bd6633909f743ffde52b961a50a53173.ppt

- Количество слайдов: 29

Drug and Therapeutics Committee Session 5. Pharmaceutical Quality Assurance

Drug and Therapeutics Committee Session 5. Pharmaceutical Quality Assurance

Acknowledgment Material for this session is adapted from Chapter 18, “Quality Assurance for Drug Procurement, ” of Managing Drug Supply 2 nd ed. Management Sciences for Health and World Health Organization, 1997.

Acknowledgment Material for this session is adapted from Chapter 18, “Quality Assurance for Drug Procurement, ” of Managing Drug Supply 2 nd ed. Management Sciences for Health and World Health Organization, 1997.

Objectives § Define medicine quality § Understand how medicine quality is assessed § Understand how medicine quality is ensured § Describe the role of the DTC in pharmaceutical quality assurance

Objectives § Define medicine quality § Understand how medicine quality is assessed § Understand how medicine quality is ensured § Describe the role of the DTC in pharmaceutical quality assurance

Outline § § § Key definitions Introduction Determinants of medicine quality How is quality assessed? How is quality assured? Important pharmaceutical quality issues for the DTC § Implications for the DTC

Outline § § § Key definitions Introduction Determinants of medicine quality How is quality assessed? How is quality assured? Important pharmaceutical quality issues for the DTC § Implications for the DTC

Key Definitions (1) Pharmaceutical quality assurance (QA)—Sum of all activities and responsibilities required to ensure that the medicine that reaches the patient is safe, effective, and acceptable to the patient Pharmaceutical quality control—Process concerned with medicine sampling, specifications, and testing, and with the organization’s release procedures that ensure that the necessary tests are carried out and that the materials are not released for use, nor products released for sale or supply, until their quality has been judged satisfactory

Key Definitions (1) Pharmaceutical quality assurance (QA)—Sum of all activities and responsibilities required to ensure that the medicine that reaches the patient is safe, effective, and acceptable to the patient Pharmaceutical quality control—Process concerned with medicine sampling, specifications, and testing, and with the organization’s release procedures that ensure that the necessary tests are carried out and that the materials are not released for use, nor products released for sale or supply, until their quality has been judged satisfactory

Key Definitions (2) Good Manufacturing Practices (GMP)— Performance standards that WHO and many national governments established for pharmaceutical manufacturers covering, for example, personnel, facilities, packaging, and quality control. GMPs are part of the quality assurance activities that ensure that products are consistently produced and controlled to the quality standards appropriate to their intended use and required by the drug regulatory authorities.

Key Definitions (2) Good Manufacturing Practices (GMP)— Performance standards that WHO and many national governments established for pharmaceutical manufacturers covering, for example, personnel, facilities, packaging, and quality control. GMPs are part of the quality assurance activities that ensure that products are consistently produced and controlled to the quality standards appropriate to their intended use and required by the drug regulatory authorities.

Introduction: Goals of Medicine QA Programs § To make certain that each medicine reaching a patient is safe, effective, and of standard quality § Obtaining quality products that are safe and effective through structured selection and procurement methods § Maintaining quality products through the appropriate storage, distribution, monitoring, and use by prescribers, dispensers, and consumers

Introduction: Goals of Medicine QA Programs § To make certain that each medicine reaching a patient is safe, effective, and of standard quality § Obtaining quality products that are safe and effective through structured selection and procurement methods § Maintaining quality products through the appropriate storage, distribution, monitoring, and use by prescribers, dispensers, and consumers

Characteristics of a Comprehensive QA Program (1) § Medicines are selected on the basis of safety and efficacy, in an appropriate dosage form with the longest shelf life § Suppliers with acceptable quality standards are selected § Medicines received from suppliers and donors are monitored to meet quality standards § Medicine packaging meets contract specifications

Characteristics of a Comprehensive QA Program (1) § Medicines are selected on the basis of safety and efficacy, in an appropriate dosage form with the longest shelf life § Suppliers with acceptable quality standards are selected § Medicines received from suppliers and donors are monitored to meet quality standards § Medicine packaging meets contract specifications

