1d44cd78c86a1e8d73e11d8dee337716.ppt

- Количество слайдов: 21

Discrete events simulation and genetic algorithm-based manufacturing execution Content of the presentation • Introduction and context • Problem • Proposed solution • Results • Conclusions and perspectives Keywords • discrete-event simulation, genetic algorithm, multicriterion optimization 1 Franck FONTANILI - CGI IMSM'07

Introduction and context Overview • Manufacturing context: assembly of mixed models • Stage of preparation of the release of a campaign • How to determine a « good » value of control parameters ? Coupling DES and optimization algorithm 2 Franck FONTANILI - CGI IMSM'07

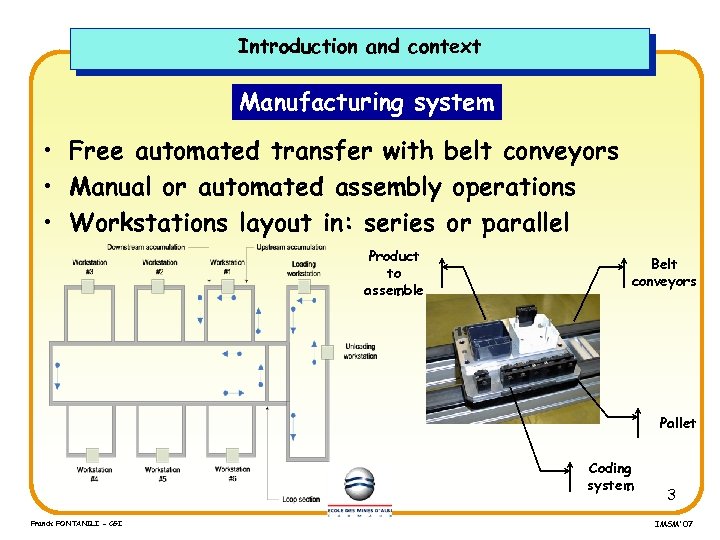

Introduction and context Manufacturing system • Free automated transfer with belt conveyors • Manual or automated assembly operations • Workstations layout in: series or parallel Product to assemble Belt conveyors Pallet Coding system Franck FONTANILI - CGI 3 IMSM'07

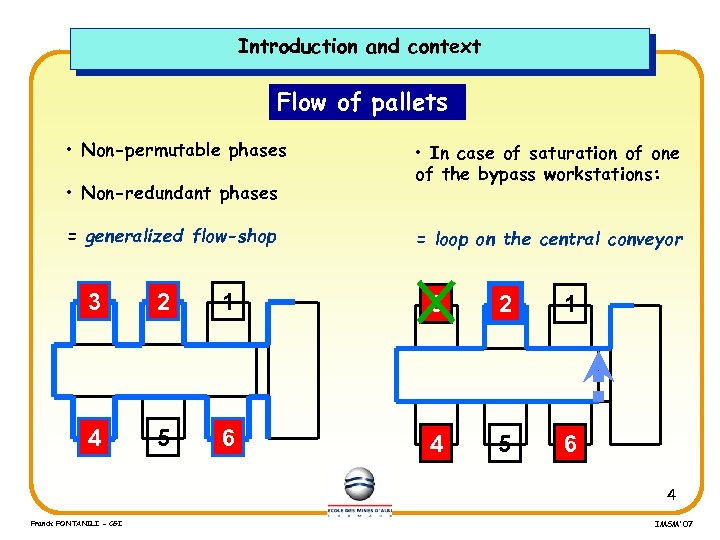

Introduction and context Flow of pallets • Non-permutable phases • Non-redundant phases = generalized flow-shop • In case of saturation of one of the bypass workstations: = loop on the central conveyor 3 2 1 4 5 6 4 Franck FONTANILI - CGI IMSM'07

