a69e33615047a872407e6784fdd0942b.ppt

- Количество слайдов: 65

DOM 511: OPERATIONS MANAGEMENT PRACTICE Magutu Obara Peterson/S. O Nyamwange University of Nairobi School of Business Département of Management Science Jan – April 2013 magutumop 2011 1

TOPIC ONE: OVERVIEW OF OPERATIONS MANAGEMENT Introduction Definition of Operations Management Historical Perspective Transformation Process Model Framework for analysing OM decisions Productions/Operations Management Strategy Current Issues/Strategic Role of Operations Management Why Study Operations Management? magutumop 2011 2

Introduction Operations Management is: The business function responsible for planning, coordinating, and controlling the resources needed to produce products and services for a company Operations management may be defined as the design, operation, and improvement of the production system that creates the firm’s primary products and services. magutumop 2011 3

Operations Management is: • An organization’s core function • In every organization whether Service or Manufacturing, profit or Not for profit • Operations Management affects: – Companies’ ability to compete – Nation’s ability to compete internationally magutumop 2011 4

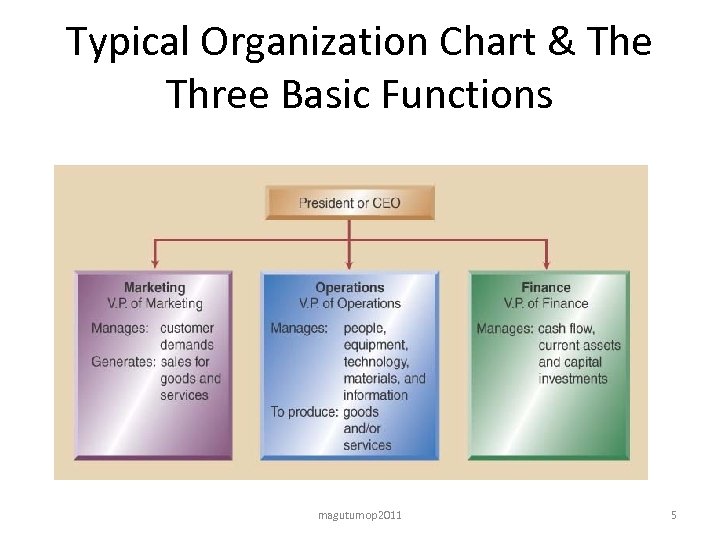

Typical Organization Chart & The Three Basic Functions magutumop 2011 5

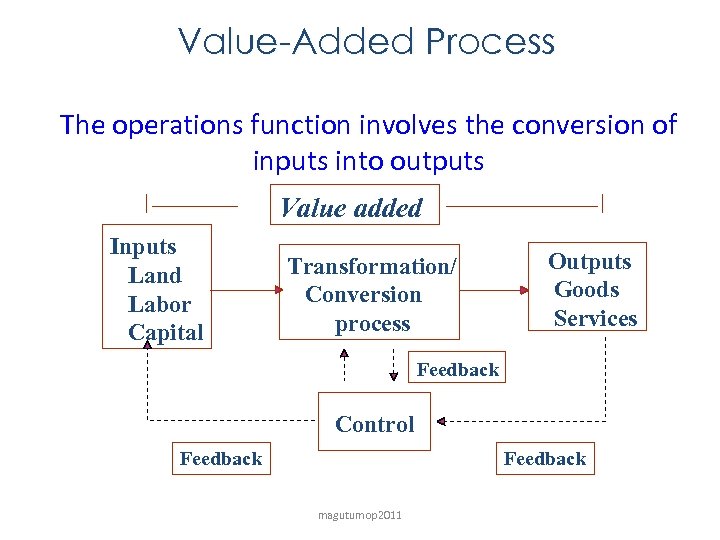

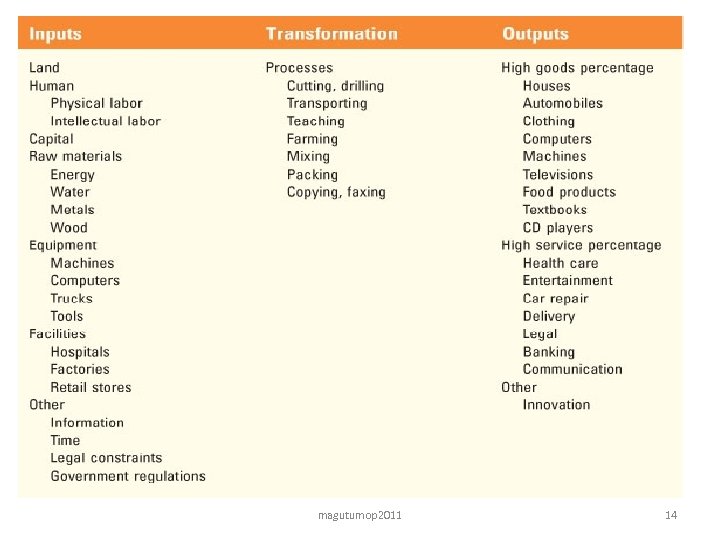

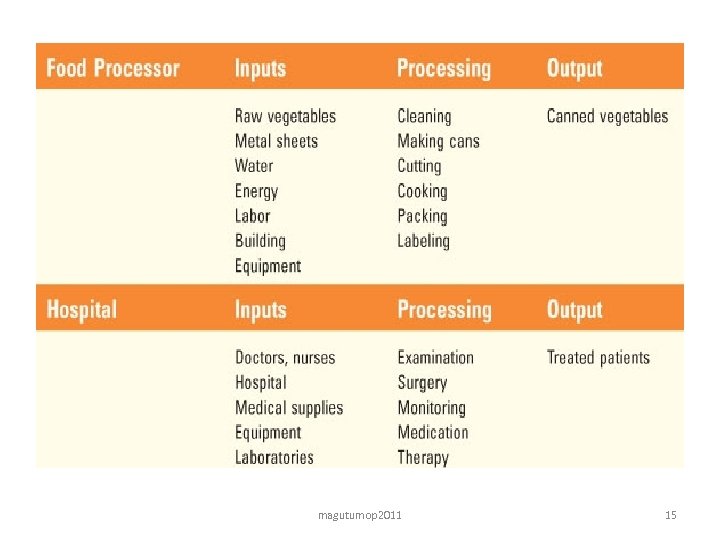

What is Role of OM? • OM Transforms inputs to outputs – Inputs are resources such as People, Material, and Money – Outputs are goods and services • To add value – Increase product value at each stage – Value added is the net increase between output product value and input material value magutumop 2011 6

What is Role of OM? • Provide an efficient transformation – Efficiency – means performing activities well for least possible cost • Physical--manufacturing • Locational--transportation • Exchange--retailing • Storage--warehousing • Physiological--health care • Informational--telecommunications magutumop 2011 7