Characteristics of a Comprehensive QA Program (2) § Repackaging activities and dispensing practices maintain quality § Adequate storage conditions in all pharmaceutical areas are maintained § Transportation conditions are adequate § Product quality concerns are reported and monitored

Characteristics of a Comprehensive QA Program (2) § Repackaging activities and dispensing practices maintain quality § Adequate storage conditions in all pharmaceutical areas are maintained § Transportation conditions are adequate § Product quality concerns are reported and monitored

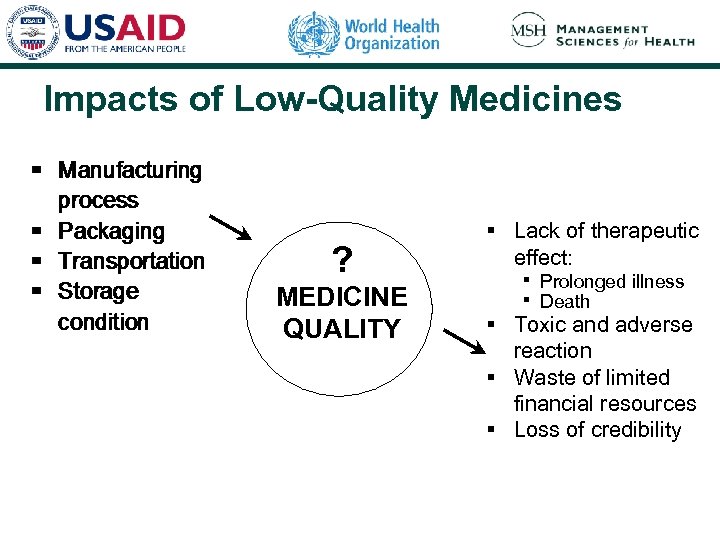

Impacts of Low-Quality Medicines ? MEDICINE QUALITY § Lack of therapeutic effect: § Prolonged illness § Death § Toxic and adverse reaction § Waste of limited financial resources § Loss of credibility

Impacts of Low-Quality Medicines ? MEDICINE QUALITY § Lack of therapeutic effect: § Prolonged illness § Death § Toxic and adverse reaction § Waste of limited financial resources § Loss of credibility

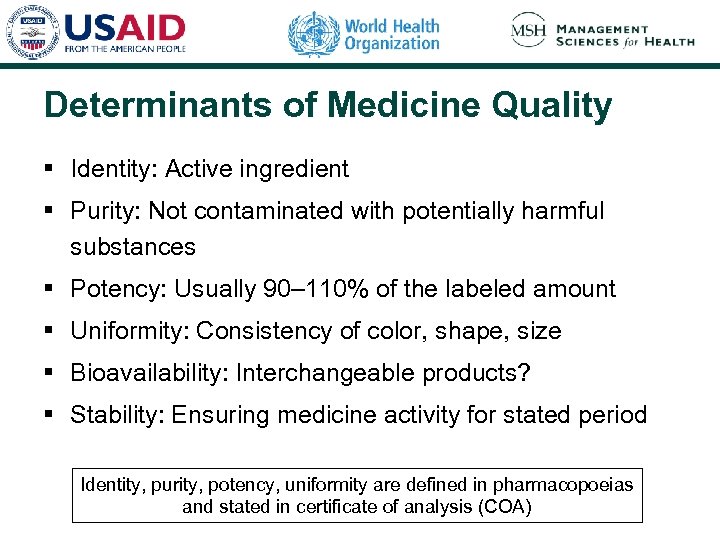

Determinants of Medicine Quality § Identity: Active ingredient § Purity: Not contaminated with potentially harmful substances § Potency: Usually 90– 110% of the labeled amount § Uniformity: Consistency of color, shape, size § Bioavailability: Interchangeable products? § Stability: Ensuring medicine activity for stated period Identity, purity, potency, uniformity are defined in pharmacopoeias and stated in certificate of analysis (COA)

