c0b3d4d7a9fdf11544346359a568d0f5.ppt

- Количество слайдов: 52

DOM 511 : Operations Management Practice 1 - Overview By: Munyao-mulwa Uo. N School of Business 2016

DOM 511 : Operations Management Practice 1 - Overview By: Munyao-mulwa Uo. N School of Business 2016

What is Operation Management? Typical Operations Manufacturing: Getting the products a company makes to an agreed specification, in due time Transport: Ensuring the transport runs to an agreed schedule Retailing: Pushing the merchandise through the store to the consumer Service: Providing satisfactory, according to an agreed schedule, the service to the customer Operations Manager: The supplier of products or services required by the market place Utilises the organization resources to meet the product or service specifications efficiently & effectively

What is Operation Management? Typical Operations Manufacturing: Getting the products a company makes to an agreed specification, in due time Transport: Ensuring the transport runs to an agreed schedule Retailing: Pushing the merchandise through the store to the consumer Service: Providing satisfactory, according to an agreed schedule, the service to the customer Operations Manager: The supplier of products or services required by the market place Utilises the organization resources to meet the product or service specifications efficiently & effectively

Operations Management Definition § Applying analytical tools and frameworks to improve business processes that cross internal functional boundaries 4

Operations Management Definition § Applying analytical tools and frameworks to improve business processes that cross internal functional boundaries 4

Operations Management Definition § OM is the science & art of ensuring that goods & services are created & delivered successfully to customers. § Applying the principles of OM entails a solid understanding of people, processes, & how they are integrated within a business to create value 4

Operations Management Definition § OM is the science & art of ensuring that goods & services are created & delivered successfully to customers. § Applying the principles of OM entails a solid understanding of people, processes, & how they are integrated within a business to create value 4

From General Management To Operations Management § Traditional Management paradigm revolves around planning, organizing, directing & controlling § OM is the only means by which managers can directly affect the value provided to all stakeholders – customers, employees, investors & society hence OM is a more diverse discipline & spans multiple functional areas 4

From General Management To Operations Management § Traditional Management paradigm revolves around planning, organizing, directing & controlling § OM is the only means by which managers can directly affect the value provided to all stakeholders – customers, employees, investors & society hence OM is a more diverse discipline & spans multiple functional areas 4

Activities of OM Discipline q Layout planning - to give smooth and effective flow of customers, work in process etc ( process design) q Making sure that all staff can contribute to the company’s success (job design); q Avoiding running out of products for sale (inventory management); q Monitoring and enhancing quality of service to customers (Quality management); 4

Activities of OM Discipline q Layout planning - to give smooth and effective flow of customers, work in process etc ( process design) q Making sure that all staff can contribute to the company’s success (job design); q Avoiding running out of products for sale (inventory management); q Monitoring and enhancing quality of service to customers (Quality management); 4

Activities of OM Discipline q Locating stores of an appropriate size in the most effective place (supply network design); q Arranging for the delivery of products to stores (Supply chain management) q Coping with fluctuations in demand (Capacity management) q Maintaining cleanliness and safety of storage area ( failure prevention); 4

Activities of OM Discipline q Locating stores of an appropriate size in the most effective place (supply network design); q Arranging for the delivery of products to stores (Supply chain management) q Coping with fluctuations in demand (Capacity management) q Maintaining cleanliness and safety of storage area ( failure prevention); 4

Activities for OM discipline § Understanding the needs of customers, measuring customer satisfaction & using the information to develop new & improved goods & services § Using information about customers, goods/services, operations, suppliers, employees etc to make better decisions 4

Activities for OM discipline § Understanding the needs of customers, measuring customer satisfaction & using the information to develop new & improved goods & services § Using information about customers, goods/services, operations, suppliers, employees etc to make better decisions 4

Activities for OM discipline § Exploiting technology to design goods & services that respond rapidly & flexibly to customer requirements & improve productivity (product Design) § Continually learning from co-workers, competitors & customers & adapting the organization to global & environmental changes (Operations Improvement) 4

Activities for OM discipline § Exploiting technology to design goods & services that respond rapidly & flexibly to customer requirements & improve productivity (product Design) § Continually learning from co-workers, competitors & customers & adapting the organization to global & environmental changes (Operations Improvement) 4

OM Discipline OM principles are not complicated for they constitute the “basics” of everyday life eg ü ü ü Respect for customer experience Focus on the dynamics of demand Recognition that experience is delivered by people etc >>The fundamental purpose of OM is to deliver ever-improving value to customers through the continuous improvement of overall company performance & capabilities 4

OM Discipline OM principles are not complicated for they constitute the “basics” of everyday life eg ü ü ü Respect for customer experience Focus on the dynamics of demand Recognition that experience is delivered by people etc >>The fundamental purpose of OM is to deliver ever-improving value to customers through the continuous improvement of overall company performance & capabilities 4

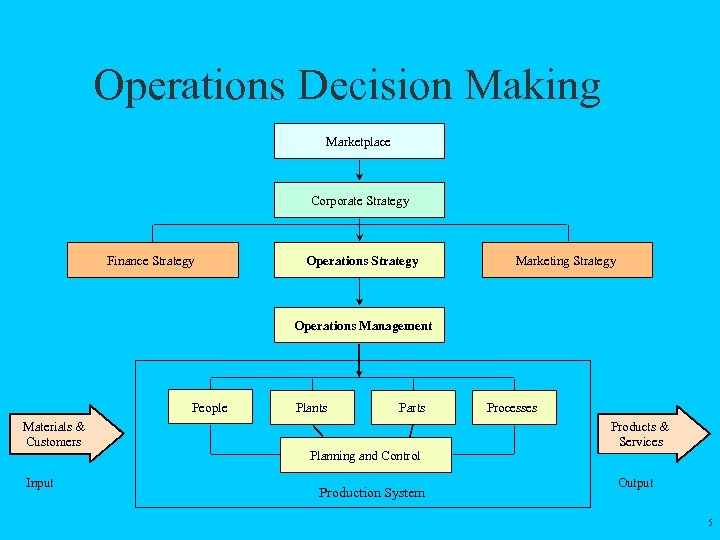

Operations Decision Making Marketplace Corporate Strategy Finance Strategy Operations Strategy Marketing Strategy Operations Management People Materials & Customers Input Plants Parts Planning and Control Production System Processes Products & Services Output 5

