22012aa64d6844d5d0fd4c62ca4fbe8c.ppt

- Количество слайдов: 38

Do I Need a Big Ass Fan? Active Soil Depressurization Fan Selection Chad Robinson – Building Performance Company Bruce Snead – MURC-KSU

Now It’s Gonna’ Hit the Fan!

Everybody Keep Their Cool!

How “Big” a Fan Do I Need? • Is this the right question?

What Does the Fan Have to Do? • The appropriate fan will have the capacity to: • move sufficient air. . . • to overcome the suction of the house on the soil . . and • pull air through the soil under the foundation . . and • pull and push air through the piping to the discharge point.

In Addition, the Appropriate Fan • • Is the lowest wattage fan that will accomplish the job. Lower wattage fans are almost always quieter and their long term energy costs can be significant. Is Quiet – sound/noise are often justification for fans being turned off by occupants- less than 40 d. B Moves enough air to depressurize the sub-slab zone but minimizes air drawn from the house Easily attaches to vent stack Is Durable Has no positive pressure leaks Is moisture-resistant

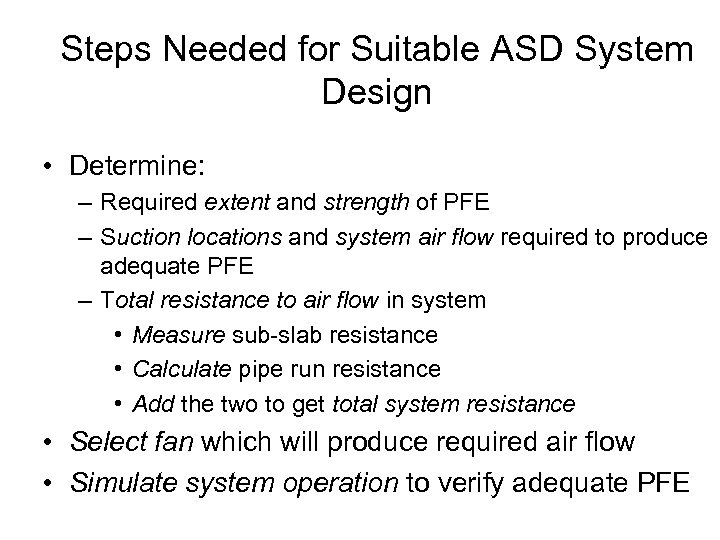

Steps Needed for Suitable ASD System Design • Determine: – Required extent and strength of PFE – Suction locations and system air flow required to produce adequate PFE – Total resistance to air flow in system • Measure sub-slab resistance • Calculate pipe run resistance • Add the two to get total system resistance • Select fan which will produce required air flow • Simulate system operation to verify adequate PFE

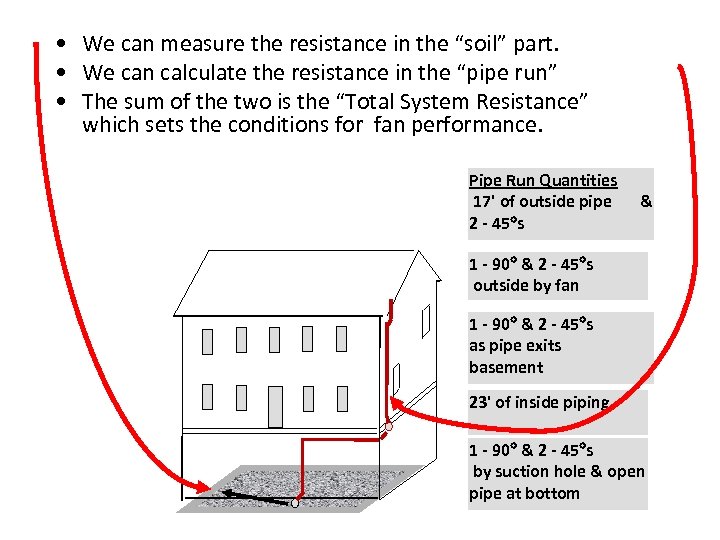

• We can measure the resistance in the “soil” part. • We can calculate the resistance in the “pipe run” • The sum of the two is the “Total System Resistance” which sets the conditions for fan performance. Pipe Run Quantities 17' of outside pipe 2 - 45 s & 1 - 90 & 2 - 45 s outside by fan 1 - 90 & 2 - 45 s as pipe exits basement 23' of inside piping 1 - 90 & 2 - 45 s by suction hole & open pipe at bottom

Which Fan Will Do This? • The fan has to overcome this pressure differential to reverse the flow of air into the house. • In addition, the fan has to work against the resistance of the soil materials under the basement slab. • It also has to work against the resistance created by the piping length and configuration.

