e77e477fd75905be99b8fc9d159bfdd5.ppt

- Количество слайдов: 31

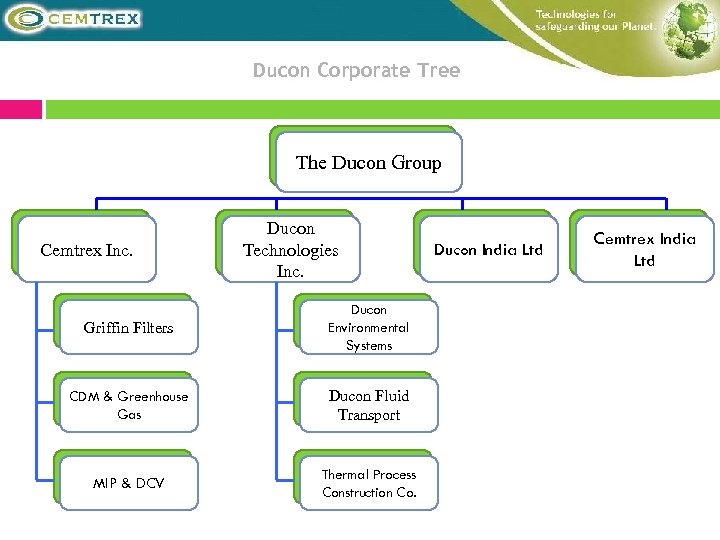

Ducon Corporate Tree The Ducon Group Cemtrex Inc. Ducon Technologies Inc. Griffin Filters Ducon Environmental Systems CDM & Greenhouse Gas Ducon Fluid Transport MIP & DCV Thermal Process Construction Co. Ducon India Ltd Cemtrex India Ltd

Ducon Corporate Tree The Ducon Group Cemtrex Inc. Ducon Technologies Inc. Griffin Filters Ducon Environmental Systems CDM & Greenhouse Gas Ducon Fluid Transport MIP & DCV Thermal Process Construction Co. Ducon India Ltd Cemtrex India Ltd

Cemtrex History 1938 - Ducon Inc founded 2000 - Cemtrex established as subsidiary of Ducon 2001 - Cemtrex purchase KVB Enertec 2005 - Cemtrex purchase Griffin Environmental 2006 - Cemtrex establishes Greenhouse Gases division 2006 - Cemtrex launches Mercury CEMS for CAMR 2007 - Cemtrex listed for public trading (CTEI. OTC) 2008 - Cemtrex builds World’s First VAM Catalytic Reactor 2012 – Cemtrex MIP expands into Oil & Gas market through partnership with Modcon 2012 – Cemtrex recognized as a Fast 500 Company by Deloitte 2013 – Cemtrex acquires the ROB Group, forming ROB Cemtrex

Cemtrex History 1938 - Ducon Inc founded 2000 - Cemtrex established as subsidiary of Ducon 2001 - Cemtrex purchase KVB Enertec 2005 - Cemtrex purchase Griffin Environmental 2006 - Cemtrex establishes Greenhouse Gases division 2006 - Cemtrex launches Mercury CEMS for CAMR 2007 - Cemtrex listed for public trading (CTEI. OTC) 2008 - Cemtrex builds World’s First VAM Catalytic Reactor 2012 – Cemtrex MIP expands into Oil & Gas market through partnership with Modcon 2012 – Cemtrex recognized as a Fast 500 Company by Deloitte 2013 – Cemtrex acquires the ROB Group, forming ROB Cemtrex

Cemtrex Capability Headquartered in Farmingdale, New York Subsidiaries in India, China, & Mexico In-house engineering for: mechanical, structural, & electrical Experienced in-house Project Management organization System Integration facility at Farmingdale NY Gas Analyzer manufacturing facility at Orange CA Sampling system manufacturing facility in Carson City NV

Cemtrex Capability Headquartered in Farmingdale, New York Subsidiaries in India, China, & Mexico In-house engineering for: mechanical, structural, & electrical Experienced in-house Project Management organization System Integration facility at Farmingdale NY Gas Analyzer manufacturing facility at Orange CA Sampling system manufacturing facility in Carson City NV

Cemtrex Global Presence Headquarters Subsidiaries Sales Offices

Cemtrex Global Presence Headquarters Subsidiaries Sales Offices

Some of Cemtrex Customers Advanced Boiler Services Conectiv Energy Arkansas Lime Corning Glass Marathon Ashland Refinery Mathews Furnaces Atlantic States I & S Covanta Rahway NJ Metso Minerals BP Amoco Covanta York PA Montana Refinery Bechtel / NDIA Danisco MPW Energy Citgo Mitsubishi Heavy Electric NRG Energy Carbo Ceramics Energizer Ontario Power Carmeuse Lime Erco Worldwide NV Energy CH 2 M Paper Mill Essroc Cements Peru Utilities Chemical Lime Fauske PQ Corporation Citgo Petroleum Foster Wheeler Rayonier Paper City of Bellingham GE Energy Seminole Electric CMS Energy Heartland Cement Siemens Coffeeville Refinery Hollman Corporation Steel Dynamics TXI Chaparral Steel JEA Power Saint Gobain Glass Clean Harbor Lehigh Cement Chevron & Valero Westar Energy

