d3bf2fa19182e6ecd168d0cd6ffcc9f6.ppt

- Количество слайдов: 55

Driver Product & Safety Training MDI / TDI Bulk Liquid Transportation 1 ISOPA Driver Training Program Revision 2017

Driver Product & Safety Training MDI / TDI Bulk Liquid Transportation 1 ISOPA Driver Training Program Revision 2017

![Driver Training MDI / TDI Company Location [place] Date 3/18/2018 Trainer 2 [name] ISOPA Driver Training MDI / TDI Company Location [place] Date 3/18/2018 Trainer 2 [name] ISOPA](https://present5.com/presentation/d3bf2fa19182e6ecd168d0cd6ffcc9f6/image-2.jpg) Driver Training MDI / TDI Company Location [place] Date 3/18/2018 Trainer 2 [name] ISOPA Driver Training Program Revision 2017

Driver Training MDI / TDI Company Location [place] Date 3/18/2018 Trainer 2 [name] ISOPA Driver Training Program Revision 2017

Background This programme helps in the safe transport of these chemicals by ensuring proper training of drivers The training package is a joint effort of ISOPA and the carriers based on practical experience. 3 MDI / TDI can be handled safely and are in widespread use across the world. Drivers who successfully complete the driver training are issued with a MDI / TDI Driver Training Card ISOPA Driver Training Program Revision 2017

Background This programme helps in the safe transport of these chemicals by ensuring proper training of drivers The training package is a joint effort of ISOPA and the carriers based on practical experience. 3 MDI / TDI can be handled safely and are in widespread use across the world. Drivers who successfully complete the driver training are issued with a MDI / TDI Driver Training Card ISOPA Driver Training Program Revision 2017

Introduction ISOPA European ISOcyanate P olyo roducers Association See website www. isopa. org Member companies: 4 ISOPA Driver Training Program Revision 2017

Introduction ISOPA European ISOcyanate P olyo roducers Association See website www. isopa. org Member companies: 4 ISOPA Driver Training Program Revision 2017

ISOPA Member Companies 5 ISOPA Driver Training Program Revision 2017

ISOPA Member Companies 5 ISOPA Driver Training Program Revision 2017

Applications Polyurethanes are used in many products and articles: 6 Car seats, Steering wheels Sports shoes Sofas, Chairs and Mattresses Fibre board (MDF) Expansion joints & Gasket seals Insulation foam (refrigerators, tanks, buildings) Coatings, Paints. . . and many more ISOPA Driver Training Program Revision 2017

Applications Polyurethanes are used in many products and articles: 6 Car seats, Steering wheels Sports shoes Sofas, Chairs and Mattresses Fibre board (MDF) Expansion joints & Gasket seals Insulation foam (refrigerators, tanks, buildings) Coatings, Paints. . . and many more ISOPA Driver Training Program Revision 2017

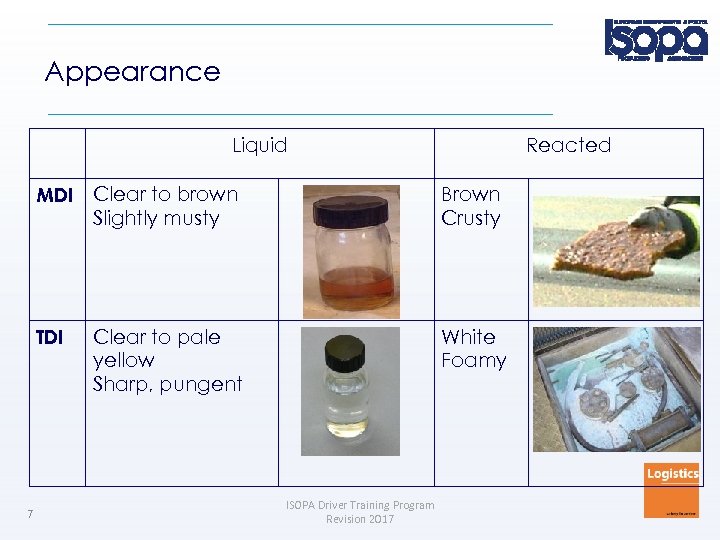

Appearance Liquid Reacted MDI Clear to brown Slightly musty TDI 7 Brown Crusty White Foamy Clear to pale yellow Sharp, pungent ISOPA Driver Training Program Revision 2017

Appearance Liquid Reacted MDI Clear to brown Slightly musty TDI 7 Brown Crusty White Foamy Clear to pale yellow Sharp, pungent ISOPA Driver Training Program Revision 2017

MAC Maximum Allowable Concentration MAC: 5. 0 – 10. 0 ppb Odour threshold : 0. 2 – 0. 4 ppm Therefore: When you smell it, it’s above the limit ! No used PPE in the cabin 8 ISOPA Driver Training Program Revision 2017

MAC Maximum Allowable Concentration MAC: 5. 0 – 10. 0 ppb Odour threshold : 0. 2 – 0. 4 ppm Therefore: When you smell it, it’s above the limit ! No used PPE in the cabin 8 ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (1) Vapour pressure: Dangers of MDI and TDI are of the same magnitude but… vapour pressure of TDI is much higher (20 x), therefore the RISKS of TDI are much bigger Vapour density = 6× Air density i. e. the vapours are heavier than air! 9 ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (1) Vapour pressure: Dangers of MDI and TDI are of the same magnitude but… vapour pressure of TDI is much higher (20 x), therefore the RISKS of TDI are much bigger Vapour density = 6× Air density i. e. the vapours are heavier than air! 9 ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (2) Density range 1. 20 – 1. 29 (For TDI filling degree conform ADR see next slide) Important temperatures (TDI): • Crystallization starts at ± 15°C (product temp. ) • Melting when reheated to ± 45°C (product temp. ) 10 ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (2) Density range 1. 20 – 1. 29 (For TDI filling degree conform ADR see next slide) Important temperatures (TDI): • Crystallization starts at ± 15°C (product temp. ) • Melting when reheated to ± 45°C (product temp. ) 10 ISOPA Driver Training Program Revision 2017

