1c49523d3fc0ae80f8388db9a7651166.ppt

- Количество слайдов: 27

e Magnitude® Magnetic Bearing Chiller © 2014 Daikin Applied People and ideas you can trust. TM

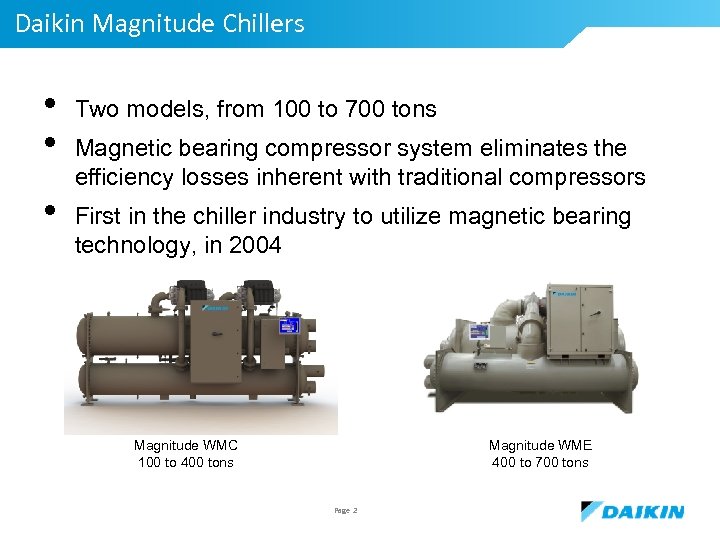

Daikin Magnitude Chillers • • • Two models, from 100 to 700 tons Magnetic bearing compressor system eliminates the efficiency losses inherent with traditional compressors First in the chiller industry to utilize magnetic bearing technology, in 2004 Magnitude WMC 100 to 400 tons Magnitude WME 400 to 700 tons Page 2