Some of Cemtrex Customers Advanced Boiler Services Conectiv Energy Arkansas Lime Corning Glass Marathon Ashland Refinery Mathews Furnaces Atlantic States I & S Covanta Rahway NJ Metso Minerals BP Amoco Covanta York PA Montana Refinery Bechtel / NDIA Danisco MPW Energy Citgo Mitsubishi Heavy Electric NRG Energy Carbo Ceramics Energizer Ontario Power Carmeuse Lime Erco Worldwide NV Energy CH 2 M Paper Mill Essroc Cements Peru Utilities Chemical Lime Fauske PQ Corporation Citgo Petroleum Foster Wheeler Rayonier Paper City of Bellingham GE Energy Seminole Electric CMS Energy Heartland Cement Siemens Coffeeville Refinery Hollman Corporation Steel Dynamics TXI Chaparral Steel JEA Power Saint Gobain Glass Clean Harbor Lehigh Cement Chevron & Valero Westar Energy

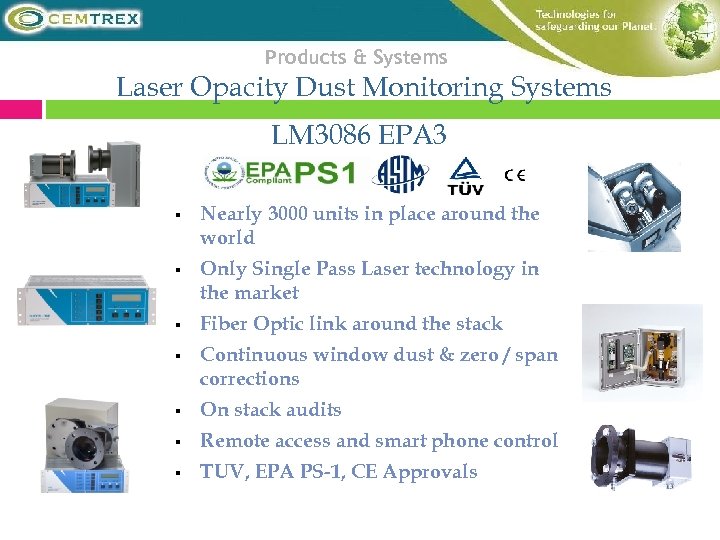

Products & Systems Laser Opacity Dust Monitoring Systems LM 3086 EPA 3 § § Nearly 3000 units in place around the world Only Single Pass Laser technology in the market Fiber Optic link around the stack Continuous window dust & zero / span corrections § On stack audits § Remote access and smart phone control § TUV, EPA PS-1, CE Approvals

Products & Systems Laser Opacity Dust Monitoring Systems LM 3086 EPA 3 § § Nearly 3000 units in place around the world Only Single Pass Laser technology in the market Fiber Optic link around the stack Continuous window dust & zero / span corrections § On stack audits § Remote access and smart phone control § TUV, EPA PS-1, CE Approvals

MIP LM 3086 Laser Opacity Monitor Simple Hardware www. cemtrex. com “Leaders in Emissions Monitoring Technologies”

MIP LM 3086 Laser Opacity Monitor Simple Hardware www. cemtrex. com “Leaders in Emissions Monitoring Technologies”

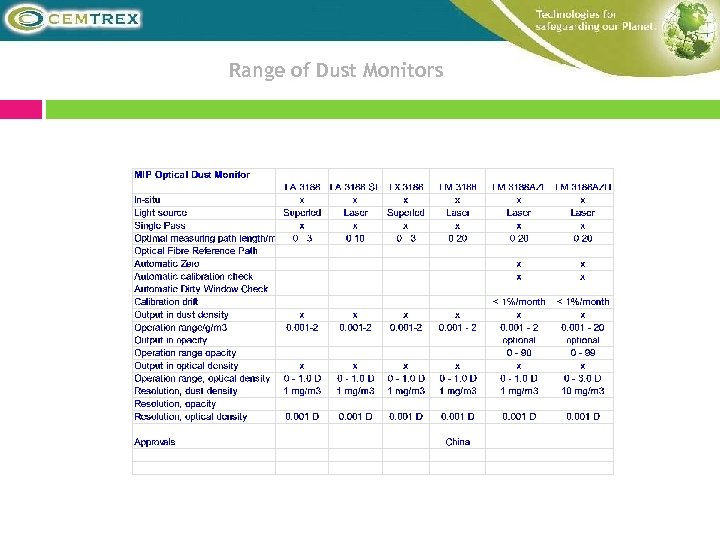

Range of Dust Monitors

Range of Dust Monitors

Simple Dust Monitors LM 3188 Semiconductor Laser Monitor ü Complete three-part system ü Laser light source (655 nm, red laser) and analogue electronics. üLaser allows long measuring paths (up to 200 ft) or higher concentrations üVery easy alignment of the transmitter üCompact size & lightweight üTransmitter: 1. 5 lbs üReceiver: 2 lbs üDisplay Unit: 3 lbs üMeets OSHA regulations

