06eccdd771cf36166d1cc1911cfb43ad.ppt

- Количество слайдов: 33

Dolomite Case Studies Dolomite Microfluidics: Novel Microfluidic Applications for Chemists © The Dolomite Centre 2014

Dolomite Case Studies Dolomite Microfluidics: Novel Microfluidic Applications for Chemists © The Dolomite Centre 2014

Topics Covered • Company Background • New Applications • Demonstration preview • Summary • Questions

Topics Covered • Company Background • New Applications • Demonstration preview • Summary • Questions

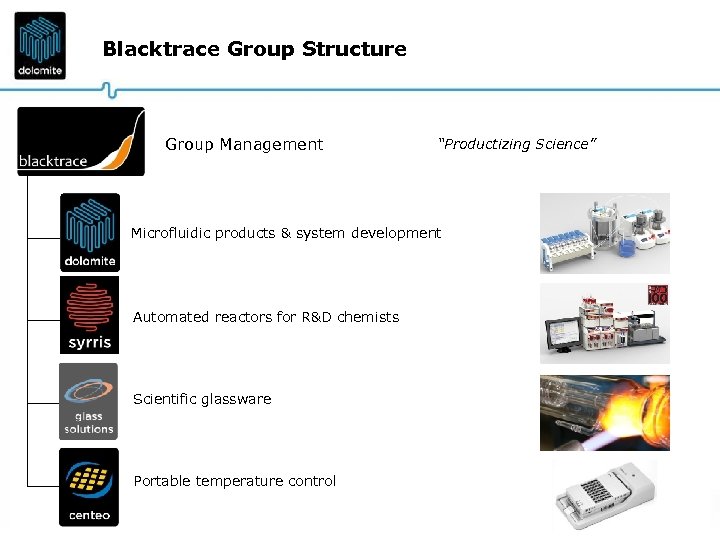

Blacktrace Group Structure Group Management “Productizing Science” Microfluidic products & system development Automated reactors for R&D chemists Scientific glassware Portable temperature control

Blacktrace Group Structure Group Management “Productizing Science” Microfluidic products & system development Automated reactors for R&D chemists Scientific glassware Portable temperature control

Dolomite products

Dolomite products

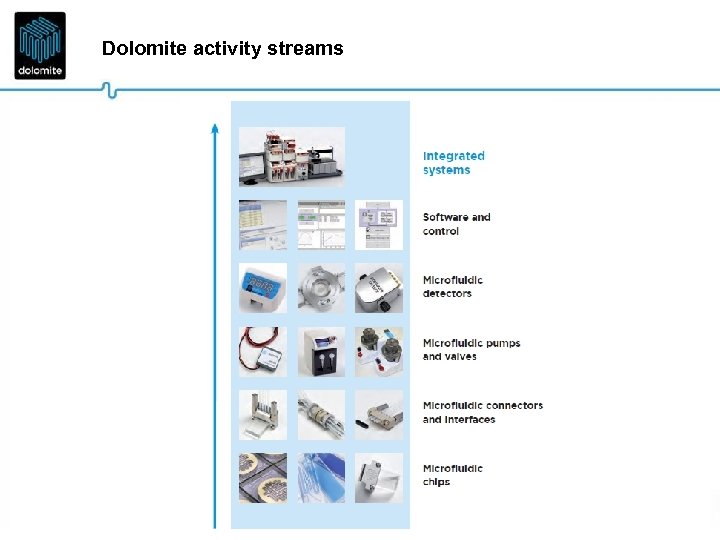

Background: Dolomite Activity Streams Dolomite has 3 primary streams of activity: • Standard Products • Dolomite offers a range of standard devices • Device Design and Fabrication • Customer describes device requirements • Dolomite designs device and interfaces • Dolomite fabricates and supplies devices • Instrument/System Solutions • Customer describes full problem • Dolomite develops Instrument, software and devices

Background: Dolomite Activity Streams Dolomite has 3 primary streams of activity: • Standard Products • Dolomite offers a range of standard devices • Device Design and Fabrication • Customer describes device requirements • Dolomite designs device and interfaces • Dolomite fabricates and supplies devices • Instrument/System Solutions • Customer describes full problem • Dolomite develops Instrument, software and devices