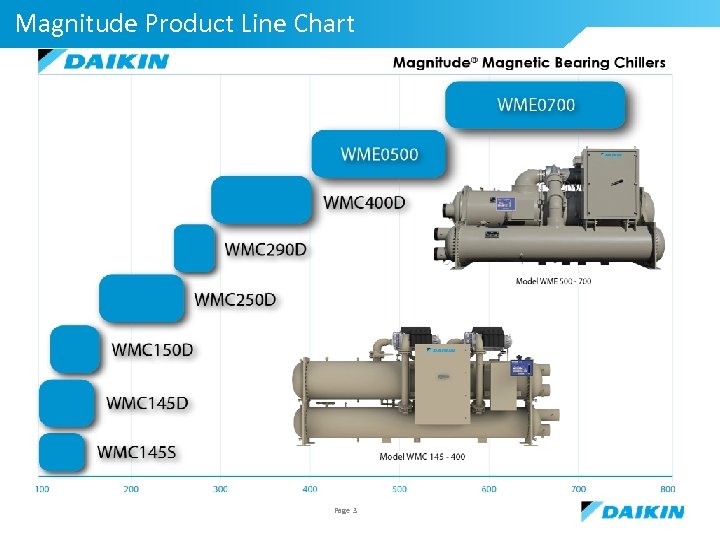

Magnitude Product Line Chart Page 3

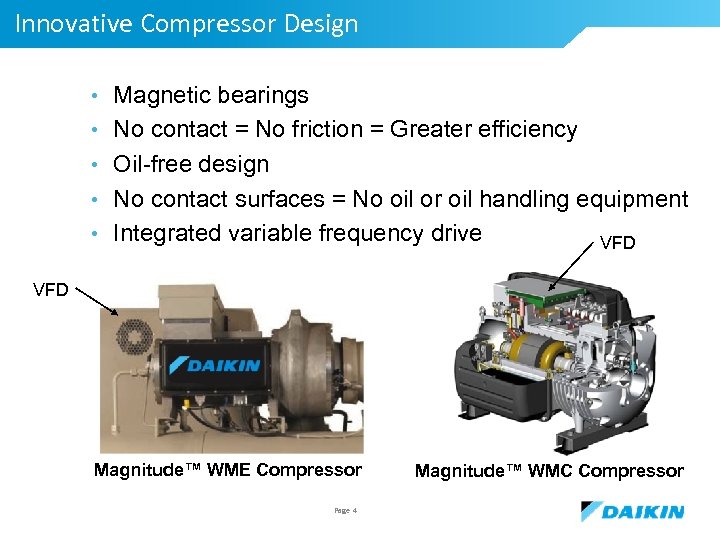

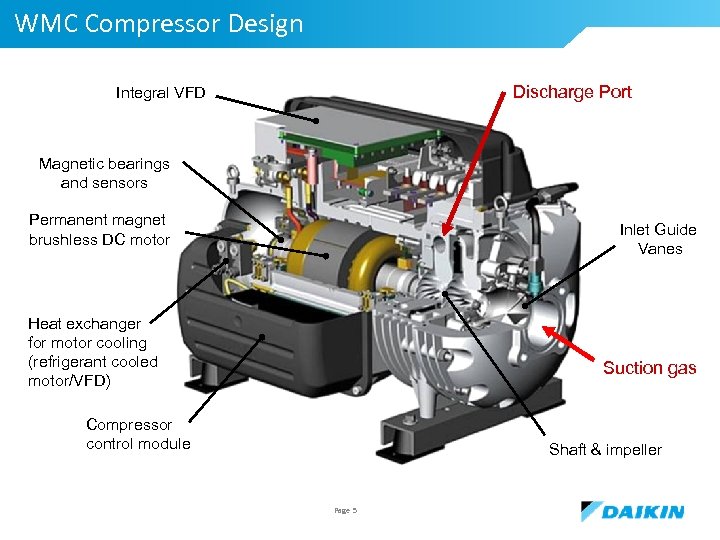

Innovative Compressor Design • Magnetic bearings • No contact = No friction = Greater efficiency • Oil-free design • No contact surfaces = No oil or oil handling equipment • Integrated variable frequency drive VFD Magnitude™ WME Compressor Page 4 Magnitude™ WMC Compressor

WMC Compressor Design Discharge Port Integral VFD Magnetic bearings and sensors Permanent magnet brushless DC motor Inlet Guide Vanes Heat exchanger for motor cooling (refrigerant cooled motor/VFD) Suction gas Compressor control module Shaft & impeller Page 5

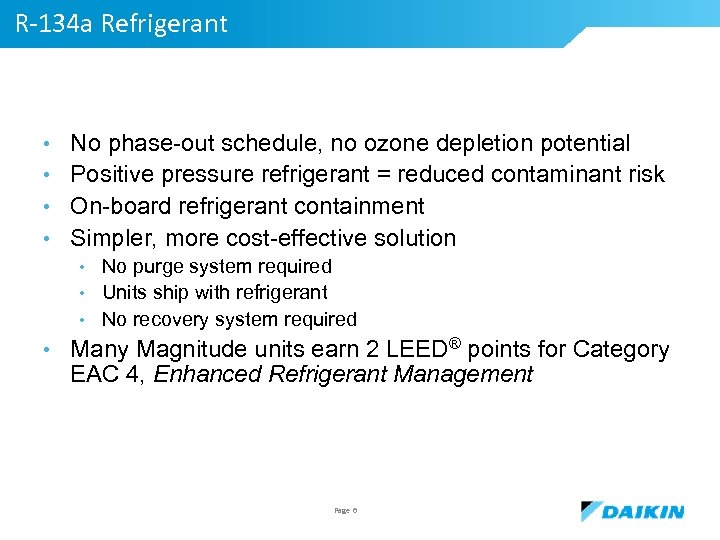

R-134 a Refrigerant • No phase-out schedule, no ozone depletion potential • Positive pressure refrigerant = reduced contaminant risk • On-board refrigerant containment • Simpler, more cost-effective solution • No purge system required • Units ship with refrigerant • No recovery system required • Many Magnitude units earn 2 LEED® points for Category EAC 4, Enhanced Refrigerant Management Page 6

