6b658fdc699e1c24c0f112c14f08349b.ppt

- Количество слайдов: 29

e. Commerce and e. Business REQUIRE e. Manufacturing to keep up! Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 1

ERP, MES, APS, Quality Management: How do these Pieces EFFECTIVELY fit Together? Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 2

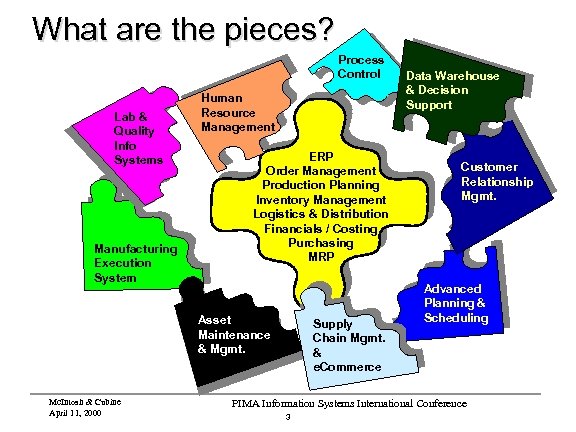

What are the pieces? Process Control Lab & Quality Info Systems Manufacturing Execution System Human Resource Management ERP Order Management Production Planning Inventory Management Logistics & Distribution Financials / Costing Purchasing MRP Asset Maintenance & Mgmt. Mc. Intosh & Cubine April 11, 2000 Supply Chain Mgmt. & e. Commerce Data Warehouse & Decision Support Customer Relationship Mgmt. Advanced Planning & Scheduling PIMA Information Systems International Conference 3

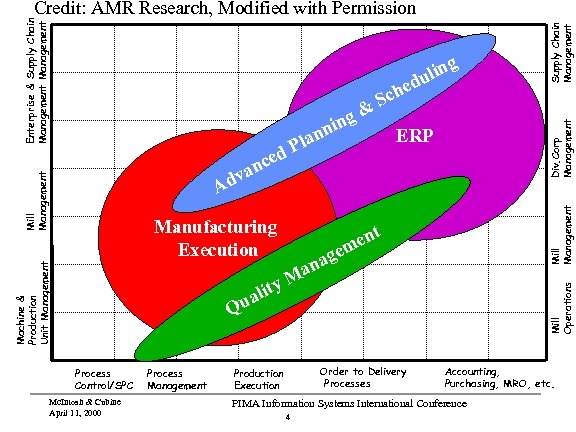

g nin & n Pla d d ERP e Mill Management c van d ent m M Mill Operations Machine & Production Unit Management y alit u e nag a Mill Management A Manufacturing Execution Q Process Control/SPC Mc. Intosh & Cubine April 11, 2000 Process Management Order to Delivery Processes Production Execution Accounting, Purchasing, MRO, etc. PIMA Information Systems International Conference 4 Supply Chain Management e Sch g n uli Div. Corp Management Enterprise & Supply Chain Management Credit: AMR Research, Modified with Permission

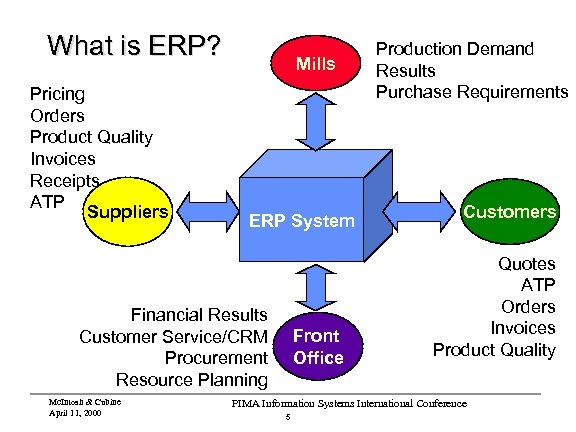

What is ERP? Pricing Orders Product Quality Invoices Receipts ATP Suppliers Mills ERP System Financial Results Customer Service/CRM Procurement Resource Planning Mc. Intosh & Cubine April 11, 2000 Front Office Production Demand Results Purchase Requirements Customers Quotes ATP Orders Invoices Product Quality PIMA Information Systems International Conference 5