Operations Decision Making Marketplace Corporate Strategy Finance Strategy Operations Strategy Marketing Strategy Operations Management People Materials & Customers Input Plants Parts Planning and Control Production System Processes Products & Services Output 5

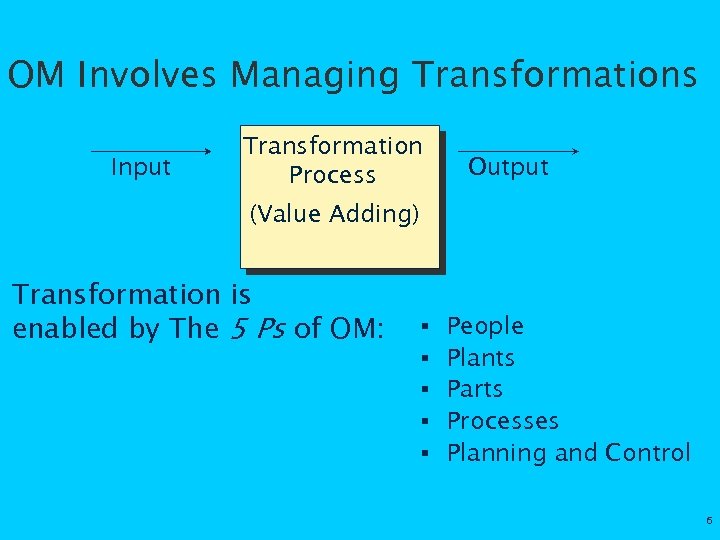

OM Involves Managing Transformations Input Transformation Process Output (Value Adding) Transformation is enabled by The 5 Ps of OM: § People § Plants § Parts § Processes § Planning and Control 6

OM Involves Managing Transformations Input Transformation Process Output (Value Adding) Transformation is enabled by The 5 Ps of OM: § People § Plants § Parts § Processes § Planning and Control 6

Why Do customers buy products /Services? § Value = quality / price § How can an organization increase customer value? 4

Why Do customers buy products /Services? § Value = quality / price § How can an organization increase customer value? 4

OM’s Transformation Role To add value n Increase product value at each stage n Value added is the net increase between output product value and input material value Provide an efficient transformation n Efficiency – perform activities well at lowest possible cost 7

OM’s Transformation Role To add value n Increase product value at each stage n Value added is the net increase between output product value and input material value Provide an efficient transformation n Efficiency – perform activities well at lowest possible cost 7

Transformations Physical--manufacturing Locational--transportation Exchange--retailing Storage--warehousing Physiological--health care Informational--telecommunications 7

Transformations Physical--manufacturing Locational--transportation Exchange--retailing Storage--warehousing Physiological--health care Informational--telecommunications 7

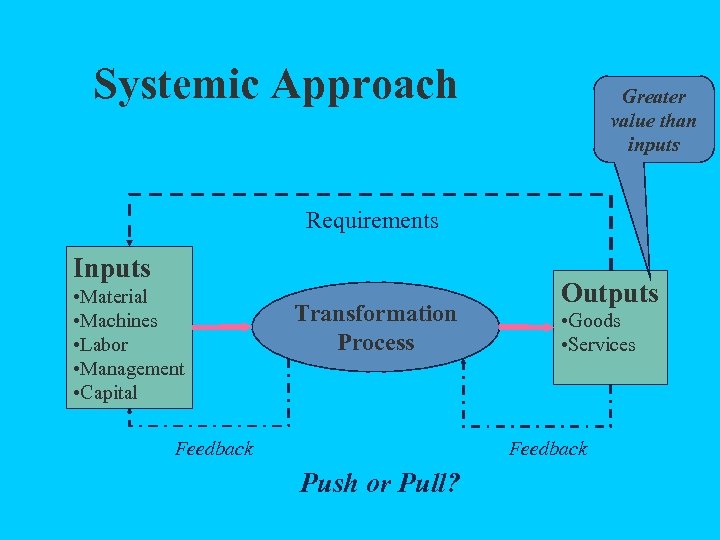

Systemic Approach Greater value than inputs Requirements Inputs • Material • Machines • Labor • Management • Capital Transformation Process Feedback Outputs • Goods • Services Feedback Push or Pull?

Systemic Approach Greater value than inputs Requirements Inputs • Material • Machines • Labor • Management • Capital Transformation Process Feedback Outputs • Goods • Services Feedback Push or Pull?

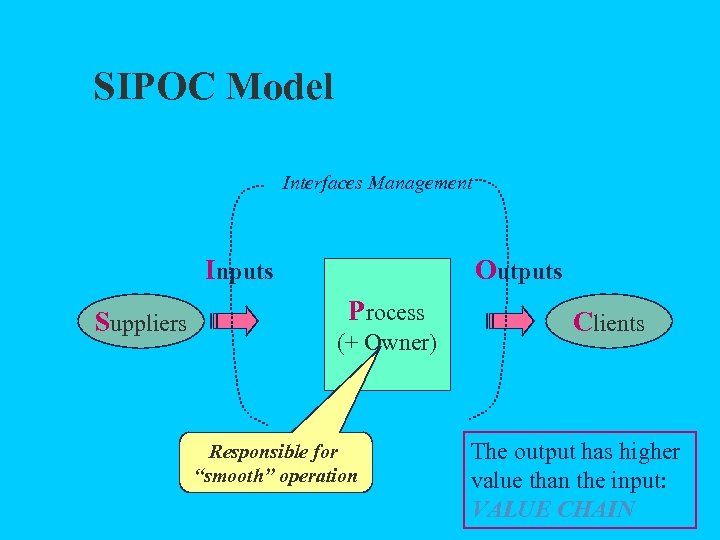

SIPOC Model Interfaces Management Inputs Suppliers Outputs Process (+ Owner) Responsible for “smooth” operation Clients The output has higher value than the input: VALUE CHAIN