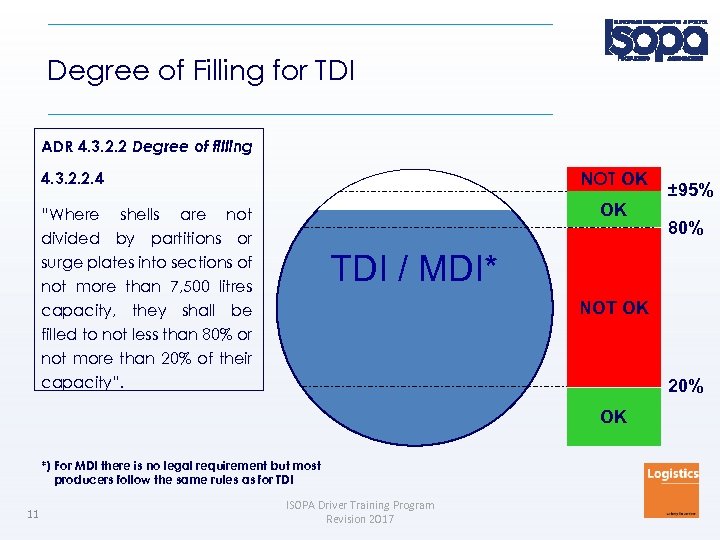

Degree of Filling for TDI ADR 4. 3. 2. 2 Degree of filling NOT OK 4. 3. 2. 2. 4 OK “Where shells are not divided by partitions or surge plates into sections of not more than 7, 500 litres capacity, they shall be filled to not less than 80% or not more than 20% of their capacity”. 80% TDI / MDI* NOT OK 20% OK *) For MDI there is no legal requirement but most producers follow the same rules as for TDI 11 ± 95% ISOPA Driver Training Program Revision 2017

Degree of Filling for TDI ADR 4. 3. 2. 2 Degree of filling NOT OK 4. 3. 2. 2. 4 OK “Where shells are not divided by partitions or surge plates into sections of not more than 7, 500 litres capacity, they shall be filled to not less than 80% or not more than 20% of their capacity”. 80% TDI / MDI* NOT OK 20% OK *) For MDI there is no legal requirement but most producers follow the same rules as for TDI 11 ± 95% ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (3) MDI / TDI reacts with water (including air!) 12 Temperature and pressure (CO 2 release) goes up significantly in transit without external heating Possible water sources can be: • Tank cleaning operations • Opening manlids – for: sampling, discharge etc. – by: customs, customers, drivers etc. • Non-dried air from customer’s installation • Silica gel filter malfunction ISOPA Driver Training Program Revision 2017

Main Physical and Chemical Properties (3) MDI / TDI reacts with water (including air!) 12 Temperature and pressure (CO 2 release) goes up significantly in transit without external heating Possible water sources can be: • Tank cleaning operations • Opening manlids – for: sampling, discharge etc. – by: customs, customers, drivers etc. • Non-dried air from customer’s installation • Silica gel filter malfunction ISOPA Driver Training Program Revision 2017

Effect of MDI/TDI on your Health Short term / one-off exposure above safe level - Do hid not tr ep y rob to lem s Irritates mouth, throat, lungs Tight chest, coughing Difficulty in breathing Eyes watering Itching, red skin (immediately or delayed) See May be hot or burn ! km edi imm cal a Symptoms can occur up to 24 hrs ssist edi anc ate after exposure ly ! e 13 ISOPA Driver Training Program Revision 2017

Effect of MDI/TDI on your Health Short term / one-off exposure above safe level - Do hid not tr ep y rob to lem s Irritates mouth, throat, lungs Tight chest, coughing Difficulty in breathing Eyes watering Itching, red skin (immediately or delayed) See May be hot or burn ! km edi imm cal a Symptoms can occur up to 24 hrs ssist edi anc ate after exposure ly ! e 13 ISOPA Driver Training Program Revision 2017

Effect of MDI/TDI on your Health Long term/repeated over- exposure from breathing or skin contact leads to risk of sensitisation Symptoms such as occasional breathing difficulties similar to asthma, hay fever, sneezing When sensitised, potentially severe asthma in the case of even low MDI/TDI exposure Sensitisation could prevent working with diisocyanates for life; early and prompt removal from exposure can typically result in cessation of allergic responses Sensitisation is non-reversible and is a reaction of the immune system. Not to be confused with irritation 14 ISOPA Driver Training Program Revision 2017

Effect of MDI/TDI on your Health Long term/repeated over- exposure from breathing or skin contact leads to risk of sensitisation Symptoms such as occasional breathing difficulties similar to asthma, hay fever, sneezing When sensitised, potentially severe asthma in the case of even low MDI/TDI exposure Sensitisation could prevent working with diisocyanates for life; early and prompt removal from exposure can typically result in cessation of allergic responses Sensitisation is non-reversible and is a reaction of the immune system. Not to be confused with irritation 14 ISOPA Driver Training Program Revision 2017

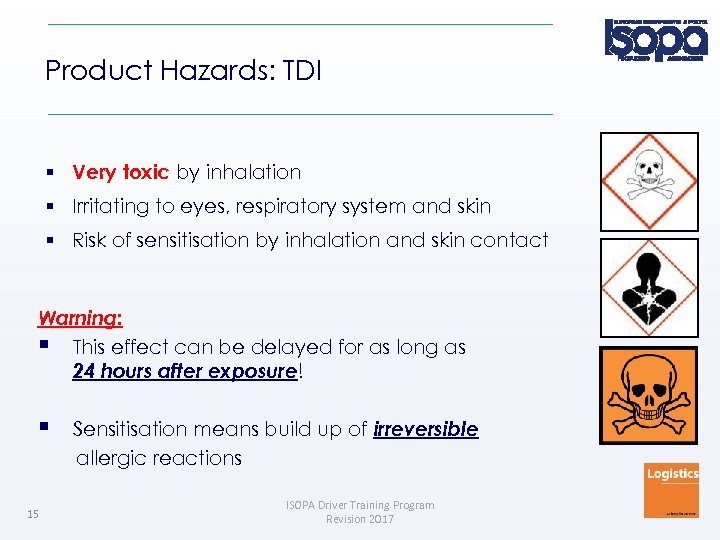

Product Hazards: TDI Very toxic by inhalation Irritating to eyes, respiratory system and skin Risk of sensitisation by inhalation and skin contact Warning: This effect can be delayed for as long as 24 hours after exposure! 15 Sensitisation means build up of irreversible allergic reactions ISOPA Driver Training Program Revision 2017

Product Hazards: TDI Very toxic by inhalation Irritating to eyes, respiratory system and skin Risk of sensitisation by inhalation and skin contact Warning: This effect can be delayed for as long as 24 hours after exposure! 15 Sensitisation means build up of irreversible allergic reactions ISOPA Driver Training Program Revision 2017

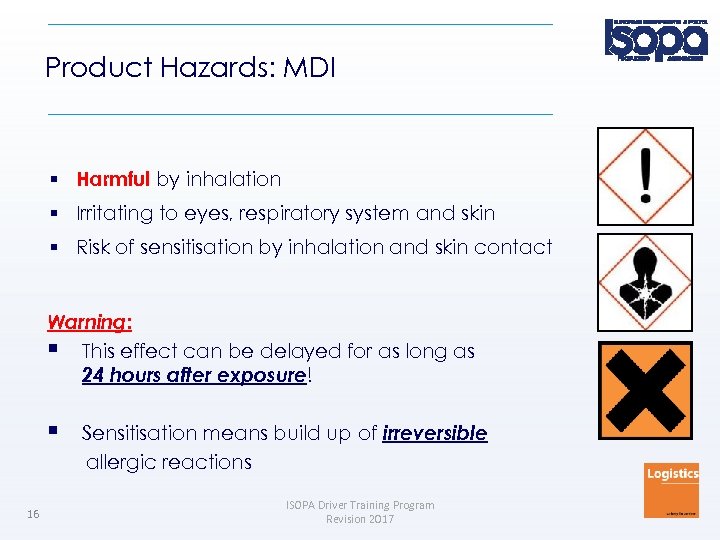

Product Hazards: MDI Harmful by inhalation Irritating to eyes, respiratory system and skin Risk of sensitisation by inhalation and skin contact Warning: This effect can be delayed for as long as 24 hours after exposure! 16 Sensitisation means build up of irreversible allergic reactions ISOPA Driver Training Program Revision 2017

