c2ca59401be9bf5cc142a6dc679f9cd9.ppt

- Количество слайдов: 17

E 2 C 2 FST Obsolescence Management Team Do. D Teaming Group May 2, 2001 Francisco Rios riosf@navair. navy. mil 619 -545 -7727

E 2 C 2 Obsolescence Team • FY 00 Charlie Haliscak Assigned PMA-231 Obsolescence Coordinator • PMA-231 DMSMS/Obsolescence Management Plan Developed (February 01) • PMA-231 DMSMS/Obsolescence Team Charter Developed (February 01) • North Island Team Formed and Kick-off Meeting Held 5 February 01

E-2 C Aircraft Obsolescence Issues • 50 of 64 total Aircraft have over 7 years in service • Many Avionics Systems in New Production Aircraft are Configured with Legacy Systems • Many of the Systems in Newer Production Aircraft are recycled from Retired Aircraft • L-304 Mission Computer (Case Study) • APS-125/138/145 Radar WRA’s • Trailing Wire Antenna

Obsolescence Management Process • Obsolescence Coordinator Establish Priorities as: ü AN/APS-145 ü AN/APS-138 ü L-304 Mission Computer ü CPU-140 A SCADC / NSIU (C-2 A Peculiar) • Create Bills of Material/Indentured Parts List (BOM/IPL) ü Electronic Format ü Electronic BOM/IPL Loaded into TACTRAC ü Appoint Server Administrator

Obsolescence Management Process • Identify Obsolete Parts or Those at Risk ü TACTRAC Output Reports (Green/Yellow/Red Format) ü Use Other Tool to Resolve Not Reported Parts (Haystack, Parts Plus, etc…) ü May Require Re-Formatting BOM/IPL and Re-Loading • Resolve Unreported Parts Due to Suppliers or SCD’s ü Convert SCD’s to Manufacturer or Generic P/N’s or find NSN’s ü Re-Load BOM/IPL

Obsolescence Management Process • Assess Component/SRA/WRA/System Availability and Demand Rates ü Requires Logistics Analysis ü Use Data from USN Fleet Maintenance (NALDA) ü Also Depot Usage Data

Case Study • E-2 C Mission Computer Upgrade Planned – MCU/ACIS, Only for New Production Aircraft – MC Re. PLACE Planned for E-2 C GR II • Currently Unfunded? – No Retrofit for Group I Aircraft

Case Study • In 1998 Litton Industries discontinued support for L-304 Mission Computer – North Island visited Litton and Tagged Inventory – All Inventory Turned over to N-G • In the Mean Time, components for L-304 were Becoming Scarce – Shop Request Alerted Engineering of L-304 Component Availability Issues

Case Study • Components made by DDC used on L-304 MC were not in Production/Available – North Island Production Contacted FISC regarding Litton P/N (19645) 861814 – FISC contacted DLA – Item Manager – DMEA Contacted by DLA and Began Redesign of Component P/N (19645) 2158 • Same as Litton Part Number 861814 • DMEA Effort Separate from North Island – DMEA/DLA Requested North Island Perform Board Level Qualifying Test of Redesigned Part

Case Study • Qualification and Bench Testing performed at NADEP North Island Feb – March 2001 – First Built a Golden SRA to Test Unit in Circuit – SRA was as Close to Center Test Values as Possible. – After Witnessing Test/Values, P/N 861814 Approved by Engineering for Removal from SRA

Case Study • Qualification and Bench Testing (cont. ) – First Article Inserted into SRA – Initial Test Discovered Inconsistencies in First Article Component • Thought to be Circuit Trace Problem

Case Study • Qualification and Bench Testing (cont. ) – A Second Unit was Produced by DMEA and Rushed to North Island • Recommended NOT to Encase New Item

Case Study • Qualification and Bench Testing (cont. ) – The Second DMEA Prototype 861814 was received March 16 th – Testing Began March 19 th – End to End Testing of SRA Found No Faults – Bench Testing Results Forwarded to DLA/NAVICP/PMA-231 – MIL-Qual Testing to be Performed by DMEA • North Island Recommended MIL-Q-883

Case Study • Royal Singapore Air Force requested PMA Assistance in Obtaining Part for ASN-92 – P/N 861812 no Longer Supported by Litton – PMA Contacted North Island for Assistance – North Island Contacted Litton for Spec of Part • North Island noticed ASN-92 Part, also made by Litton, was Common to L-304 MC – Found Component RSAF was looking for was Family Member of Part Recently Redesigned – North Island Already Affected by Unavailability of Litton P/N 861814, 861812, and 861815 – Forwarded information to PMA-231/NAVICP

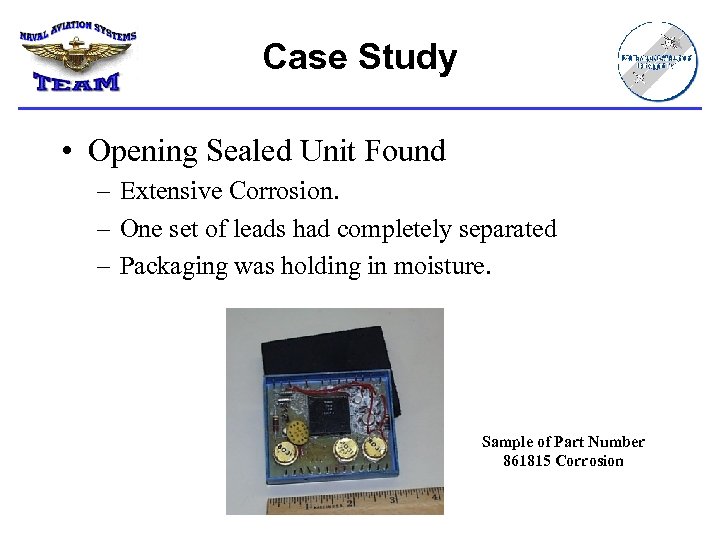

Case Study • Opening Sealed Unit Found – Extensive Corrosion. – One set of leads had completely separated – Packaging was holding in moisture. Sample of Part Number 861815 Corrosion

Case Study • North Island Requested NAVICP/DLA Response for Navy and FMS Issues • NAVICP Requested DMEA Quote on Fourteen Components – NAVICP has received bid for rest of Components • North Island Awaiting Funding Decision – Potential candidates for Rapid Retargeting • Would Not Help Singapore Issue

Questions?

c2ca59401be9bf5cc142a6dc679f9cd9.ppt