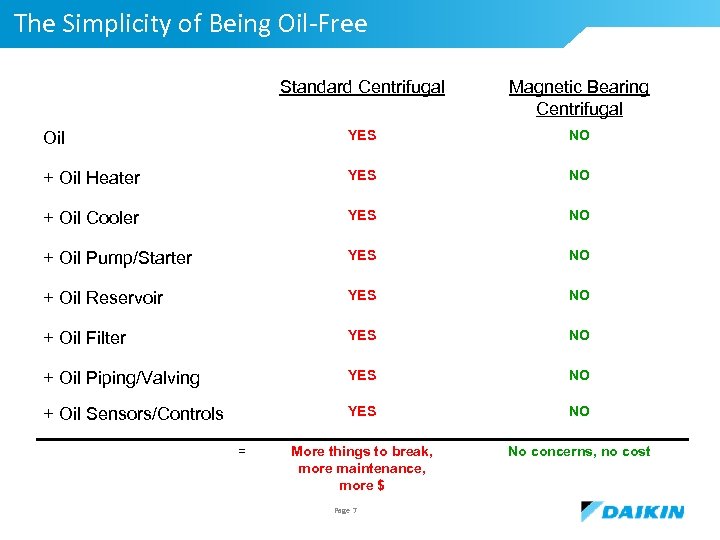

The Simplicity of Being Oil-Free Standard Centrifugal Magnetic Bearing Centrifugal Oil YES NO + Oil Heater YES NO + Oil Cooler YES NO + Oil Pump/Starter YES NO + Oil Reservoir YES NO + Oil Filter YES NO + Oil Piping/Valving YES NO + Oil Sensors/Controls YES NO More things to break, more maintenance, more $ No concerns, no cost = Page 7

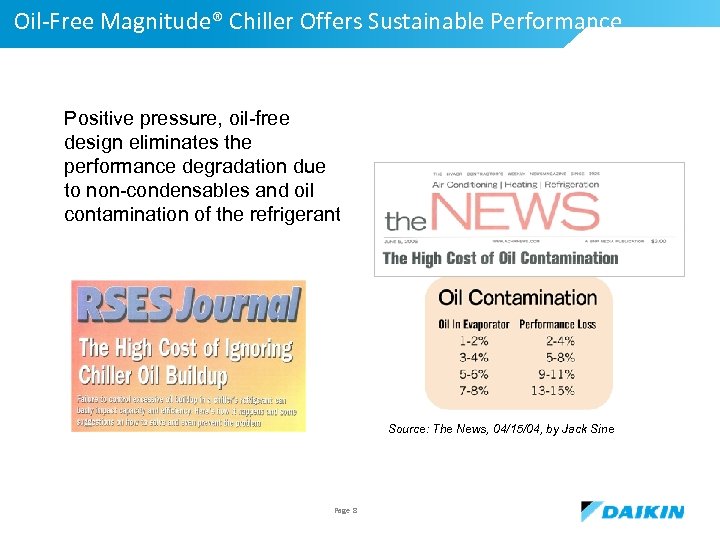

Oil-Free Magnitude® Chiller Offers Sustainable Performance Positive pressure, oil-free design eliminates the performance degradation due to non-condensables and oil contamination of the refrigerant Source: The News, 04/15/04, by Jack Sine Page 8