Fan Performance and Capacity How is it Rated? • One of the most valuable pieces of information supplied by fan manufacturers is the fan performance curve. • These curves show the relationship between the quantity of air a fan will deliver and the pressure generated at various air quantities.

Common Radon Fan Curves • Note that fan curves indicate quantity of air fan will move (CFM) working against different levels of resistance or static pressure (inches of Water Column) • Curves derived by bench-testing fans connected to PVC pipe

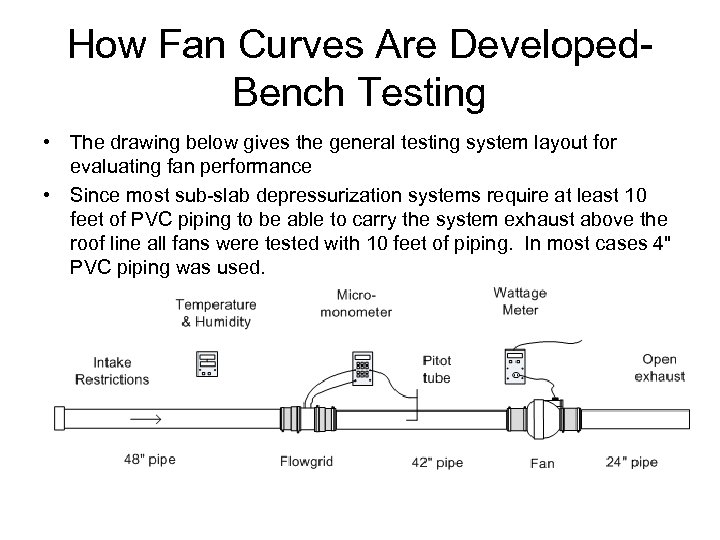

How Fan Curves Are Developed. Bench Testing • The drawing below gives the general testing system layout for evaluating fan performance • Since most sub-slab depressurization systems require at least 10 feet of PVC piping to be able to carry the system exhaust above the roof line all fans were tested with 10 feet of piping. In most cases 4" PVC piping was used.

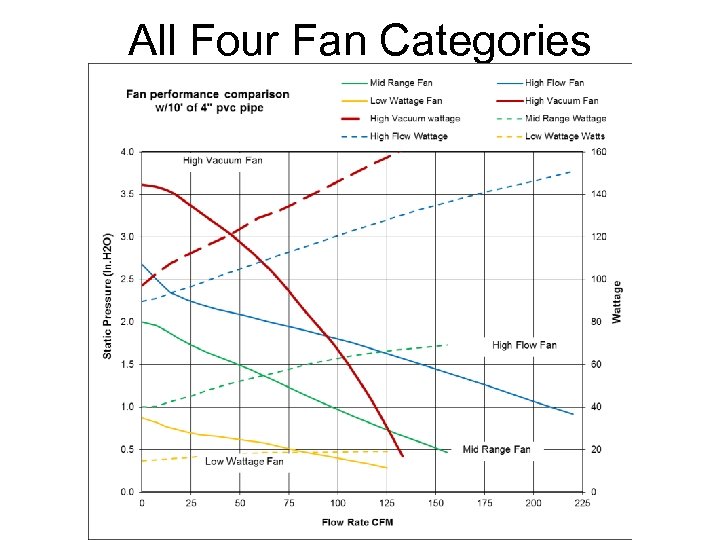

Four General Categories of Radon Fans • Low Wattage Fans - good sub-slab gravel and slab sealing. • Mid Range Fans - less than optimal subslab aggregate and/or slab leakage • High Flow Fans - Lots of slab leaks or very porous soil or multiple foundations to treat • High Vacuum Fans - Packed dirt under the slab with likely low system airflow.