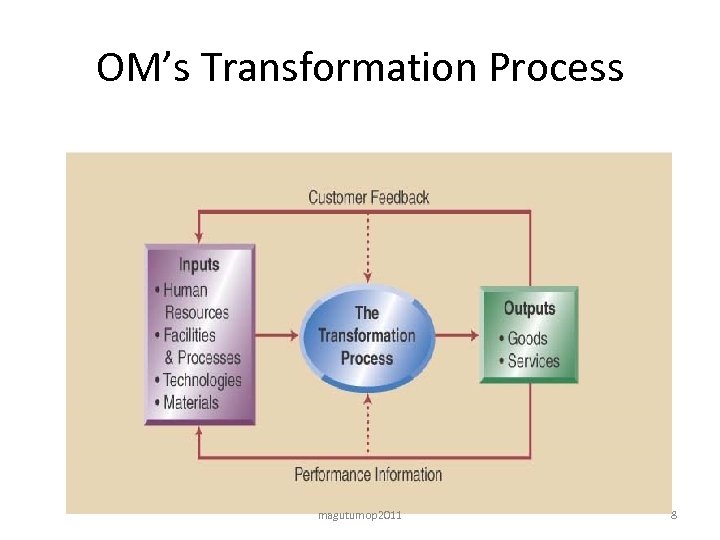

OM’s Transformation Process magutumop 2011 8

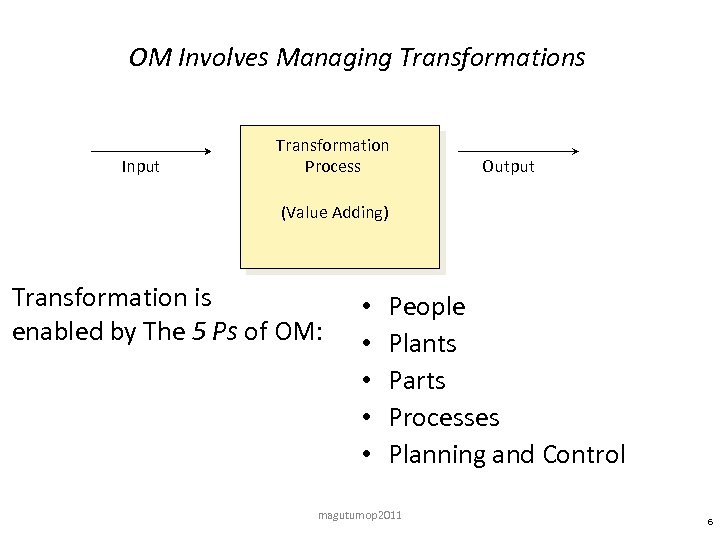

OM Involves Managing Transformations Input Transformation Process Output (Value Adding) Transformation is enabled by The 5 Ps of OM: • • • People Plants Parts Processes Planning and Control magutumop 2011 6

Value-Added Process The operations function involves the conversion of inputs into outputs Value added Inputs Land Labor Capital Transformation/ Conversion process Outputs Goods Services Feedback Control Feedback magutumop 2011

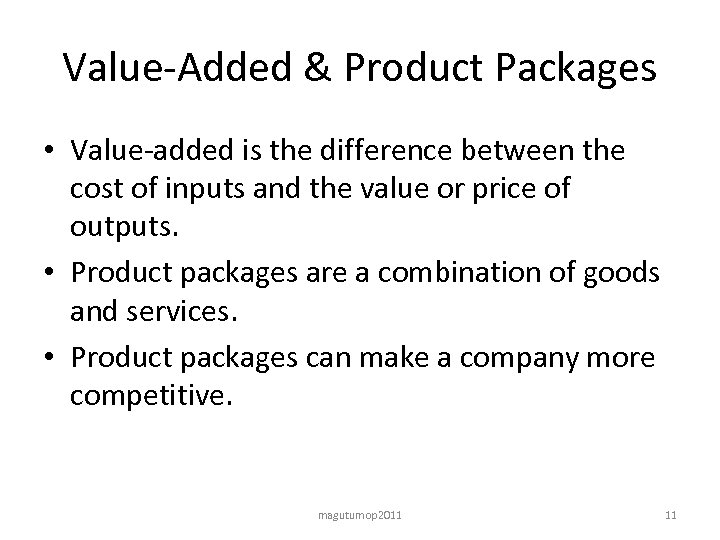

Value-Added & Product Packages • Value-added is the difference between the cost of inputs and the value or price of outputs. • Product packages are a combination of goods and services. • Product packages can make a company more competitive. magutumop 2011 11

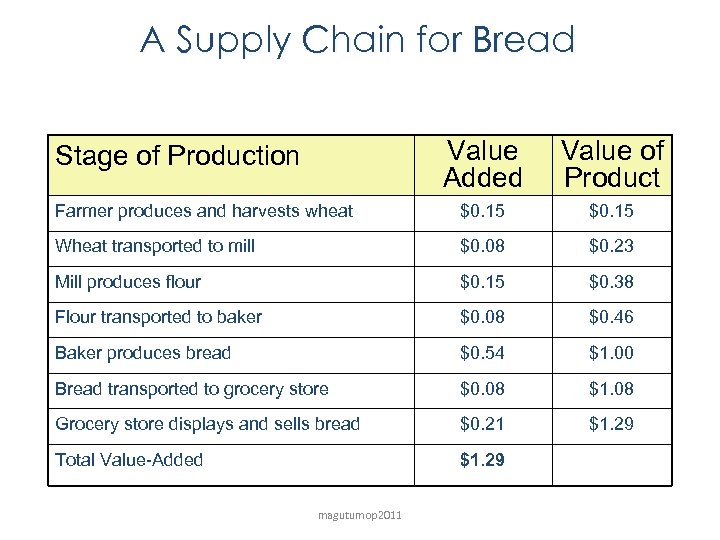

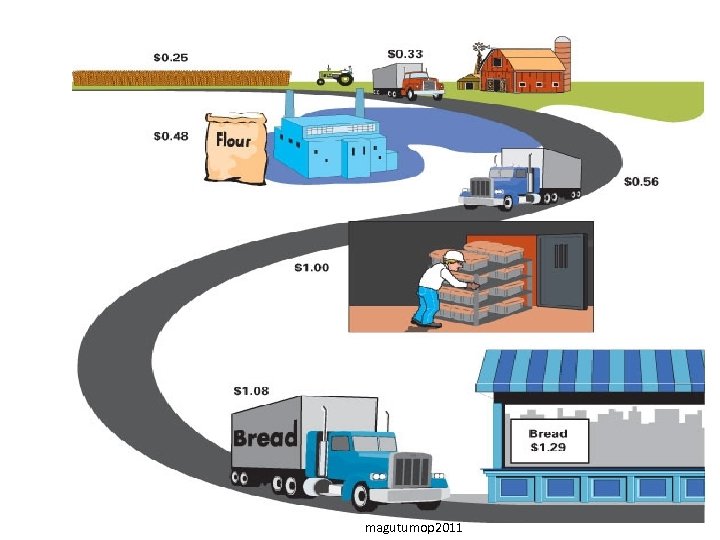

A Supply Chain for Bread Value Added Value of Product Farmer produces and harvests wheat $0. 15 Wheat transported to mill $0. 08 $0. 23 Mill produces flour $0. 15 $0. 38 Flour transported to baker $0. 08 $0. 46 Baker produces bread $0. 54 $1. 00 Bread transported to grocery store $0. 08 $1. 08 Grocery store displays and sells bread $0. 21 $1. 29 Total Value-Added $1. 29 Stage of Production magutumop 2011

