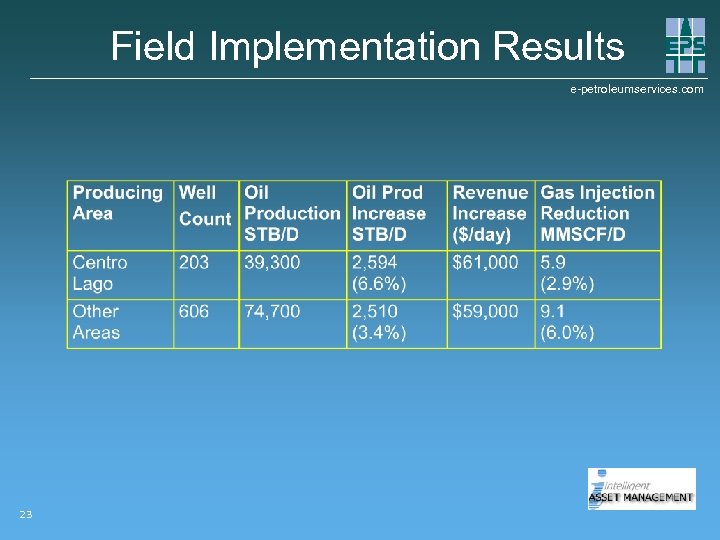

Field Implementation Results e-petroleumservices. com 23

Field Implementation Results e-petroleumservices. com 23

POIS e-petroleumservices. com • • POIS = Production Operation Information System Northern fields of Kuwait Performed by consortium including EPS, Aspentech, Daelim EPS role was to provide the optimization software, software integration and detailed engineering models for five fields in North Kuwait. • The fields included 197 wells (411 well strings) – 33 water injectors, – 91 gas lifted producers and – 30 produced with ESPs. • The wells and fields are connected through a complex network allowing wells to be switched between high, medium and low pressure as well as ‘wet’ and ‘dry’ separator trains • Total production 600 Mstb/day 25

POIS e-petroleumservices. com • • POIS = Production Operation Information System Northern fields of Kuwait Performed by consortium including EPS, Aspentech, Daelim EPS role was to provide the optimization software, software integration and detailed engineering models for five fields in North Kuwait. • The fields included 197 wells (411 well strings) – 33 water injectors, – 91 gas lifted producers and – 30 produced with ESPs. • The wells and fields are connected through a complex network allowing wells to be switched between high, medium and low pressure as well as ‘wet’ and ‘dry’ separator trains • Total production 600 Mstb/day 25

Design Brief e-petroleumservices. com • Hydraulic model of GL Distribution System • Compressor Station behaviour and Performance – Power turbines, compression, gearboxes, intercoolers, gas recycling – Surge and stonewall constraints • • Multiphase Flow Scalable to >1000 wells Optimise non-hierarchical networks Online Integration with – Production Management System – DCS/SCADA System 26

Design Brief e-petroleumservices. com • Hydraulic model of GL Distribution System • Compressor Station behaviour and Performance – Power turbines, compression, gearboxes, intercoolers, gas recycling – Surge and stonewall constraints • • Multiphase Flow Scalable to >1000 wells Optimise non-hierarchical networks Online Integration with – Production Management System – DCS/SCADA System 26

Objectives e-petroleumservices. com • Data acquisition via SCADA to MIS (Aspentech) • GL optimisation for new GL wells – GL being installed following water injection • • 27 Automatic acquisition of WT data Automatic well model recalibration Automatic online GL optimisation calculation Manual setting of optimised setpoints (initially)

Objectives e-petroleumservices. com • Data acquisition via SCADA to MIS (Aspentech) • GL optimisation for new GL wells – GL being installed following water injection • • 27 Automatic acquisition of WT data Automatic well model recalibration Automatic online GL optimisation calculation Manual setting of optimised setpoints (initially)

PAS Concept e-petroleumservices. com POIS Data Transfer Past data PAS New Well Test Well. Flo Well Model Compare with trend Fail Engineer intervention Pass Rerun or retune Automatic Model Retune Manual Model Retune Rerun Welltest 28

PAS Concept e-petroleumservices. com POIS Data Transfer Past data PAS New Well Test Well. Flo Well Model Compare with trend Fail Engineer intervention Pass Rerun or retune Automatic Model Retune Manual Model Retune Rerun Welltest 28