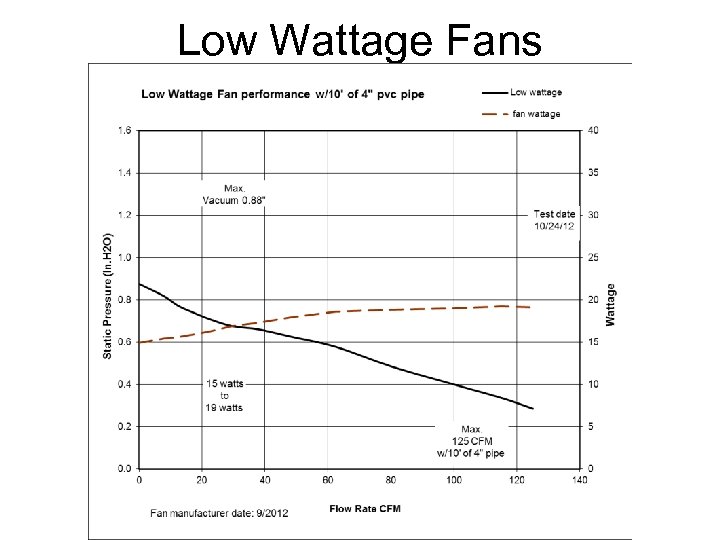

Low Wattage Fans

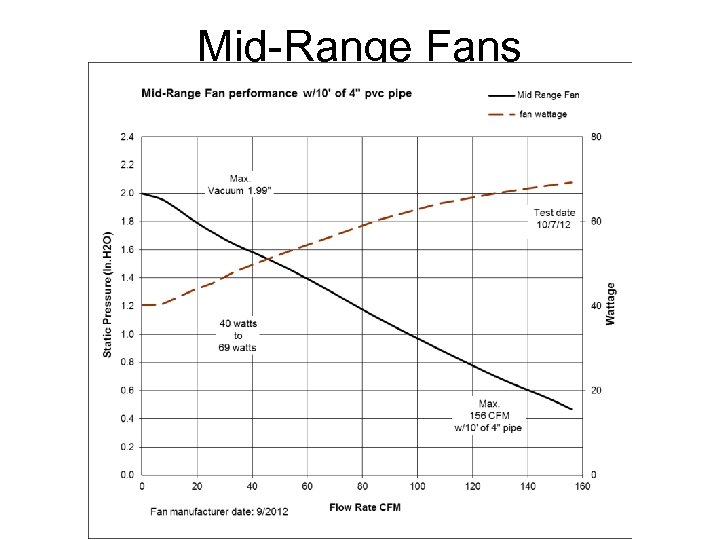

Mid-Range Fans

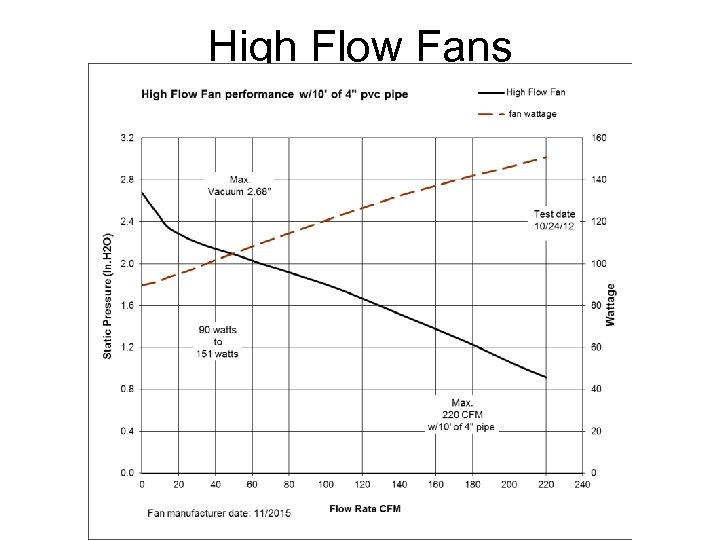

High Flow Fans

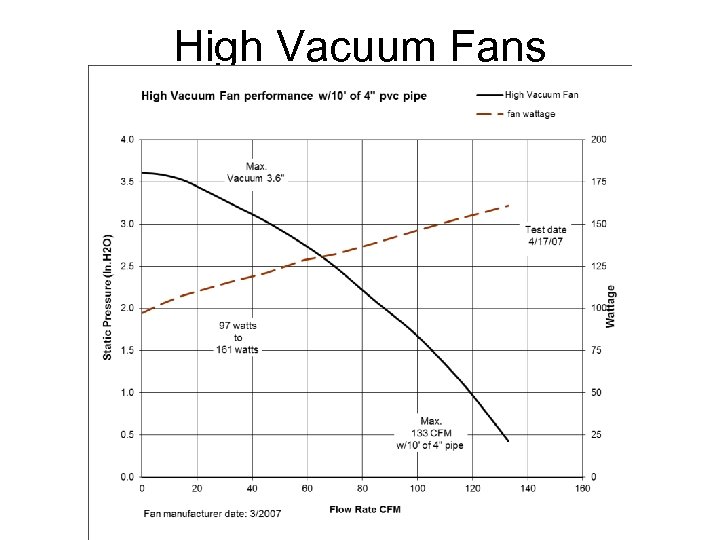

High Vacuum Fans

All Four Fan Categories

Measuring Air Flows • How Many of You Measure Air Flows? • How Do You Measure the Flows? – Pitot Tube? – Flow Grid? – Manufacturer’s chart? • What Are the Average CFMs in the Housing Stock You Mitigate?

What Will It Take to Get Fan Man Up? • Vent stack mounted air flow supported fan figures to draw attention to your mitigation systems!!! • Seasonal, holiday, and special versions…. • You know your fans……