© Wiley 2010 magutumop 2011 13

magutumop 2011 14

magutumop 2011 15

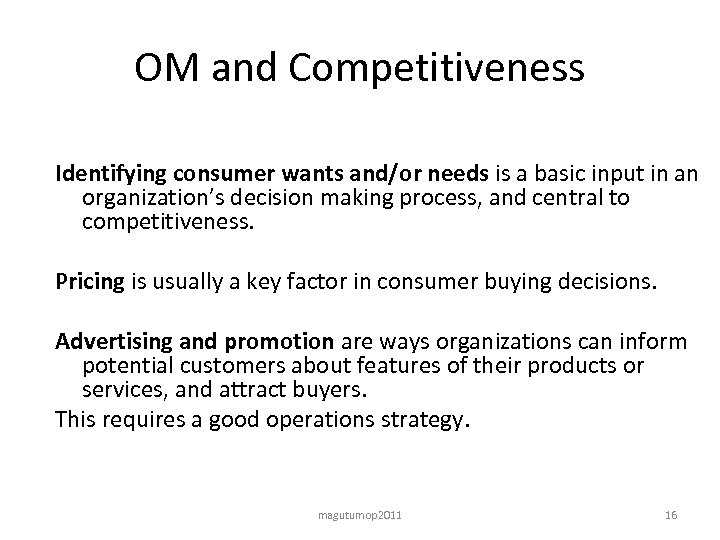

OM and Competitiveness Identifying consumer wants and/or needs is a basic input in an organization’s decision making process, and central to competitiveness. Pricing is usually a key factor in consumer buying decisions. Advertising and promotion are ways organizations can inform potential customers about features of their products or services, and attract buyers. This requires a good operations strategy. magutumop 2011 16

Strategy Mission: Live a good life. Goal: Successful career, good income. Strategy: Obtain a college education. Tactics: Select a college and a major; decide how to finance college. Operations: Register, buy books, take courses, study. magutumop 2011 17

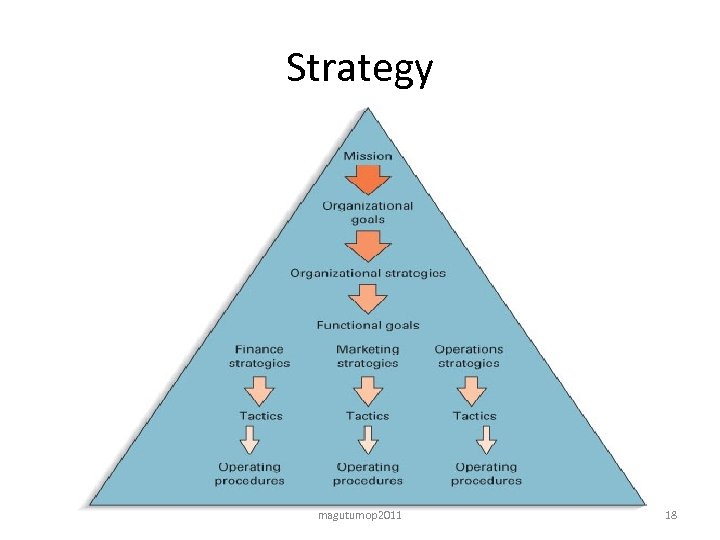

Strategy magutumop 2011 18

Operations Strategy and Competitiveness • Operations strategy is the “HOW” in any corporate and market strategy. • Operations strategy is no longer a tool for continuous improvement and sustainable competitive advantage in the manufacturing sector only, since it can be now applied in the service industry and public organizations. • The operations strategy has three levels: ü first, alignment of resources with requirements (fit); ü secondly, developing sustainable competitive advantage (sustainability) and ü lastly including the impact of uncertainty magutumop 2011 19

http: //www. baskent. edu. tr/~kilter magutumop 2011 20

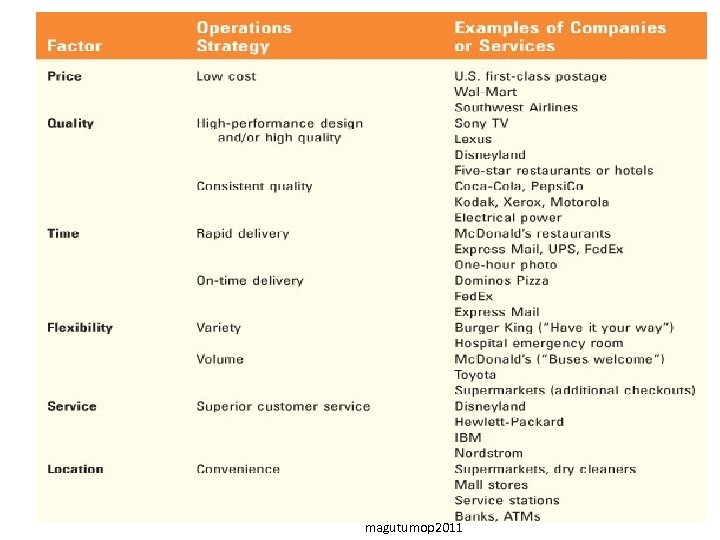

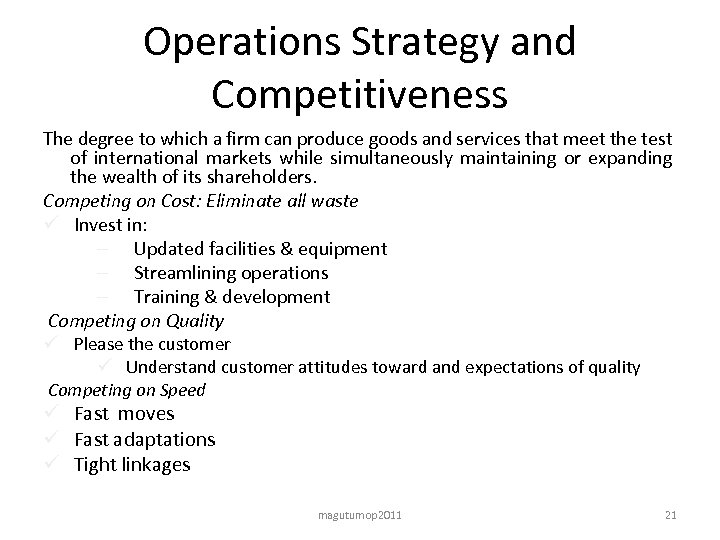

Operations Strategy and Competitiveness The degree to which a firm can produce goods and services that meet the test of international markets while simultaneously maintaining or expanding the wealth of its shareholders. Competing on Cost: Eliminate all waste ü Invest in: – Updated facilities & equipment – Streamlining operations – Training & development Competing on Quality ü Please the customer ü Understand customer attitudes toward and expectations of quality Competing on Speed ü Fast moves ü Fast adaptations ü Tight linkages magutumop 2011 21