GLO Concept e-petroleumservices. com POIS GLO Re. O System Model Network model Wells Initiate GLO run 29 Get Updated well models Wells Generate well performance Wells Run GLO Wells New Settings New gas allocation Convert to choke settings

GLO Concept e-petroleumservices. com POIS GLO Re. O System Model Network model Wells Initiate GLO run 29 Get Updated well models Wells Generate well performance Wells Run GLO Wells New Settings New gas allocation Convert to choke settings

Implementation e-petroleumservices. com • • • 30 Well modelling of all 411 wells (Well. Flo) Construction and tuning of network Model (Re. O) Automatic tuning of Well models Automatic GL optimisation Integration with Aspentech MIS Model maintenance and development

Implementation e-petroleumservices. com • • • 30 Well modelling of all 411 wells (Well. Flo) Construction and tuning of network Model (Re. O) Automatic tuning of Well models Automatic GL optimisation Integration with Aspentech MIS Model maintenance and development

Important Issues Identified e-petroleumservices. com • Data Quality – Well data – production data – Surface network data • Business processes – building use of POIS model into std. procedures – model maintenance – model enhancement • Compressor optimisation • Multistage separation optimisation 31

Important Issues Identified e-petroleumservices. com • Data Quality – Well data – production data – Surface network data • Business processes – building use of POIS model into std. procedures – model maintenance – model enhancement • Compressor optimisation • Multistage separation optimisation 31

Network Config Modelling e-petroleumservices. com Individual fields (viz. , RA, SA, RQ, AD & BH) modelled as separate sub-sheets All fields interconnected through 3 Gathering Centres: GC-15, GC-23, and GC-25 Each GC has 7 headers that can take inflow from any or all wells 32

Network Config Modelling e-petroleumservices. com Individual fields (viz. , RA, SA, RQ, AD & BH) modelled as separate sub-sheets All fields interconnected through 3 Gathering Centres: GC-15, GC-23, and GC-25 Each GC has 7 headers that can take inflow from any or all wells 32

Network Config Modelling e-petroleumservices. com Multiple GC & MF options for all the wells made network very flexible to accommodate any future flow path definition Optimiser easily handled this huge network - over 40, 000 objects! 33

Network Config Modelling e-petroleumservices. com Multiple GC & MF options for all the wells made network very flexible to accommodate any future flow path definition Optimiser easily handled this huge network - over 40, 000 objects! 33

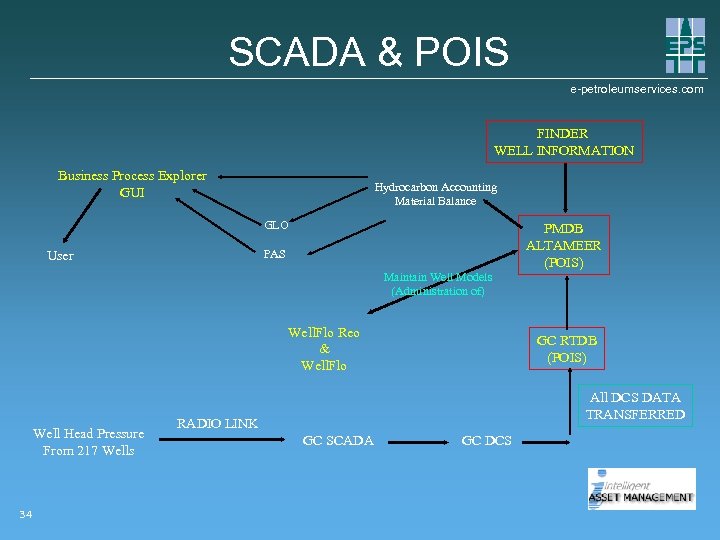

SCADA & POIS e-petroleumservices. com FINDER WELL INFORMATION Business Process Explorer GUI Hydrocarbon Accounting Material Balance GLO PMDB ALTAMEER (POIS) PAS User Maintain Well Models (Administration of) Well. Flo Reo & Well. Flo Well Head Pressure From 217 Wells 34 GC RTDB (POIS) All DCS DATA TRANSFERRED RADIO LINK GC SCADA GC DCS

SCADA & POIS e-petroleumservices. com FINDER WELL INFORMATION Business Process Explorer GUI Hydrocarbon Accounting Material Balance GLO PMDB ALTAMEER (POIS) PAS User Maintain Well Models (Administration of) Well. Flo Reo & Well. Flo Well Head Pressure From 217 Wells 34 GC RTDB (POIS) All DCS DATA TRANSFERRED RADIO LINK GC SCADA GC DCS

