DRILLING OF DEEP HOLES Student: Kazagachev Timur Group: 8 LM 41

DRILLING OF DEEP HOLES Student: Kazagachev Timur Group: 8 LM 41

• Drilling of deep holes is difficult operation. Owing to small hardness of long drills under the influence of forces of cutting there is their longitudinal bend that can lead to a hole axis curvature. Besides, with increase in length of a hole adverse conditions of formation of shaving are created and its extraction from a hole during an operating time is at a loss.

• Drilling of deep holes is difficult operation. Owing to small hardness of long drills under the influence of forces of cutting there is their longitudinal bend that can lead to a hole axis curvature. Besides, with increase in length of a hole adverse conditions of formation of shaving are created and its extraction from a hole during an operating time is at a loss.

Two methods of receiving deep holes: continuous drilling and ring drilling. • The method of continuous drilling consists in receiving a hole by means of transformation into shaving of all metal which is subject to deleting formation of the given size of a hole.

Two methods of receiving deep holes: continuous drilling and ring drilling. • The method of continuous drilling consists in receiving a hole by means of transformation into shaving of all metal which is subject to deleting formation of the given size of a hole.

Two methods of receiving deep holes: continuous drilling and ring drilling. • The method of continuous drilling consists in receiving a hole by means of transformation into shaving of all metal which is subject to deleting formation of the given size of a hole. This method is applied generally to drilling of deep holes with a diameter more than 100 mm special drills on special horizontal drilling machines for deep drilling.

Two methods of receiving deep holes: continuous drilling and ring drilling. • The method of continuous drilling consists in receiving a hole by means of transformation into shaving of all metal which is subject to deleting formation of the given size of a hole. This method is applied generally to drilling of deep holes with a diameter more than 100 mm special drills on special horizontal drilling machines for deep drilling.

• When drilling deep holes it is necessary to bring to the cutting edges of the tool in large numbers lubricant cooling liquid which facilitates cutting process, provides reliable and timely washing away of the formed shaving and leadout of warmth from the cutting tool edges. • The most perfect method is submission of liquid through the holes passing in drill pens. Instrumental plants a row of constructions of spiral drills with the holes for an application LCL passing through a shaft of a drill or through radial holes is issued. • Such drills are produced from special rolling with screw holes, from the preparations received by radial forging, rolling of preparations with use of solid fillers, rolling of tubular preparations, casting.

• When drilling deep holes it is necessary to bring to the cutting edges of the tool in large numbers lubricant cooling liquid which facilitates cutting process, provides reliable and timely washing away of the formed shaving and leadout of warmth from the cutting tool edges. • The most perfect method is submission of liquid through the holes passing in drill pens. Instrumental plants a row of constructions of spiral drills with the holes for an application LCL passing through a shaft of a drill or through radial holes is issued. • Such drills are produced from special rolling with screw holes, from the preparations received by radial forging, rolling of preparations with use of solid fillers, rolling of tubular preparations, casting.

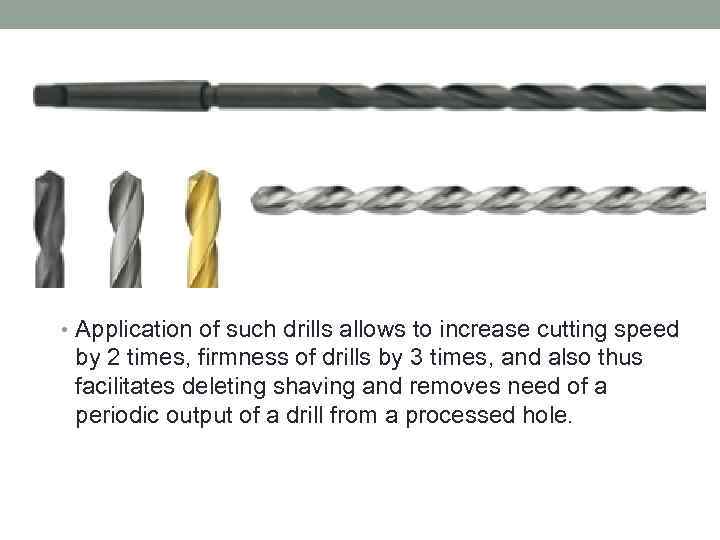

• Application of such drills allows to increase cutting speed by 2 times, firmness of drills by 3 times, and also thus facilitates deleting shaving and removes need of a periodic output of a drill from a processed hole.

• Application of such drills allows to increase cutting speed by 2 times, firmness of drills by 3 times, and also thus facilitates deleting shaving and removes need of a periodic output of a drill from a processed hole.

Thank you for your attention

Thank you for your attention