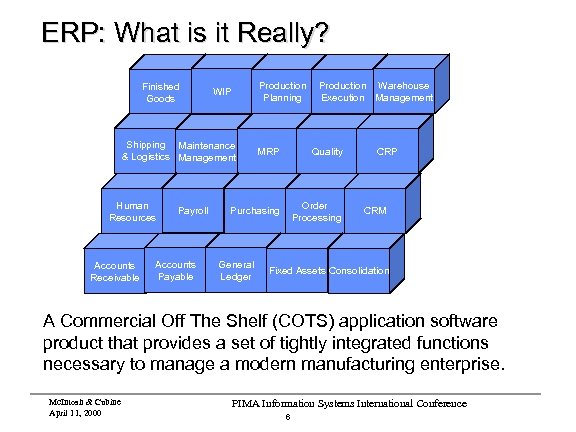

ERP: What is it Really? Finished Goods Production Planning WIP Shipping Maintenance & Logistics Management Human Resources Accounts Receivable Payroll Accounts Payable Production Warehouse Execution Management MRP Quality Purchasing Order Processing General Ledger CRP CRM Fixed Assets Consolidation A Commercial Off The Shelf (COTS) application software product that provides a set of tightly integrated functions necessary to manage a modern manufacturing enterprise. Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 6

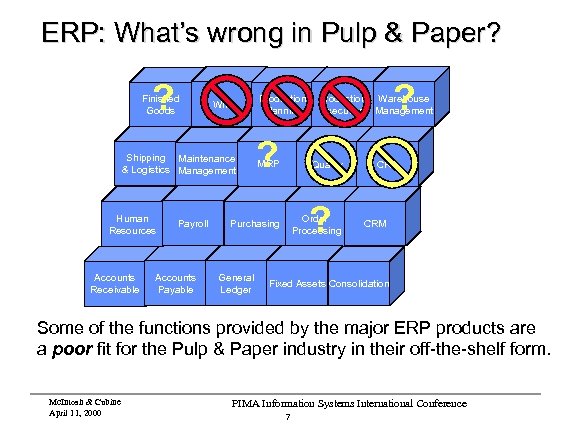

ERP: What’s wrong in Pulp & Paper? ? Finished Goods Production Planning WIP Shipping Maintenance & Logistics Management Human Resources Accounts Receivable Payroll Accounts Payable ? ? Production Warehouse Execution Management MRP Quality Purchasing Order Processing General Ledger ? CRP CRM Fixed Assets Consolidation Some of the functions provided by the major ERP products are a poor fit for the Pulp & Paper industry in their off-the-shelf form. Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 7

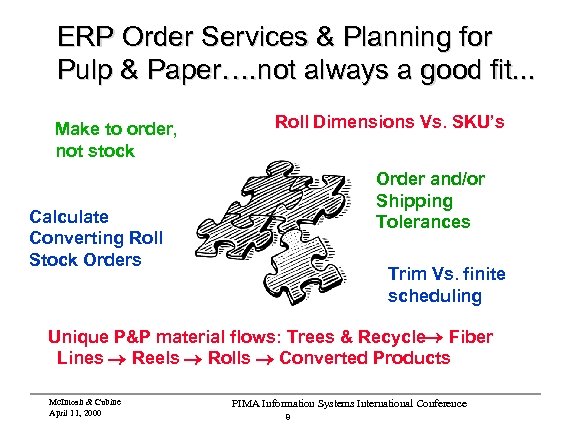

ERP Order Services & Planning for Pulp & Paper…. not always a good fit. . . Make to order, not stock Roll Dimensions Vs. SKU’s Order and/or Shipping Tolerances Calculate Converting Roll Stock Orders Trim Vs. finite scheduling Unique P&P material flows: Trees & Recycle Fiber Lines Reels Rolls Converted Products Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 8

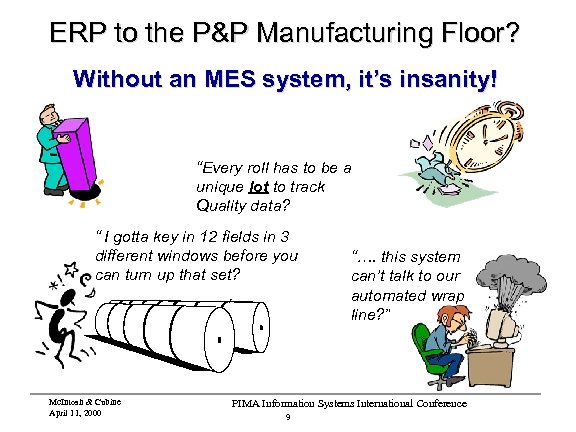

ERP to the P&P Manufacturing Floor? Without an MES system, it’s insanity! “Every roll has to be a unique lot to track Quality data? “ I gotta key in 12 fields in 3 different windows before you can turn up that set? Mc. Intosh & Cubine April 11, 2000 “…. this system can’t talk to our automated wrap line? ” PIMA Information Systems International Conference 9