Determinants of Medicine Quality § Identity: Active ingredient § Purity: Not contaminated with potentially harmful substances § Potency: Usually 90– 110% of the labeled amount § Uniformity: Consistency of color, shape, size § Bioavailability: Interchangeable products? § Stability: Ensuring medicine activity for stated period Identity, purity, potency, uniformity are defined in pharmacopoeias and stated in certificate of analysis (COA)

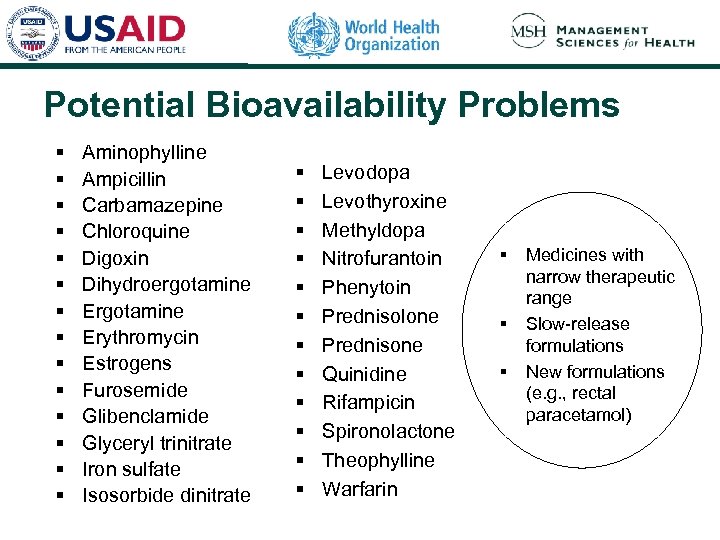

Potential Bioavailability Problems § § § § Aminophylline Ampicillin Carbamazepine Chloroquine Digoxin Dihydroergotamine Erythromycin Estrogens Furosemide Glibenclamide Glyceryl trinitrate Iron sulfate Isosorbide dinitrate § § § Levodopa Levothyroxine Methyldopa Nitrofurantoin Phenytoin Prednisolone Prednisone Quinidine Rifampicin Spironolactone Theophylline Warfarin § § § Medicines with narrow therapeutic range Slow-release formulations New formulations (e. g. , rectal paracetamol)

Potential Bioavailability Problems § § § § Aminophylline Ampicillin Carbamazepine Chloroquine Digoxin Dihydroergotamine Erythromycin Estrogens Furosemide Glibenclamide Glyceryl trinitrate Iron sulfate Isosorbide dinitrate § § § Levodopa Levothyroxine Methyldopa Nitrofurantoin Phenytoin Prednisolone Prednisone Quinidine Rifampicin Spironolactone Theophylline Warfarin § § § Medicines with narrow therapeutic range Slow-release formulations New formulations (e. g. , rectal paracetamol)

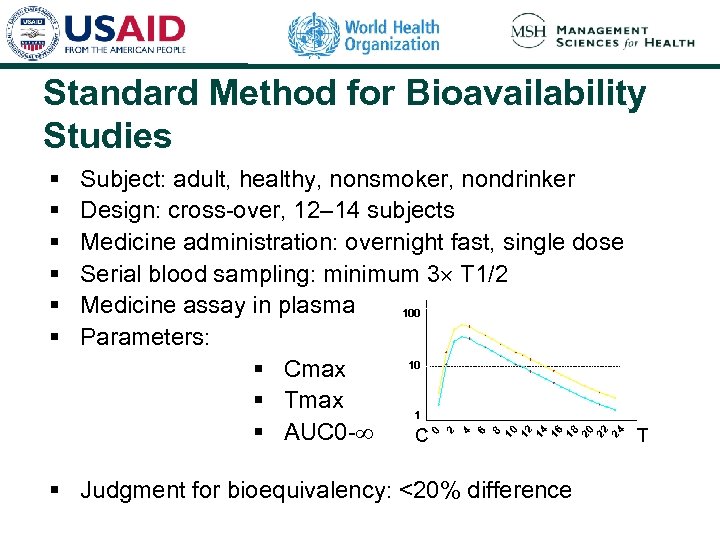

Standard Method for Bioavailability Studies Subject: adult, healthy, nonsmoker, nondrinker Design: cross-over, 12– 14 subjects Medicine administration: overnight fast, single dose Serial blood sampling: minimum 3 T 1/2 Medicine assay in plasma 100 Parameters: 10 § Cmax § Tmax 1 § AUC 0 - C 0 2 4 6 8 10 12 14 16 18 20 22 24 § § § § Judgment for bioequivalency: <20% difference T