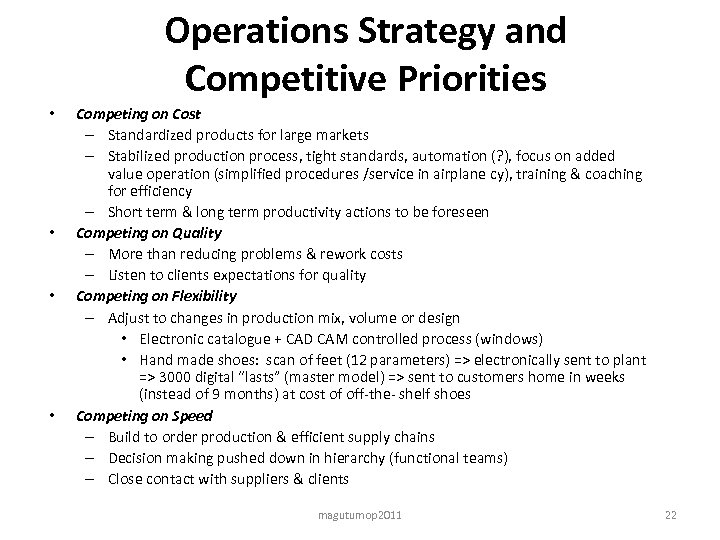

Operations Strategy and Competitive Priorities • • Competing on Cost – Standardized products for large markets – Stabilized production process, tight standards, automation (? ), focus on added value operation (simplified procedures /service in airplane cy), training & coaching for efficiency – Short term & long term productivity actions to be foreseen Competing on Quality – More than reducing problems & rework costs – Listen to clients expectations for quality Competing on Flexibility – Adjust to changes in production mix, volume or design • Electronic catalogue + CAD CAM controlled process (windows) • Hand made shoes: scan of feet (12 parameters) => electronically sent to plant => 3000 digital “lasts” (master model) => sent to customers home in weeks (instead of 9 months) at cost of off-the- shelf shoes Competing on Speed – Build to order production & efficient supply chains – Decision making pushed down in hierarchy (functional teams) – Close contact with suppliers & clients magutumop 2011 22

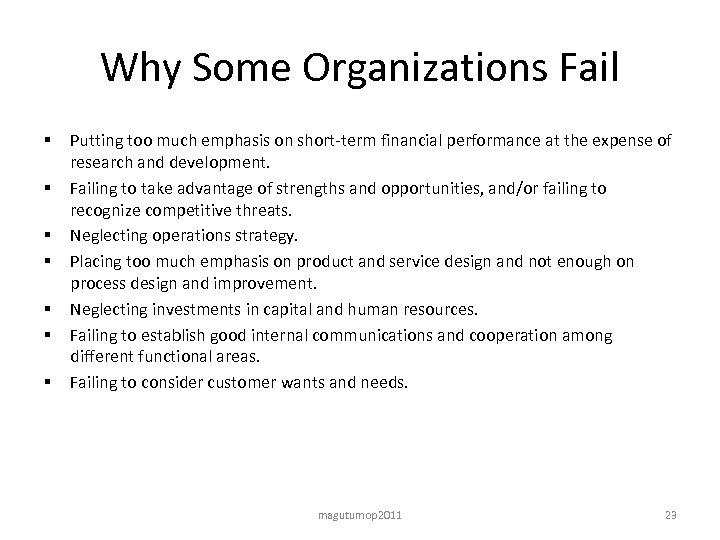

Why Some Organizations Fail § § § § Putting too much emphasis on short-term financial performance at the expense of research and development. Failing to take advantage of strengths and opportunities, and/or failing to recognize competitive threats. Neglecting operations strategy. Placing too much emphasis on product and service design and not enough on process design and improvement. Neglecting investments in capital and human resources. Failing to establish good internal communications and cooperation among different functional areas. Failing to consider customer wants and needs. magutumop 2011 23

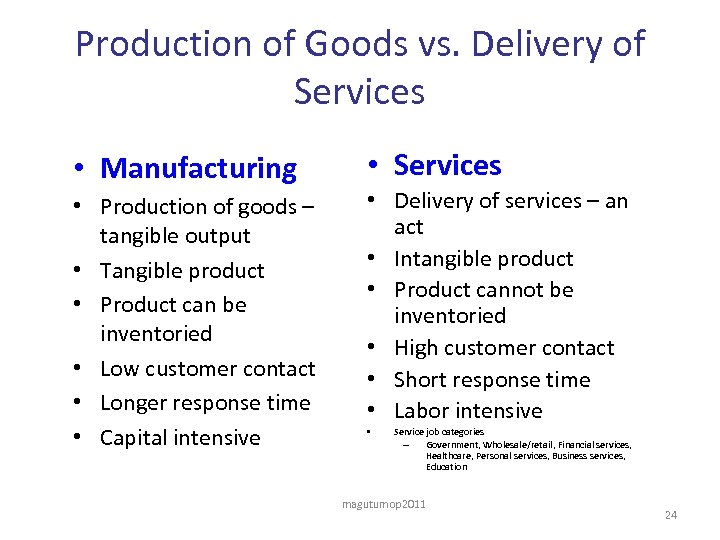

Production of Goods vs. Delivery of Services • Manufacturing • Production of goods – tangible output • Tangible product • Product can be inventoried • Low customer contact • Longer response time • Capital intensive • Services • Delivery of services – an act • Intangible product • Product cannot be inventoried • High customer contact • Short response time • Labor intensive • Service job categories – Government, Wholesale/retail, Financial services, Healthcare, Personal services, Business services, Education magutumop 2011 24

Challenges of Managing Services • Service jobs are often less structured than manufacturing jobs • Customer contact is higher • Worker skill levels are lower • Services hire many low-skill, entry-level workers • Employee turnover is higher • Input variability is higher • Service performance can be affected by worker’s personal factors magutumop 2011 25

On the other hand… Both use technology Both have quality, productivity, & response issues Both must forecast demand Both will have capacity, layout, and location issues Both have customers, suppliers, scheduling and staffing issues • Manufacturing often provides services • Services often provides tangible goods • • • magutumop 2011 26

Core “Factory Services” Operations whether in manufacturing or in a service organization can be treated as service. The core services customer want; • Quality • Flexibility • Delivery Speed • Price (or production cost) magutumop 2011 27

Value-Added Factory Services: These make external or internal customer’s life easier • Information – ability to furnish critical data on product performance, process parameters & cost • Problem Solving – especially in quality • Sales Support – By demonstrating the technology, equipment or production systems the company is trying to sell. • Field Support – Ability to replace defective parts quickly magutumop 2011 28

Hybrid organizations • Some organizations are a blend of service/manufacturing/quasimanufacturing Quasi-Manufacturing (QM) organizations • QM characteristics include – Low customer contact & Capital Intensive magutumop 2011 29

Key Decisions of Operations Managers • What – plants and parts What resources/what amounts • When - Planning and Control Needed/scheduled/ordered • Where - place Work to be done • How – Processes Designed • Who – People To do the work magutumop 2011 30