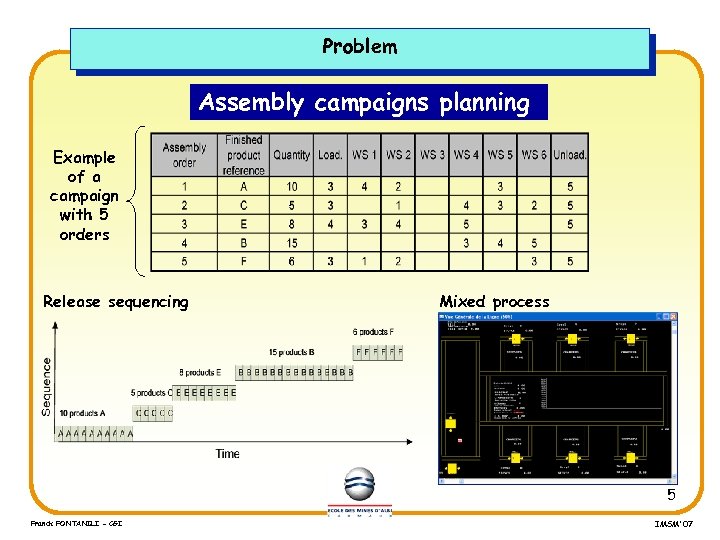

Problem Assembly campaigns planning Example of a campaign with 5 orders Release sequencing Mixed process 5 Franck FONTANILI - CGI IMSM'07

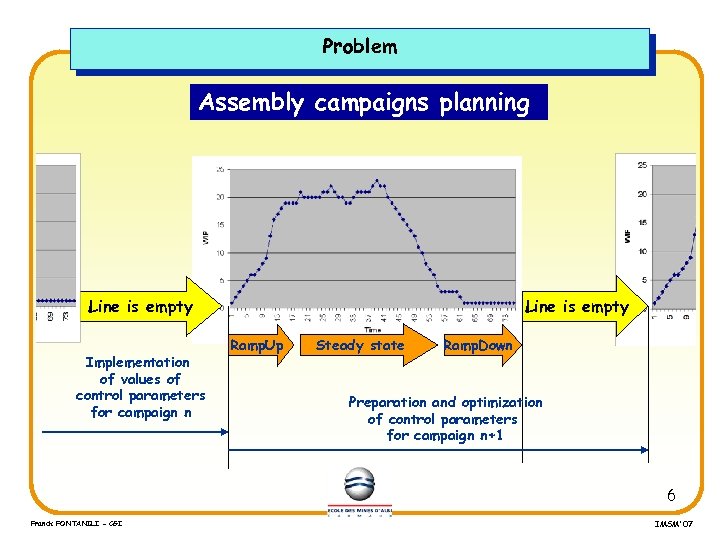

Problem Assembly campaigns planning Line is empty Implementation of values of control parameters for campaign n Line is empty Ramp. Up Steady state Ramp. Down Preparation and optimization of control parameters for campaign n+1 6 Franck FONTANILI - CGI IMSM'07

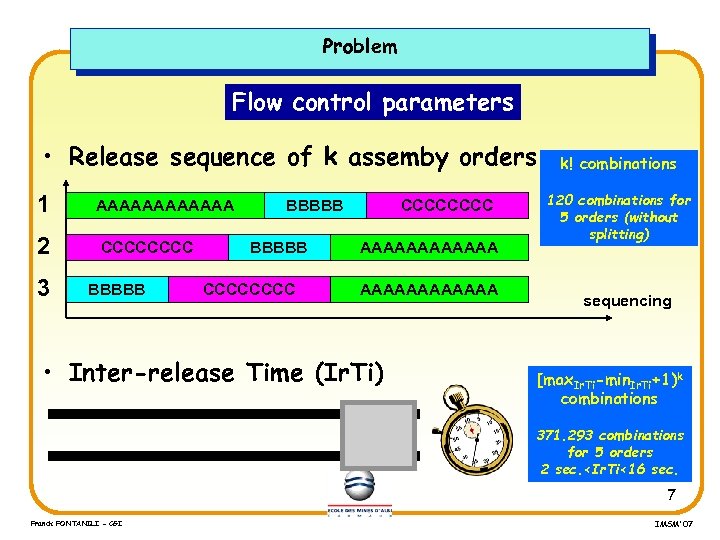

Problem Flow control parameters • Release sequence of k assemby orders 1 2 3 AAAAAA CCCC BBBBB CCCCCCCC AAAAAAAAAAAA • Inter-release Time (Ir. Ti) k! combinations 120 combinations for 5 orders (without splitting) sequencing [max. Ir. Ti-min. Ir. Ti+1)k combinations 371. 293 combinations for 5 orders 2 sec. <Ir. Ti<16 sec. 7 Franck FONTANILI - CGI IMSM'07