SIPOC Model Interfaces Management Inputs Suppliers Outputs Process (+ Owner) Responsible for “smooth” operation Clients The output has higher value than the input: VALUE CHAIN

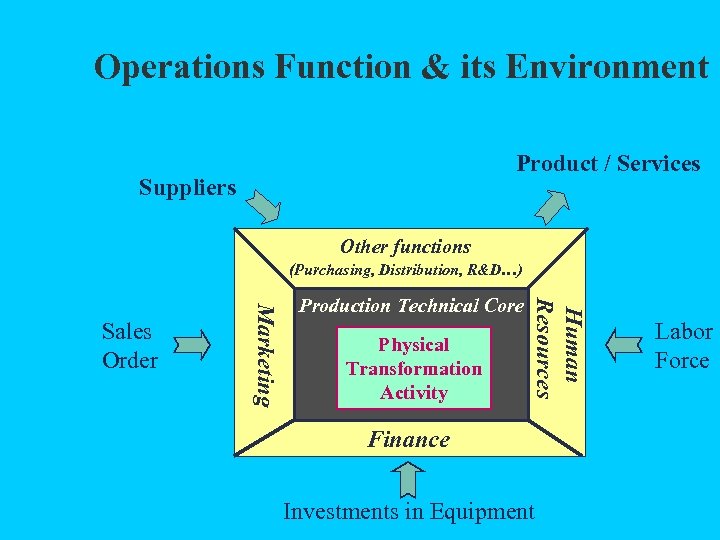

Operations Function & its Environment Product / Services Suppliers Other functions (Purchasing, Distribution, R&D…) Physical Transformation Activity Human Resources Marketing Sales Order Production Technical Core Finance Investments in Equipment Labor Force

Operations Function & its Environment Product / Services Suppliers Other functions (Purchasing, Distribution, R&D…) Physical Transformation Activity Human Resources Marketing Sales Order Production Technical Core Finance Investments in Equipment Labor Force

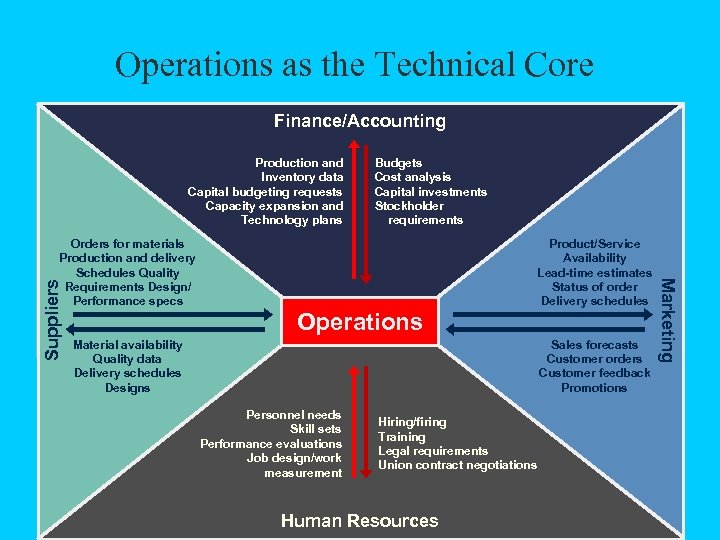

Operations as the Technical Core Finance/Accounting Production and Inventory data Capital budgeting requests Capacity expansion and Technology plans Budgets Cost analysis Capital investments Stockholder requirements Suppliers Product/Service Availability Lead-time estimates Status of order Delivery schedules Operations Material availability Quality data Delivery schedules Designs Sales forecasts Customer orders Customer feedback Promotions Personnel needs Skill sets Performance evaluations Job design/work measurement Hiring/firing Training Legal requirements Union contract negotiations Human Resources Marketing Orders for materials Production and delivery Schedules Quality Requirements Design/ Performance specs

Operations as the Technical Core Finance/Accounting Production and Inventory data Capital budgeting requests Capacity expansion and Technology plans Budgets Cost analysis Capital investments Stockholder requirements Suppliers Product/Service Availability Lead-time estimates Status of order Delivery schedules Operations Material availability Quality data Delivery schedules Designs Sales forecasts Customer orders Customer feedback Promotions Personnel needs Skill sets Performance evaluations Job design/work measurement Hiring/firing Training Legal requirements Union contract negotiations Human Resources Marketing Orders for materials Production and delivery Schedules Quality Requirements Design/ Performance specs

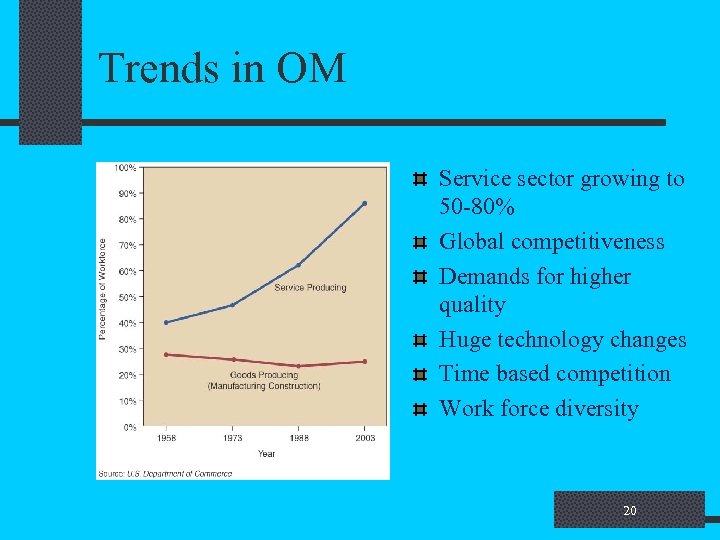

Trends in OM Service sector growing to 50 -80% Global competitiveness Demands for higher quality Huge technology changes Time based competition Work force diversity 20