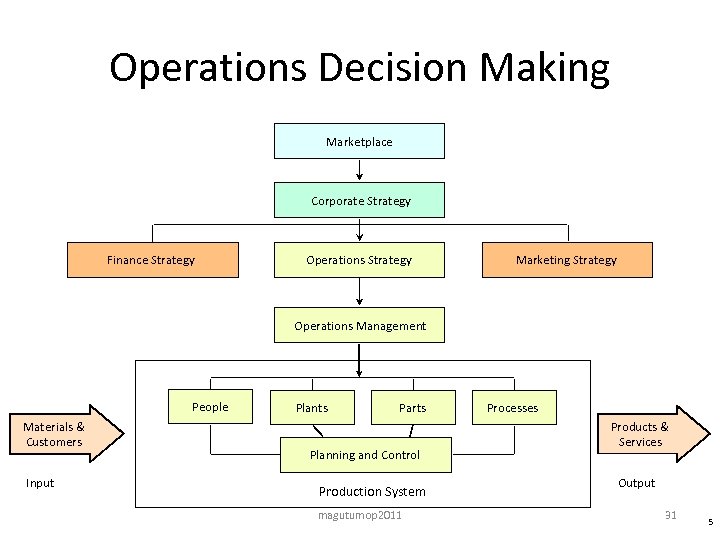

Operations Decision Making Marketplace Corporate Strategy Finance Strategy Operations Strategy Marketing Strategy Operations Management People Materials & Customers Input Plants Parts Planning and Control Production System magutumop 2011 Processes Products & Services Output 31 5

magutumop 2011 32

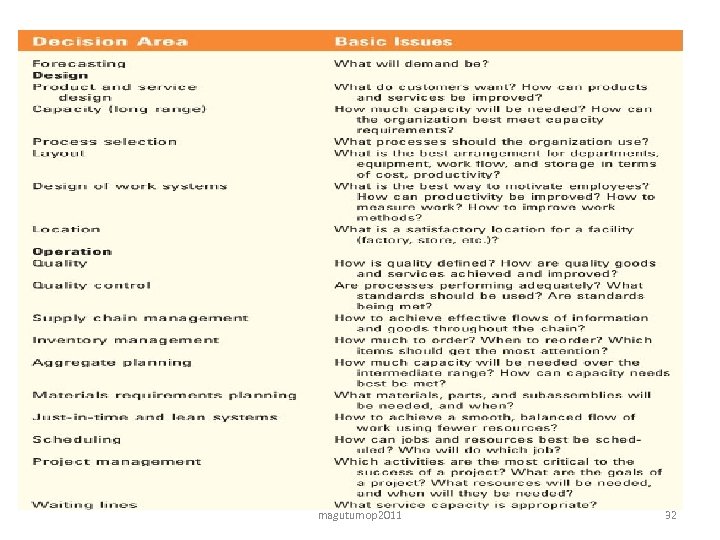

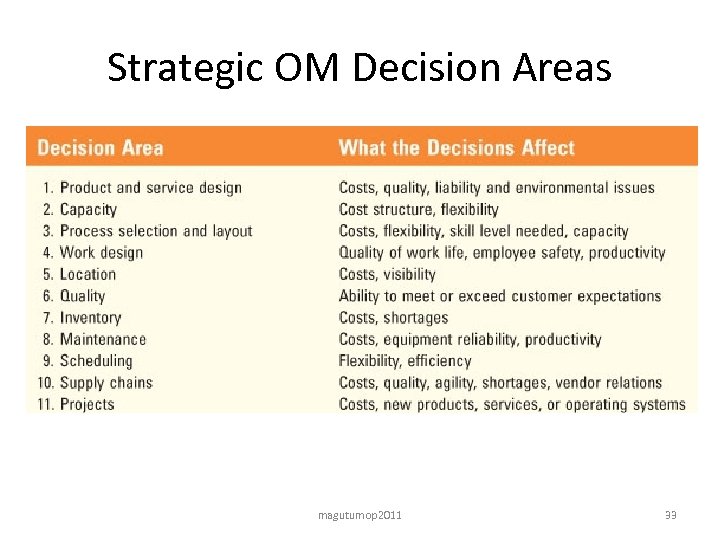

Strategic OM Decision Areas magutumop 2011 33

Scope of Operations Management • Operations Management includes: – Forecasting – Capacity planning – Scheduling – Managing inventories – Assuring quality – Motivating employees – Deciding where to locate facilities – Supply chain management – And more. . . magutumop 2011 34

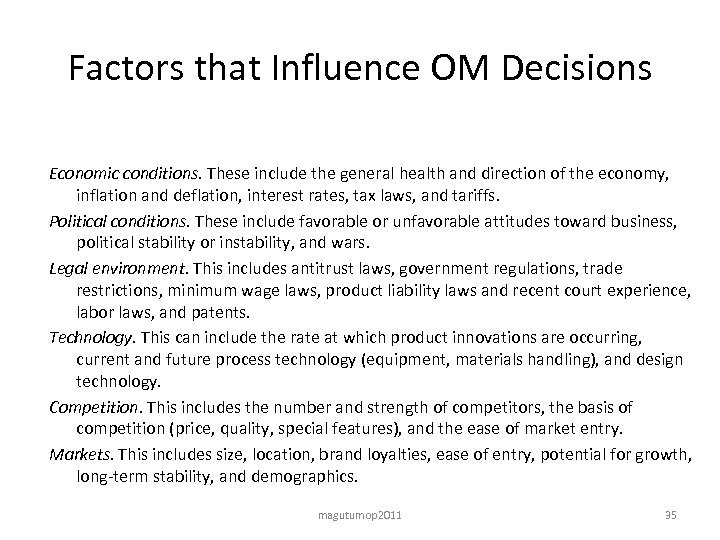

Factors that Influence OM Decisions Economic conditions. These include the general health and direction of the economy, inflation and deflation, interest rates, tax laws, and tariffs. Political conditions. These include favorable or unfavorable attitudes toward business, political stability or instability, and wars. Legal environment. This includes antitrust laws, government regulations, trade restrictions, minimum wage laws, product liability laws and recent court experience, labor laws, and patents. Technology. This can include the rate at which product innovations are occurring, current and future process technology (equipment, materials handling), and design technology. Competition. This includes the number and strength of competitors, the basis of competition (price, quality, special features), and the ease of market entry. Markets. This includes size, location, brand loyalties, ease of entry, potential for growth, long-term stability, and demographics. magutumop 2011 35

Human resources. These include the skills and abilities of managers and workers; special talents (creativity, designing, problem solving); loyalty to the organization; expertise; dedication; and experience. Facilities and equipment. Capacities, location, age, and cost to maintain or replace can have a significant impact on operations. Financial resources. Cash flow, access to additional funding, existing debt burden, and cost of capital are important considerations. Customers. Loyalty, existing relationships, and understanding of wants and needs are important. Products and services. These include existing products and services, and the potential for new products and services. Technology. This includes existing technology, the ability to integrate new technology, and the probable impact of technology on current and future operations. Supplier relationships, dependability of suppliers, quality, flexibility, and service are typical considerations. Other factors include patents, labor relations, company or product image, distribution channels, relationships with distributors, maintenance of facilities and equipment, access to resources, and access to markets. magutumop 2011 36