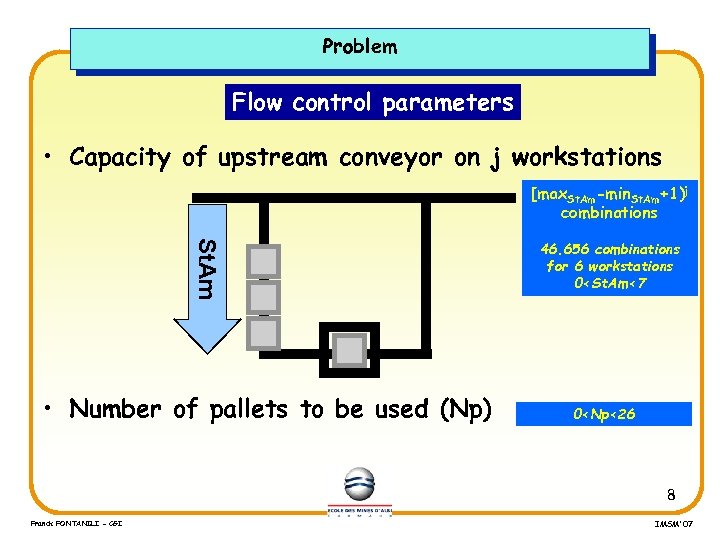

Problem Flow control parameters • Capacity of upstream conveyor on j workstations [max. St. Am-min. St. Am+1)j combinations St. Am • Number of pallets to be used (Np) 46. 656 combinations for 6 workstations 0<St. Am<7 0<Np<26 8 Franck FONTANILI - CGI IMSM'07

Problem Flow control parameters • • Capacity of downstream conveyor Priority rule on the exit of workstation Splitting of the sequence of the assembly orders Etc. With only the 3 most sensitive parameters : • Inter-Release Time (Ir. Ti) • Capacity of upstream conveyor (St. Am) • Number of pallets (Np) More than 1011 combinations What combination to be used ? 9 Franck FONTANILI - CGI IMSM'07

Proposed solution Use of Simulation • Simulation is a frequently used tool during stage of: § Design § Improvement of manufacturing systems (existent or to be built) • Proposal: use of simulation during stage of: § preparation the execution of a campaign to provide a decision-making aid for the choice of the values to fix at the flow control parameters 10 Franck FONTANILI - CGI IMSM'07

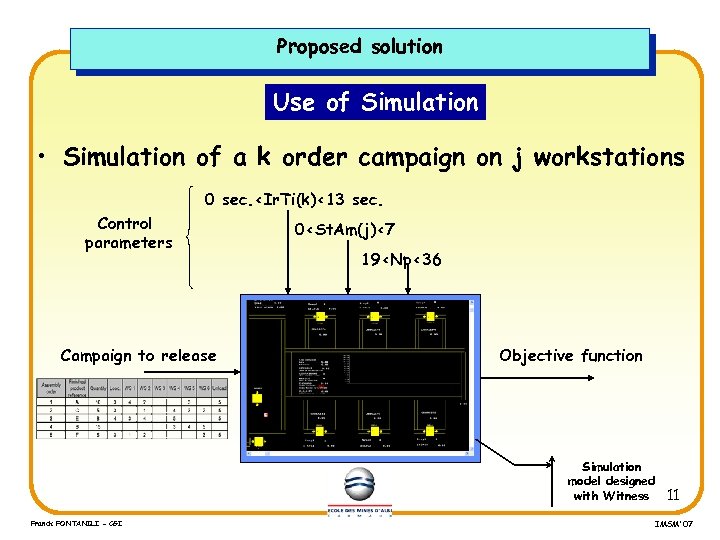

Proposed solution Use of Simulation • Simulation of a k order campaign on j workstations 0 sec. <Ir. Ti(k)<13 sec. Control parameters Campaign to release 0<St. Am(j)<7 19<Np<36 Objective function Simulation model designed with Witness Franck FONTANILI - CGI 11 IMSM'07