Trends in OM Service sector growing to 50 -80% Global competitiveness Demands for higher quality Huge technology changes Time based competition Work force diversity 20

Why OM? For long-run success companies must place much importance on their operations n n The 1950 -1960 era was the U. S. golden era where primary opportunities were marketing The 1970 -1980 U. S. companies experienced a large decline in productivity growth – international firms began to challenge in many markets The 1970 -1980 era saw U. S. firms lagging behind in methods and processes The resurgence of American business in the 1990’s capitalized on improved operations 21

Why OM? For long-run success companies must place much importance on their operations n n The 1950 -1960 era was the U. S. golden era where primary opportunities were marketing The 1970 -1980 U. S. companies experienced a large decline in productivity growth – international firms began to challenge in many markets The 1970 -1980 era saw U. S. firms lagging behind in methods and processes The resurgence of American business in the 1990’s capitalized on improved operations 21

Today’s OM Environment Customers demand better quality, greater speed, and lower costs Companies implementing lean systems concepts – a total systems approach to efficient operations Recognized need to better manage information using ERP and CRM systems Increased cross-functional decision making 22

Today’s OM Environment Customers demand better quality, greater speed, and lower costs Companies implementing lean systems concepts – a total systems approach to efficient operations Recognized need to better manage information using ERP and CRM systems Increased cross-functional decision making 22

OM in Practice OM is the most diverse organizational function Manages the transformation process OM has many faces and names such as; n n Chief Operating Officer, V. P. operations, Director of supply chain, Manufacturing manager Plant manger, Quality specialist, etc. All business functions need information from OM in order to perform their tasks 23

OM in Practice OM is the most diverse organizational function Manages the transformation process OM has many faces and names such as; n n Chief Operating Officer, V. P. operations, Director of supply chain, Manufacturing manager Plant manger, Quality specialist, etc. All business functions need information from OM in order to perform their tasks 23

Historical Events in OM ü Industrial Revolution ü Scientific Management ü Human Relations ü Management Science ü Quality Revolution ü Globalization ü Information Age/Internet Revolution

Historical Events in OM ü Industrial Revolution ü Scientific Management ü Human Relations ü Management Science ü Quality Revolution ü Globalization ü Information Age/Internet Revolution

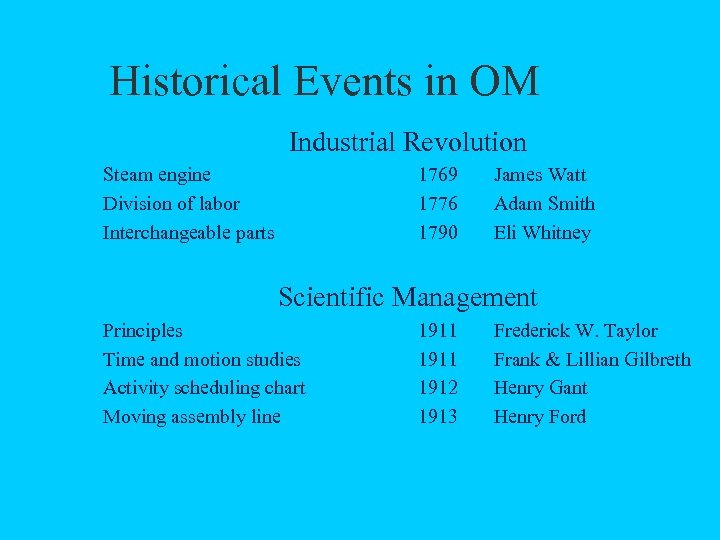

Historical Events in OM Industrial Revolution Steam engine Division of labor Interchangeable parts 1769 1776 1790 James Watt Adam Smith Eli Whitney Scientific Management Principles Time and motion studies Activity scheduling chart Moving assembly line 1911 1912 1913 Frederick W. Taylor Frank & Lillian Gilbreth Henry Gant Henry Ford

Historical Events in OM Industrial Revolution Steam engine Division of labor Interchangeable parts 1769 1776 1790 James Watt Adam Smith Eli Whitney Scientific Management Principles Time and motion studies Activity scheduling chart Moving assembly line 1911 1912 1913 Frederick W. Taylor Frank & Lillian Gilbreth Henry Gant Henry Ford

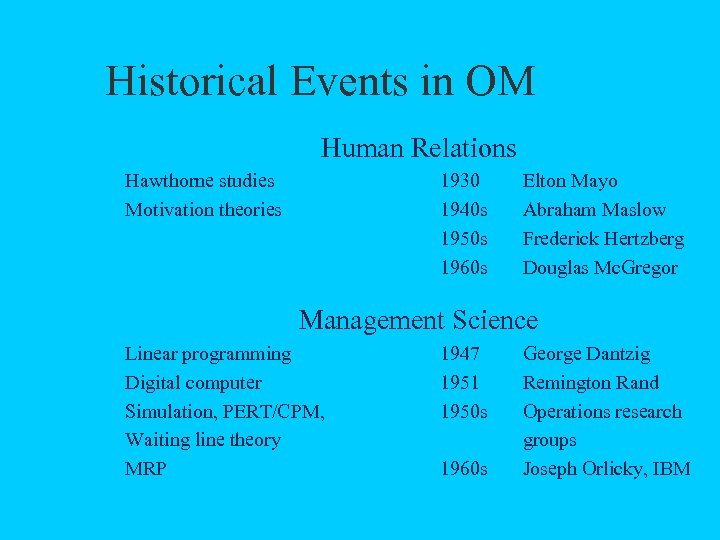

Historical Events in OM Human Relations Hawthorne studies Motivation theories 1930 1940 s 1950 s 1960 s Elton Mayo Abraham Maslow Frederick Hertzberg Douglas Mc. Gregor Management Science Linear programming Digital computer Simulation, PERT/CPM, Waiting line theory MRP 1947 1951 1950 s 1960 s George Dantzig Remington Rand Operations research groups Joseph Orlicky, IBM