Product Hazards: MDI Harmful by inhalation Irritating to eyes, respiratory system and skin Risk of sensitisation by inhalation and skin contact Warning: This effect can be delayed for as long as 24 hours after exposure! 16 Sensitisation means build up of irreversible allergic reactions ISOPA Driver Training Program Revision 2017

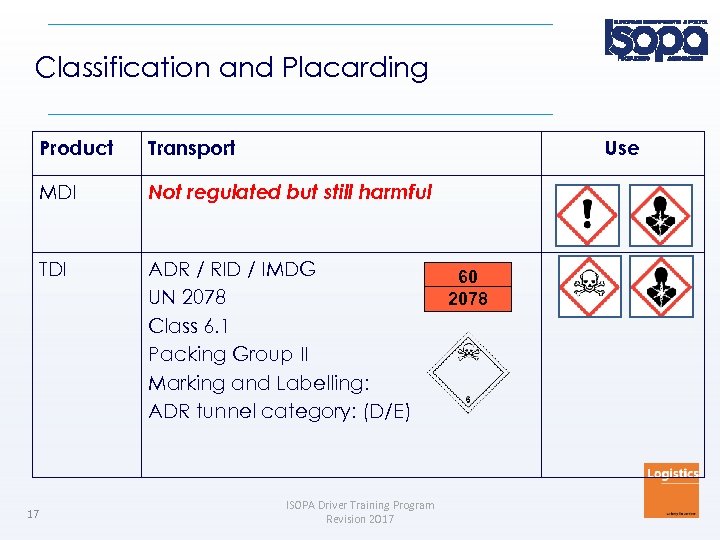

Classification and Placarding Product MDI Not regulated but still harmful TDI 17 Transport Use ADR / RID / IMDG UN 2078 Class 6. 1 Packing Group II Marking and Labelling: ADR tunnel category: (D/E) ISOPA Driver Training Program Revision 2017 60 2078

Classification and Placarding Product MDI Not regulated but still harmful TDI 17 Transport Use ADR / RID / IMDG UN 2078 Class 6. 1 Packing Group II Marking and Labelling: ADR tunnel category: (D/E) ISOPA Driver Training Program Revision 2017 60 2078

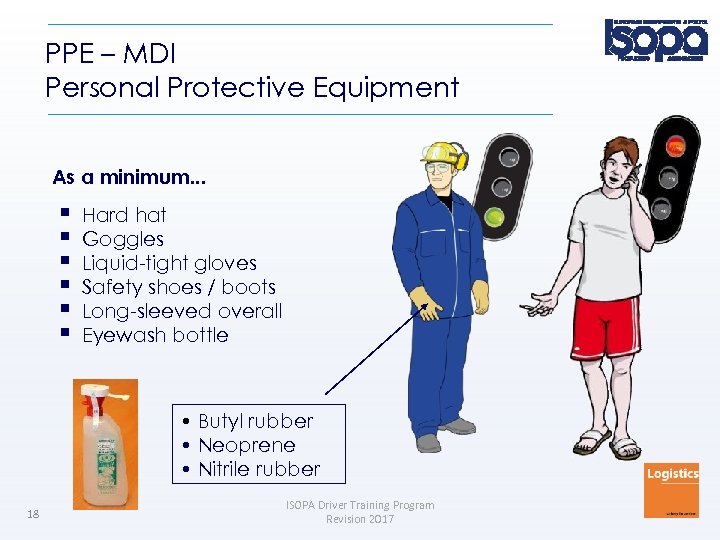

PPE – MDI Personal Protective Equipment As a minimum. . . Hard hat Goggles Liquid-tight gloves Safety shoes / boots Long-sleeved overall Eyewash bottle • Butyl rubber • Neoprene • Nitrile rubber 18 ISOPA Driver Training Program Revision 2017

PPE – MDI Personal Protective Equipment As a minimum. . . Hard hat Goggles Liquid-tight gloves Safety shoes / boots Long-sleeved overall Eyewash bottle • Butyl rubber • Neoprene • Nitrile rubber 18 ISOPA Driver Training Program Revision 2017

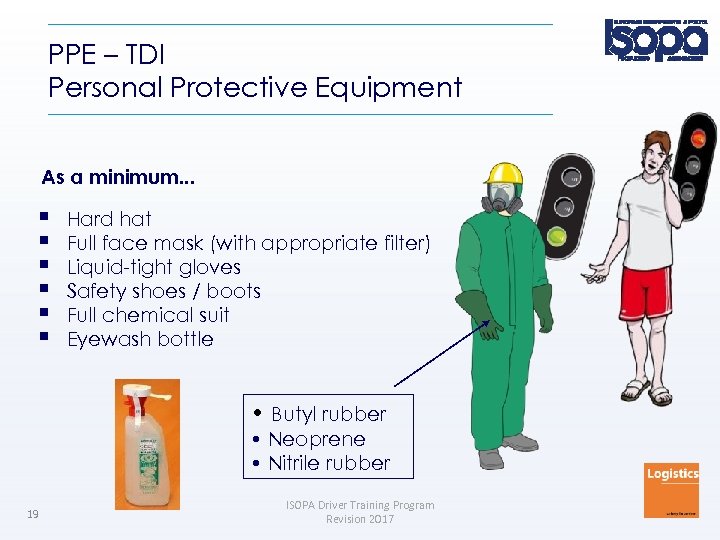

PPE – TDI Personal Protective Equipment As a minimum. . . Hard hat Full face mask (with appropriate filter) Liquid-tight gloves Safety shoes / boots Full chemical suit Eyewash bottle • Butyl rubber • Neoprene • Nitrile rubber 19 ISOPA Driver Training Program Revision 2017

PPE – TDI Personal Protective Equipment As a minimum. . . Hard hat Full face mask (with appropriate filter) Liquid-tight gloves Safety shoes / boots Full chemical suit Eyewash bottle • Butyl rubber • Neoprene • Nitrile rubber 19 ISOPA Driver Training Program Revision 2017