OM Decision Making Framework • • Models Quantitative approaches Analysis of trade-offs Systems approach magutumop 2011 37

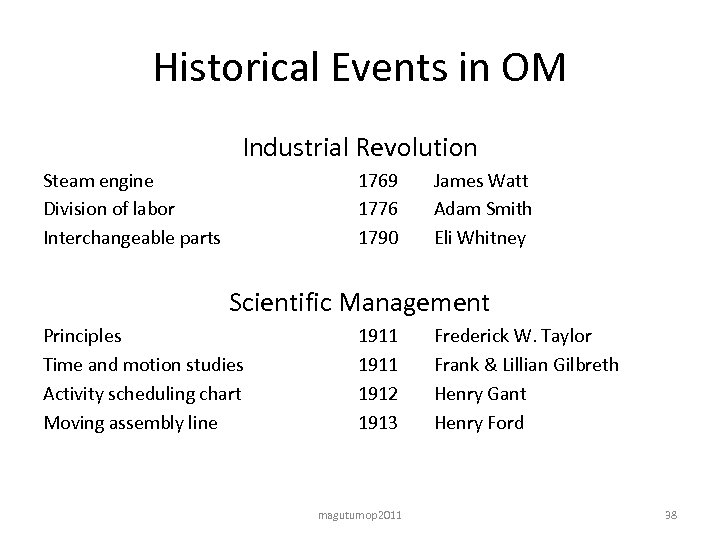

Historical Events in OM Industrial Revolution Steam engine Division of labor Interchangeable parts 1769 1776 1790 James Watt Adam Smith Eli Whitney Scientific Management Principles Time and motion studies Activity scheduling chart Moving assembly line 1911 1912 1913 magutumop 2011 Frederick W. Taylor Frank & Lillian Gilbreth Henry Gant Henry Ford 38

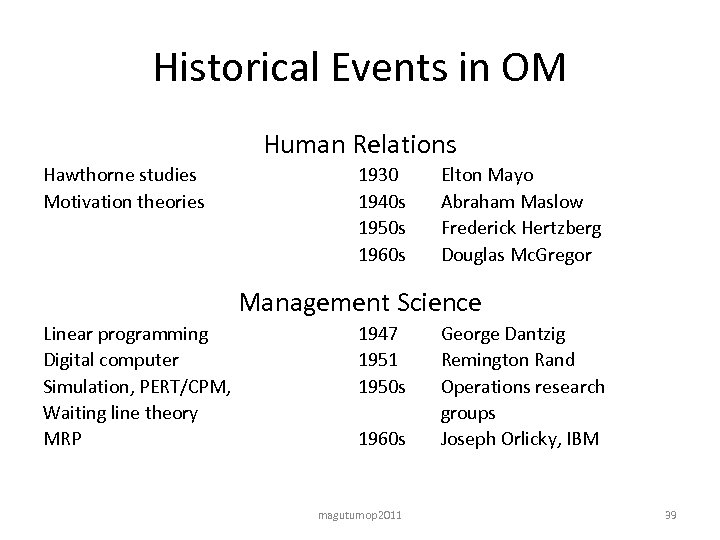

Historical Events in OM Human Relations Hawthorne studies Motivation theories 1930 1940 s 1950 s 1960 s Elton Mayo Abraham Maslow Frederick Hertzberg Douglas Mc. Gregor Management Science Linear programming Digital computer Simulation, PERT/CPM, Waiting line theory MRP 1947 1951 1950 s 1960 s magutumop 2011 George Dantzig Remington Rand Operations research groups Joseph Orlicky, IBM 39

Historical Events in OM Quality Revolution JIT TQM 1970 s 1980 s Strategy and operations Reengineering World Trade Organization 1990 s Taiichi Ohno, Toyota W. Edwards Deming, Joseph Juran, et. al. Skinner, Hayes Hammer, Champy Numerous countries and companies Globalization European Union and other trade agreements EDI, EFT, CIM 1970 s IBM and others 1980 s magutumop 2011 40

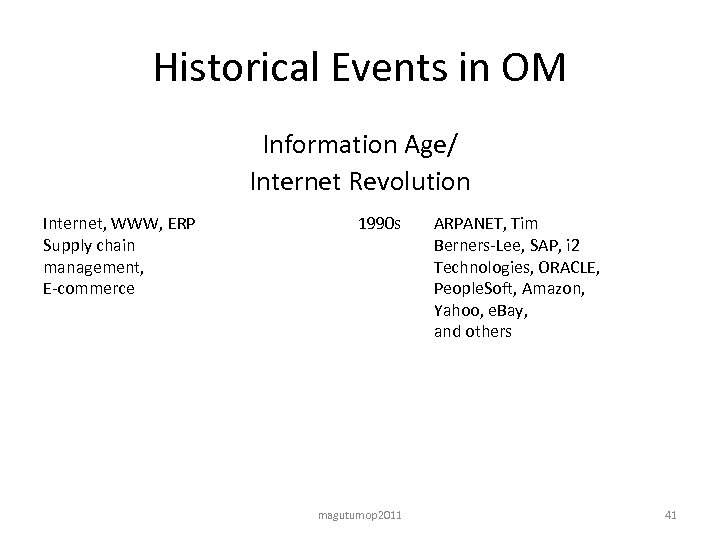

Historical Events in OM Information Age/ Internet Revolution Internet, WWW, ERP Supply chain management, E-commerce 1990 s magutumop 2011 ARPANET, Tim Berners-Lee, SAP, i 2 Technologies, ORACLE, People. Soft, Amazon, Yahoo, e. Bay, and others 41

Trends in Business • Major trends – The Internet, e-commerce, e-business – Management technology – Globalization – Management of supply chains – Outsourcing – Agility – Ethical behavior magutumop 2011 42

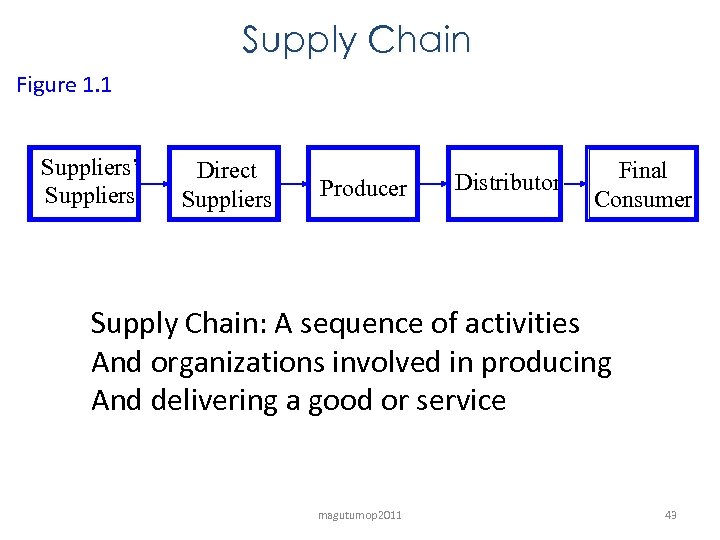

Supply Chain Figure 1. 1 Suppliers’ Suppliers Direct Suppliers Producer Distributor Final Consumer Supply Chain: A sequence of activities And organizations involved in producing And delivering a good or service magutumop 2011 43