Dolomite fabrication facilities • ISO 9000 approved design and manufacturing facility • 700 sq ft class 1000 clean room facility, fully equipped for manufacture of microfluidic devices • 4, 000 sq ft development facility including design, test, and assembly facilities for mechanical and electronic systems • Full range of computer aided design tools, including Pro/Engineer solid modelling • Advanced project management tools based on Hydra software platform

Dolomite fabrication facilities • ISO 9000 approved design and manufacturing facility • 700 sq ft class 1000 clean room facility, fully equipped for manufacture of microfluidic devices • 4, 000 sq ft development facility including design, test, and assembly facilities for mechanical and electronic systems • Full range of computer aided design tools, including Pro/Engineer solid modelling • Advanced project management tools based on Hydra software platform

Dolomite activity streams

Dolomite activity streams

Topics Covered Novel Microfluidic applications for Chemists

Topics Covered Novel Microfluidic applications for Chemists

Microfluidics and Chemistry • As we have seen, Microfluidics is becoming well established as a key technology for Chemistry: • Synthesis • Purification • What other areas could benefit from microfluidic technology? • This Workshop discusses some interesting new applications “at the edges” of the Chemist’s workflow…

Microfluidics and Chemistry • As we have seen, Microfluidics is becoming well established as a key technology for Chemistry: • Synthesis • Purification • What other areas could benefit from microfluidic technology? • This Workshop discusses some interesting new applications “at the edges” of the Chemist’s workflow…

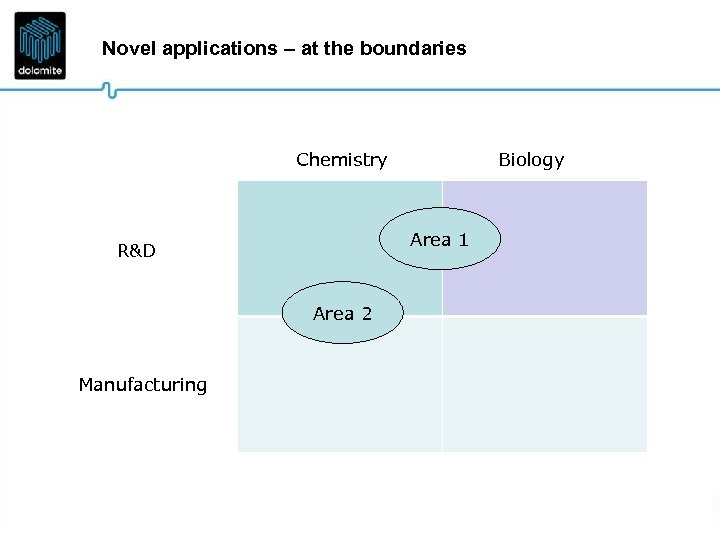

Novel applications – at the boundaries Chemistry Area 1 R&D Area 2 Manufacturing Biology

Novel applications – at the boundaries Chemistry Area 1 R&D Area 2 Manufacturing Biology

Novel Applications • Area 1: the interface between Chemistry and Biology • Screening • Drug/cell interactions • Area 2: the interface between Chemistry and Manufacturing • Particle production for Drug Delivery • Scale-up

Novel Applications • Area 1: the interface between Chemistry and Biology • Screening • Drug/cell interactions • Area 2: the interface between Chemistry and Manufacturing • Particle production for Drug Delivery • Scale-up