Historical Events in OM Human Relations Hawthorne studies Motivation theories 1930 1940 s 1950 s 1960 s Elton Mayo Abraham Maslow Frederick Hertzberg Douglas Mc. Gregor Management Science Linear programming Digital computer Simulation, PERT/CPM, Waiting line theory MRP 1947 1951 1950 s 1960 s George Dantzig Remington Rand Operations research groups Joseph Orlicky, IBM

Historical Events in OM Quality Revolution JIT TQM 1970 s 1980 s Strategy and operations Reengineering World Trade Organization 1990 s Taiichi Ohno, Toyota W. Edwards Deming, Joseph Juran, et. al. Skinner, Hayes Hammer, Champy Numerous countries and companies Globalization European Union and other trade agreements EDI, EFT, CIM 1970 s 1980 s IBM and others

Historical Events in OM Quality Revolution JIT TQM 1970 s 1980 s Strategy and operations Reengineering World Trade Organization 1990 s Taiichi Ohno, Toyota W. Edwards Deming, Joseph Juran, et. al. Skinner, Hayes Hammer, Champy Numerous countries and companies Globalization European Union and other trade agreements EDI, EFT, CIM 1970 s 1980 s IBM and others

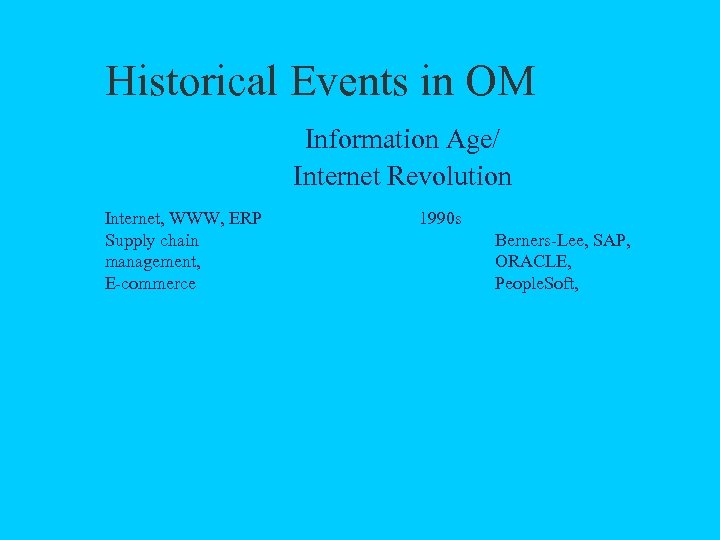

Historical Events in OM Information Age/ Internet Revolution Internet, WWW, ERP Supply chain management, E-commerce 1990 s Berners-Lee, SAP, ORACLE, People. Soft,

Historical Events in OM Information Age/ Internet Revolution Internet, WWW, ERP Supply chain management, E-commerce 1990 s Berners-Lee, SAP, ORACLE, People. Soft,

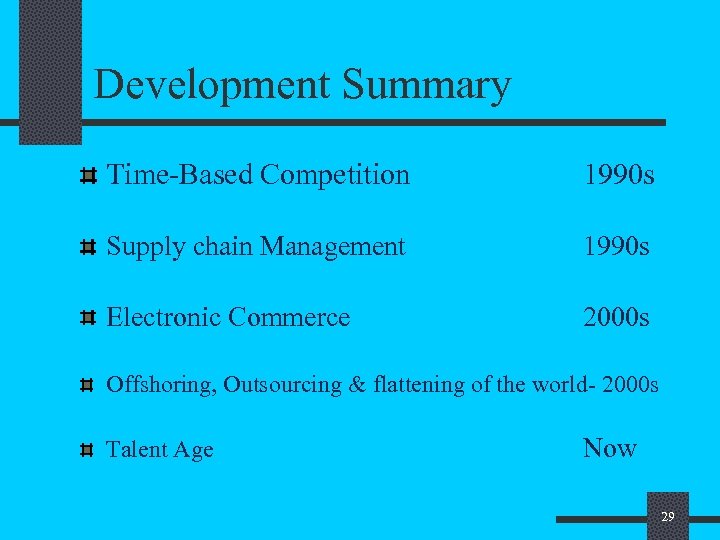

Development Summary Time-Based Competition 1990 s Supply chain Management 1990 s Electronic Commerce 2000 s Offshoring, Outsourcing & flattening of the world- 2000 s Talent Age Now 29

Development Summary Time-Based Competition 1990 s Supply chain Management 1990 s Electronic Commerce 2000 s Offshoring, Outsourcing & flattening of the world- 2000 s Talent Age Now 29