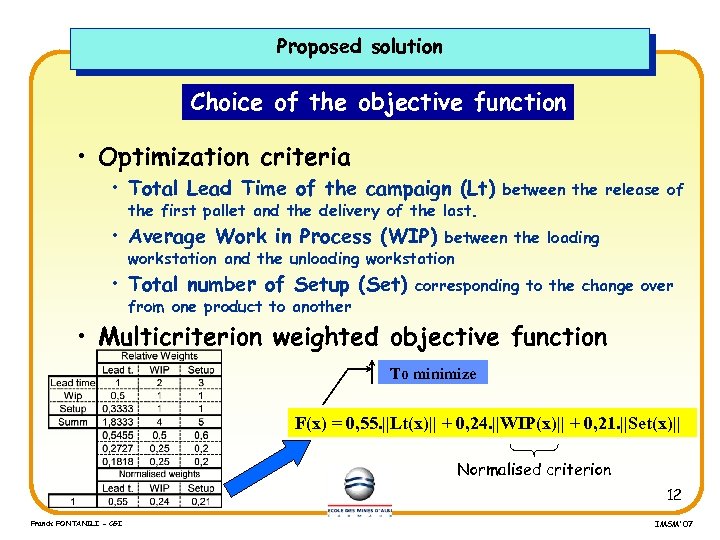

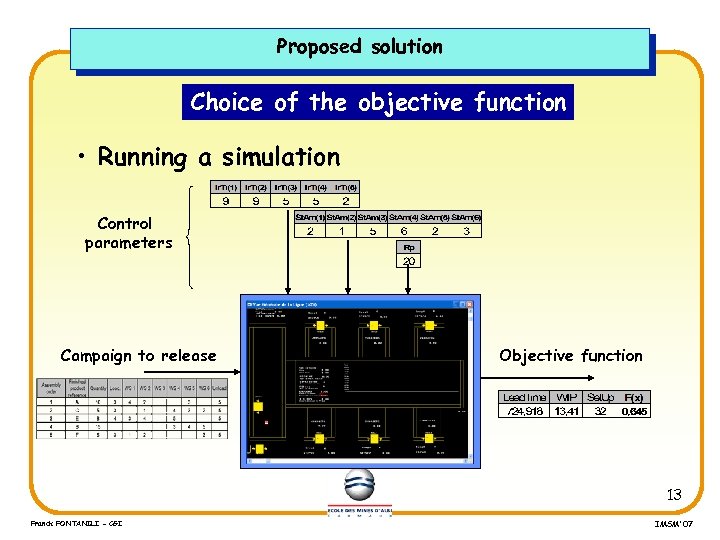

Proposed solution Choice of the objective function • Optimization criteria • Total Lead Time of the campaign (Lt) the first pallet and the delivery of the last. between the release of • Average Work in Process (WIP) between the loading workstation and the unloading workstation • Total number of Setup (Set) from one product to another corresponding to the change over • Multicriterion weighted objective function To minimize F(x) = 0, 55. ||Lt(x)|| + 0, 24. ||WIP(x)|| + 0, 21. ||Set(x)|| Normalised criterion 12 Franck FONTANILI - CGI IMSM'07

Proposed solution Choice of the objective function • Running a simulation Control parameters Campaign to release Objective function 13 Franck FONTANILI - CGI IMSM'07

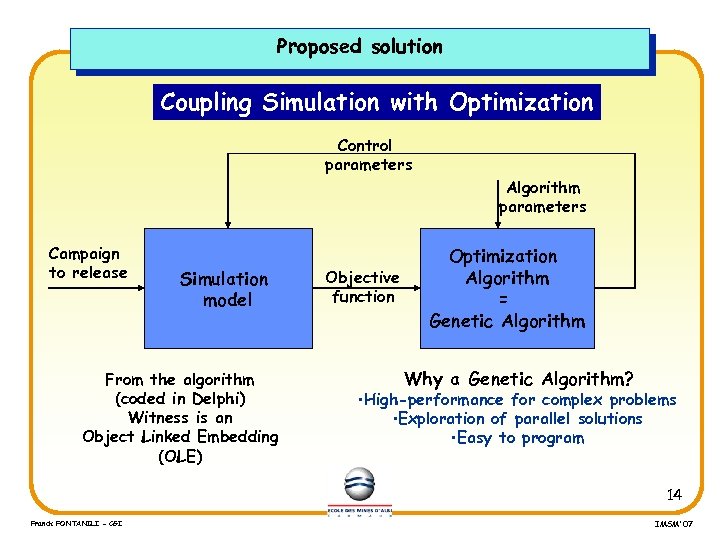

Proposed solution Coupling Simulation with Optimization Control parameters Algorithm parameters Campaign to release Simulation model From the algorithm (coded in Delphi) Witness is an Object Linked Embedding (OLE) Objective function Optimization Algorithm = Genetic Algorithm Why a Genetic Algorithm? • High-performance for complex problems • Exploration of parallel solutions • Easy to program 14 Franck FONTANILI - CGI IMSM'07

