Dissertation topic.pptx

- Количество слайдов: 10

Dissertation topic: Development of a virtual model of the automatic DC motor control in an environment Labview Done by first year postgraduate student Aitkul Asemgul

Dissertation topic: Development of a virtual model of the automatic DC motor control in an environment Labview Done by first year postgraduate student Aitkul Asemgul

Purpose and tasks • Purpose: • Development and research of the virtual model of the system of automatic control • • • of a DC motor. Tasks: 1. Consider the types of DC electric motor and their operating principles. 2. To consider the main elements of the electric drive. 3. Build the block diagram of the electric motor. 4. Prepare a virtual model of a DC motor automatic control.

Purpose and tasks • Purpose: • Development and research of the virtual model of the system of automatic control • • • of a DC motor. Tasks: 1. Consider the types of DC electric motor and their operating principles. 2. To consider the main elements of the electric drive. 3. Build the block diagram of the electric motor. 4. Prepare a virtual model of a DC motor automatic control.

Keywords • • • DC DRIVE-ПРИВОД ПОСТОЯННОГО ТОКА MOTOR, ENGINE-ДВИГАТЕЛЬ COLLECTOR ARMATURE CURRENT, WIND, COIL, INDUCER

Keywords • • • DC DRIVE-ПРИВОД ПОСТОЯННОГО ТОКА MOTOR, ENGINE-ДВИГАТЕЛЬ COLLECTOR ARMATURE CURRENT, WIND, COIL, INDUCER

DC motor • DC motor - DC electric machine that converts DC electric power into mechanical energy. • Electric DC motors are composed of an inductor and armature, separated by an air gap. • A DC motor consists of • - Inducer (stator); • - Armature (rotor); • - Collector; • - Current collecting brushes; • - Structural elements.

DC motor • DC motor - DC electric machine that converts DC electric power into mechanical energy. • Electric DC motors are composed of an inductor and armature, separated by an air gap. • A DC motor consists of • - Inducer (stator); • - Armature (rotor); • - Collector; • - Current collecting brushes; • - Structural elements.

Design of the DC motor • An anchor and the inductor are separated by an air gap. The inductor consists of a base frame, which serves to fix the main and additional pole of the magnetic system of the engine. In the main field winding poles are located, and additional - special coil that improves switching. • The collector carries a constant current to the working coil, which is embedded in the grooves of the rotor. The collector is a cylinder and consists of plates insulated from each other, it is impaled on the motor shaft. Brushes are pickup current collector, they are mounted in the brush holders to ensure correct positioning and reliable clicking on the collector surface.

Design of the DC motor • An anchor and the inductor are separated by an air gap. The inductor consists of a base frame, which serves to fix the main and additional pole of the magnetic system of the engine. In the main field winding poles are located, and additional - special coil that improves switching. • The collector carries a constant current to the working coil, which is embedded in the grooves of the rotor. The collector is a cylinder and consists of plates insulated from each other, it is impaled on the motor shaft. Brushes are pickup current collector, they are mounted in the brush holders to ensure correct positioning and reliable clicking on the collector surface.

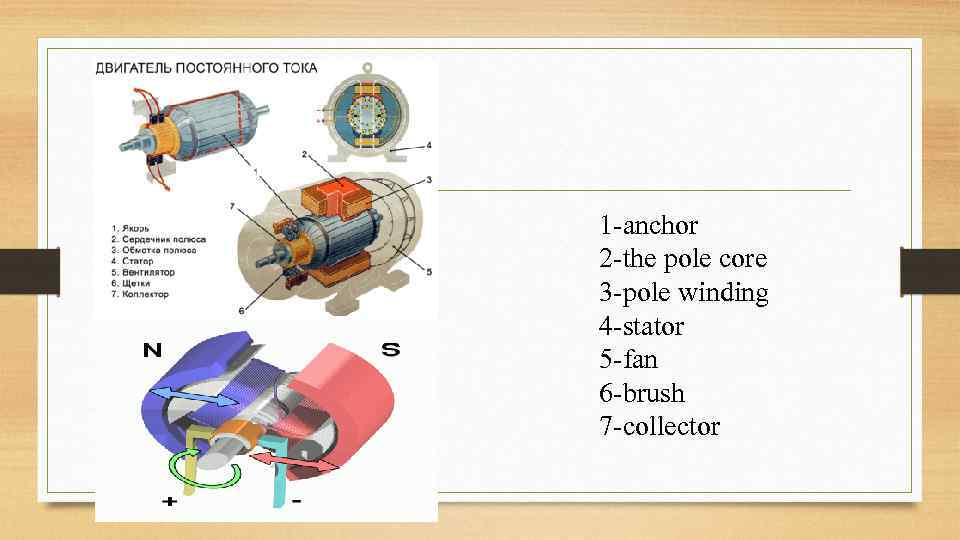

1 -anchor 2 -the pole core 3 -pole winding 4 -stator 5 -fan 6 -brush 7 -collector

1 -anchor 2 -the pole core 3 -pole winding 4 -stator 5 -fan 6 -brush 7 -collector

• • • the advantage of a DC motor - Flexible starting and control characteristics; - Two-zone regulation, which allows to reach a speed of 3000 rev / min. The disadvantage of a DC motor - The difficulty in manufacturing and high cost; - In the process must be continuous service as a collector and current collector brushes have a small share of the work.

• • • the advantage of a DC motor - Flexible starting and control characteristics; - Two-zone regulation, which allows to reach a speed of 3000 rev / min. The disadvantage of a DC motor - The difficulty in manufacturing and high cost; - In the process must be continuous service as a collector and current collector brushes have a small share of the work.