Standard Method for Bioavailability Studies Subject: adult, healthy, nonsmoker, nondrinker Design: cross-over, 12– 14 subjects Medicine administration: overnight fast, single dose Serial blood sampling: minimum 3 T 1/2 Medicine assay in plasma 100 Parameters: 10 § Cmax § Tmax 1 § AUC 0 - C 0 2 4 6 8 10 12 14 16 18 20 22 24 § § § § Judgment for bioequivalency: <20% difference T

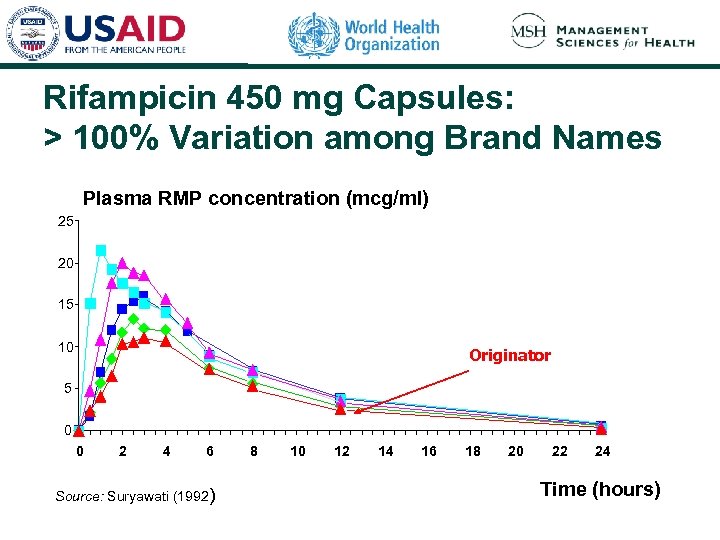

Rifampicin 450 mg Capsules: > 100% Variation among Brand Names Plasma RMP concentration (mcg/ml) 25 20 15 10 Originator 5 0 0 2 4 6 Source: Suryawati (1992) 8 10 12 14 16 18 20 22 24 Time (hours)

Rifampicin 450 mg Capsules: > 100% Variation among Brand Names Plasma RMP concentration (mcg/ml) 25 20 15 10 Originator 5 0 0 2 4 6 Source: Suryawati (1992) 8 10 12 14 16 18 20 22 24 Time (hours)