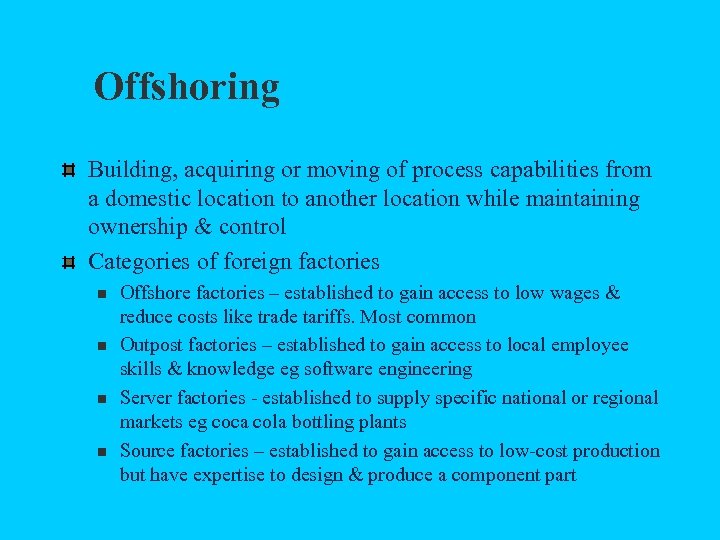

Offshoring Building, acquiring or moving of process capabilities from a domestic location to another location while maintaining ownership & control Categories of foreign factories n n Offshore factories – established to gain access to low wages & reduce costs like trade tariffs. Most common Outpost factories – established to gain access to local employee skills & knowledge eg software engineering Server factories - established to supply specific national or regional markets eg coca cola bottling plants Source factories – established to gain access to low-cost production but have expertise to design & produce a component part

Offshoring Building, acquiring or moving of process capabilities from a domestic location to another location while maintaining ownership & control Categories of foreign factories n n Offshore factories – established to gain access to low wages & reduce costs like trade tariffs. Most common Outpost factories – established to gain access to local employee skills & knowledge eg software engineering Server factories - established to supply specific national or regional markets eg coca cola bottling plants Source factories – established to gain access to low-cost production but have expertise to design & produce a component part

Offshoring Categories of foreign factories n n Contributor factories – established to serve a local market and conduct activities like product design & customization Lead factories – to innovate & create new processes, products & technologies eg HP established an offshore factory in 1970 in singapore

Offshoring Categories of foreign factories n n Contributor factories – established to serve a local market and conduct activities like product design & customization Lead factories – to innovate & create new processes, products & technologies eg HP established an offshore factory in 1970 in singapore

Issues to Consider in Offshoring Dcns Labour talent pool Low labor costs Lower import duties & fees Lower capital costs Grow global market share Avoid national currency fluctuations Preempt competitors from entering global market(s) Hire worldwide skills & knowledge workers Build relationships with suppliers Learn foreign markets & cultures Develop secure sources of supply & reduce risks

Issues to Consider in Offshoring Dcns Labour talent pool Low labor costs Lower import duties & fees Lower capital costs Grow global market share Avoid national currency fluctuations Preempt competitors from entering global market(s) Hire worldwide skills & knowledge workers Build relationships with suppliers Learn foreign markets & cultures Develop secure sources of supply & reduce risks

Current Issues in OM Coordinating the relationships between mutually supportive but separate organizations. n n n Dramatic surge in the outsourcing of parts and services that had previously been produced internally. New breed of contract manufacturers that specialize in performing focused manufacturing activities now exists Companies considering outsourcing other major corporate functions such as information systems, product development and design, engineering services, packaging, testing, and distribution. .

Current Issues in OM Coordinating the relationships between mutually supportive but separate organizations. n n n Dramatic surge in the outsourcing of parts and services that had previously been produced internally. New breed of contract manufacturers that specialize in performing focused manufacturing activities now exists Companies considering outsourcing other major corporate functions such as information systems, product development and design, engineering services, packaging, testing, and distribution. .

Current Issues in OM Optimizing global supplier, production, and distribution networks. n n The implementation of global enterprise resource planning systems, now common in large companies, has challenged managers to use all of this information. Requires a careful understanding of where centralized control and autonomy should be to optimally control such resources as inventory, transportation, and production equipment

Current Issues in OM Optimizing global supplier, production, and distribution networks. n n The implementation of global enterprise resource planning systems, now common in large companies, has challenged managers to use all of this information. Requires a careful understanding of where centralized control and autonomy should be to optimally control such resources as inventory, transportation, and production equipment

Current Issues in OM Increased co-production of goods and services. n n n The Internet has opened new ways for the customer to interact directly with a firm. Simple direct entry and monitoring of orders is now possible Intelligent use of information technology will allow the shedding of entire layers of inefficient customer-oriented functions within a firm, resulting in dramatic reductions in cost while actually improving service to the customer

Current Issues in OM Increased co-production of goods and services. n n n The Internet has opened new ways for the customer to interact directly with a firm. Simple direct entry and monitoring of orders is now possible Intelligent use of information technology will allow the shedding of entire layers of inefficient customer-oriented functions within a firm, resulting in dramatic reductions in cost while actually improving service to the customer

Current Issues in OM Managing customer touch points n n As companies strive to become superefficient, they often scrimp on customer support personnel (and training) required to effectively staff service departments, help lines, and checkout counters Making resource utilization decisions must capture the implicit costs of lost customers as well as the direct costs of staffing

Current Issues in OM Managing customer touch points n n As companies strive to become superefficient, they often scrimp on customer support personnel (and training) required to effectively staff service departments, help lines, and checkout counters Making resource utilization decisions must capture the implicit costs of lost customers as well as the direct costs of staffing

Current Issues in OM Raising senior management awareness of operations as a significant competitive weapon n n Many senior executives entered many organizations through finance, strategy, or marketing and built their reputations on work in these areas, and as a result often take operations for granted. Executives of profitable companies such as Toyota, Dell, Taco Bell, and Southwest Airlines have creatively used operations management for competitive advantage

Current Issues in OM Raising senior management awareness of operations as a significant competitive weapon n n Many senior executives entered many organizations through finance, strategy, or marketing and built their reputations on work in these areas, and as a result often take operations for granted. Executives of profitable companies such as Toyota, Dell, Taco Bell, and Southwest Airlines have creatively used operations management for competitive advantage

Objectives of Productive Systems Volume of output Cost (materials, labor, delivery, scrap…) Utilization (labor & equipment) Quality & product reliability On-time delivery Investments (ROI) Flexibility for product change Flexibility for Volume change