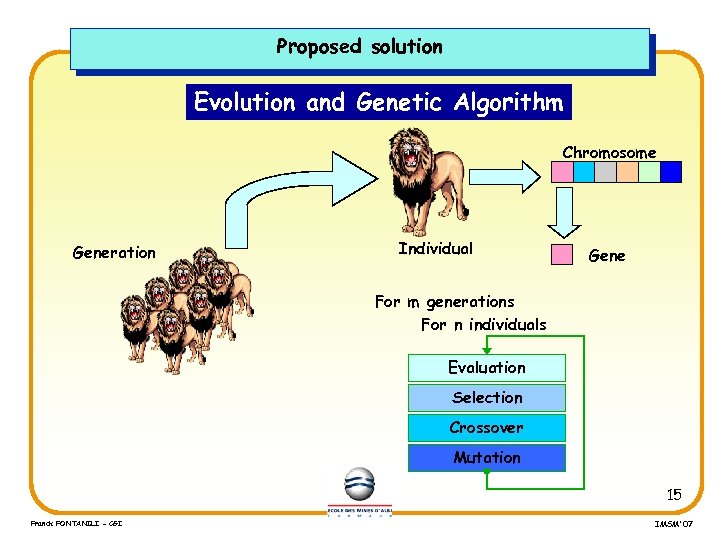

Proposed solution Evolution and Genetic Algorithm Chromosome Generation Individual Gene For m generations For n individuals Evaluation Selection Crossover Mutation 15 Franck FONTANILI - CGI IMSM'07

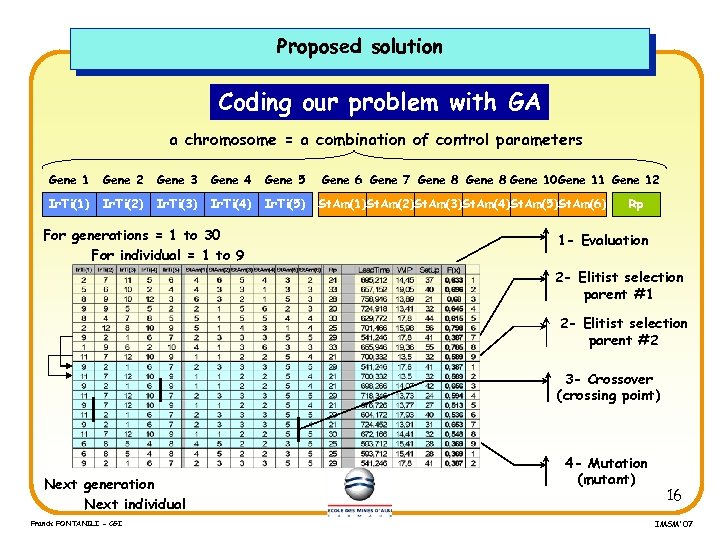

Proposed solution Coding our problem with GA a chromosome = a combination of control parameters Gene 1 Gene 2 Gene 3 Gene 4 Gene 5 Ir. Ti(1) Ir. Ti(2) Ir. Ti(3) Ir. Ti(4) Ir. Ti(5) For generations = 1 to 30 For individual = 1 to 9 Gene 6 Gene 7 Gene 8 Gene 10 Gene 11 Gene 12 St. Am(1)St. Am(2)St. Am(3)St. Am(4)St. Am(5)St. Am(6) Rp 1 - Evaluation 2 - Elitist selection parent #1 2 - Elitist selection parent #2 3 - Crossover (crossing point) Next generation Next individual Franck FONTANILI - CGI 4 - Mutation (mutant) 16 IMSM'07

Proposed solution Running simulation and GA 17 Franck FONTANILI - CGI IMSM'07

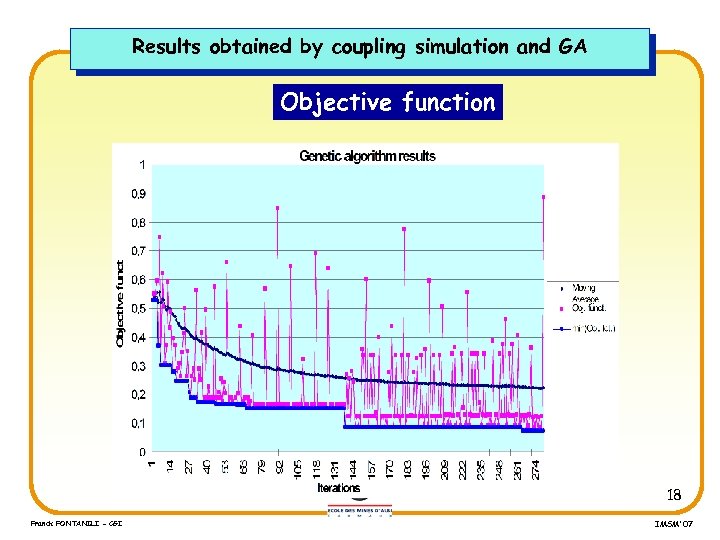

Results obtained by coupling simulation and GA Objective function 18 Franck FONTANILI - CGI IMSM'07