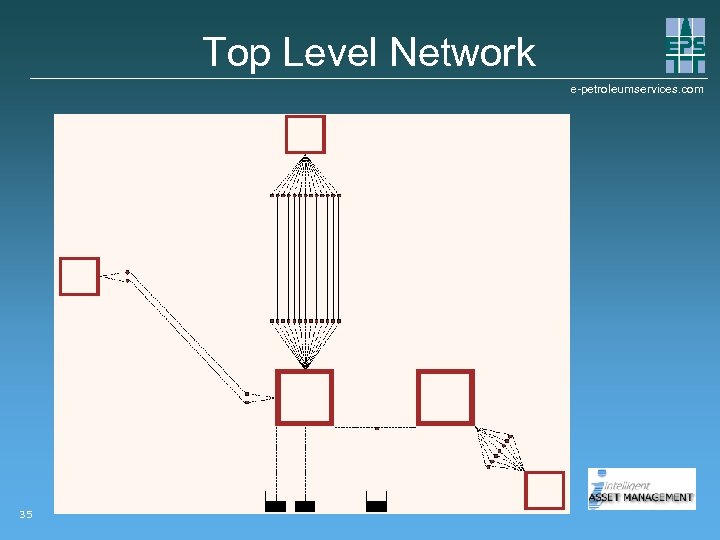

Top Level Network e-petroleumservices. com 35

Top Level Network e-petroleumservices. com 35

Network Config Modelling e-petroleumservices. com Abdali: 16 Wells to 2 GC via 13 6 in lines Ratqa: 20 Wells 378 producers with choice of producing into any of 3 GCs through any of 21 MFs to 2 GC via 36 in & 10 in lines Sabriyah: 142 Wells to 1 GC thru’ 7 MF Raudhatain: 195 Wells to 3 GC Bahra: thru’ 7 MF each 5 Wells to 1 GC thru’ 7 MF 36

Network Config Modelling e-petroleumservices. com Abdali: 16 Wells to 2 GC via 13 6 in lines Ratqa: 20 Wells 378 producers with choice of producing into any of 3 GCs through any of 21 MFs to 2 GC via 36 in & 10 in lines Sabriyah: 142 Wells to 1 GC thru’ 7 MF Raudhatain: 195 Wells to 3 GC Bahra: thru’ 7 MF each 5 Wells to 1 GC thru’ 7 MF 36

RA Field Network e-petroleumservices. com 37

RA Field Network e-petroleumservices. com 37

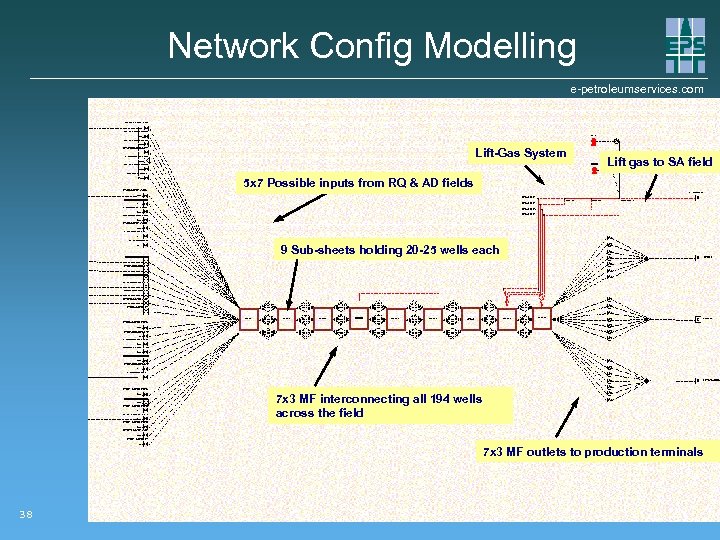

Network Config Modelling e-petroleumservices. com Lift-Gas System Lift gas to SA field 5 x 7 Possible inputs from RQ & AD fields 9 Sub-sheets holding 20 -25 wells each 7 x 3 MF interconnecting all 194 wells across the field 7 x 3 MF outlets to production terminals 38