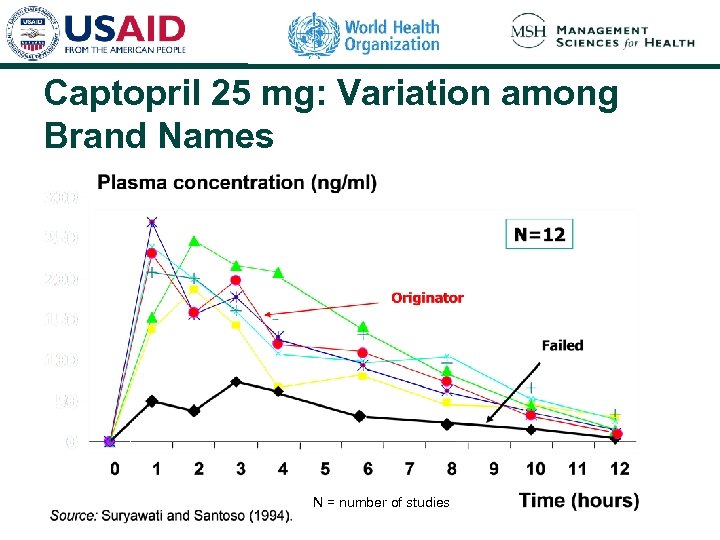

Captopril 25 mg: Variation among Brand Names N = number of studies

Captopril 25 mg: Variation among Brand Names N = number of studies

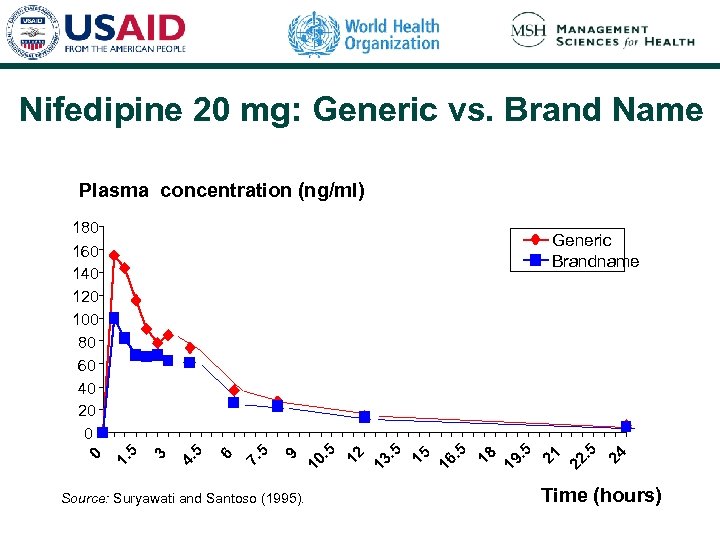

Nifedipine 20 mg: Generic vs. Brand Name Plasma concentration (ng/ml) Source: Suryawati and Santoso (1995). 24 . 5 22 21 . 5 19 18 . 5 16 15 . 5 13 12 . 5 10 9 5 7. 6 5 4. 3 5 Generic Brandname 1. 0 180 160 140 120 100 80 60 40 20 0 Time (hours)

Nifedipine 20 mg: Generic vs. Brand Name Plasma concentration (ng/ml) Source: Suryawati and Santoso (1995). 24 . 5 22 21 . 5 19 18 . 5 16 15 . 5 13 12 . 5 10 9 5 7. 6 5 4. 3 5 Generic Brandname 1. 0 180 160 140 120 100 80 60 40 20 0 Time (hours)

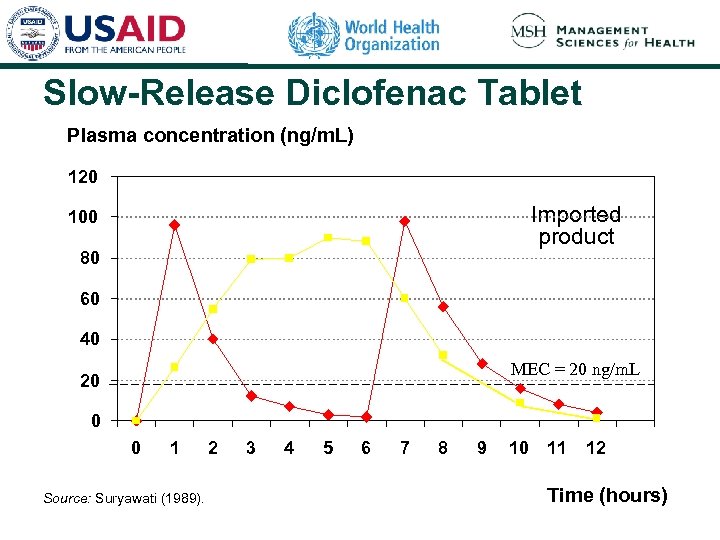

Slow-Release Diclofenac Tablet Plasma concentration (ng/m. L) 120 Imported product 100 80 60 40 MEC = 20 ng/m. L 20 0 0 1 Source: Suryawati (1989). 2 3 4 5 6 7 8 9 10 11 12 Time (hours)