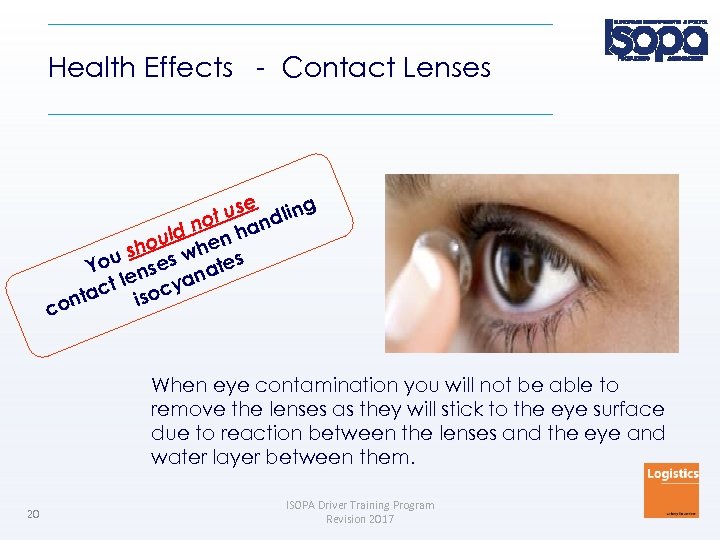

Health Effects - Contact Lenses e g t us ndlin o n a uld en h sho s wh s You nse nate e ct l socya a i ont c When eye contamination you will not be able to remove the lenses as they will stick to the eye surface due to reaction between the lenses and the eye and water layer between them. 20 ISOPA Driver Training Program Revision 2017

Health Effects - Contact Lenses e g t us ndlin o n a uld en h sho s wh s You nse nate e ct l socya a i ont c When eye contamination you will not be able to remove the lenses as they will stick to the eye surface due to reaction between the lenses and the eye and water layer between them. 20 ISOPA Driver Training Program Revision 2017

Personal Health (1) Use an appropriate cartridge / canister (min. AP 2) For normal use, once opened, use max 8 hours within any 48 hours time span After any spill change the cartridge Face mask should not be used for Emergency Response 21 ISOPA Driver Training Program Revision 2017

Personal Health (1) Use an appropriate cartridge / canister (min. AP 2) For normal use, once opened, use max 8 hours within any 48 hours time span After any spill change the cartridge Face mask should not be used for Emergency Response 21 ISOPA Driver Training Program Revision 2017

Personal Health (2) Wash hands (& face) before eating, drinking, smoking or going to the toilet Keep contaminated PPE out of the cabin • A quantity of vapor equal to the size of a one Eurocent coin is enough to increase the concentration in the average cabin well above the MAC value • Imagine working / sleeping in this atmosphere for 8 hours ! 22 ISOPA Driver Training Program Revision 2017

Personal Health (2) Wash hands (& face) before eating, drinking, smoking or going to the toilet Keep contaminated PPE out of the cabin • A quantity of vapor equal to the size of a one Eurocent coin is enough to increase the concentration in the average cabin well above the MAC value • Imagine working / sleeping in this atmosphere for 8 hours ! 22 ISOPA Driver Training Program Revision 2017

Product Quality Control Samples (Not recommended) • Co. A is strongly preferred to a sample • Drivers should not take samples ! • Never take a sample in your cab !!! Not even for 1 minute !!! 23 Certificate of Analysis (Co. A) Temperature (Customer specific) ISOPA Driver Training Program Revision 2017

Product Quality Control Samples (Not recommended) • Co. A is strongly preferred to a sample • Drivers should not take samples ! • Never take a sample in your cab !!! Not even for 1 minute !!! 23 Certificate of Analysis (Co. A) Temperature (Customer specific) ISOPA Driver Training Program Revision 2017

Site Safety Make yourself familiar with the site emergency policy and location of following items: 24 Signs & Alarms Wind direction indicator Emergency stop button Emergency shower Assembly point Waste bin (for used gaskets, gloves, etc. ) Decontamination & Absorption material ISOPA Driver Training Program Revision 2017

Site Safety Make yourself familiar with the site emergency policy and location of following items: 24 Signs & Alarms Wind direction indicator Emergency stop button Emergency shower Assembly point Waste bin (for used gaskets, gloves, etc. ) Decontamination & Absorption material ISOPA Driver Training Program Revision 2017

Spill Handling (by Emergency Services) Always wear PPE !! Drivers should observe from a safe distance and remain available to provide information Emergency services should: 1. Cover sewer system 2. Absorb the spill 3. Wait (15 minutes) 4. Neutralise 5. Wait (30– 60 minutes after reaction has finished) 6. Remove spill after reaction has finished. 7. Put residues in designated chemicals waste bin 8. Apply decontamination fluid 25 ISOPA Driver Training Program Revision 2017

Spill Handling (by Emergency Services) Always wear PPE !! Drivers should observe from a safe distance and remain available to provide information Emergency services should: 1. Cover sewer system 2. Absorb the spill 3. Wait (15 minutes) 4. Neutralise 5. Wait (30– 60 minutes after reaction has finished) 6. Remove spill after reaction has finished. 7. Put residues in designated chemicals waste bin 8. Apply decontamination fluid 25 ISOPA Driver Training Program Revision 2017

Loading: Key Items Tank equipment 26 PPE must be worn 3 -Minutes check before & after loading ISOPA Driver Training Program Revision 2017

Loading: Key Items Tank equipment 26 PPE must be worn 3 -Minutes check before & after loading ISOPA Driver Training Program Revision 2017

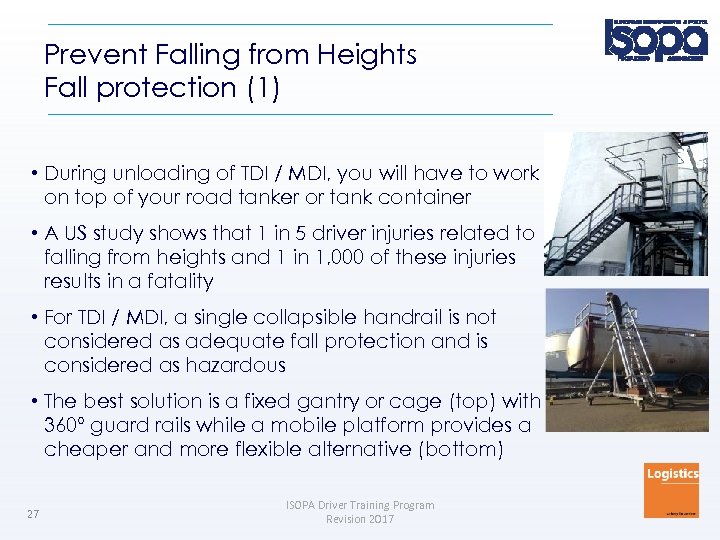

Prevent Falling from Heights Fall protection (1) • During unloading of TDI / MDI, you will have to work on top of your road tanker or tank container • A US study shows that 1 in 5 driver injuries related to falling from heights and 1 in 1, 000 of these injuries results in a fatality • For TDI / MDI, a single collapsible handrail is not considered as adequate fall protection and is considered as hazardous • The best solution is a fixed gantry or cage (top) with 360° guard rails while a mobile platform provides a cheaper and more flexible alternative (bottom) 27 ISOPA Driver Training Program Revision 2017