What Airflow Will Get Fan Man Up? • • • 10 -20 CFM 20 -40 CFM 40 -60 CFM 60 -100 CFM Over 100 CFM He won’t make it up…. .

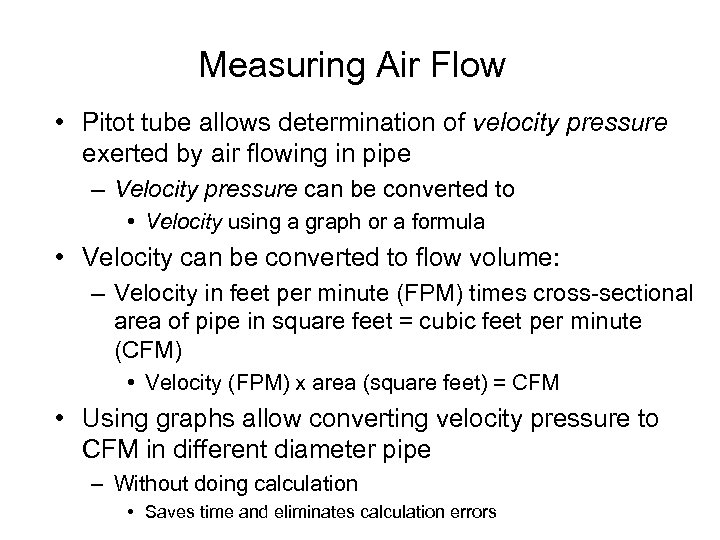

Measuring Air Flow • Pitot tube allows determination of velocity pressure exerted by air flowing in pipe – Velocity pressure can be converted to • Velocity using a graph or a formula • Velocity can be converted to flow volume: – Velocity in feet per minute (FPM) times cross-sectional area of pipe in square feet = cubic feet per minute (CFM) • Velocity (FPM) x area (square feet) = CFM • Using graphs allow converting velocity pressure to CFM in different diameter pipe – Without doing calculation • Saves time and eliminates calculation errors