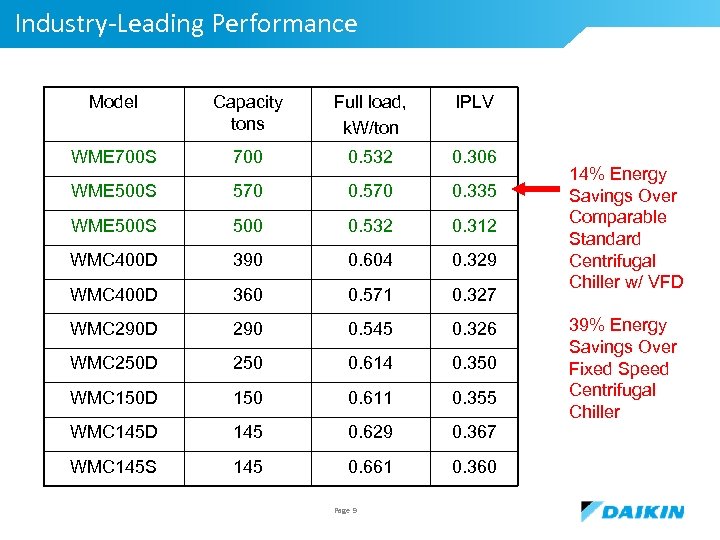

Industry-Leading Performance Model Capacity tons Full load, k. W/ton IPLV WME 700 S 700 0. 532 0. 306 WME 500 S 570 0. 335 WME 500 S 500 0. 532 0. 312 WMC 400 D 390 0. 604 0. 329 WMC 400 D 360 0. 571 0. 327 WMC 290 D 290 0. 545 0. 326 WMC 250 D 250 0. 614 0. 350 WMC 150 D 150 0. 611 0. 355 WMC 145 D 145 0. 629 0. 367 WMC 145 S 145 0. 661 0. 360 Page 9 14% Energy Savings Over Comparable Standard Centrifugal Chiller w/ VFD 39% Energy Savings Over Fixed Speed Centrifugal Chiller

Industry-Leading Performance • Up to 40% more energy efficient than standard centrifugal chillers • Saving more than $2 million over the life of the chiller! Page 10

Industry-Leading Performance What this means for owners. . . • • • Energy savings at non-peak loads LEED Energy and Atmosphere Credit 1 (EAc 1), Optimize Energy Efficiency, for 1 to 19 possible points Potential qualification for rebate programs Page 11

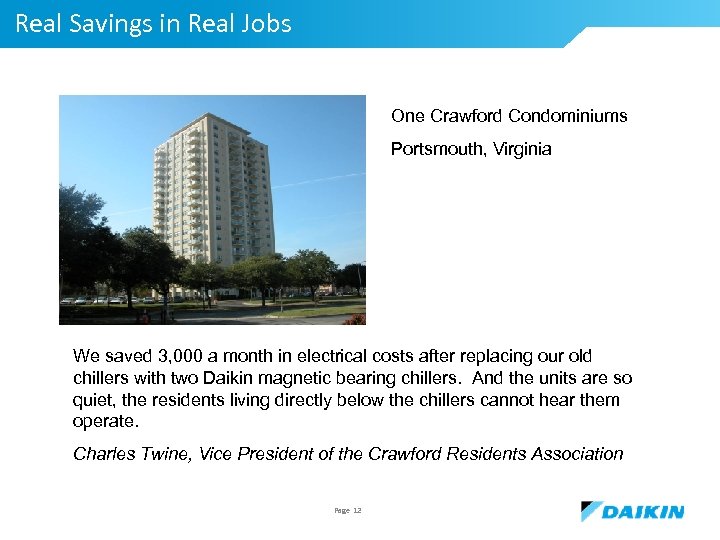

Real Savings in Real Jobs One Crawford Condominiums Portsmouth, Virginia We saved 3, 000 a month in electrical costs after replacing our old chillers with two Daikin magnetic bearing chillers. And the units are so quiet, the residents living directly below the chillers cannot hear them operate. Charles Twine, Vice President of the Crawford Residents Association Page 12

Real Savings in Real Jobs Florida Community College, North Campus Jacksonville, Florida We installed a 300 -ton Daikin magnetic bearing centrifugal chillers as part of an upgrade to our campus chiller plant and BAS system. The North Campus reduced its electrical usage by 519, 514 k. Wh in the first six months. This chiller contributes 30 to 40% of our energy savings for the entire system upgrade. Mark Gandy, North Campus HVAC Facilities Manager Page 13