Prevent Falling from Heights Fall protection (1) • During unloading of TDI / MDI, you will have to work on top of your road tanker or tank container • A US study shows that 1 in 5 driver injuries related to falling from heights and 1 in 1, 000 of these injuries results in a fatality • For TDI / MDI, a single collapsible handrail is not considered as adequate fall protection and is considered as hazardous • The best solution is a fixed gantry or cage (top) with 360° guard rails while a mobile platform provides a cheaper and more flexible alternative (bottom) 27 ISOPA Driver Training Program Revision 2017

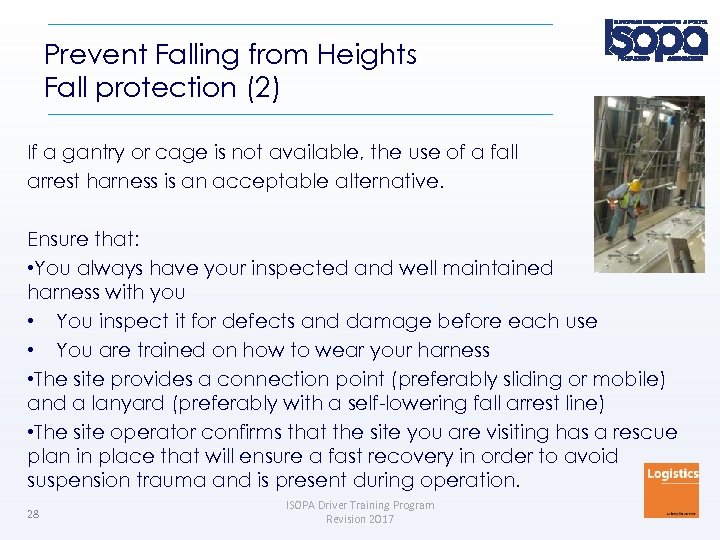

Prevent Falling from Heights Fall protection (2) If a gantry or cage is not available, the use of a fall arrest harness is an acceptable alternative. Ensure that: • You always have your inspected and well maintained harness with you • You inspect it for defects and damage before each use • You are trained on how to wear your harness • The site provides a connection point (preferably sliding or mobile) and a lanyard (preferably with a self-lowering fall arrest line) • The site operator confirms that the site you are visiting has a rescue plan in place that will ensure a fast recovery in order to avoid suspension trauma and is present during operation. 28 ISOPA Driver Training Program Revision 2017

Prevent Falling from Heights Fall protection (2) If a gantry or cage is not available, the use of a fall arrest harness is an acceptable alternative. Ensure that: • You always have your inspected and well maintained harness with you • You inspect it for defects and damage before each use • You are trained on how to wear your harness • The site provides a connection point (preferably sliding or mobile) and a lanyard (preferably with a self-lowering fall arrest line) • The site operator confirms that the site you are visiting has a rescue plan in place that will ensure a fast recovery in order to avoid suspension trauma and is present during operation. 28 ISOPA Driver Training Program Revision 2017

Tank Equipment Manlid must be kept closed! (moisture prevention) Ensure customs letter (if applicable) is present Do not mix-up the vapour return and liquid line !!! Tank depressurised? Cleaned tanks must be dry ! Capacity (keep filling degree in mind!) 29 ISOPA Driver Training Program Revision 2017

Tank Equipment Manlid must be kept closed! (moisture prevention) Ensure customs letter (if applicable) is present Do not mix-up the vapour return and liquid line !!! Tank depressurised? Cleaned tanks must be dry ! Capacity (keep filling degree in mind!) 29 ISOPA Driver Training Program Revision 2017

3 -Minutes Check before Loading Equipment 30 Tanker exterior clean? Spillage tray clean? Tanker correctly labelled and placarded? All valves closed, blind flanges/caps in place? Manlid closed and bolts tightened? Check temperature ISOPA Driver Training Program Revision 2017

3 -Minutes Check before Loading Equipment 30 Tanker exterior clean? Spillage tray clean? Tanker correctly labelled and placarded? All valves closed, blind flanges/caps in place? Manlid closed and bolts tightened? Check temperature ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Loading Equipment – Disconnected? – Free of spillages including spillage tray? – Safety handrail down? – Valves closed, blind-flanged and new gasket? – Only slight overpressure (max 0. 1 bar)? – Temperature setting correct? – Sample (if necessary)? Documentation – Transport document, Customs letter, Co. A, Weight ticket, DGD? – Instructions in writing? 31 ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Loading Equipment – Disconnected? – Free of spillages including spillage tray? – Safety handrail down? – Valves closed, blind-flanged and new gasket? – Only slight overpressure (max 0. 1 bar)? – Temperature setting correct? – Sample (if necessary)? Documentation – Transport document, Customs letter, Co. A, Weight ticket, DGD? – Instructions in writing? 31 ISOPA Driver Training Program Revision 2017

Transport Hours / Speed Check temperature (and pressure) Reporting unsafe conditions / incidents Parking 32 ISOPA Driver Training Program Revision 2017

Transport Hours / Speed Check temperature (and pressure) Reporting unsafe conditions / incidents Parking 32 ISOPA Driver Training Program Revision 2017

Opening of Tanks in Transit by Customs Officials ISOPA issued a letter to Customs Officials explaining the reasons why Letter is available in 14 languages i. e. CZ - DE - EN - ES - FR - HU IT - LV - PL - RO - RU - SK - TUR - UA 33 Tanks should not be opened whilst in transit because of the dangers to human health Letter can be downloaded from the ISOPA website http: //isopa. org/product-stewardship/logistics/letter-to-customs-officers/ ISOPA Driver Training Program Revision 2017

Opening of Tanks in Transit by Customs Officials ISOPA issued a letter to Customs Officials explaining the reasons why Letter is available in 14 languages i. e. CZ - DE - EN - ES - FR - HU IT - LV - PL - RO - RU - SK - TUR - UA 33 Tanks should not be opened whilst in transit because of the dangers to human health Letter can be downloaded from the ISOPA website http: //isopa. org/product-stewardship/logistics/letter-to-customs-officers/ ISOPA Driver Training Program Revision 2017

Security en Route What to do & not to do: Do not leave the vehicle unlocked Do not disclose information about product carried, customer, route or destination Park preferably on secure parking areas 34 ISOPA Driver Training Program Revision 2017

Security en Route What to do & not to do: Do not leave the vehicle unlocked Do not disclose information about product carried, customer, route or destination Park preferably on secure parking areas 34 ISOPA Driver Training Program Revision 2017