Network Config Modelling e-petroleumservices. com Lift-Gas System Lift gas to SA field 5 x 7 Possible inputs from RQ & AD fields 9 Sub-sheets holding 20 -25 wells each 7 x 3 MF interconnecting all 194 wells across the field 7 x 3 MF outlets to production terminals 38

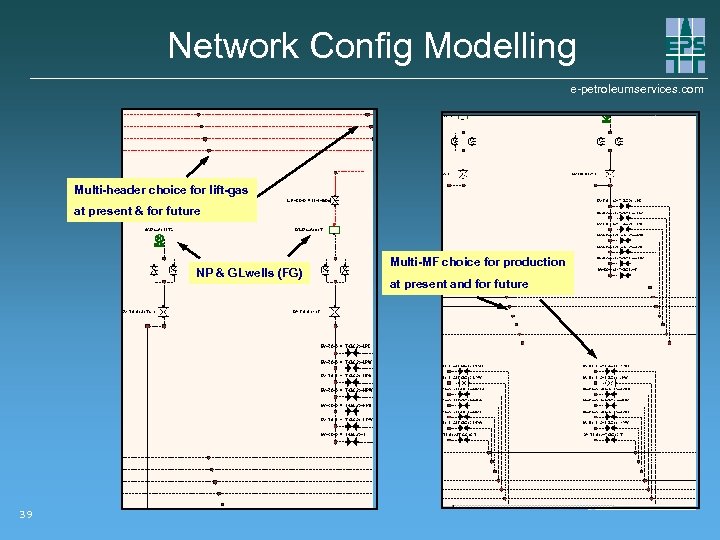

Network Config Modelling e-petroleumservices. com Multi-header choice for lift-gas at present & for future NP & GLwells (FG) 39 Multi-MF choice for production at present and for future

Network Config Modelling e-petroleumservices. com Multi-header choice for lift-gas at present & for future NP & GLwells (FG) 39 Multi-MF choice for production at present and for future

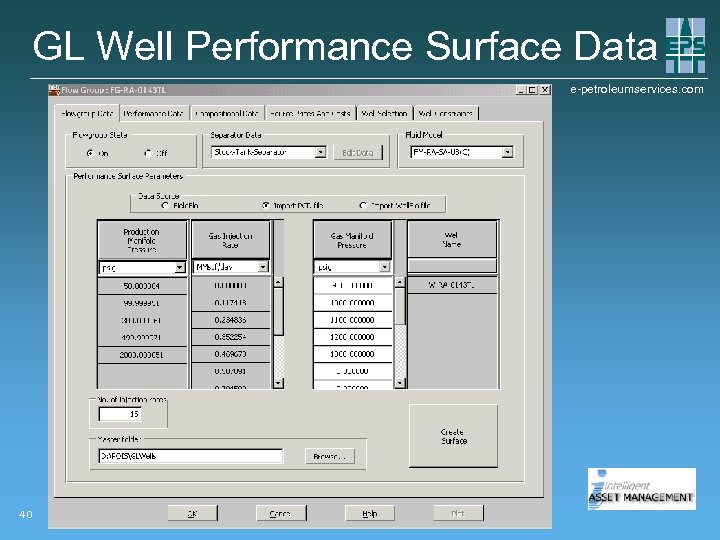

GL Well Performance Surface Data e-petroleumservices. com 40

GL Well Performance Surface Data e-petroleumservices. com 40

Conclusions e-petroleumservices. com • KOC currently producing to quota – Current capacity higher than quota • (how much higher is unknown) – However additional production can be allocated to NK – Cost reduction is additional benefit • • Reduction in admin overhead Reduction in flaring Potential reduction in new well requirement Network reconfiguration • Work practices need to change to extract full value from the system 41

Conclusions e-petroleumservices. com • KOC currently producing to quota – Current capacity higher than quota • (how much higher is unknown) – However additional production can be allocated to NK – Cost reduction is additional benefit • • Reduction in admin overhead Reduction in flaring Potential reduction in new well requirement Network reconfiguration • Work practices need to change to extract full value from the system 41

POIS project e-petroleumservices. com • Client - Kuwait Oil Company • Year of Contract Award – 2000 • Projected Value Generated: – $100 million - $175 million per annum (projected) 42

POIS project e-petroleumservices. com • Client - Kuwait Oil Company • Year of Contract Award – 2000 • Projected Value Generated: – $100 million - $175 million per annum (projected) 42

e-petroleumservices. com Questions? 43

e-petroleumservices. com Questions? 43