Among the quietest Chiller in its Size Range • Sound pressure levels as low as 76 d. BA per ARI Standard 575 • Ideal for schools, condos, libraries and healthcare facilities Page 14

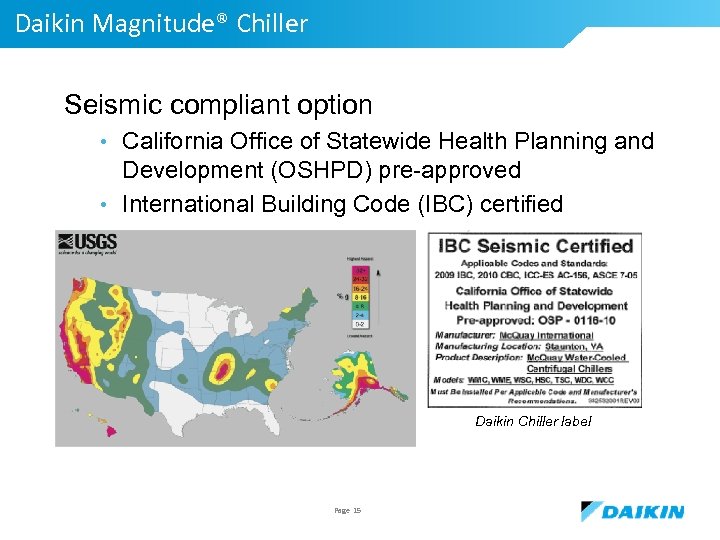

Daikin Magnitude® Chiller Seismic compliant option • California Office of Statewide Health Planning and Development (OSHPD) pre-approved • International Building Code (IBC) certified Daikin Chiller label Page 15

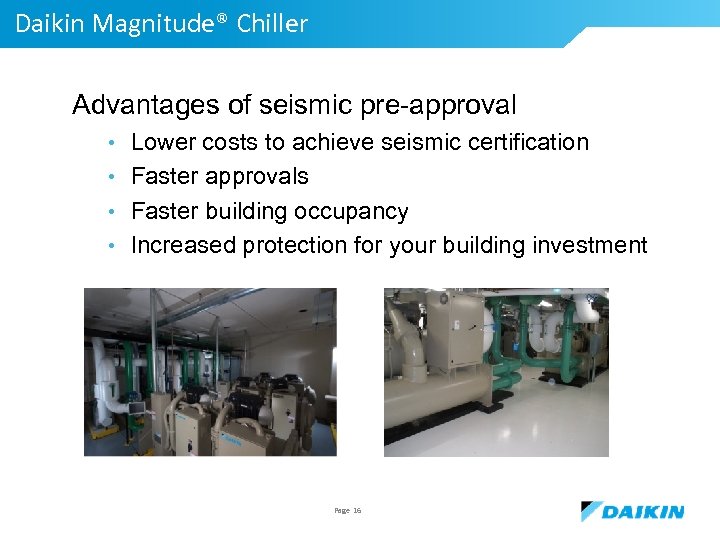

Daikin Magnitude® Chiller Advantages of seismic pre-approval • Lower costs to achieve seismic certification • Faster approvals • Faster building occupancy • Increased protection for your building investment Page 16