Objectives of Productive Systems Volume of output Cost (materials, labor, delivery, scrap…) Utilization (labor & equipment) Quality & product reliability On-time delivery Investments (ROI) Flexibility for product change Flexibility for Volume change

The Lifecycle of a Productive System Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System

The Lifecycle of a Productive System Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System n n What are the goals of the firm? What product or service will be offered? Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System n n What are the goals of the firm? What product or service will be offered? Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection n n Form & Appearance of Product? Technologically, how should the product be made? Design of the System Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection n n Form & Appearance of Product? Technologically, how should the product be made? Design of the System Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System n n n n Capacity? Location? Lay-out? How to maintain quality? How to determine forecast for demand? What job is each worker to perform? How will the job be performed & measured? How will the workers be rewarded? Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System n n n n Capacity? Location? Lay-out? How to maintain quality? How to determine forecast for demand? What job is each worker to perform? How will the job be performed & measured? How will the workers be rewarded? Start-up of the System The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System n n How do you get the system in operation? How long will it take to reach desired level of output? The System in steady state Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System n n How do you get the system in operation? How long will it take to reach desired level of output? The System in steady state Termination of the System

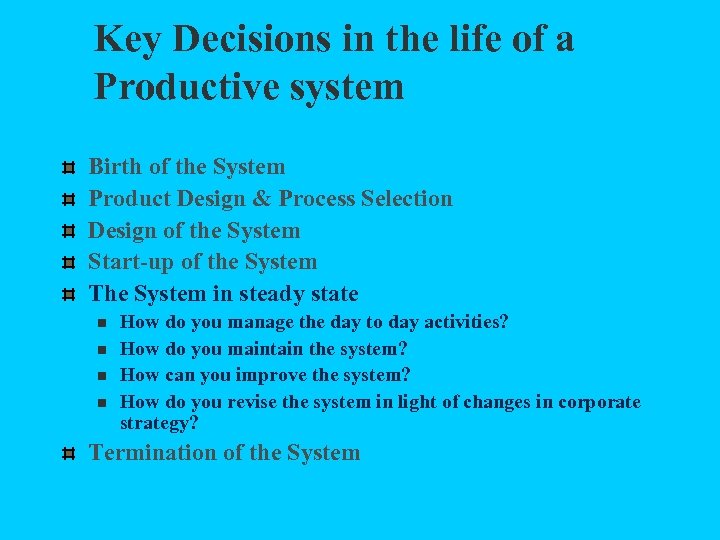

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state n n How do you manage the day to day activities? How do you maintain the system? How can you improve the system? How do you revise the system in light of changes in corporate strategy? Termination of the System

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state n n How do you manage the day to day activities? How do you maintain the system? How can you improve the system? How do you revise the system in light of changes in corporate strategy? Termination of the System

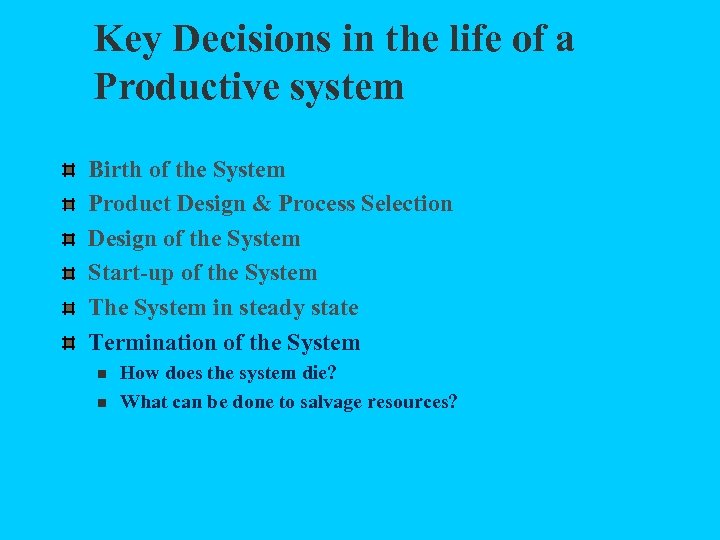

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System n n How does the system die? What can be done to salvage resources?

Key Decisions in the life of a Productive system Birth of the System Product Design & Process Selection Design of the System Start-up of the System The System in steady state Termination of the System n n How does the system die? What can be done to salvage resources?

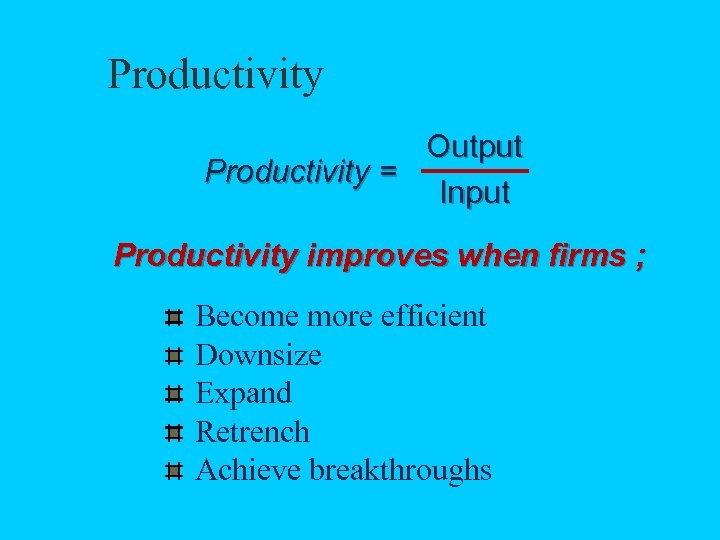

Productivity Output Productivity = Input Productivity improves when firms ; Become more efficient Downsize Expand Retrench Achieve breakthroughs

Productivity Output Productivity = Input Productivity improves when firms ; Become more efficient Downsize Expand Retrench Achieve breakthroughs