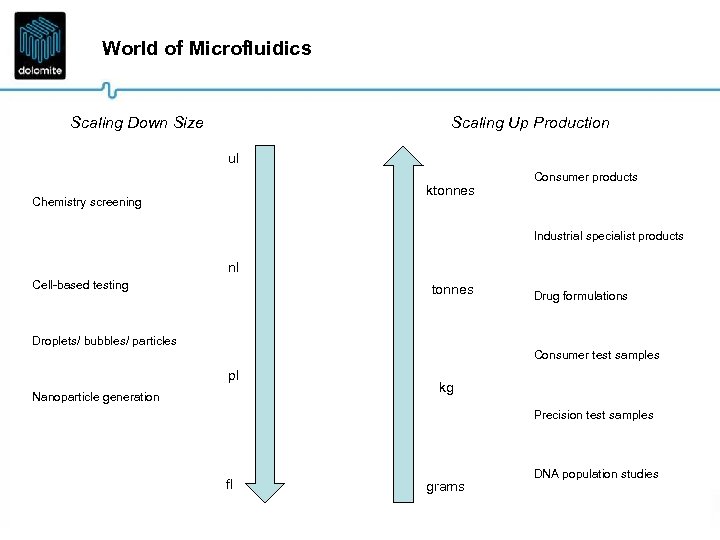

World of Microfluidics Scaling Down Size Scaling Up Production ul ktonnes Chemistry screening Consumer products Industrial specialist products nl Cell-based testing tonnes Drug formulations Droplets/ bubbles/ particles Consumer test samples pl Nanoparticle generation kg Precision test samples fl grams DNA population studies

World of Microfluidics Scaling Down Size Scaling Up Production ul ktonnes Chemistry screening Consumer products Industrial specialist products nl Cell-based testing tonnes Drug formulations Droplets/ bubbles/ particles Consumer test samples pl Nanoparticle generation kg Precision test samples fl grams DNA population studies

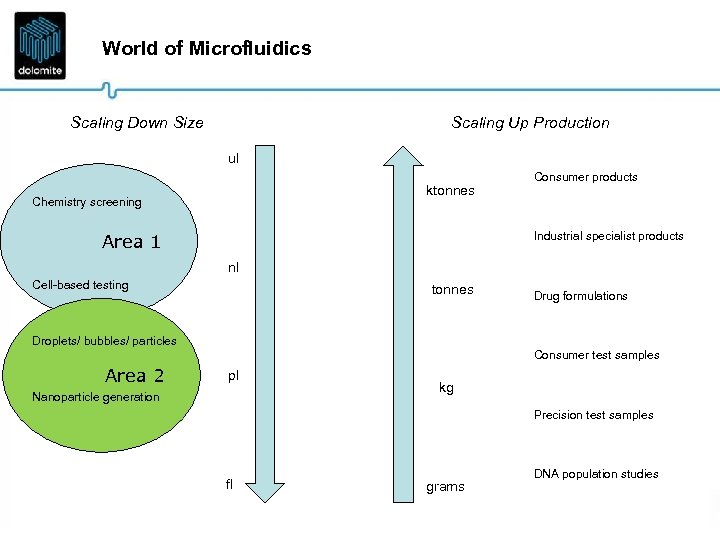

World of Microfluidics Scaling Down Size Scaling Up Production ul ktonnes Chemistry screening Consumer products Industrial specialist products Area 1 nl Cell-based testing tonnes Drug formulations Droplets/ bubbles/ particles Consumer test samples Area 2 pl Nanoparticle generation kg Precision test samples fl grams DNA population studies

World of Microfluidics Scaling Down Size Scaling Up Production ul ktonnes Chemistry screening Consumer products Industrial specialist products Area 1 nl Cell-based testing tonnes Drug formulations Droplets/ bubbles/ particles Consumer test samples Area 2 pl Nanoparticle generation kg Precision test samples fl grams DNA population studies

Topics Covered 1: The Interface between Chemistry and Biology

Topics Covered 1: The Interface between Chemistry and Biology

Applications at the Chemistry/ Biology Interface • Dolomite is developing 2 new technologies which help Chemists test compounds: • Dropix: Droplet on demand system • Cell encapsulation systems

Applications at the Chemistry/ Biology Interface • Dolomite is developing 2 new technologies which help Chemists test compounds: • Dropix: Droplet on demand system • Cell encapsulation systems