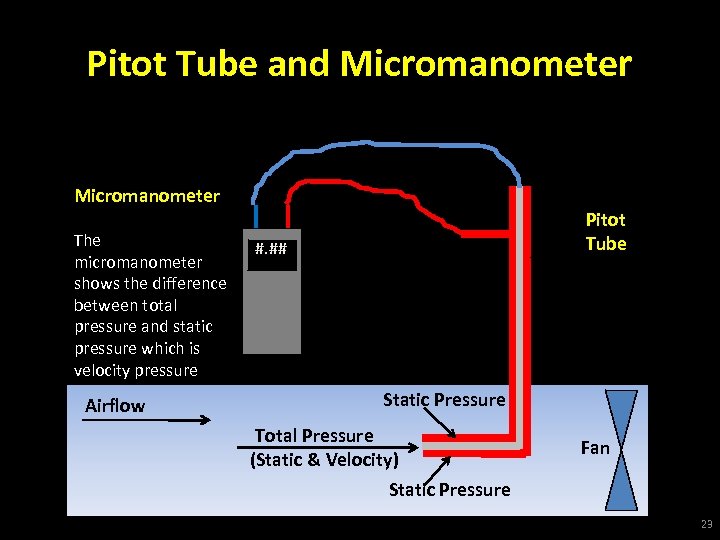

Pitot Tube and Micromanometer The micromanometer shows the difference between total pressure and static pressure which is velocity pressure Airflow Pitot Tube #. ## Pipe Static Pressure Total Pressure (Static & Velocity) Static Pressure Fan 23

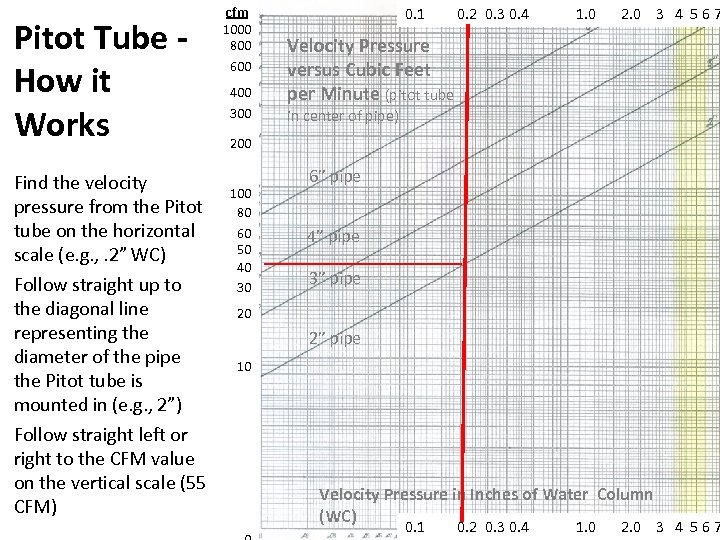

Pitot Tube How it Works Find the velocity pressure from the Pitot tube on the horizontal scale (e. g. , . 2” WC) Follow straight up to the diagonal line representing the diameter of the pipe the Pitot tube is mounted in (e. g. , 2”) Follow straight left or right to the CFM value on the vertical scale (55 CFM) cfm 1000 800 600 400 300 0. 1 0. 2 0. 3 0. 4 1. 0 2. 0 3 4 5 6 7 Velocity Pressure versus Cubic Feet per Minute (pitot tube in center of pipe) 200 100 80 60 50 40 30 6” pipe 4” pipe 3” pipe 20 2” pipe 10 Velocity Pressure in Inches of Water Column (WC) 0. 1 0. 2 0. 3 0. 4 1. 0 2. 0 3 4 5 6 7

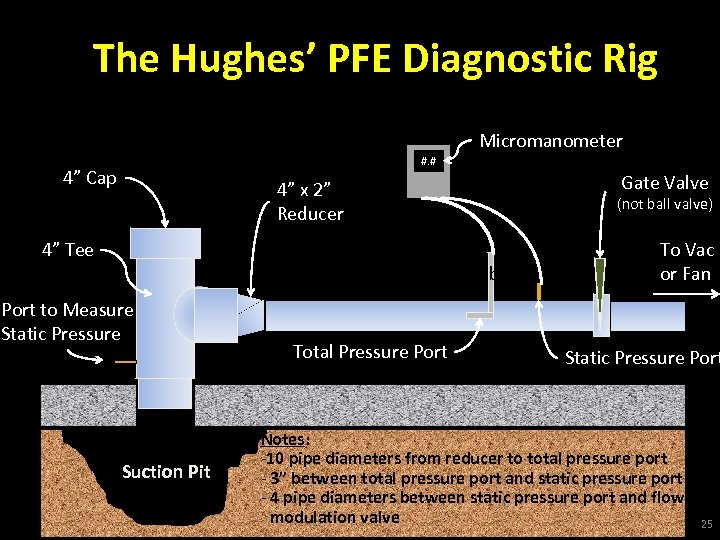

The Hughes’ PFE Diagnostic Rig Micromanometer #. # 4” Cap 4” x 2” Reducer 4” Tee 2” Custom- Made Pitot Tube Port to Measure Static Pressure Suction Pit Total Pressure Port Gate Valve (not ball valve) To Vac or Fan Static Pressure Port Notes: -10 pipe diameters from reducer to total pressure port - 3” between total pressure port and static pressure port - 4 pipe diameters between static pressure port and flow modulation valve 25

What About the Pipe Resistance? • We can estimate the resistance of any pipe configuration based on established resistance information about common pipe diameters, the length of pipe needed, and resistance created by each pipe coupling, expressed as equivalent to a number of feet of straight pipe resistance.