Other Important Trends • • Ethical behavior Operations strategy Working with fewer resources Revenue management Process analysis and improvement Increased regulation and product liability Lean production magutumop 2011 44

Today’s OM Environment • Customers demand better quality, greater speed, and lower costs • Companies implementing lean system concepts – a total systems approach to efficient operations • Recognized need to better manage information using ERP and CRM systems • Increased cross-functional decision making magutumop 2011 45

OM in Practice • OM has the most diverse organizational function • Manages the transformation process • OM has many faces and names such as; – V. P. operations, Director of supply chains, Manufacturing manager – Plant manger, Quality specialists, etc. • All business functions need information from OM in order to perform their tasks magutumop 2011 46

Current Issues in OM Practice • Speeding up the time it takes to get new products into production. • Developing flexible production systems to enable mass customization of products and services. • Managing global production networks. • Developing and integrating new production technologies into existing production systems. • Achieving high quality quickly and keeping it up in the face of restructuring. • Managing a diverse workforce. • Conforming to environmental constraints, ethical standards, and government regulations. magutumop 2011 47

A New Paradigm for OM • Post-War U. S. Dominance in Manufacturing – Available capacity built to support the war effort – Pent-up demand for consumer goods – Destruction of overseas production capabilities • Proactive Operations Function (Skinner) – Add value to products, increase profit margins. – Compete on dimensions other than costs: • Quality • Speed of delivery • Process flexibility

The Ever-Changing World of OM • Increased Global Competition – Transformation into a global economy – Pressure to excel on multiple competitive dimensions – Increased emphasis on logistics • Advances in Technology – Information technology (IT) – Internet email and commerce (B 2 B) – Automation and robotics

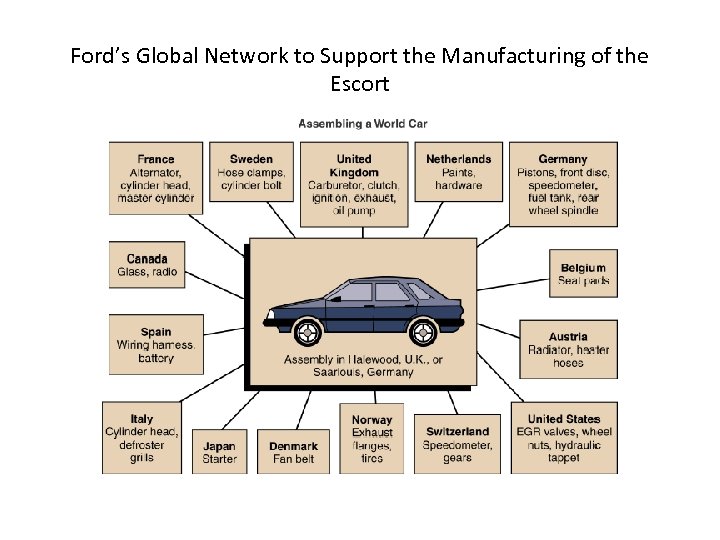

Ford’s Global Network to Support the Manufacturing of the Escort

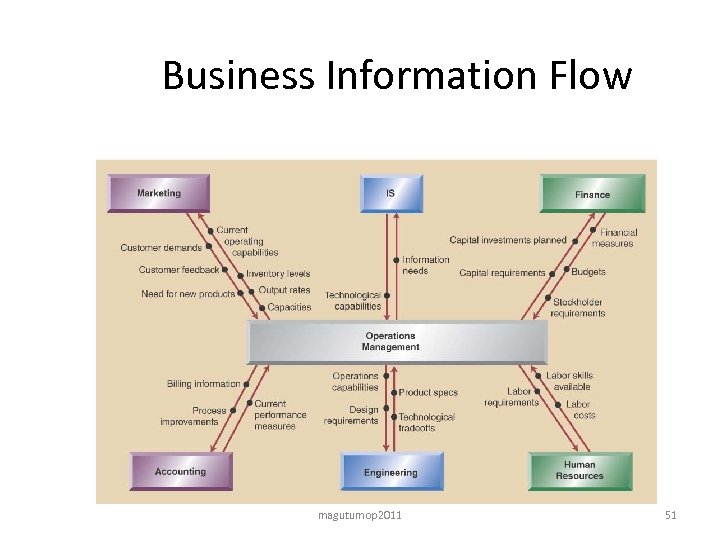

Business Information Flow magutumop 2011 51

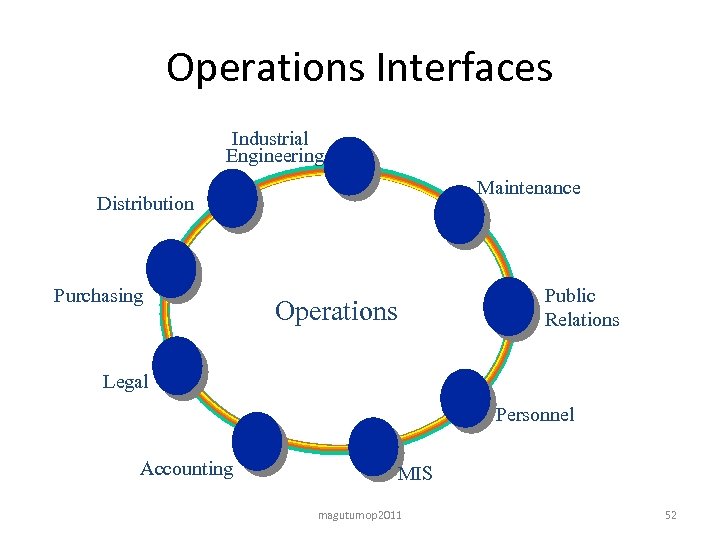

Operations Interfaces Industrial Engineering Maintenance Distribution Purchasing Operations Public Relations Legal Personnel Accounting MIS magutumop 2011 52

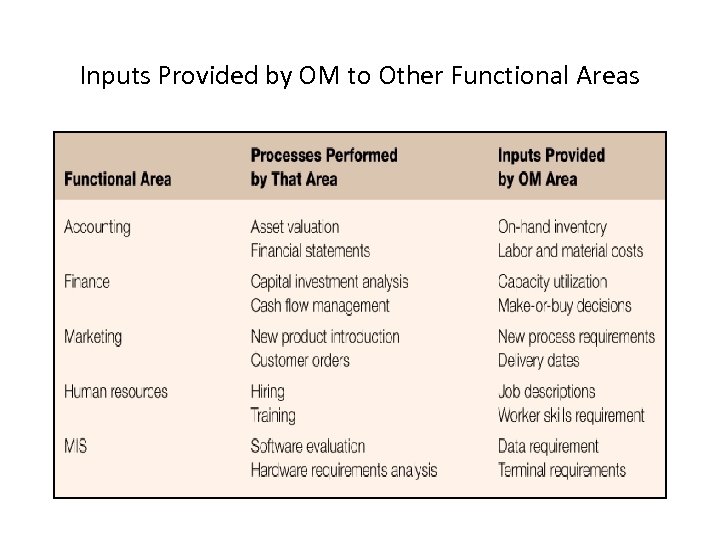

Inputs Provided by OM to Other Functional Areas

OM Across the Organization • Most businesses are supported by the functions of operations, marketing, and finance • The major functional areas must interact to achieve the organization goals magutumop 2011 54