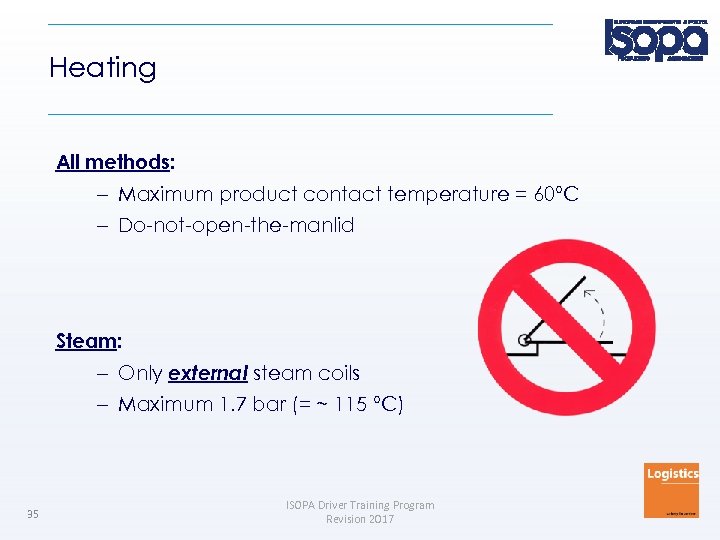

Heating All methods: – Maximum product contact temperature = 60°C – Do-not-open-the-manlid Steam: – Only external steam coils – Maximum 1. 7 bar (= ~ 115 °C) 35 ISOPA Driver Training Program Revision 2017

Heating All methods: – Maximum product contact temperature = 60°C – Do-not-open-the-manlid Steam: – Only external steam coils – Maximum 1. 7 bar (= ~ 115 °C) 35 ISOPA Driver Training Program Revision 2017

Unloading: Key Points (1) Follow site regulations Behavior You are the supplier’s representative Know the operational responsibilities between operator and driver as described in the CEFIC / ECTA / FECC Best Practice for safe (un)loading of Road Freight Vehicles Behavior Based Safety Guidelines Report unsafe conditions at customers (including near misses) 36 ISOPA Driver Training Program Revision 2017

Unloading: Key Points (1) Follow site regulations Behavior You are the supplier’s representative Know the operational responsibilities between operator and driver as described in the CEFIC / ECTA / FECC Best Practice for safe (un)loading of Road Freight Vehicles Behavior Based Safety Guidelines Report unsafe conditions at customers (including near misses) 36 ISOPA Driver Training Program Revision 2017

Unloading: Key Points (2) Storage tank capacity • communication driver / operator PPE must be worn Observe connections, pressure during unloading Samples (Report back if you have to take a sample) Unloading methods (Details on next slides) 37 ISOPA Driver Training Program Revision 2017

Unloading: Key Points (2) Storage tank capacity • communication driver / operator PPE must be worn Observe connections, pressure during unloading Samples (Report back if you have to take a sample) Unloading methods (Details on next slides) 37 ISOPA Driver Training Program Revision 2017

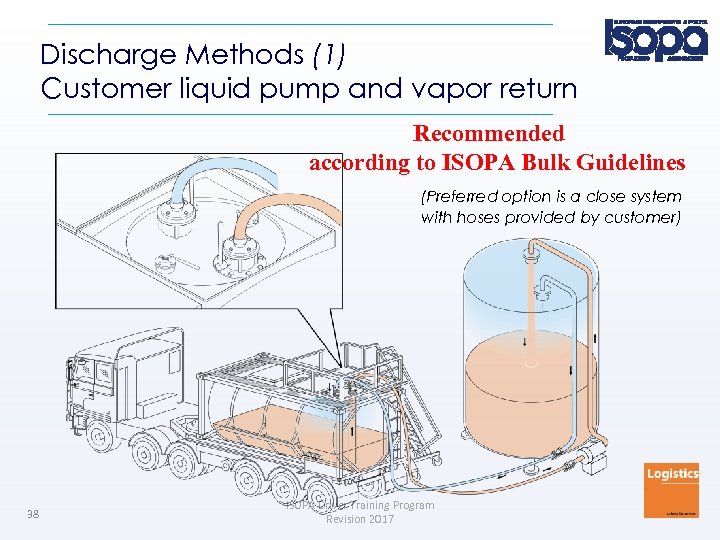

Discharge Methods (1) Customer liquid pump and vapor return Recommended according to ISOPA Bulk Guidelines (Preferred option is a close system with hoses provided by customer) 38 ISOPA Driver Training Program Revision 2017

Discharge Methods (1) Customer liquid pump and vapor return Recommended according to ISOPA Bulk Guidelines (Preferred option is a close system with hoses provided by customer) 38 ISOPA Driver Training Program Revision 2017

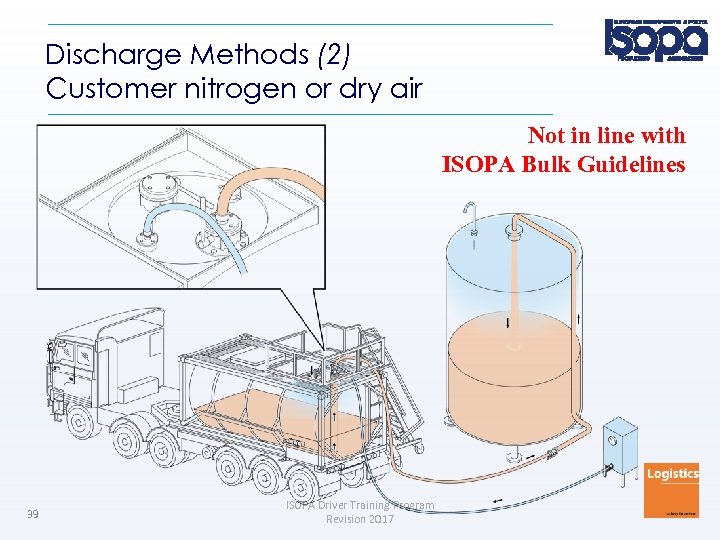

Discharge Methods (2) Customer nitrogen or dry air Not in line with ISOPA Bulk Guidelines 39 ISOPA Driver Training Program Revision 2017

Discharge Methods (2) Customer nitrogen or dry air Not in line with ISOPA Bulk Guidelines 39 ISOPA Driver Training Program Revision 2017

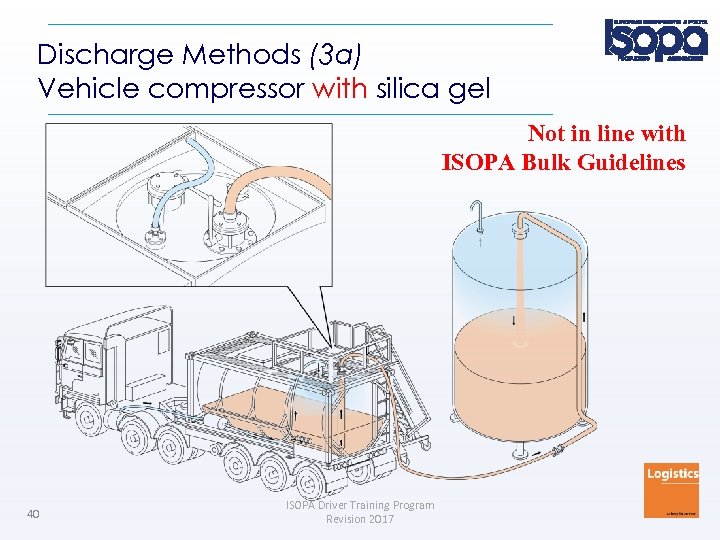

Discharge Methods (3 a) Vehicle compressor with silica gel Not in line with ISOPA Bulk Guidelines 40 ISOPA Driver Training Program Revision 2017