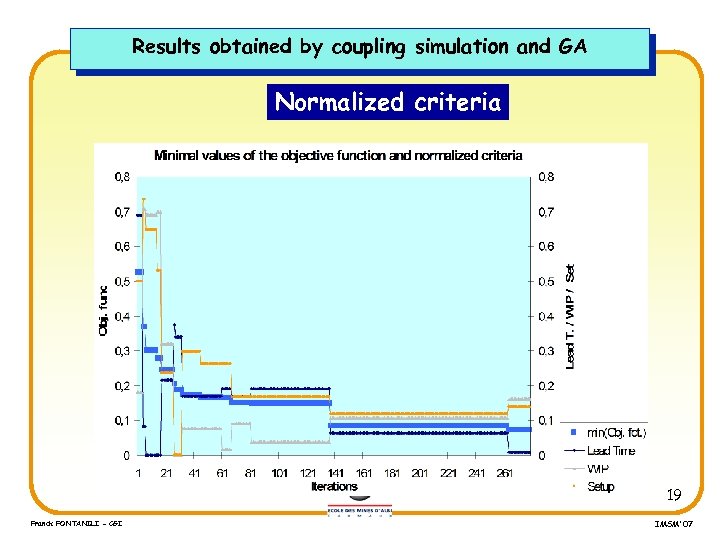

Results obtained by coupling simulation and GA Normalized criteria 19 Franck FONTANILI - CGI IMSM'07

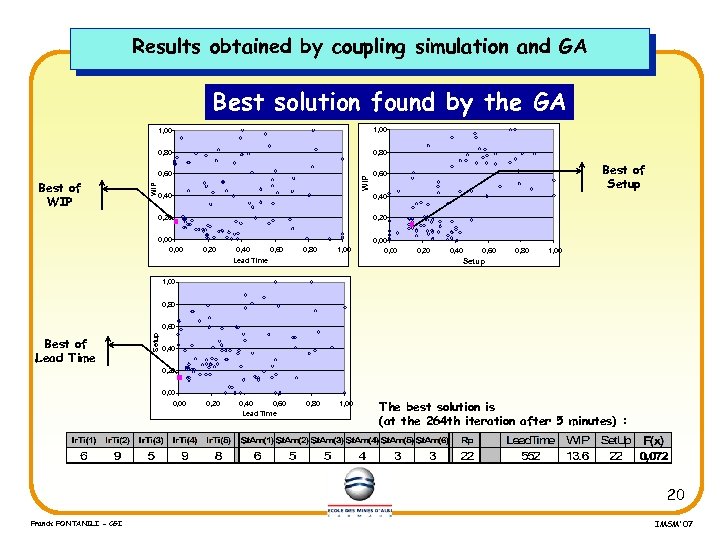

Results obtained by coupling simulation and GA Best solution found by the GA 0, 60 WIP 0, 80 0, 60 Best of WIP 1, 00 0, 80 WIP 1, 00 0, 40 0, 20 Best of Setup 0, 20 0, 00 0, 20 0, 40 0, 60 0, 80 1, 00 Lead Time 0, 00 0, 20 0, 40 0, 60 0, 80 1, 00 Setup 1, 00 0, 80 Best of Lead Time Setup 0, 60 0, 40 0, 20 0, 00 0, 20 0, 40 0, 60 Lead Time 0, 80 1, 00 The best solution is (at the 264 th iteration after 5 minutes) : 20 Franck FONTANILI - CGI IMSM'07

Conclusions and perspectives Conclusions • • GA finds a « good » solution in less than 5 minutes allowing its use during the preparation time (idle time) Simulation coupled with GA provides a decisionmaking aid to the manager. Perspectives • • Take into account other parameters: sequencing and orders splitting Take into account other constraints : scheduling on each workstation 21 Franck FONTANILI - CGI IMSM'07

1d44cd78c86a1e8d73e11d8dee337716.ppt