Slow-Release Diclofenac Tablet Plasma concentration (ng/m. L) 120 Imported product 100 80 60 40 MEC = 20 ng/m. L 20 0 0 1 Source: Suryawati (1989). 2 3 4 5 6 7 8 9 10 11 12 Time (hours)

Medicines with a Stability Problem § Tablets: § Acetylsalicylic acid § Amoxicillin § Ampicillin § Penicillin V § Retinol § Oral liquids: § Paracetamol § Injectable: § Ergometrine § Methylergometrine § Select the most stable formulation with adequate packaging

Medicines with a Stability Problem § Tablets: § Acetylsalicylic acid § Amoxicillin § Ampicillin § Penicillin V § Retinol § Oral liquids: § Paracetamol § Injectable: § Ergometrine § Methylergometrine § Select the most stable formulation with adequate packaging

How Is Quality Assessed? § INSPECTION of products on arrival § § § 1 LABORATORY TESTING for compliance with pharmacopoeial standards § § § Visual inspection Product specification review (including expiration dates) International Pharmacopoeia European Pharmacopoeia U. S. Pharmacopeia 3 British Pharmacopoeia National Pharmacopoeia BIOAVAILABILITY DATA COA 2

How Is Quality Assessed? § INSPECTION of products on arrival § § § 1 LABORATORY TESTING for compliance with pharmacopoeial standards § § § Visual inspection Product specification review (including expiration dates) International Pharmacopoeia European Pharmacopoeia U. S. Pharmacopeia 3 British Pharmacopoeia National Pharmacopoeia BIOAVAILABILITY DATA COA 2

How Is Medicine Quality Assured? (1) § Product selection § Long shelf-life § Acceptable stability § Acceptable bioavailability § Selection of appropriate suppliers § Supplier pre-qualification § Request samples from new suppliers § Request specific reports and data for certain medicines (e. g. , bioavailability and stability studies) § Collect and maintain information on supplier performance § Product certification § GMP certificate of manufacturer § Product/batch certification (COA) § Random local testing

How Is Medicine Quality Assured? (1) § Product selection § Long shelf-life § Acceptable stability § Acceptable bioavailability § Selection of appropriate suppliers § Supplier pre-qualification § Request samples from new suppliers § Request specific reports and data for certain medicines (e. g. , bioavailability and stability studies) § Collect and maintain information on supplier performance § Product certification § GMP certificate of manufacturer § Product/batch certification (COA) § Random local testing

How Is Medicine Quality Assured? (2) § Contract and procurement specifications § Pharmacopeia reference standard § Local language for product label § Standards for packaging to meet specific storage and transport conditions

How Is Medicine Quality Assured? (2) § Contract and procurement specifications § Pharmacopeia reference standard § Local language for product label § Standards for packaging to meet specific storage and transport conditions

How Is Medicine Quality Assured? (3) § Appropriate storage, transport, dispensing, and use procedures § Pharmaceutical distribution and inventory control procedures § Provision for appropriate storage and transport including adequate temperature control, security, and cleanliness § Explicit enforcement of cold chain procedures § Appropriate dispensing: containers, labeling, counseling § Avoidance of repacking unless quality control in place

How Is Medicine Quality Assured? (3) § Appropriate storage, transport, dispensing, and use procedures § Pharmaceutical distribution and inventory control procedures § Provision for appropriate storage and transport including adequate temperature control, security, and cleanliness § Explicit enforcement of cold chain procedures § Appropriate dispensing: containers, labeling, counseling § Avoidance of repacking unless quality control in place

How Is Medicine Quality Assured? (4) § Product monitoring system § Problem reporting: who, how, where, and to whom; what additional measures; what follow-up information § Product recalls: hospital or country level

How Is Medicine Quality Assured? (4) § Product monitoring system § Problem reporting: who, how, where, and to whom; what additional measures; what follow-up information § Product recalls: hospital or country level