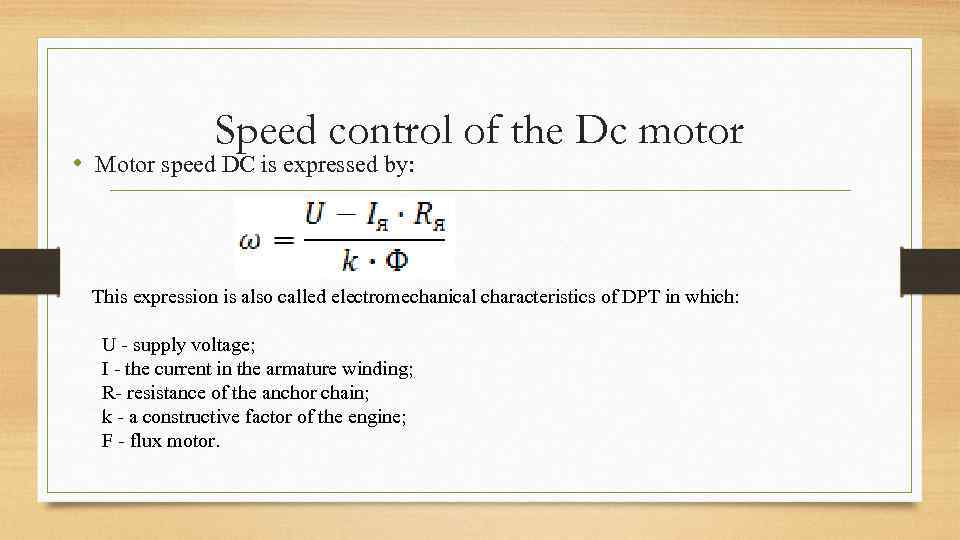

Speed control of the Dc motor • Motor speed DC is expressed by: This expression is also called electromechanical characteristics of DPT in which: U - supply voltage; I - the current in the armature winding; R- resistance of the anchor chain; k - a constructive factor of the engine; F - flux motor.

Speed control of the Dc motor • Motor speed DC is expressed by: This expression is also called electromechanical characteristics of DPT in which: U - supply voltage; I - the current in the armature winding; R- resistance of the anchor chain; k - a constructive factor of the engine; F - flux motor.

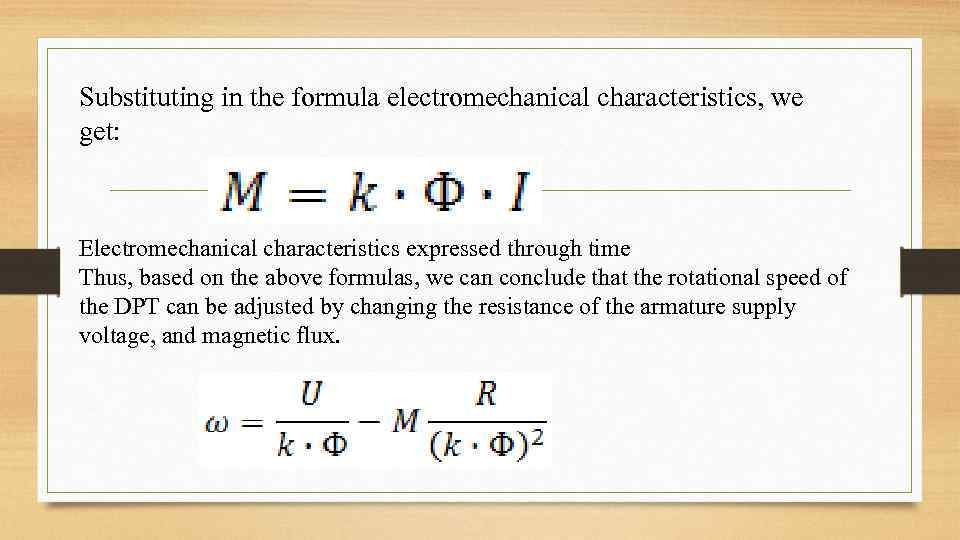

Substituting in the formula electromechanical characteristics, we get: Electromechanical characteristics expressed through time Thus, based on the above formulas, we can conclude that the rotational speed of the DPT can be adjusted by changing the resistance of the armature supply voltage, and magnetic flux.

Substituting in the formula electromechanical characteristics, we get: Electromechanical characteristics expressed through time Thus, based on the above formulas, we can conclude that the rotational speed of the DPT can be adjusted by changing the resistance of the armature supply voltage, and magnetic flux.

DC DRIVES • Today, the main means of controlling DC motors are modern thyristor (let's call them "DC Drives"), they produce a lot of firms specializing in drive technology (for example, Control Techniques, Siemens, Sprint-Electric, etc. ). Modern DC drives allow you to control not only the speed of the engine, but also its momentum (for example, on the lines of the winding). Due to the different interfaces in signal communication with an automated control system, change the parameters of the engine is simple and easy. • DC drives can operate in one quadrant and all four, thus modifying not only the current of the armature winding, but the current of the field winding - many drives have built-in "field controller" that allows to adjust the speed of the engine in the widest range.

DC DRIVES • Today, the main means of controlling DC motors are modern thyristor (let's call them "DC Drives"), they produce a lot of firms specializing in drive technology (for example, Control Techniques, Siemens, Sprint-Electric, etc. ). Modern DC drives allow you to control not only the speed of the engine, but also its momentum (for example, on the lines of the winding). Due to the different interfaces in signal communication with an automated control system, change the parameters of the engine is simple and easy. • DC drives can operate in one quadrant and all four, thus modifying not only the current of the armature winding, but the current of the field winding - many drives have built-in "field controller" that allows to adjust the speed of the engine in the widest range.