Simple Dust Monitors LM 3188 Semiconductor Laser Monitor ü Complete three-part system ü Laser light source (655 nm, red laser) and analogue electronics. üLaser allows long measuring paths (up to 200 ft) or higher concentrations üVery easy alignment of the transmitter üCompact size & lightweight üTransmitter: 1. 5 lbs üReceiver: 2 lbs üDisplay Unit: 3 lbs üMeets OSHA regulations

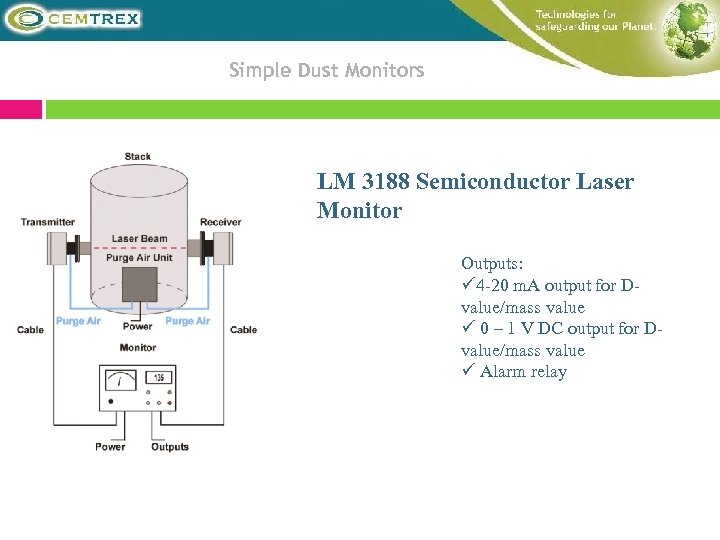

Simple Dust Monitors LM 3188 Semiconductor Laser Monitor Outputs: ü 4 -20 m. A output for Dvalue/mass value ü 0 – 1 V DC output for Dvalue/mass value ü Alarm relay

Simple Dust Monitors LM 3188 Semiconductor Laser Monitor Outputs: ü 4 -20 m. A output for Dvalue/mass value ü 0 – 1 V DC output for Dvalue/mass value ü Alarm relay

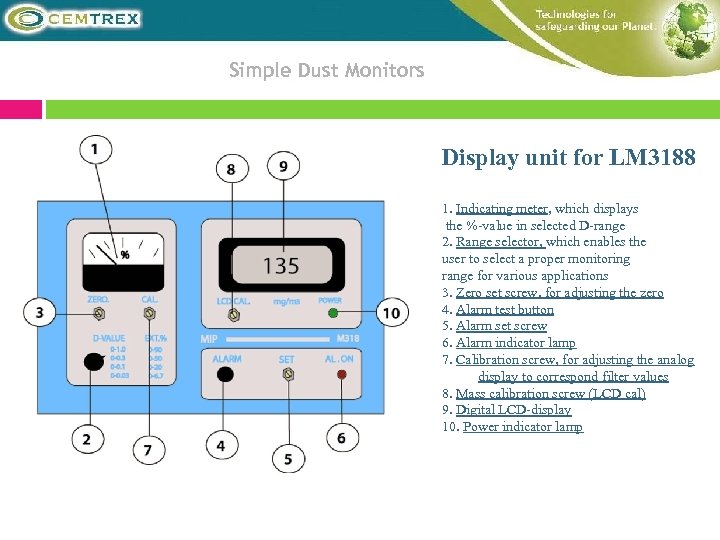

Simple Dust Monitors Display unit for LM 3188 1. Indicating meter, which displays the %-value in selected D-range 2. Range selector, which enables the user to select a proper monitoring range for various applications 3. Zero set screw, for adjusting the zero 4. Alarm test button 5. Alarm set screw 6. Alarm indicator lamp 7. Calibration screw, for adjusting the analog display to correspond filter values 8. Mass calibration screw (LCD cal) 9. Digital LCD-display 10. Power indicator lamp

Simple Dust Monitors Display unit for LM 3188 1. Indicating meter, which displays the %-value in selected D-range 2. Range selector, which enables the user to select a proper monitoring range for various applications 3. Zero set screw, for adjusting the zero 4. Alarm test button 5. Alarm set screw 6. Alarm indicator lamp 7. Calibration screw, for adjusting the analog display to correspond filter values 8. Mass calibration screw (LCD cal) 9. Digital LCD-display 10. Power indicator lamp