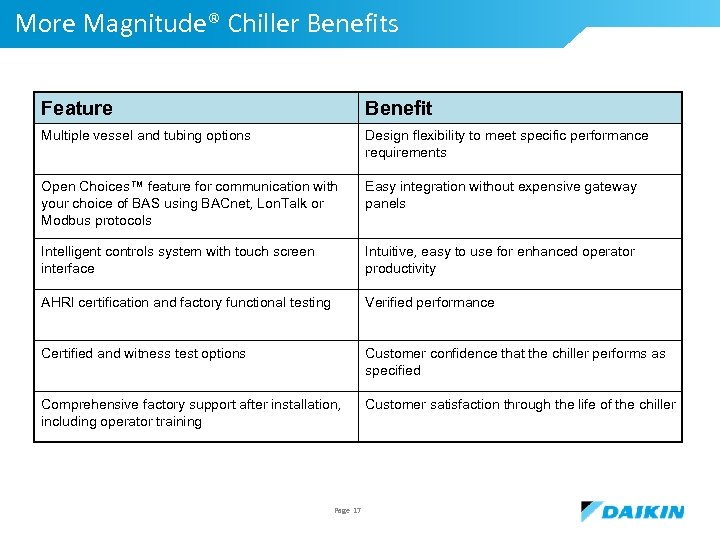

More Magnitude® Chiller Benefits Feature Benefit Multiple vessel and tubing options Design flexibility to meet specific performance requirements Open Choices™ feature for communication with your choice of BAS using BACnet, Lon. Talk or Modbus protocols Easy integration without expensive gateway panels Intelligent controls system with touch screen interface Intuitive, easy to use for enhanced operator productivity AHRI certification and factory functional testing Verified performance Certified and witness test options Customer confidence that the chiller performs as specified Comprehensive factory support after installation, including operator training Customer satisfaction through the life of the chiller Page 17

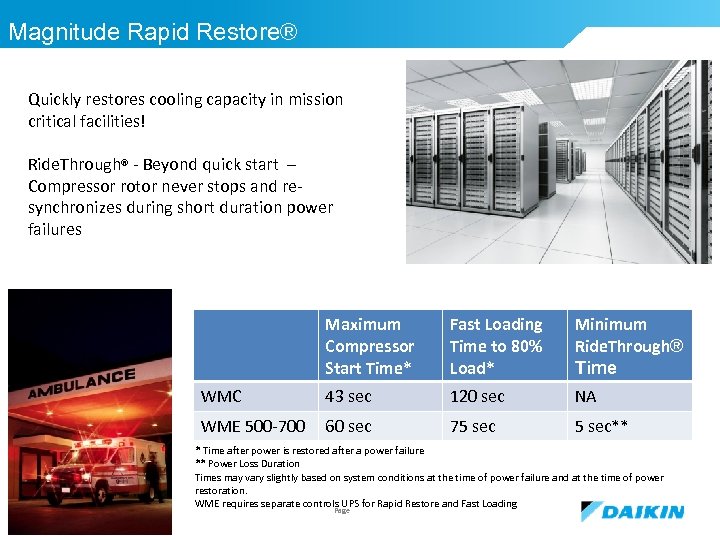

Magnitude Rapid Restore® Quickly restores cooling capacity in mission critical facilities! Ride. Through® - Beyond quick start – Compressor rotor never stops and resynchronizes during short duration power failures Maximum Compressor Start Time* Fast Loading Time to 80% Load* Minimum Ride. Through® Time WMC 43 sec 120 sec NA WME 500 -700 60 sec 75 sec** * Time after power is restored after a power failure ** Power Loss Duration Times may vary slightly based on system conditions at the time of power failure and at the time of power restoration. WME requires separate controls UPS for Rapid Restore and Fast Loading Page

Magnitude® Chillers—a Great Choice for • Areas with high electric rates • Immediate savings and quick payback • Sound-sensitive environments • It’s the quietest chiller in its size range • Buildings with high lease rates • Small footprint means smaller equipment rooms and more space available for leasing • Limited space for moving or install units • WMC models fit through standard 4’ wide doors Page 19