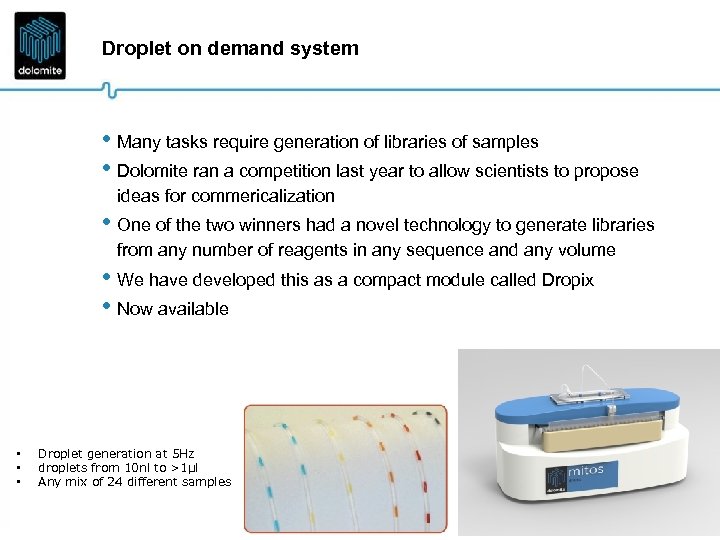

Droplet on demand system • Many tasks require generation of libraries of samples • Dolomite ran a competition last year to allow scientists to propose ideas for commericalization • One of the two winners had a novel technology to generate libraries from any number of reagents in any sequence and any volume • We have developed this as a compact module called Dropix • Now available • • • Droplet generation at 5 Hz droplets from 10 nl to >1μl Any mix of 24 different samples

Droplet on demand system • Many tasks require generation of libraries of samples • Dolomite ran a competition last year to allow scientists to propose ideas for commericalization • One of the two winners had a novel technology to generate libraries from any number of reagents in any sequence and any volume • We have developed this as a compact module called Dropix • Now available • • • Droplet generation at 5 Hz droplets from 10 nl to >1μl Any mix of 24 different samples

Dropix Video

Dropix Video

Dropix Application areas A least 3 clear Dropix application areas: • Screening libraries of compounds/ mixtures • Dose/response characterization using concentration gradients • Crystallization screening (proteins and small molecules) Dropix used to generate samples for screening

Dropix Application areas A least 3 clear Dropix application areas: • Screening libraries of compounds/ mixtures • Dose/response characterization using concentration gradients • Crystallization screening (proteins and small molecules) Dropix used to generate samples for screening

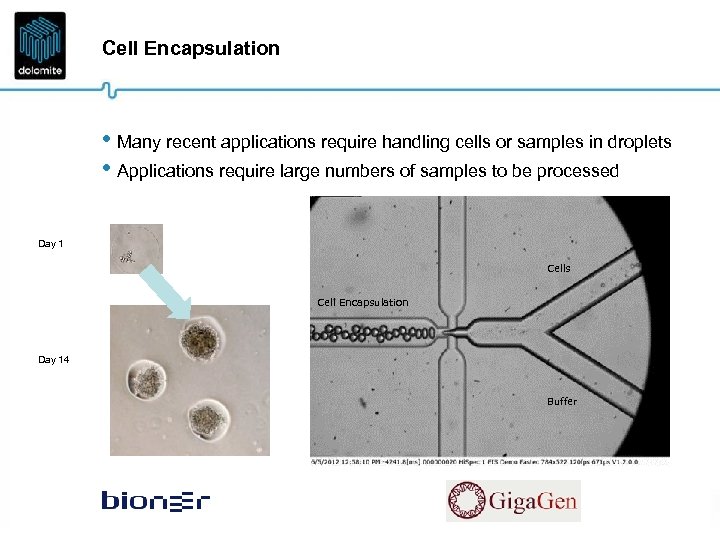

Cell Encapsulation • Many recent applications require handling cells or samples in droplets • Applications require large numbers of samples to be processed Day 1 Cells Cell Encapsulation Day 14 Buffer

Cell Encapsulation • Many recent applications require handling cells or samples in droplets • Applications require large numbers of samples to be processed Day 1 Cells Cell Encapsulation Day 14 Buffer