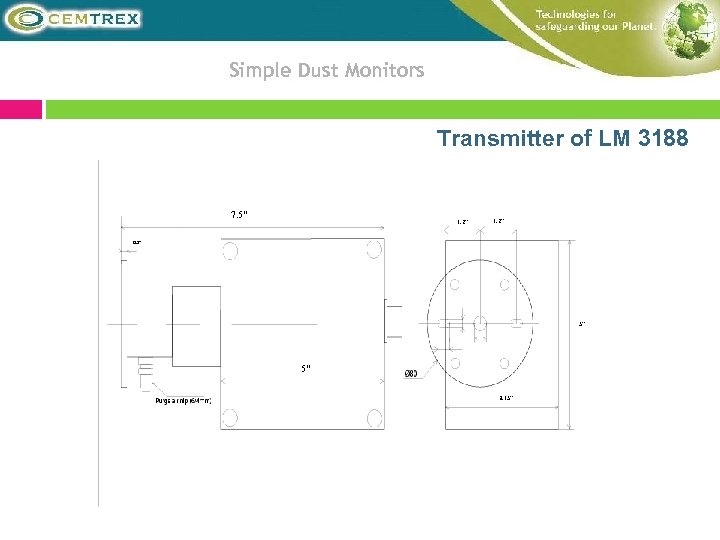

Simple Dust Monitors Transmitter of LM 3188 7. 5” 1. 2” 0. 2” 5” 5” 3. 15”

Simple Dust Monitors Transmitter of LM 3188 7. 5” 1. 2” 0. 2” 5” 5” 3. 15”

Optional Features for Simple Dust Monitors (LM 3188) 100 mm receiver unit • For longer measuring distances or higher vibration • Requires more purging air than 200 ft receiver • Bigger flange required

Optional Features for Simple Dust Monitors (LM 3188) 100 mm receiver unit • For longer measuring distances or higher vibration • Requires more purging air than 200 ft receiver • Bigger flange required

Optional Features for Simple Dust Monitors (LM 3188) Field calibration set Optical filter set Weather proof Enclosure Explosion Proof Certification Available

Optional Features for Simple Dust Monitors (LM 3188) Field calibration set Optical filter set Weather proof Enclosure Explosion Proof Certification Available

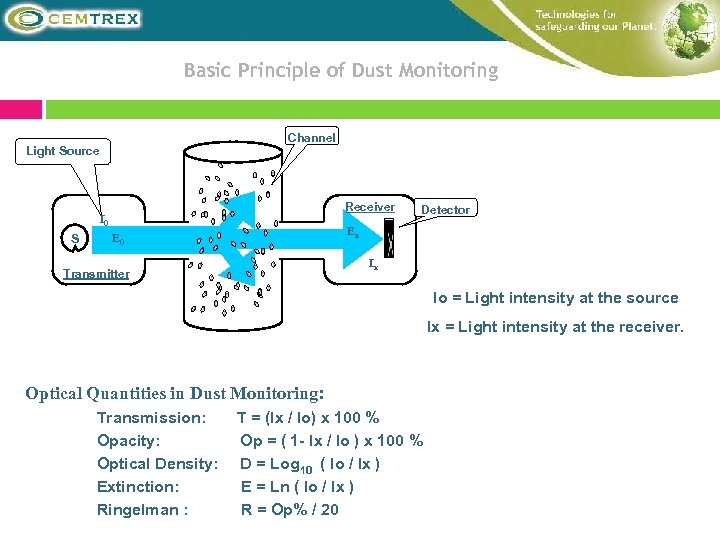

Basic Principle of Dust Monitoring Channel Light Source Receiver I 0 S E 0 Transmitter Detector Ex Ix Io = Light intensity at the source Ix = Light intensity at the receiver. Optical Quantities in Dust Monitoring: Transmission: T = (Ix / Io) x 100 % Opacity: Op = ( 1 - Ix / Io ) x 100 % Optical Density: D = Log 10 ( Io / Ix ) Extinction: E = Ln ( Io / Ix ) Ringelman : R = Op% / 20

Basic Principle of Dust Monitoring Channel Light Source Receiver I 0 S E 0 Transmitter Detector Ex Ix Io = Light intensity at the source Ix = Light intensity at the receiver. Optical Quantities in Dust Monitoring: Transmission: T = (Ix / Io) x 100 % Opacity: Op = ( 1 - Ix / Io ) x 100 % Optical Density: D = Log 10 ( Io / Ix ) Extinction: E = Ln ( Io / Ix ) Ringelman : R = Op% / 20

Relation with Optical Values and Mass Concentration 1. Using a calculation formula: Concentration is as follows : M = (800 x x d / L ) x D, where M = Mass concentration in ( mg / m 3 ) = Specific gravity of the particulate matter in ( kg / dm 3 ) d = Average diameter of the particles in ( m ) L= Length of the light passage inside dust in ( m ) D = Optical Density ( Dimensionless number )

Relation with Optical Values and Mass Concentration 1. Using a calculation formula: Concentration is as follows : M = (800 x x d / L ) x D, where M = Mass concentration in ( mg / m 3 ) = Specific gravity of the particulate matter in ( kg / dm 3 ) d = Average diameter of the particles in ( m ) L= Length of the light passage inside dust in ( m ) D = Optical Density ( Dimensionless number )