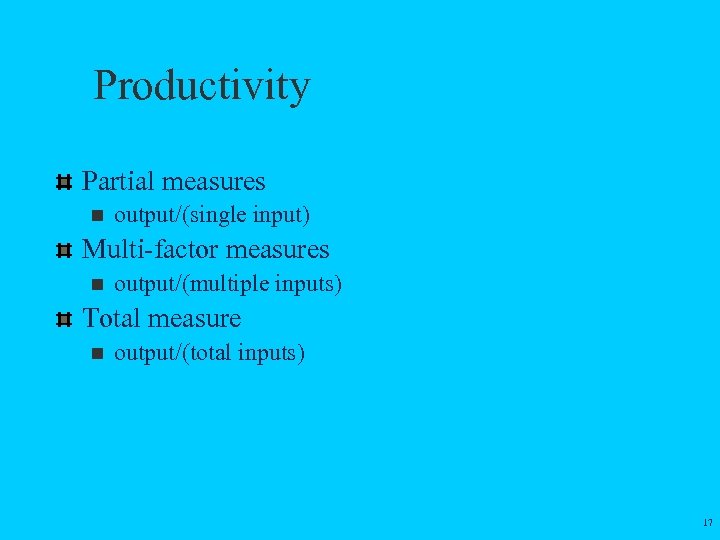

Productivity Partial measures n output/(single input) Multi-factor measures n output/(multiple inputs) Total measure n output/(total inputs) 17

Productivity Partial measures n output/(single input) Multi-factor measures n output/(multiple inputs) Total measure n output/(total inputs) 17

Productivity Analysis Ø Trend analysis: Studying productivity changes for the firm over a period of time. Ø Horizontal analysis: Studying productivity in comparison with other firms of same size and engaged in similar business. Ø Vertical analysis: Studying productivity in comparison with other industries and other firms of different sizes in the same industry. 17

Productivity Analysis Ø Trend analysis: Studying productivity changes for the firm over a period of time. Ø Horizontal analysis: Studying productivity in comparison with other firms of same size and engaged in similar business. Ø Vertical analysis: Studying productivity in comparison with other industries and other firms of different sizes in the same industry. 17

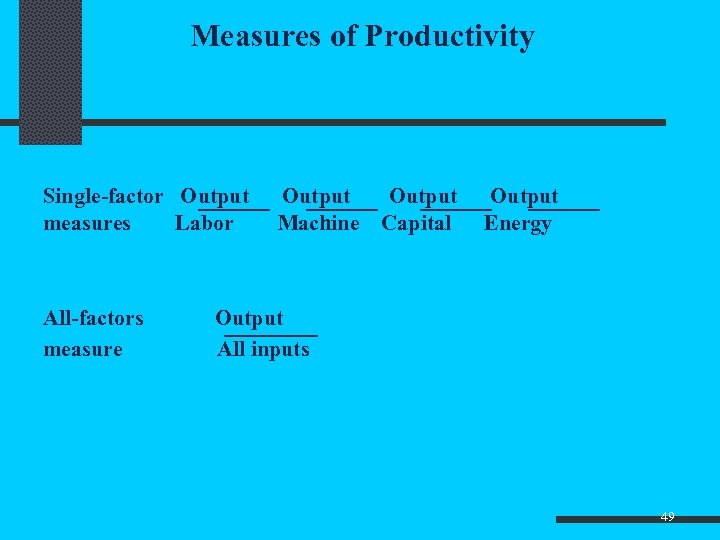

Measures of Productivity Single-factor Output measures Labor All-factors measure Output Machine Output Capital Output Energy Output All inputs 49

Measures of Productivity Single-factor Output measures Labor All-factors measure Output Machine Output Capital Output Energy Output All inputs 49

Example 10, 000 Units Produced Sold for $10/unit 500 labor hours Labor rate: $9/hr What is the labor productivity? Cost of raw material: $5, 000 Cost of purchased material: $25, 000 18

Example 10, 000 Units Produced Sold for $10/unit 500 labor hours Labor rate: $9/hr What is the labor productivity? Cost of raw material: $5, 000 Cost of purchased material: $25, 000 18

What are the factors that affect productivity? Training Technology Methods Management 51

What are the factors that affect productivity? Training Technology Methods Management 51

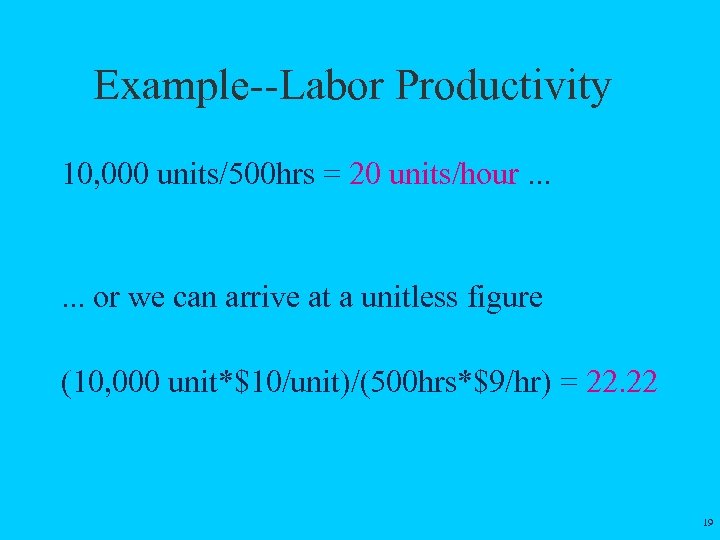

Example--Labor Productivity 10, 000 units/500 hrs = 20 units/hour. . . or we can arrive at a unitless figure (10, 000 unit*$10/unit)/(500 hrs*$9/hr) = 22. 22 19

Example--Labor Productivity 10, 000 units/500 hrs = 20 units/hour. . . or we can arrive at a unitless figure (10, 000 unit*$10/unit)/(500 hrs*$9/hr) = 22. 22 19