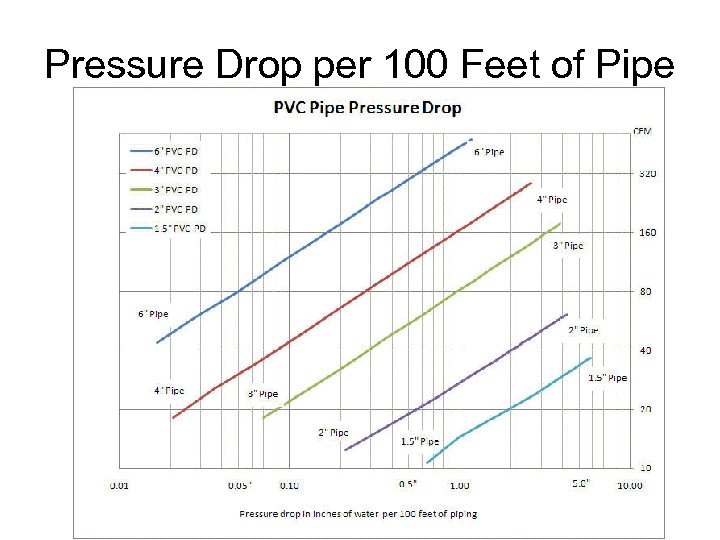

Pressure Drop per 100 Feet of Pipe

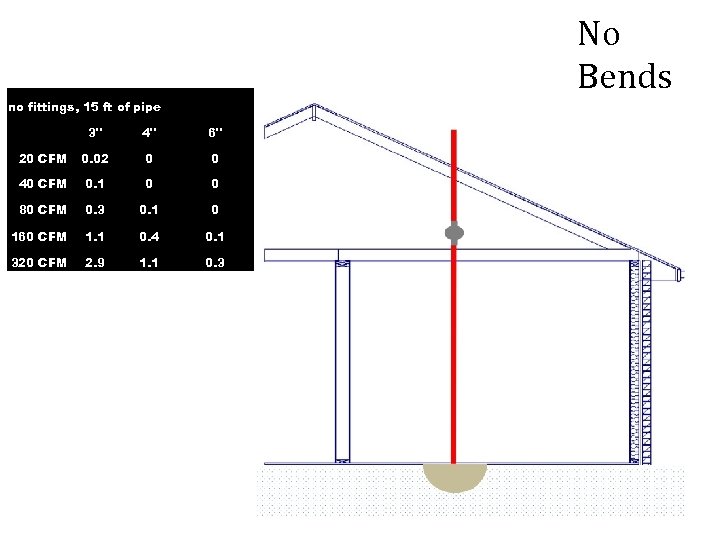

No Bends no fittings, 15 ft of pipe 3" 4" 6" 20 CFM 0. 02 0 0 40 CFM 0. 1 0 0 80 CFM 0. 3 0. 1 0 160 CFM 1. 1 0. 4 0. 1 320 CFM 2. 9 1. 1 0. 3