There are real ERP benefits for P&P companies however. . . üIntegrated financial systems üIntegrated cost systems üIntegration of purchasing, maintenance stores, human resources, payroll, etc. üGrowing functionality in some “ERP II” areas, e. g. Web commerce, customer asset management, etc. üSome P&P vertical market momentum but …. Some of the major ERP vendors will overcome critical functional deficits for the P&P market, especially customer order management issues, maybe planning/scheduling/ATP, and in some cases even integration with the shop floor. Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 10

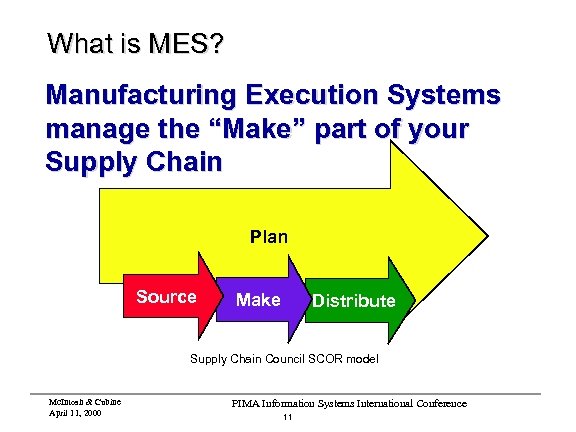

What is MES? Manufacturing Execution Systems manage the “Make” part of your Supply Chain Plan Source Make Distribute Supply Chain Council SCOR model Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 11

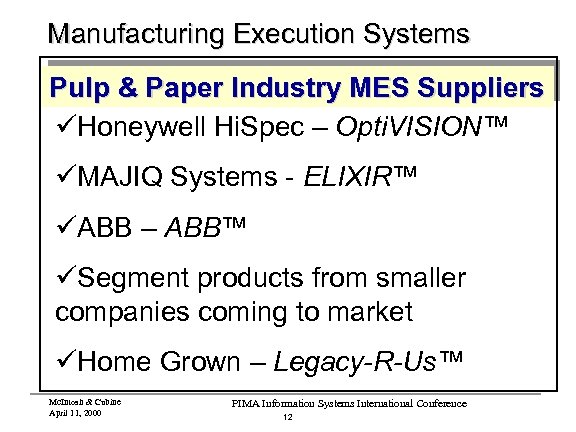

Manufacturing Execution Systems Pulp & Paper Industry MES Suppliers üHoneywell Hi. Spec – Opti. VISION™ üMAJIQ Systems - ELIXIR™ üABB – ABB™ üSegment products from smaller companies coming to market üHome Grown – Legacy-R-Us™ Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 12

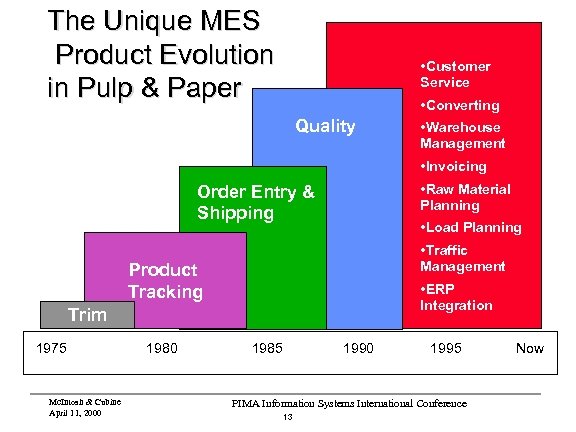

The Unique MES Product Evolution in Pulp & Paper • Customer Service • Converting Quality • Warehouse Management • Invoicing • Raw Material Planning Order Entry & Shipping • Load Planning • Traffic Management Product Tracking • ERP Integration Trim 1975 Mc. Intosh & Cubine April 11, 2000 1985 1990 1995 PIMA Information Systems International Conference 13 Now