Discharge Methods (3 a) Vehicle compressor with silica gel Not in line with ISOPA Bulk Guidelines 40 ISOPA Driver Training Program Revision 2017

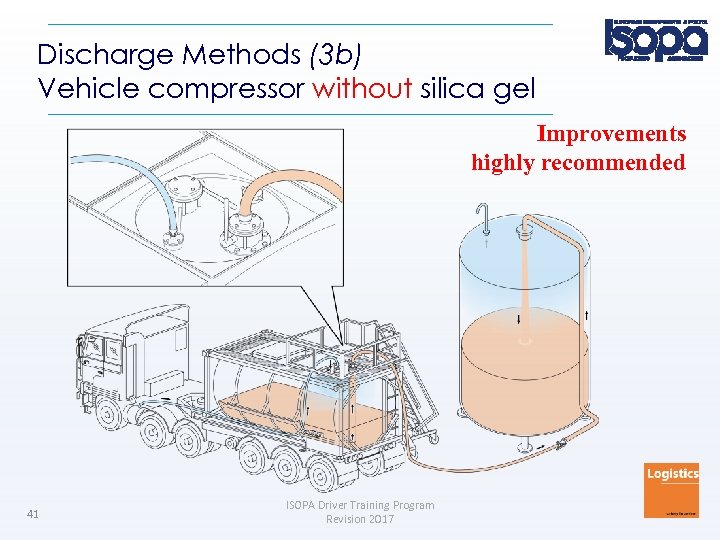

Discharge Methods (3 b) Vehicle compressor without silica gel Improvements highly recommended 41 ISOPA Driver Training Program Revision 2017

Discharge Methods (3 b) Vehicle compressor without silica gel Improvements highly recommended 41 ISOPA Driver Training Program Revision 2017

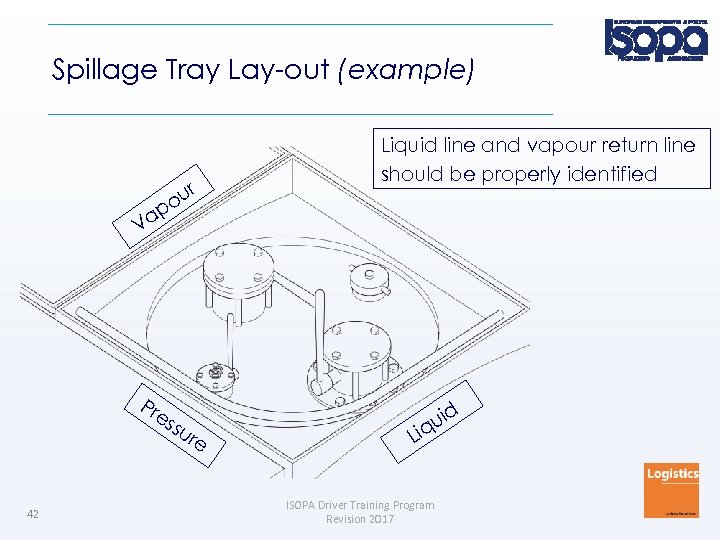

Spillage Tray Lay-out (example) ur o Liquid line and vapour return line should be properly identified ap V Pr es su re 42 uid iq L ISOPA Driver Training Program Revision 2017

Spillage Tray Lay-out (example) ur o Liquid line and vapour return line should be properly identified ap V Pr es su re 42 uid iq L ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Discharge (1) Equipment Disconnected? Free of spillages including spillage tray? Safety handrail down? Valves closed and blind-flanged, manlids closed? Spillage tray covers closed? Only slight overpressure (max 0. 1 bar)? Depressurise at the customer if possible, or inform planner Documentation (1) Handed to the customer? 43 Transport documentation signed? ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Discharge (1) Equipment Disconnected? Free of spillages including spillage tray? Safety handrail down? Valves closed and blind-flanged, manlids closed? Spillage tray covers closed? Only slight overpressure (max 0. 1 bar)? Depressurise at the customer if possible, or inform planner Documentation (1) Handed to the customer? 43 Transport documentation signed? ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Discharge (2) Documentation (2) Customer needs: • Copy of transport document signed by driver & customer • Certificate of Analysis Driver keeps: • Copy of transport document signed by driver & customer For TDI: Obtain or make transport document reading: Empty tank container*), last load: UN 2078 Toluene Diisocyanate, 6. 1, II (D/E) *) or: tank vehicle; demountable tank; portable tank 44 ISOPA Driver Training Program Revision 2017

3 -Minutes Check after Discharge (2) Documentation (2) Customer needs: • Copy of transport document signed by driver & customer • Certificate of Analysis Driver keeps: • Copy of transport document signed by driver & customer For TDI: Obtain or make transport document reading: Empty tank container*), last load: UN 2078 Toluene Diisocyanate, 6. 1, II (D/E) *) or: tank vehicle; demountable tank; portable tank 44 ISOPA Driver Training Program Revision 2017

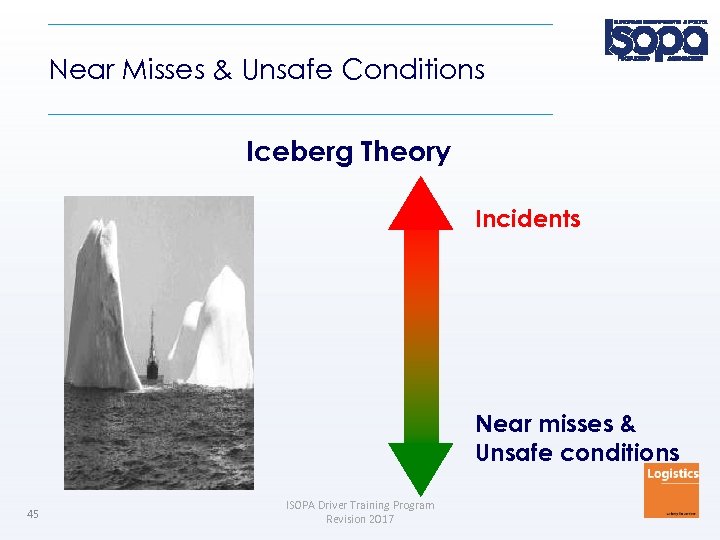

Near Misses & Unsafe Conditions Iceberg Theory Incidents Near misses & Unsafe conditions 45 ISOPA Driver Training Program Revision 2017