Topics Covered 2: The Interface between Chemistry and Manufacturing

Topics Covered 2: The Interface between Chemistry and Manufacturing

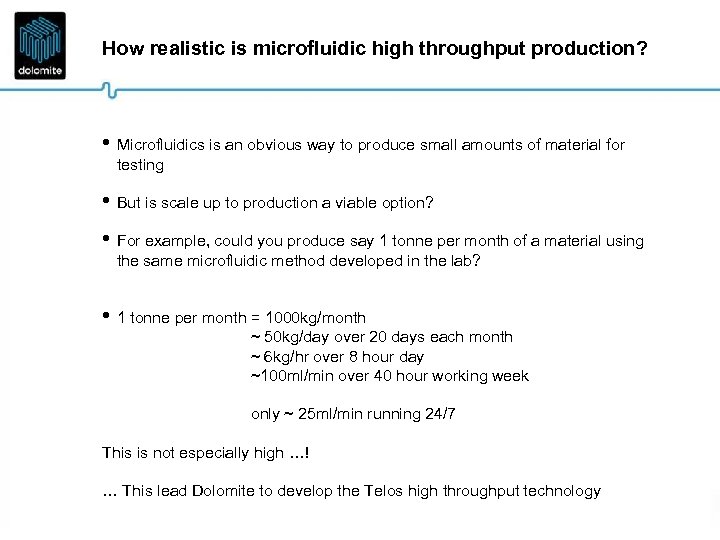

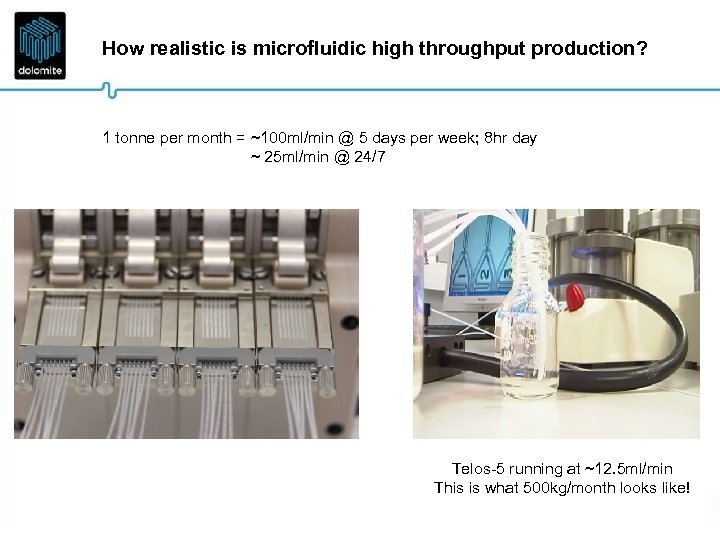

How realistic is microfluidic high throughput production? • Microfluidics is an obvious way to produce small amounts of material for testing • But is scale up to production a viable option? • For example, could you produce say 1 tonne per month of a material using the same microfluidic method developed in the lab? • 1 tonne per month = 1000 kg/month ~ 50 kg/day over 20 days each month ~ 6 kg/hr over 8 hour day ~100 ml/min over 40 hour working week only ~ 25 ml/min running 24/7 This is not especially high …! … This lead Dolomite to develop the Telos high throughput technology

How realistic is microfluidic high throughput production? • Microfluidics is an obvious way to produce small amounts of material for testing • But is scale up to production a viable option? • For example, could you produce say 1 tonne per month of a material using the same microfluidic method developed in the lab? • 1 tonne per month = 1000 kg/month ~ 50 kg/day over 20 days each month ~ 6 kg/hr over 8 hour day ~100 ml/min over 40 hour working week only ~ 25 ml/min running 24/7 This is not especially high …! … This lead Dolomite to develop the Telos high throughput technology

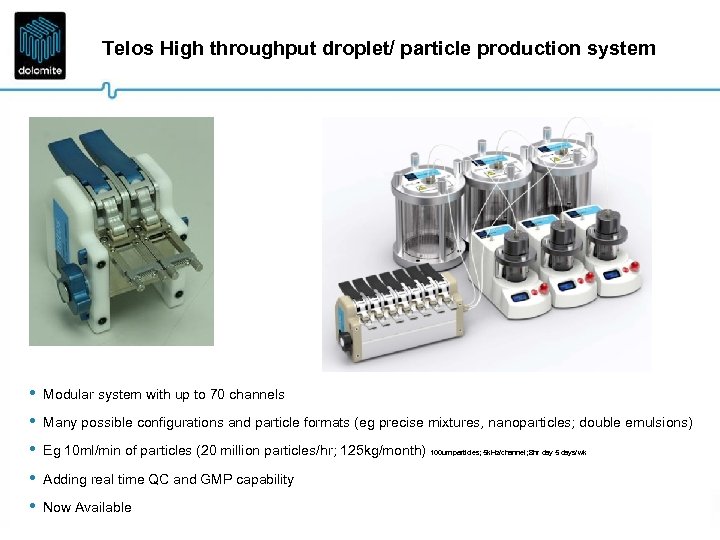

Telos High throughput droplet/ particle production system • • • Modular system with up to 70 channels Many possible configurations and particle formats (eg precise mixtures, nanoparticles; double emulsions) Eg 10 ml/min of particles (20 million particles/hr; 125 kg/month) 100 um particles; 5 k. Hz/channel; 8 hr day 5 days/wk Adding real time QC and GMP capability Now Available