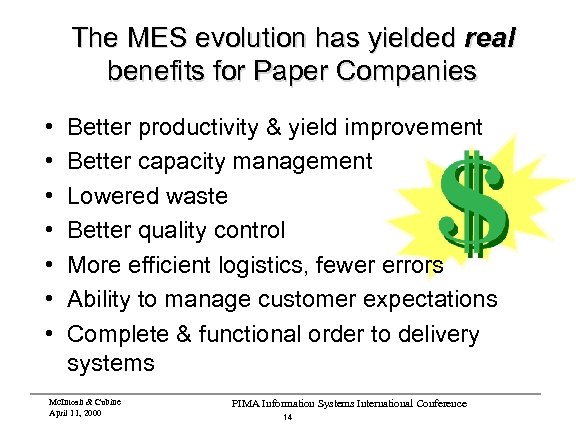

The MES evolution has yielded real benefits for Paper Companies • • Better productivity & yield improvement Better capacity management Lowered waste Better quality control More efficient logistics, fewer errors Ability to manage customer expectations Complete & functional order to delivery systems Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 14

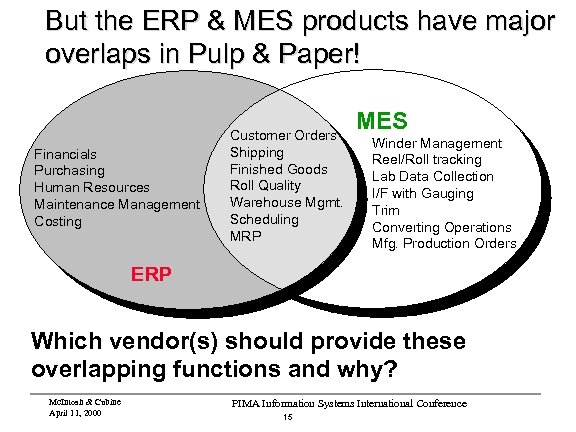

But the ERP & MES products have major overlaps in Pulp & Paper! Financials Purchasing Human Resources Maintenance Management Costing Customer Orders Shipping Finished Goods Roll Quality Warehouse Mgmt. Scheduling MRP MES Winder Management Reel/Roll tracking Lab Data Collection I/F with Gauging Trim Converting Operations Mfg. Production Orders ERP Which vendor(s) should provide these overlapping functions and why? Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 15

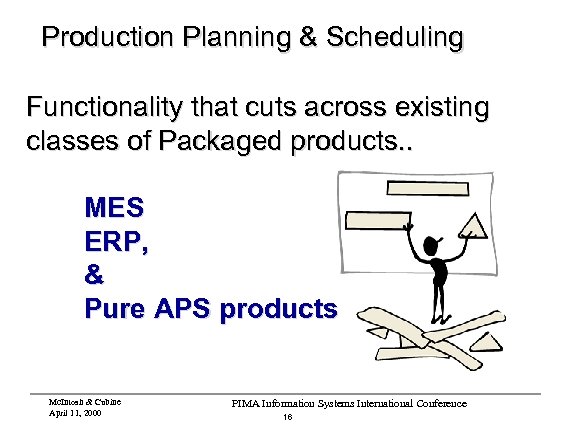

Production Planning & Scheduling Functionality that cuts across existing classes of Packaged products. . MES ERP, & Pure APS products Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 16

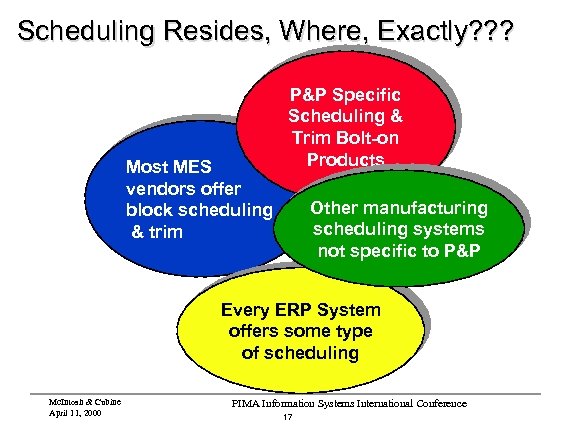

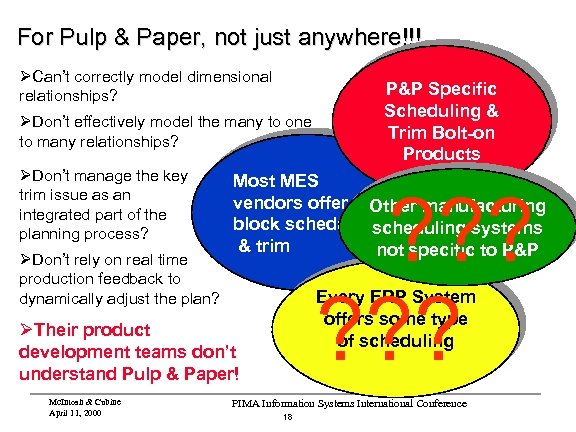

Scheduling Resides, Where, Exactly? ? ? Most MES vendors offer block scheduling & trim P&P Specific Scheduling & Trim Bolt-on Products Other manufacturing scheduling systems not specific to P&P Every ERP System offers some type of scheduling Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 17