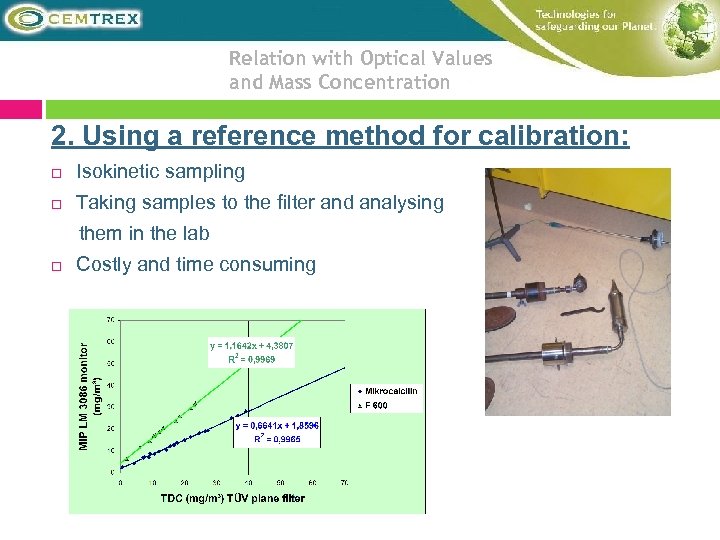

Relation with Optical Values and Mass Concentration 2. Using a reference method for calibration: Isokinetic sampling Taking samples to the filter and analysing them in the lab Costly and time consuming

Relation with Optical Values and Mass Concentration 2. Using a reference method for calibration: Isokinetic sampling Taking samples to the filter and analysing them in the lab Costly and time consuming

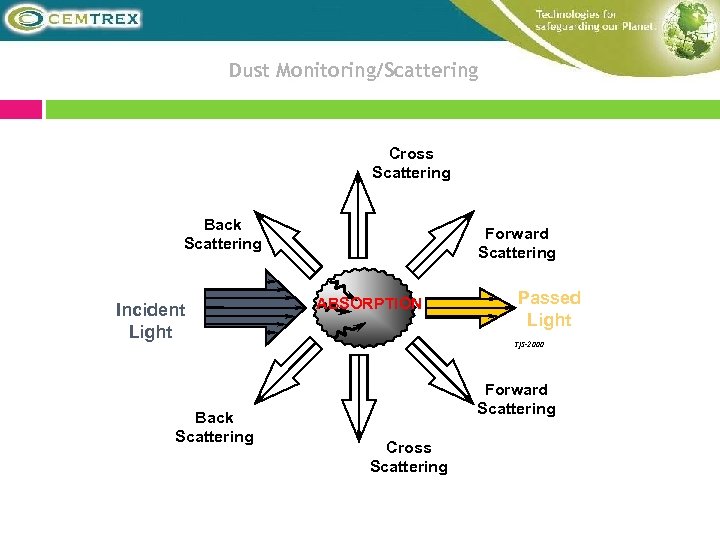

Dust Monitoring/Scattering Cross Scattering Back Scattering Incident Light Back Scattering Forward Scattering ABSORPTION Passed Light TJS-2000 Forward Scattering Cross Scattering

Dust Monitoring/Scattering Cross Scattering Back Scattering Incident Light Back Scattering Forward Scattering ABSORPTION Passed Light TJS-2000 Forward Scattering Cross Scattering

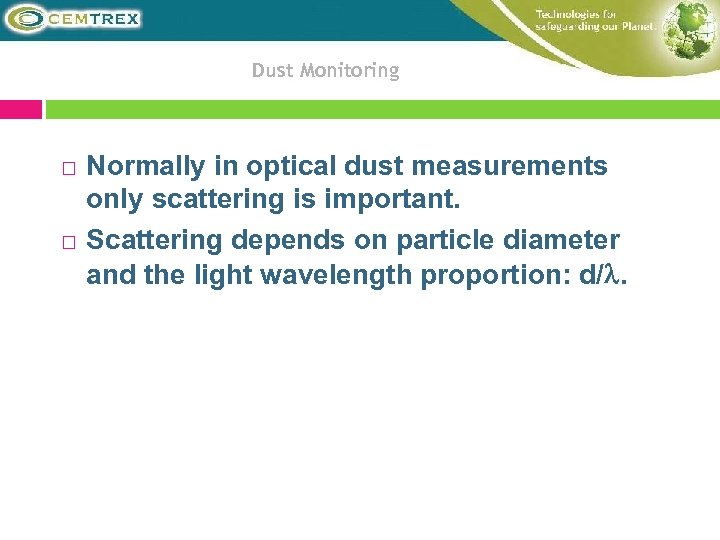

Dust Monitoring Normally in optical dust measurements only scattering is important. Scattering depends on particle diameter and the light wavelength proportion: d/.