Telos High throughput droplet/ particle production system • • • Modular system with up to 70 channels Many possible configurations and particle formats (eg precise mixtures, nanoparticles; double emulsions) Eg 10 ml/min of particles (20 million particles/hr; 125 kg/month) 100 um particles; 5 k. Hz/channel; 8 hr day 5 days/wk Adding real time QC and GMP capability Now Available

Microfluidic Production Dolomite is working on fluid, nanoparticle and particle production for: • Drug Formulation & Delivery • Bulk Precision Manufacturing (e. g. food, coatings, cosmetics) • We offer a wide range of standard products • We also offer project-based development to create custom solutions for specific applications

Microfluidic Production Dolomite is working on fluid, nanoparticle and particle production for: • Drug Formulation & Delivery • Bulk Precision Manufacturing (e. g. food, coatings, cosmetics) • We offer a wide range of standard products • We also offer project-based development to create custom solutions for specific applications

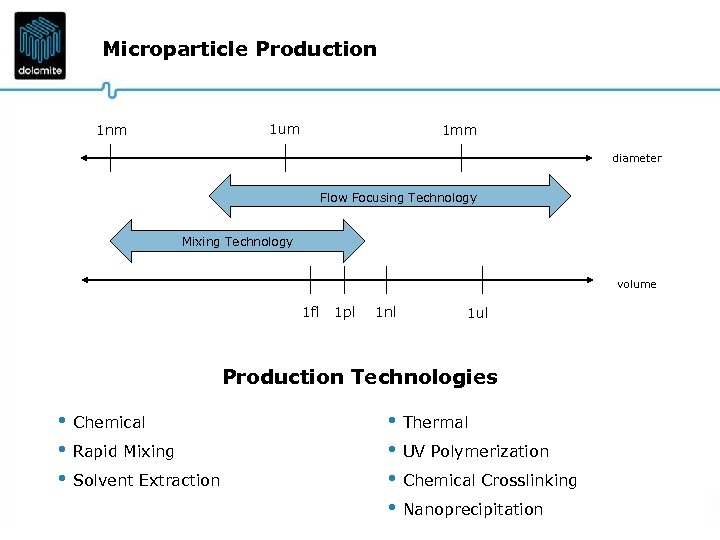

Microparticle Production 1 um 1 nm 1 mm diameter Flow Focusing Technology Mixing Technology volume 1 fl 1 pl 1 nl 1 ul Production Technologies • Chemical • Rapid Mixing • Solvent Extraction • Thermal • UV Polymerization • Chemical Crosslinking • Nanoprecipitation

Microparticle Production 1 um 1 nm 1 mm diameter Flow Focusing Technology Mixing Technology volume 1 fl 1 pl 1 nl 1 ul Production Technologies • Chemical • Rapid Mixing • Solvent Extraction • Thermal • UV Polymerization • Chemical Crosslinking • Nanoprecipitation

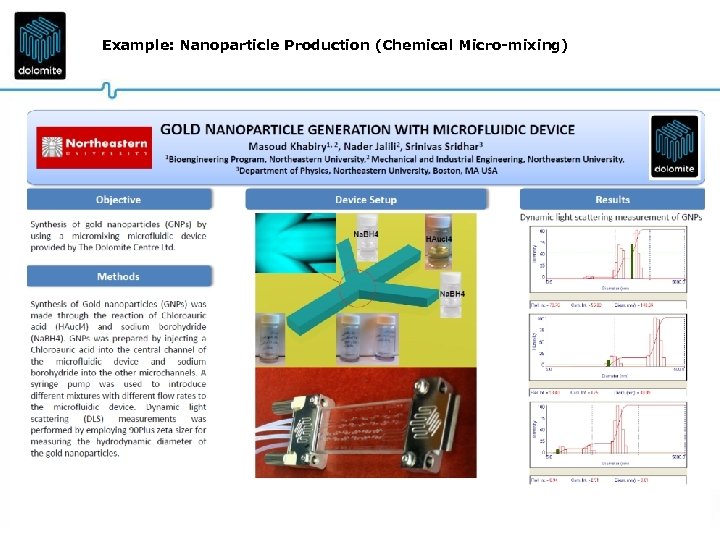

Example: Nanoparticle Production (Chemical Micro-mixing)