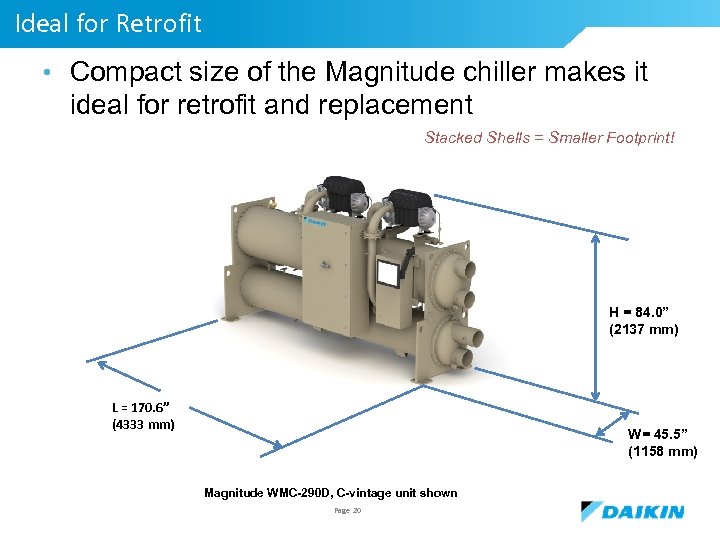

Ideal for Retrofit • Compact size of the Magnitude chiller makes it ideal for retrofit and replacement Stacked Shells = Smaller Footprint! H = 84. 0” (2137 mm) L = 170. 6” (4333 mm) W= 45. 5” (1158 mm) Magnitude WMC-290 D, C-vintage unit shown Page 20

Reliable • Magnitude® chillers have proven their reliability in 2, 900+ installations around the world Page 21

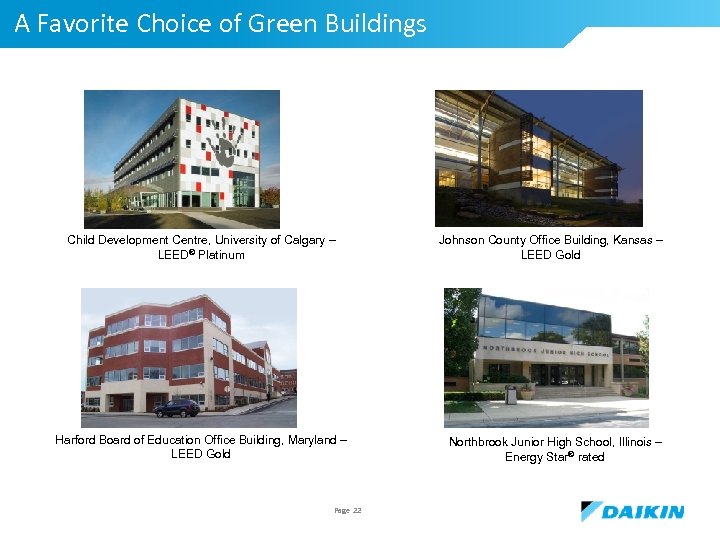

A Favorite Choice of Green Buildings Child Development Centre, University of Calgary – LEED® Platinum Harford Board of Education Office Building, Maryland – LEED Gold Page 22 Johnson County Office Building, Kansas – LEED Gold Northbrook Junior High School, Illinois – Energy Star® rated

Top 6 Reasons To Specify and Buy a Daikin Magnitude® Chiller 1. Significant energy savings 2. World-class, sustainable, and reliable performance 3. Environmental commitment 4. LEED® points and potential rebate qualifications 5. Great value with fast payback opportunity 6. Seismic certified Page 23

What a Magnitude® Chiller Means for the Facility Owner + High Efficiency = + Reduced Maintenance (no oil, no purge) Sustainability Page 24 Lowest Total Cost of Ownership

Make it a Complete Daikin System Magnitude® Chiller 100 to 700 tons Vision™ Indoor Air Handler 900 - 100, 000 cfm Roof. Pak™ Outdoor Air Handler 900 - 65, 000 cfm Skyline™ Outdoor Air Handler 900 - 65, 000 cfm Unit Ventilator 750 - 2, 000 cfm Page 25 Destiny™ Air Handler 600 - 15, 000 cfm Fan Coil units 600 - 3, 000 cfm

e Questions? © 2014 Daikin Applied People and ideas you can trust. TM

e Thank You! © 2014 Daikin Applied People and ideas you can trust. TM

1c49523d3fc0ae80f8388db9a7651166.ppt