Dust Monitoring Normally in optical dust measurements only scattering is important. Scattering depends on particle diameter and the light wavelength proportion: d/.

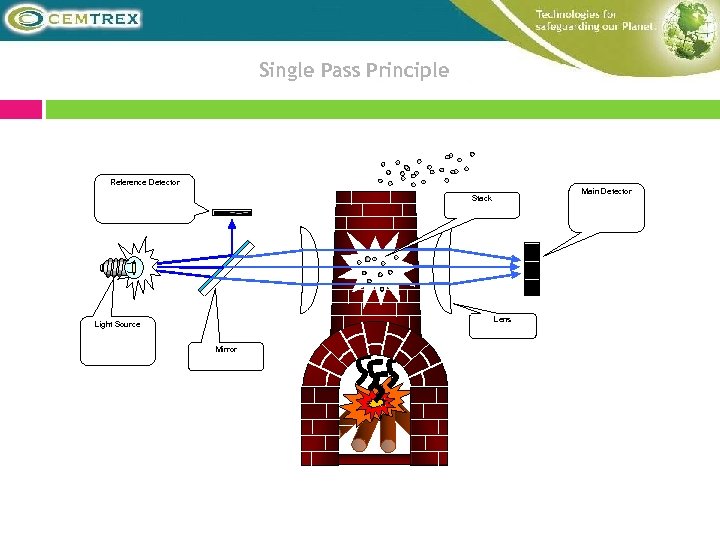

Single Pass Principle Reference Detector Main Detector Stack Lens Light Source Mirror

Single Pass Principle Reference Detector Main Detector Stack Lens Light Source Mirror

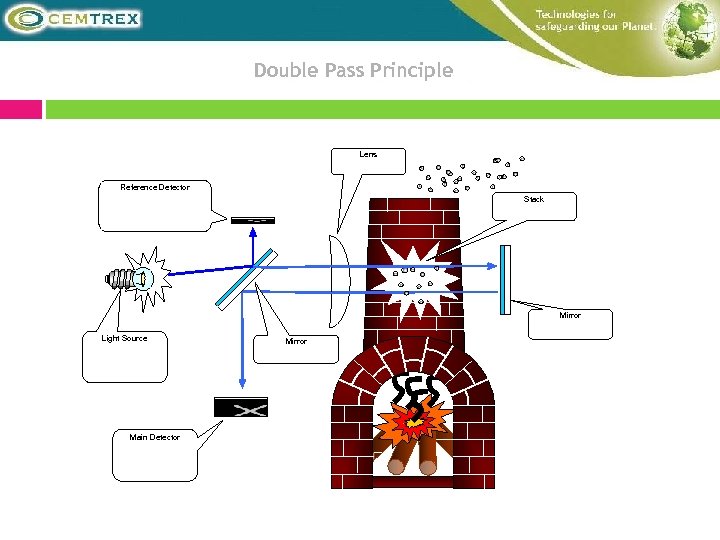

Double Pass Principle Lens Reference Detector Stack Mirror Light Source Main Detector Mirror

Double Pass Principle Lens Reference Detector Stack Mirror Light Source Main Detector Mirror