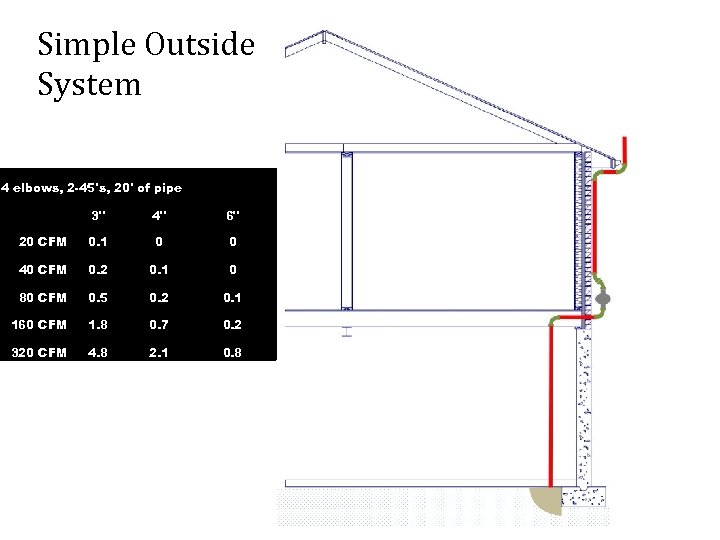

Simple Outside System 4 elbows, 2 -45's, 20' of pipe 3" 4" 6" 20 CFM 0. 1 0 0 40 CFM 0. 2 0. 1 0 80 CFM 0. 5 0. 2 0. 1 160 CFM 1. 8 0. 7 0. 2 320 CFM 4. 8 2. 1 0. 8

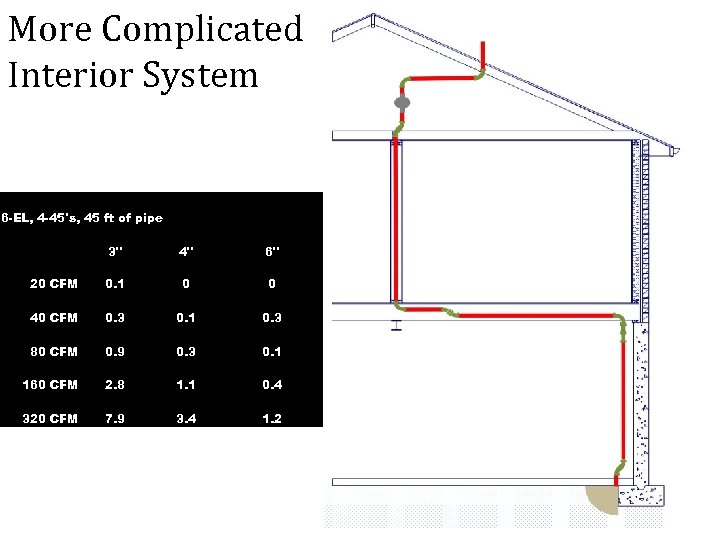

More Complicated Interior System 6 -EL, 4 -45's, 45 ft of pipe 3" 4" 6" 20 CFM 0. 1 0 0 40 CFM 0. 3 0. 1 0. 3 80 CFM 0. 9 0. 3 0. 1 160 CFM 2. 8 1. 1 0. 4 320 CFM 7. 9 3. 4 1. 2

Fan Selection Criteria • • • The appropriate fan: Must move sufficient air. . . to create the desired pressure field extension Steps in fan selection Determine desired extent and strength of pressure field • Determine resistance to airflow in sub slab and pipe run • Select fan to produce desired air flow in that situation

In Addition, the Appropriate Fan • • • Is the lowest wattage fan that will accomplish the job. Lower wattage fans are almost always quieter and their long term energy costs can be significant. Is Quiet – sound/noise are often justification for fans being turned off by occupants • less than 40 d. B Easily attaches to vent stack Is Durable Has no positive pressure leaks Is moisture-resistant

Fan Box Demonstration

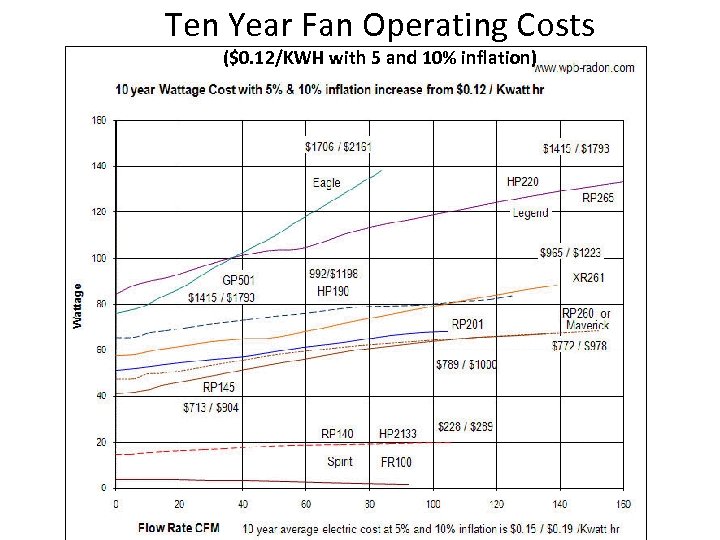

Ten Year Fan Operating Costs ($0. 12/KWH with 5 and 10% inflation)