OM Across the Organization – con’t • Marketing is not fully able to meet customer needs if they do not understand what operations can produce • Finance cannot judge the need for capital investments if they do not understand operations concepts and needs • Information systems enables the information flow throughout the organization • Human resources must understand job requirements and worker skills • Accounting needs to consider inventory management, capacity information, and labor standards magutumop 2011 55

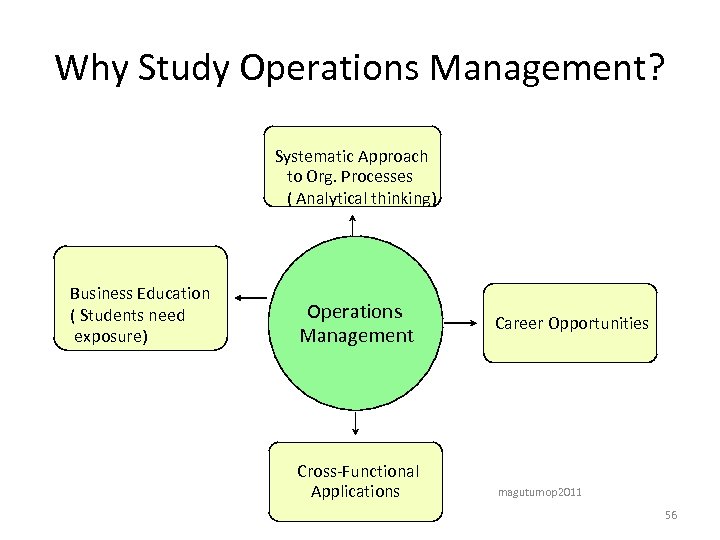

Why Study Operations Management? Systematic Approach to Org. Processes ( Analytical thinking) Business Education ( Students need exposure) Operations Management Cross-Functional Applications Career Opportunities magutumop 2011 56

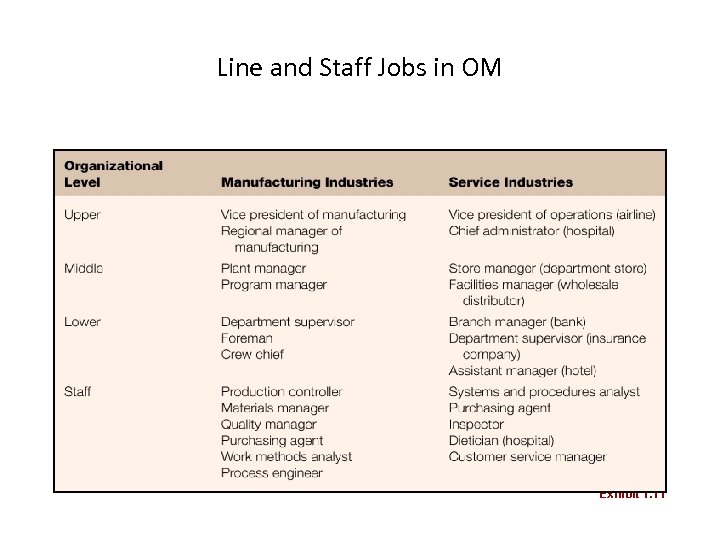

Line and Staff Jobs in OM Exhibit 1. 11

Chapter 1 Highlights • OM is the business function that is responsible for managing and coordinating the resources needed to produce a company’s products and services. • The role of OM is to transform organizational inputs into company’s products or services outputs • OM is responsible for a wide range of decisions, ranging from strategic to tactical. • Organizations can be divided into manufacturing and service organizations, which differ in the tangibility of the product or service magutumop 2011 58

Review of Learning Objectives • Define and explain OM • Explain the role of OM in business • Describe the decisions that operations managers make • Describe the differences between service and manufacturing operations • Identify major historical developments in OM magutumop 2011 59

Review of Learning Objectives – con’t • Identify current trends in OM • Describe the flow of information between OM and other business functions magutumop 2011 60

Course Outline: • Course Objectives: The objectives of this course are: • to develop an understanding of the role of operations management as a functional area of management and develop ability to apply operations management concepts in a variety of settings including manufacturing, service and non-business organizations; • to introduce the body of theory and analytical tools developed for operations management and to show they can be used to support operations management decisions. We will discuss strategic, tactical and operational issues in operations management. • A selection of key topics will be covered in depth. We will strive to maintain a fairly rigorous level of discussion throughout the course, proceeding from outlining the main concepts and tradeoffs related to each topic to the development of analytical approaches to operations issues. 61

• 1. An overview of Operations Management • � Introduction and Historical Perspective • � Transformation Process Model • � Framework for analysing OM decisions • � Productions/Operations Management Strategy • � Strategic Role of Operations Management • 2. Design Considerations • � Product/Service Design Issues • � Capacity Planning • � Facilities location • � Production flows • � Facilities layout • � Work design 62

• • • • • 3. Operative Decisions � Inventory Planning and Control � Aggregate Production Planning � Detailed scheduling of systems � Resource Requirements Planning 4. Supply Chain management � Drive towards supply chain management � Supply chain strategy Development � Performance metrics � ICT in Supply Chains � Challenges of managing supply chains 5. Quality Management � Quality Control � Quality Assurance � Total Quality Management 6. Project Management 7. Revising and Improving Operations Systems � Improvement Approaches � Technology and improvements 63

• • • • • Suggested Texts/References 1. Production and Operations Management: Manufacturing and Services by Chase, Aquilano and Jacobs 2. Operations Management by Nigel Slack and Stuart Chambers 3. Operations Management by Jay Heizer and Barry Render 4. Operations Management by William J. Stevenson. 5. Operations Management by Norman Gaither and Greg Frazier 6. The Management of Operations: A Conceptual Emphasis by Jack R. Meredith 7. Operations Management in service Industries and the Public Sector by C. Voss et al 8. Production/Operations Management by Thomas E. Hendrick and Franklin G Moore 9. Production and Operations Management by Raymond R. Mayer 10. International Journal of Production and Operations Management 11. International Journal of Supply Chain Management Course Assessment Case studies 10% Assignments 10% Term paper 10% CAT 20% Final Exam 50% 64

Accessing Notes On E-learning Portal 1. www. uonbi. ac. ke >>>Resources 2. E-Learning Portal>>>Multimedia Portal 3. User name>>>>mba Password>>>>mba 4. Chose DOM 511>>documents

a69e33615047a872407e6784fdd0942b.ppt