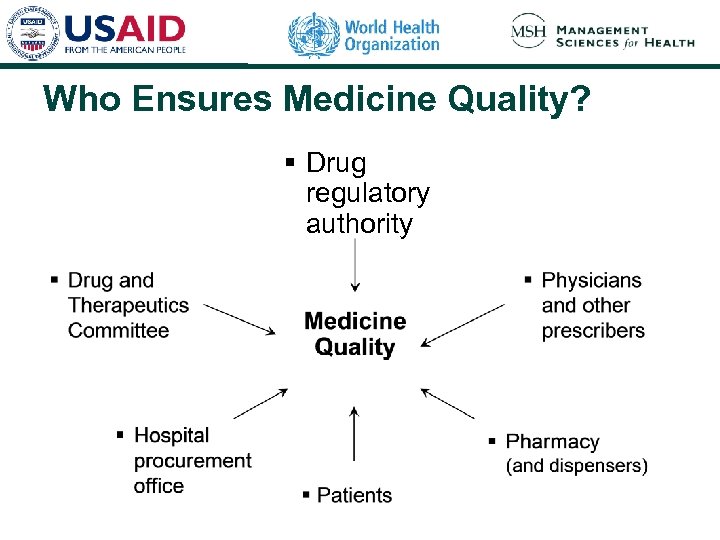

Who Ensures Medicine Quality? § Drug regulatory authority

Who Ensures Medicine Quality? § Drug regulatory authority

Implications of Pharmaceutical QA for the DTC § Providing technical advice on procurement of pharmaceuticals § Defining product specifications § Generic medicines § Bioavailability issues § Stability issues § Defining minimum laboratory testing § Providing technical advice to hospital departments § Medicine transportation and storage § Dispensing § Analyzing product problem reports § Quality complaints § Medicine recall system

Implications of Pharmaceutical QA for the DTC § Providing technical advice on procurement of pharmaceuticals § Defining product specifications § Generic medicines § Bioavailability issues § Stability issues § Defining minimum laboratory testing § Providing technical advice to hospital departments § Medicine transportation and storage § Dispensing § Analyzing product problem reports § Quality complaints § Medicine recall system

Activity (30 minutes) § Pharmaceutical quality assurance issues and concerns on— § § § Obtaining quality products Maintaining quality products Examples of poor quality at hospital level § Discussion § § § Are you satisfied with the quality of medicines you receive? Is quality maintained throughout your distribution network? Are there complaints of poor quality by patients or health workers? Is there a formal mechanism for reporting and investigating complaints? What role do you see for the DTC in improving and maintaining quality in your health care system?

Activity (30 minutes) § Pharmaceutical quality assurance issues and concerns on— § § § Obtaining quality products Maintaining quality products Examples of poor quality at hospital level § Discussion § § § Are you satisfied with the quality of medicines you receive? Is quality maintained throughout your distribution network? Are there complaints of poor quality by patients or health workers? Is there a formal mechanism for reporting and investigating complaints? What role do you see for the DTC in improving and maintaining quality in your health care system?

Summary (1) § Ensuring quality of a product from selection to use— § Obtaining quality products that are safe and effective through structured selection and procurement methods § Maintaining quality products through appropriate storage, distribution, monitoring, and use methods

Summary (1) § Ensuring quality of a product from selection to use— § Obtaining quality products that are safe and effective through structured selection and procurement methods § Maintaining quality products through appropriate storage, distribution, monitoring, and use methods

Summary (2) § Assessing quality includes— § Inspection of medicines § Laboratory testing when necessary

Summary (2) § Assessing quality includes— § Inspection of medicines § Laboratory testing when necessary

Summary (3) § Assuring quality includes— § Selection of medicines, dosage forms, and packaging § Use of prequalified suppliers § Product certification § Preparation and enforcement of quality-related contract specification § Appropriate storage, transport, dispensing, and use § Product monitoring systems

Summary (3) § Assuring quality includes— § Selection of medicines, dosage forms, and packaging § Use of prequalified suppliers § Product certification § Preparation and enforcement of quality-related contract specification § Appropriate storage, transport, dispensing, and use § Product monitoring systems