834-2.ppt

- Количество слайдов: 1

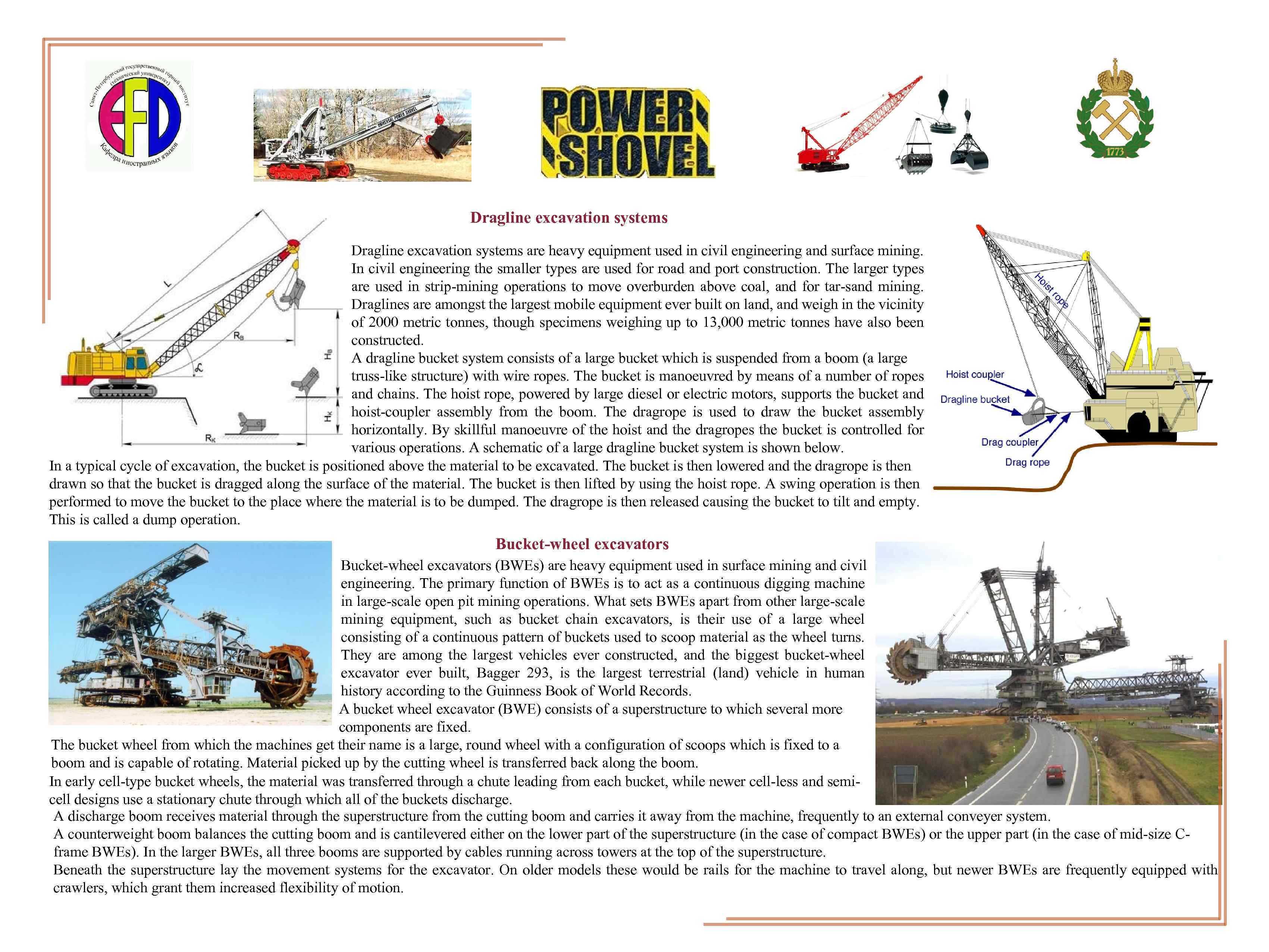

Dragline excavation systems are heavy equipment used in civil engineering and surface mining. In civil engineering the smaller types are used for road and port construction. The larger types are used in strip-mining operations to move overburden above coal, and for tar-sand mining. Draglines are amongst the largest mobile equipment ever built on land, and weigh in the vicinity of 2000 metric tonnes, though specimens weighing up to 13, 000 metric tonnes have also been constructed. A dragline bucket system consists of a large bucket which is suspended from a boom (a large truss-like structure) with wire ropes. The bucket is manoeuvred by means of a number of ropes and chains. The hoist rope, powered by large diesel or electric motors, supports the bucket and hoist-coupler assembly from the boom. The dragrope is used to draw the bucket assembly horizontally. By skillful manoeuvre of the hoist and the dragropes the bucket is controlled for various operations. A schematic of a large dragline bucket system is shown below. In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation. Bucket-wheel excavators (BWEs) are heavy equipment used in surface mining and civil engineering. The primary function of BWEs is to act as a continuous digging machine in large-scale open pit mining operations. What sets BWEs apart from other large-scale mining equipment, such as bucket chain excavators, is their use of a large wheel consisting of a continuous pattern of buckets used to scoop material as the wheel turns. They are among the largest vehicles ever constructed, and the biggest bucket-wheel excavator ever built, Bagger 293, is the largest terrestrial (land) vehicle in human history according to the Guinness Book of World Records. A bucket wheel excavator (BWE) consists of a superstructure to which several more components are fixed. The bucket wheel from which the machines get their name is a large, round wheel with a configuration of scoops which is fixed to a boom and is capable of rotating. Material picked up by the cutting wheel is transferred back along the boom. In early cell-type bucket wheels, the material was transferred through a chute leading from each bucket, while newer cell-less and semicell designs use a stationary chute through which all of the buckets discharge. A discharge boom receives material through the superstructure from the cutting boom and carries it away from the machine, frequently to an external conveyer system. A counterweight boom balances the cutting boom and is cantilevered either on the lower part of the superstructure (in the case of compact BWEs) or the upper part (in the case of mid-size Cframe BWEs). In the larger BWEs, all three booms are supported by cables running across towers at the top of the superstructure. Beneath the superstructure lay the movement systems for the excavator. On older models these would be rails for the machine to travel along, but newer BWEs are frequently equipped with crawlers, which grant them increased flexibility of motion.