Example: Nanoparticle Production (Chemical Micro-mixing)

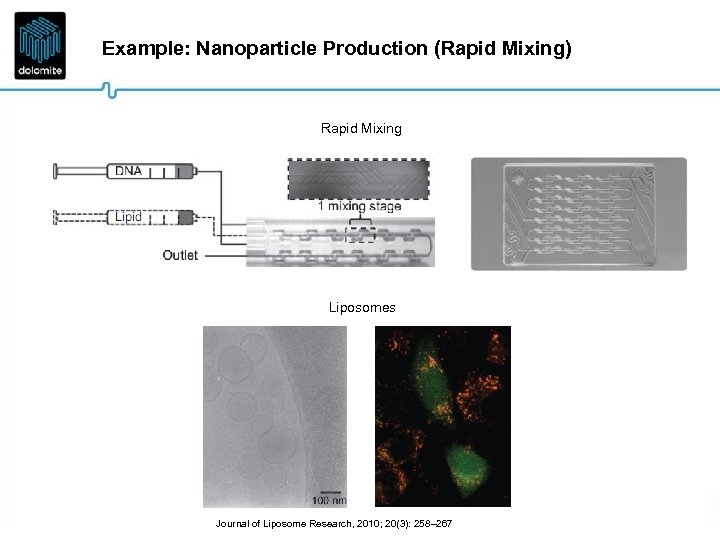

Example: Nanoparticle Production (Rapid Mixing) Rapid Mixing Liposomes Journal of Liposome Research, 2010; 20(3): 258– 267

Example: Nanoparticle Production (Rapid Mixing) Rapid Mixing Liposomes Journal of Liposome Research, 2010; 20(3): 258– 267

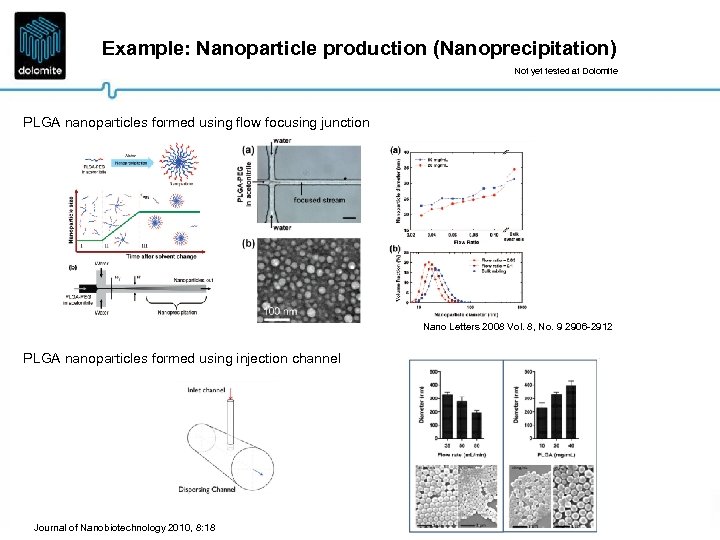

Example: Nanoparticle production (Nanoprecipitation) Not yet tested at Dolomite PLGA nanoparticles formed using flow focusing junction Nano Letters 2008 Vol. 8, No. 9 2906 -2912 PLGA nanoparticles formed using injection channel Journal of Nanobiotechnology 2010, 8: 18

Example: Nanoparticle production (Nanoprecipitation) Not yet tested at Dolomite PLGA nanoparticles formed using flow focusing junction Nano Letters 2008 Vol. 8, No. 9 2906 -2912 PLGA nanoparticles formed using injection channel Journal of Nanobiotechnology 2010, 8: 18