Near Misses & Unsafe Conditions Iceberg Theory Incidents Near misses & Unsafe conditions 45 ISOPA Driver Training Program Revision 2017

Near misses & unsafe conditions Reporting examples Active near miss reporting will reduce / avoid serious incidents: Road traffic incidents Equipment failures Incorrect human behavior Overflows Overpressure Spills Unexpected temperature rise (check regularly!) Unsafe working conditions (missing safety shower, unsafe access to top bulk equipment etc. ) Unsecure routing 46 ISOPA Driver Training Program Revision 2017

Near misses & unsafe conditions Reporting examples Active near miss reporting will reduce / avoid serious incidents: Road traffic incidents Equipment failures Incorrect human behavior Overflows Overpressure Spills Unexpected temperature rise (check regularly!) Unsafe working conditions (missing safety shower, unsafe access to top bulk equipment etc. ) Unsecure routing 46 ISOPA Driver Training Program Revision 2017

Incidents Statistics indicate: More than 80% of all incidents are related to human behavior Most incidents and accidents occur during loading & unloading So THIS is your Challenge: You are the most important safety factor (OR you will be the most important risk factor !) 47 ISOPA Driver Training Program Revision 2017

Incidents Statistics indicate: More than 80% of all incidents are related to human behavior Most incidents and accidents occur during loading & unloading So THIS is your Challenge: You are the most important safety factor (OR you will be the most important risk factor !) 47 ISOPA Driver Training Program Revision 2017

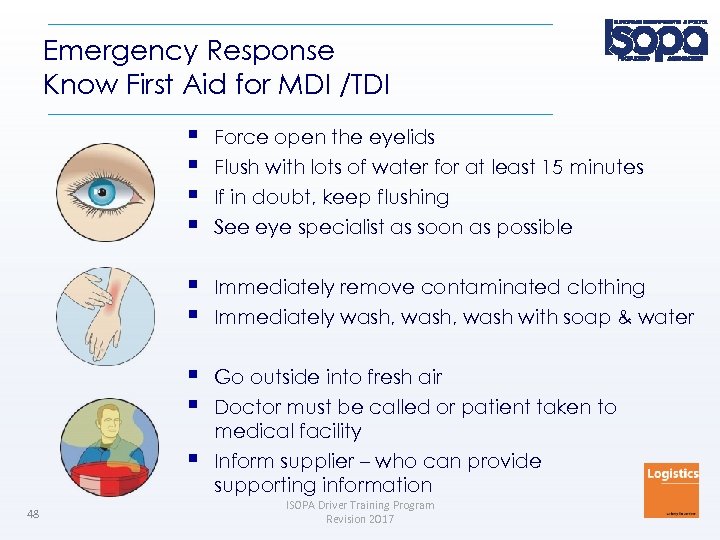

Emergency Response Know First Aid for MDI /TDI Force open the eyelids Flush with lots of water for at least 15 minutes If in doubt, keep flushing See eye specialist as soon as possible Immediately remove contaminated clothing Immediately wash, wash with soap & water Go outside into fresh air Doctor must be called or patient taken to medical facility Inform supplier – who can provide supporting information 48 ISOPA Driver Training Program Revision 2017

Emergency Response Know First Aid for MDI /TDI Force open the eyelids Flush with lots of water for at least 15 minutes If in doubt, keep flushing See eye specialist as soon as possible Immediately remove contaminated clothing Immediately wash, wash with soap & water Go outside into fresh air Doctor must be called or patient taken to medical facility Inform supplier – who can provide supporting information 48 ISOPA Driver Training Program Revision 2017

Emergency Procedures Exposure to MDI / TDI A single high exposure to MDI / TDI is one possible cause of sensitisation Early treatment is important Remember that symptoms may occur later Help is available for the doctor from ISOPA member companies Speed is essential Practice First Aid procedures Seek medical advice 49 ISOPA Driver Training Program Revision 2017

Emergency Procedures Exposure to MDI / TDI A single high exposure to MDI / TDI is one possible cause of sensitisation Early treatment is important Remember that symptoms may occur later Help is available for the doctor from ISOPA member companies Speed is essential Practice First Aid procedures Seek medical advice 49 ISOPA Driver Training Program Revision 2017

And. . . In any case of emergency: call us. . don‘t try to be a hero. . . !! 50 ISOPA Driver Training Program Revision 2017

And. . . In any case of emergency: call us. . don‘t try to be a hero. . . !! 50 ISOPA Driver Training Program Revision 2017

Emergency Response TDI Danish incident French incidents Portuguese incident Swedish incident Turkish incidents Hungarian incident Belgian incident – Packed – Bulk -Bulk -Packed MDI British incident German incident Italian incident – Bulk 51 ISOPA Driver Training Program Revision 2017

Emergency Response TDI Danish incident French incidents Portuguese incident Swedish incident Turkish incidents Hungarian incident Belgian incident – Packed – Bulk -Bulk -Packed MDI British incident German incident Italian incident – Bulk 51 ISOPA Driver Training Program Revision 2017

Emergency Response Emergency incident scenario – – 52 What went well ? What can be improved ? ISOPA Driver Training Program Revision 2017

Emergency Response Emergency incident scenario – – 52 What went well ? What can be improved ? ISOPA Driver Training Program Revision 2017

Test Corrections are allowed (as long as it is clear which answer you decided upon!) 53 20 multiple choice questions: The minimum score is 70% = 14 correct answers One correct answer only Ticking more than one answer for the same question = miss ISOPA Driver Training Program Revision 2017

Test Corrections are allowed (as long as it is clear which answer you decided upon!) 53 20 multiple choice questions: The minimum score is 70% = 14 correct answers One correct answer only Ticking more than one answer for the same question = miss ISOPA Driver Training Program Revision 2017

The End Congratulations! Certificates will be forwarded as soon as possible 54 ISOPA Driver Training Program Revision 2017

The End Congratulations! Certificates will be forwarded as soon as possible 54 ISOPA Driver Training Program Revision 2017

Disclaimer While ISOPA and its members make every effort to present accurate and reliable information in utmost good faith on the basis of the best information currently available, it is to be relied upon at the user’s own risk. No representations or warranties are made with regard to its completeness, accuracy or reliability and no liability will be accepted by ISOPA nor any company participating in ISOPA for damages of any nature whatsoever resulting from the use of or reliance on the information. 55 ISOPA Driver Training Program Revision 2017

Disclaimer While ISOPA and its members make every effort to present accurate and reliable information in utmost good faith on the basis of the best information currently available, it is to be relied upon at the user’s own risk. No representations or warranties are made with regard to its completeness, accuracy or reliability and no liability will be accepted by ISOPA nor any company participating in ISOPA for damages of any nature whatsoever resulting from the use of or reliance on the information. 55 ISOPA Driver Training Program Revision 2017