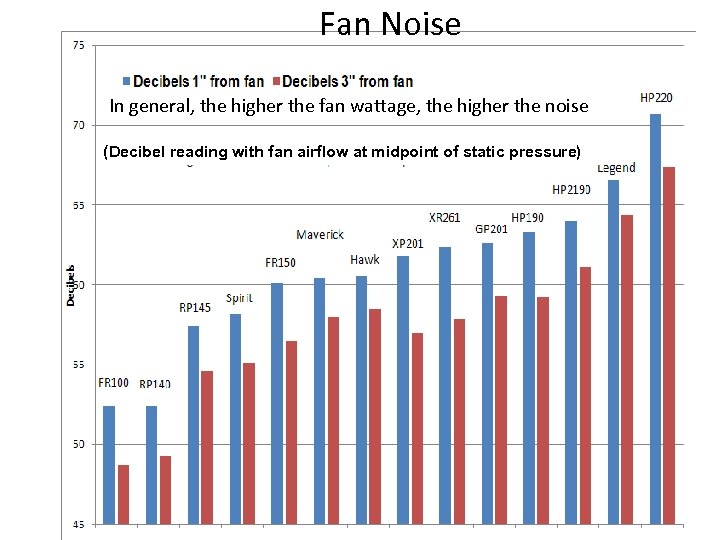

Fan Noise In general, the higher the fan wattage, the higher the noise (Decibel reading with fan airflow at midpoint of static pressure)

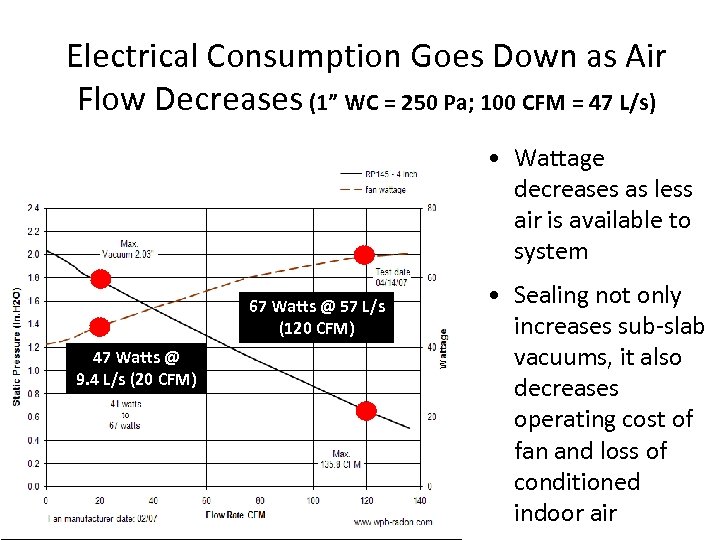

Electrical Consumption Goes Down as Air Flow Decreases (1” WC = 250 Pa; 100 CFM = 47 L/s) • Wattage decreases as less air is available to system 67 Watts @ 57 L/s (120 CFM) 47 Watts @ 9. 4 L/s (20 CFM) • Sealing not only increases sub-slab vacuums, it also decreases operating cost of fan and loss of conditioned indoor air

Additional Advantages of These Procedures • Provides the ability to predict system mechanical performance before installation and allows simulation of system with different: – Fans – Lengths and diameters of pipe run • May also reveal the need for: – More excavation in suction pit or more suction points – Additional sealing not originally anticipated • With multiple suction points, allows determination of: – Unrestricted and required flow from each suction point • So that flow control measures can be designed • Most important: – Allows accurate prediction of PFE which actual system will produce BEFORE the system is installed!

Don’t Be A Poke and Hoper! Thanks Bruce Snead 785 -532 -4992 bsnead@ksu. edu Chad Robinson 785 -787 -0180 crobinson@buildingperform. com

22012aa64d6844d5d0fd4c62ca4fbe8c.ppt