For Pulp & Paper, not just anywhere!!! ØCan’t correctly model dimensional relationships? ØDon’t effectively model the many to one to many relationships? ØDon’t manage the key trim issue as an integrated part of the planning process? ØDon’t rely on real time production feedback to dynamically adjust the plan? Most MES vendors offer Other manufacturing block scheduling systems & trim not specific to P&P ? ? ? Every ERP System offers some type of scheduling ØTheir product development teams don’t understand Pulp & Paper! Mc. Intosh & Cubine April 11, 2000 P&P Specific Scheduling & Trim Bolt-on Products PIMA Information Systems International Conference 18

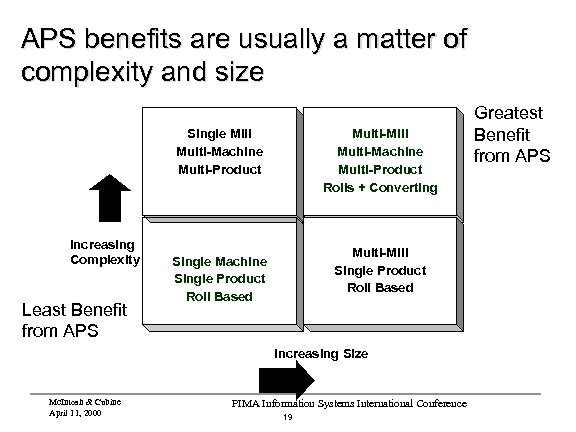

APS benefits are usually a matter of complexity and size Single Mill Multi-Machine Multi-Product Increasing Complexity Least Benefit from APS Multi-Mill Multi-Machine Multi-Product Rolls + Converting Single Mill Single Machine Single Product Roll Based Multi-Mill Single Product Roll Based Increasing Size Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 19 Greatest Benefit from APS

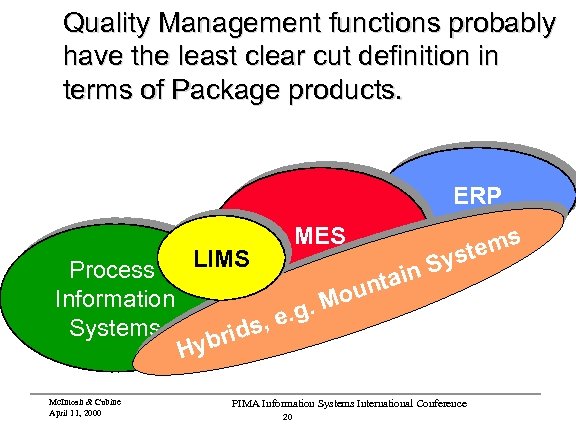

Quality Management functions probably have the least clear cut definition in terms of Package products. ERP MES LIMS S Process ain t oun Information. g. M e Systems ds, i ybr H Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 20 s stem y

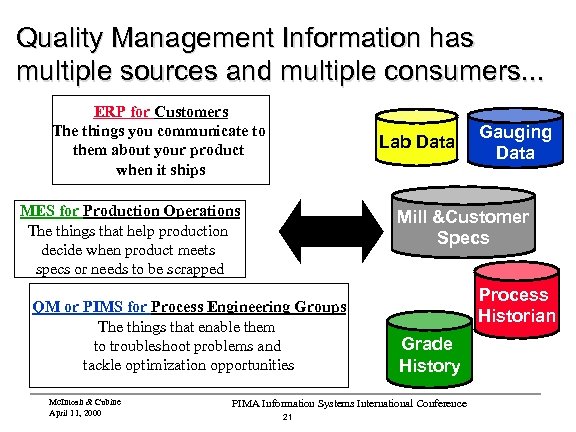

Quality Management Information has multiple sources and multiple consumers. . . ERP for Customers The things you communicate to them about your product when it ships Lab Data MES for Production Operations The things that help production decide when product meets specs or needs to be scrapped Mill &Customer Specs QM or PIMS for Process Engineering Groups The things that enable them to troubleshoot problems and tackle optimization opportunities Mc. Intosh & Cubine April 11, 2000 Gauging Data Process Historian Grade History PIMA Information Systems International Conference 21