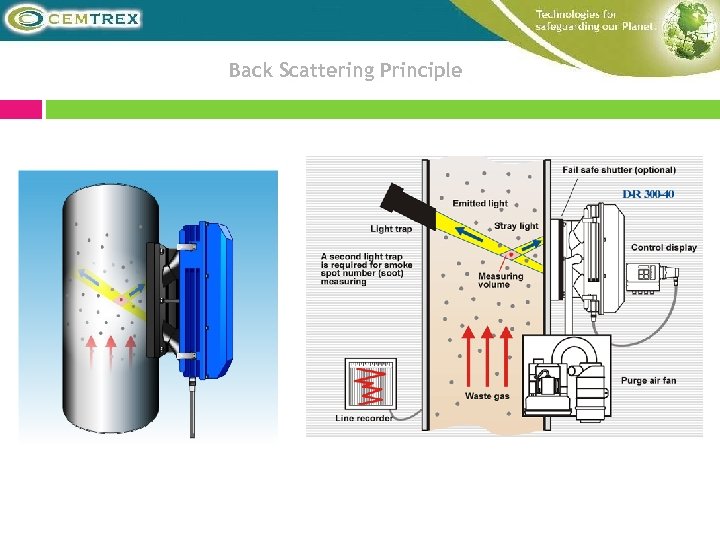

Back Scattering Principle

Back Scattering Principle

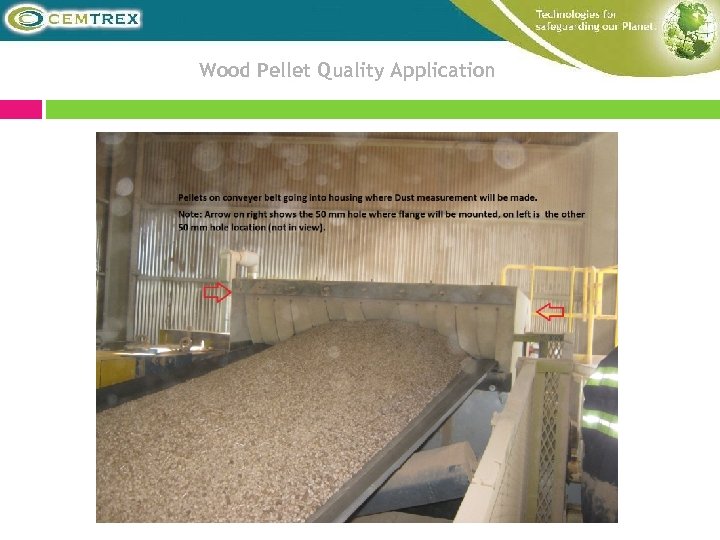

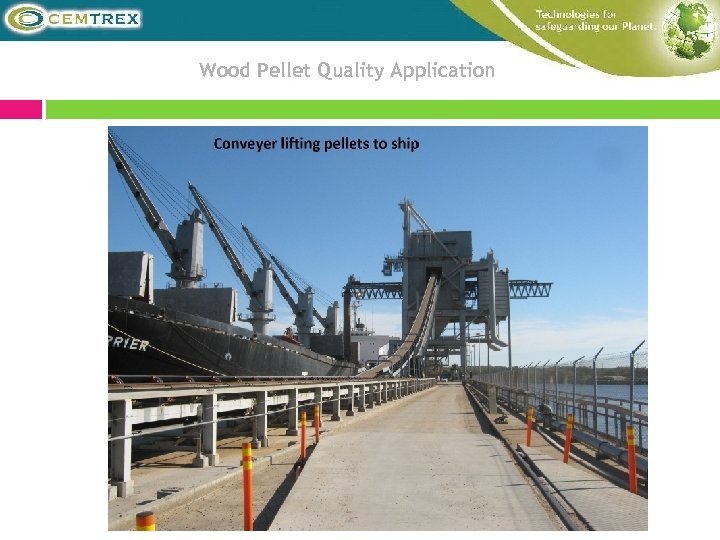

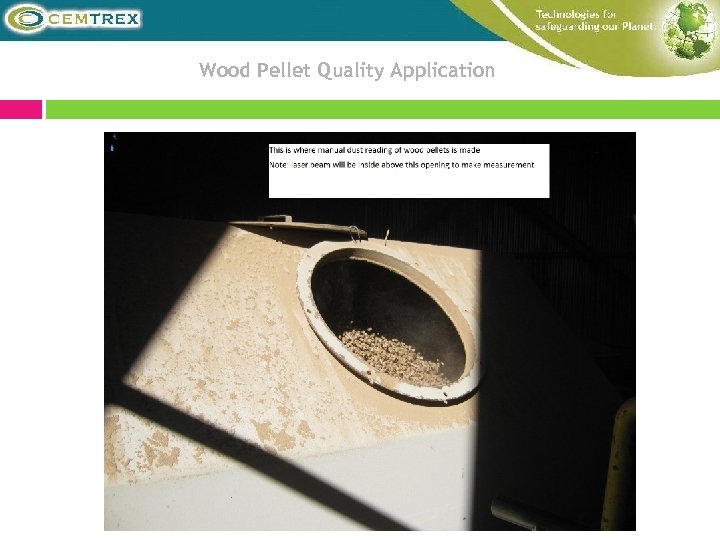

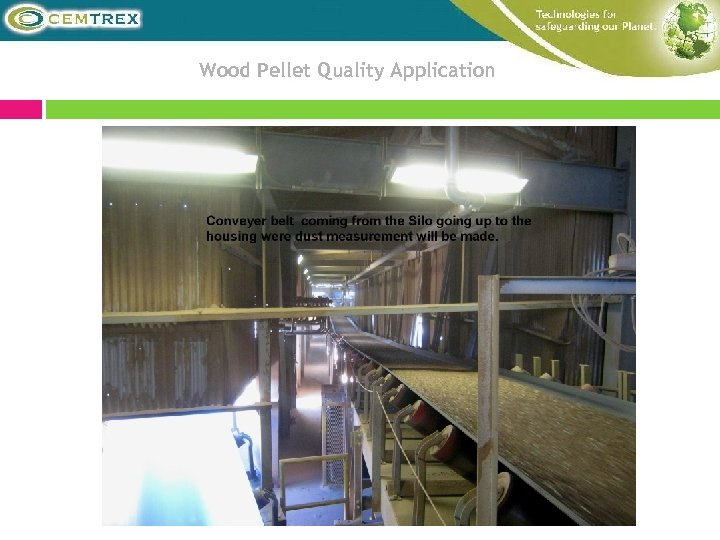

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

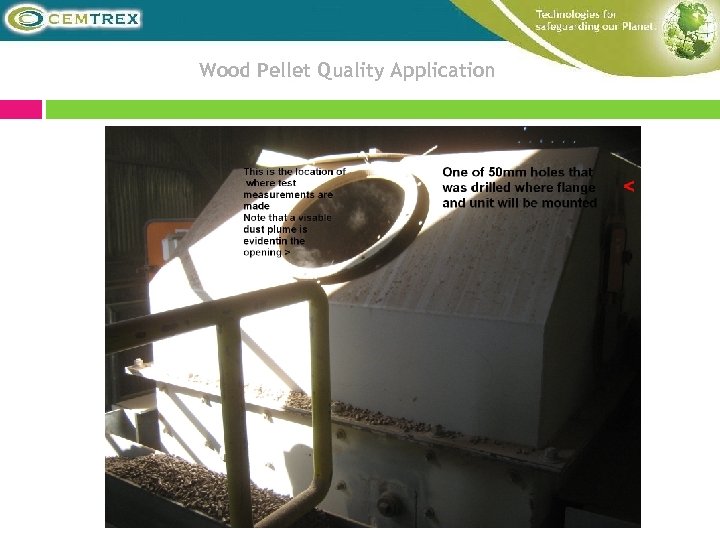

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

Wood Pellet Quality Application

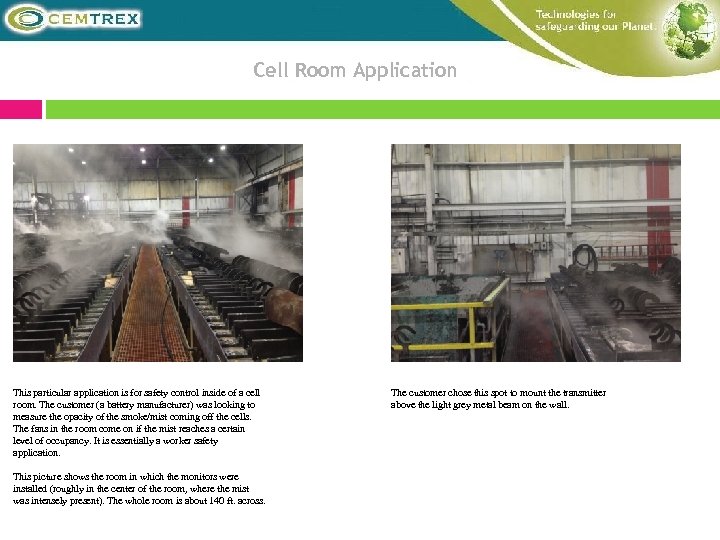

Cell Room Application This particular application is for safety control inside of a cell room. The customer (a battery manufacturer) was looking to measure the opacity of the smoke/mist coming off the cells. The fans in the room come on if the mist reaches a certain level of occupancy. It is essentially a worker safety application. This picture shows the room in which the monitors were installed (roughly in the center of the room, where the mist was intensely present). The whole room is about 140 ft. across. The customer chose this spot to mount the transmitter above the light grey metal beam on the wall.