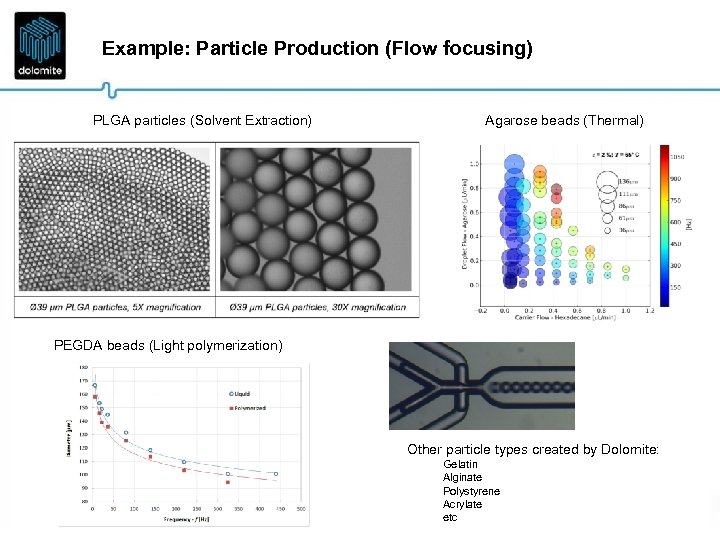

Example: Particle Production (Flow focusing) PLGA particles (Solvent Extraction) Agarose beads (Thermal) PEGDA beads (Light polymerization) Other particle types created by Dolomite: Gelatin Alginate Polystyrene Acrylate etc

Example: Particle Production (Flow focusing) PLGA particles (Solvent Extraction) Agarose beads (Thermal) PEGDA beads (Light polymerization) Other particle types created by Dolomite: Gelatin Alginate Polystyrene Acrylate etc

How realistic is microfluidic high throughput production? 1 tonne per month = ~100 ml/min @ 5 days per week; 8 hr day ~ 25 ml/min @ 24/7 Telos-5 running at ~12. 5 ml/min This is what 500 kg/month looks like!

How realistic is microfluidic high throughput production? 1 tonne per month = ~100 ml/min @ 5 days per week; 8 hr day ~ 25 ml/min @ 24/7 Telos-5 running at ~12. 5 ml/min This is what 500 kg/month looks like!

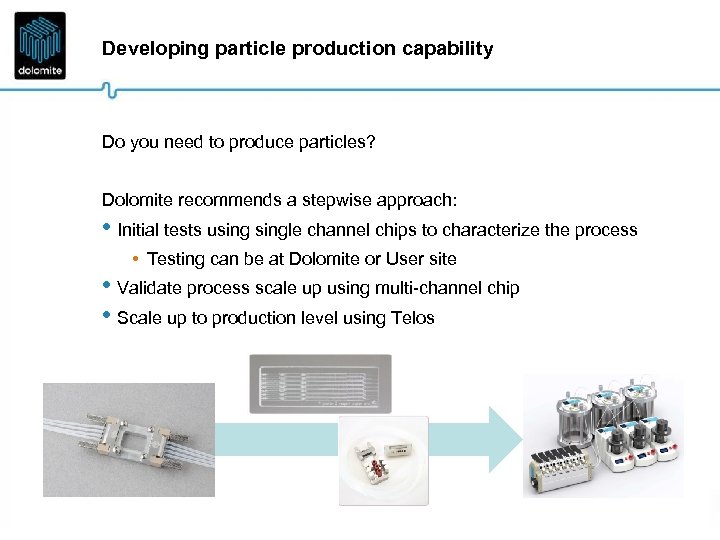

Developing particle production capability Do you need to produce particles? Dolomite recommends a stepwise approach: • Initial tests usingle channel chips to characterize the process • Testing can be at Dolomite or User site • Validate process scale up using multi-channel chip • Scale up to production level using Telos

Developing particle production capability Do you need to produce particles? Dolomite recommends a stepwise approach: • Initial tests usingle channel chips to characterize the process • Testing can be at Dolomite or User site • Validate process scale up using multi-channel chip • Scale up to production level using Telos

Today’s demonstration This afternoon we will show three systems: • Droplet formation – live demo • Dropix droplet on demand system • Telos high throughput production system

Today’s demonstration This afternoon we will show three systems: • Droplet formation – live demo • Dropix droplet on demand system • Telos high throughput production system

Summary of Workshop 4 • There are many new applications for microfluidics of interest to Chemists • New areas are always emerging • Dolomite is happy to discuss these with you • Any questions?

Summary of Workshop 4 • There are many new applications for microfluidics of interest to Chemists • New areas are always emerging • Dolomite is happy to discuss these with you • Any questions?

Thank you!

Thank you!