Dragline excavation systems are heavy equipment used in civil engineering and surface mining. In civil engineering the smaller types are used for road and port construction. The larger types are used in strip-mining operations to move overburden above coal, and for tar-sand mining. Draglines are amongst the largest mobile equipment ever built on land, and weigh in the vicinity of 2000 metric tonnes, though specimens weighing up to 13, 000 metric tonnes have also been constructed. A dragline bucket system consists of a large bucket which is suspended from a boom (a large truss-like structure) with wire ropes. The bucket is manoeuvred by means of a number of ropes and chains. The hoist rope, powered by large diesel or electric motors, supports the bucket and hoist-coupler assembly from the boom. The dragrope is used to draw the bucket assembly horizontally. By skillful manoeuvre of the hoist and the dragropes the bucket is controlled for various operations. A schematic of a large dragline bucket system is shown below. In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation. Bucket-wheel excavators (BWEs) are heavy equipment used in surface mining and civil engineering. The primary function of BWEs is to act as a continuous digging machine in large-scale open pit mining operations. What sets BWEs apart from other large-scale mining equipment, such as bucket chain excavators, is their use of a large wheel consisting of a continuous pattern of buckets used to scoop material as the wheel turns. They are among the largest vehicles ever constructed, and the biggest bucket-wheel excavator ever built, Bagger 293, is the largest terrestrial (land) vehicle in human history according to the Guinness Book of World Records. A bucket wheel excavator (BWE) consists of a superstructure to which several more components are fixed. The bucket wheel from which the machines get their name is a large, round wheel with a configuration of scoops which is fixed to a boom and is capable of rotating. Material picked up by the cutting wheel is transferred back along the boom. In early cell-type bucket wheels, the material was transferred through a chute leading from each bucket, while newer cell-less and semicell designs use a stationary chute through which all of the buckets discharge. A discharge boom receives material through the superstructure from the cutting boom and carries it away from the machine, frequently to an external conveyer system. A counterweight boom balances the cutting boom and is cantilevered either on the lower part of the superstructure (in the case of compact BWEs) or the upper part (in the case of mid-size Cframe BWEs). In the larger BWEs, all three booms are supported by cables running across towers at the top of the superstructure. Beneath the superstructure lay the movement systems for the excavator. On older models these would be rails for the machine to travel along, but newer BWEs are frequently equipped with crawlers, which grant them increased flexibility of motion.