Cell Room Application This particular application is for safety control inside of a cell room. The customer (a battery manufacturer) was looking to measure the opacity of the smoke/mist coming off the cells. The fans in the room come on if the mist reaches a certain level of occupancy. It is essentially a worker safety application. This picture shows the room in which the monitors were installed (roughly in the center of the room, where the mist was intensely present). The whole room is about 140 ft. across. The customer chose this spot to mount the transmitter above the light grey metal beam on the wall.

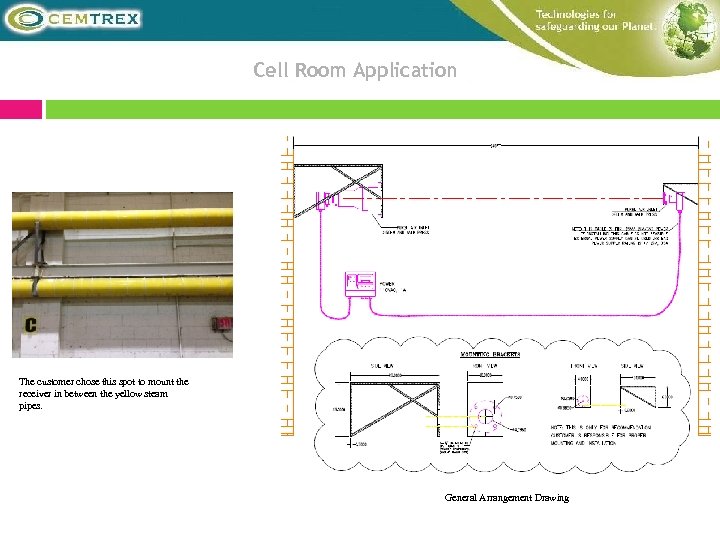

Cell Room Application The customer chose this spot to mount the receiver in between the yellow steam pipes. General Arrangement Drawing

Cell Room Application The customer chose this spot to mount the receiver in between the yellow steam pipes. General Arrangement Drawing