The concept of quality management systems is still evolving in pulp & paper • The “Hybrid Systems” vendors have an opportunity to continue to grow their role and the functionality they own • The ERP & MES vendors will have to improve the depth and scope of their offerings or risk loosing these functions completely in the paper industry • Being able to address the needs of the quality information consumers in the enterprise is the key Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 22

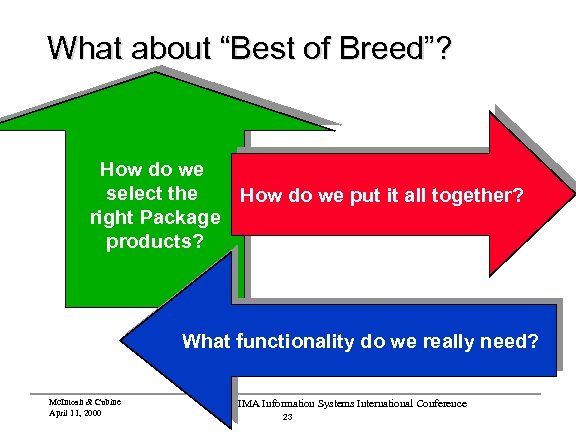

What about “Best of Breed”? How do we select the How do we put it all together? right Package products? What functionality do we really need? Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 23

You should identify your opportunities for improvement first. . a “vision” for where you want to be • Understand document your current state in terms of business & manufacturing objectives, business processes, manufacturing processes, and systems • Develop a vision of your future state that is realistic and achievable Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 24

Understand the requirements for achieving your future state • What functionality is required? • Which vendors can meet the real requirements? • What are the integration requirements? • How will you sustain, grow, and adapt? • What realistic paybacks and benefits can the enterprise or mill expect? Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 25

Develop a REALISTIC Plan for Implementation…. …neither Santa Claus, the Tooth-Fairy, or the Stork will deliver a successful COTS systems integration or implementation project…you have to plan them in detail and then have the right resources to execute the plan plus accountability for the integration Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 26

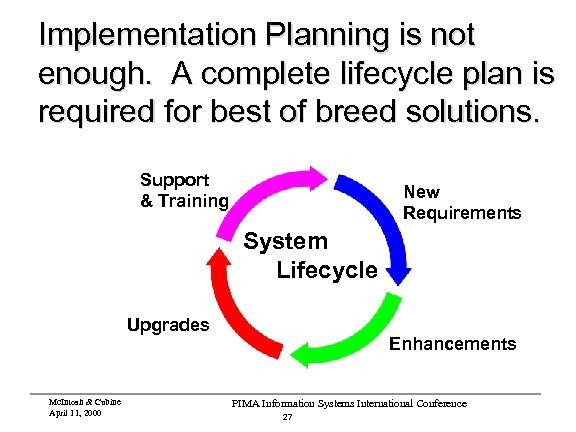

Implementation Planning is not enough. A complete lifecycle plan is required for best of breed solutions. Support & Training New Requirements System Lifecycle Upgrades Mc. Intosh & Cubine April 11, 2000 Enhancements PIMA Information Systems International Conference 27

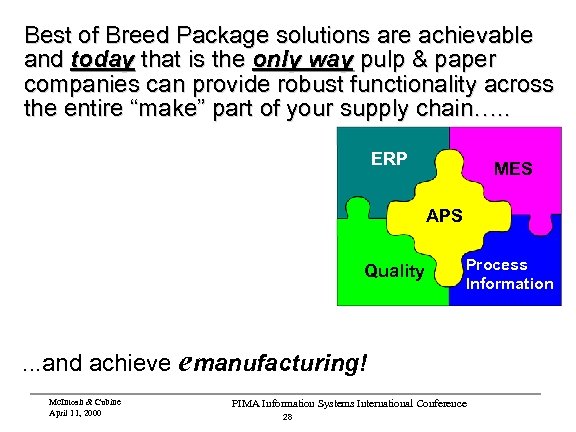

Best of Breed Package solutions are achievable and today that is the only way pulp & paper companies can provide robust functionality across the entire “make” part of your supply chain…. . ERP MES APS Quality Process Information . . . and achieve emanufacturing! Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 28

Questions, comments, electronic copies, etc. Mike Mc. Intosh Mark Cubine mark_cubine@guidementor. com Mc. Intosh & Cubine April 11, 2000 PIMA Information Systems International Conference 29

6b658fdc699e1c24c0f112c14f08349b.ppt