0224333e80f815df6038fc9b2bdbb994.ppt

- Количество слайдов: 12

Directed Light Inc. Presentation November 28, 2001 1

Multiple Module Vacuum Oven Productivity Enhancement System

The Leader in Controlled Atmosphere Technology Since 1960 n n n ISO 9001 Certified State-of-the-Art, In-House Design & Manufacturing Serving a World Class Scientific & Industrial Customer Base Customer Support by Highly Experienced Engineering & Sales Staff 78, 000 Sq. Ft. Production & Assembly Facility Over 7000 Systems in Operation Worldwide 3

High Quality, Technically Advanced, Fully Integrated Controlled Atmosphere Systems n n n n n Laser Seam Sealing Semiconductor Organic Light Emitting Diodes Medical Devices Thin Film Deposition Battery Research Air Sensitive Chemistry Pharmaceutical Nuclear 4

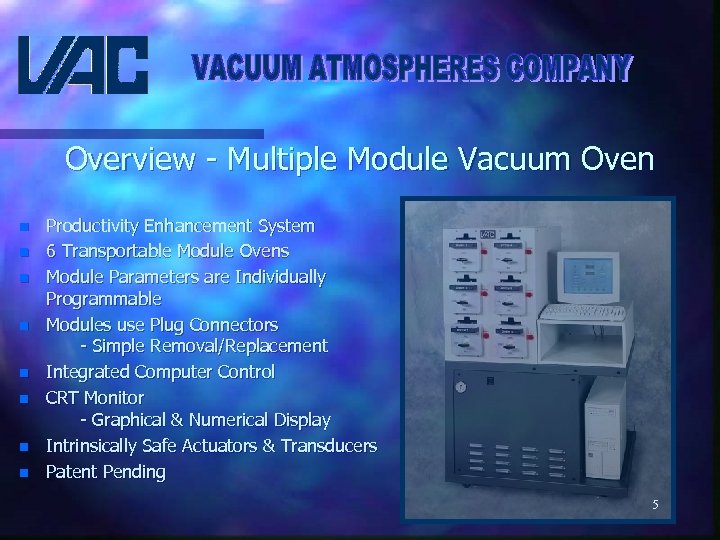

Overview - Multiple Module Vacuum Oven n n n n Productivity Enhancement System 6 Transportable Module Ovens Module Parameters are Individually Programmable Modules use Plug Connectors - Simple Removal/Replacement Integrated Computer Control CRT Monitor - Graphical & Numerical Display Intrinsically Safe Actuators & Transducers Patent Pending 5

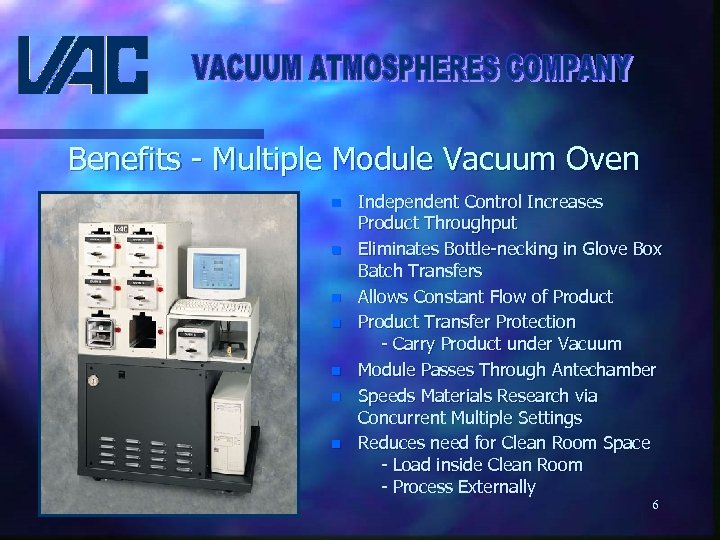

Benefits - Multiple Module Vacuum Oven n n n Independent Control Increases Product Throughput Eliminates Bottle-necking in Glove Box Batch Transfers Allows Constant Flow of Product Transfer Protection - Carry Product under Vacuum Module Passes Through Antechamber Speeds Materials Research via Concurrent Multiple Settings Reduces need for Clean Room Space - Load inside Clean Room - Process Externally 6

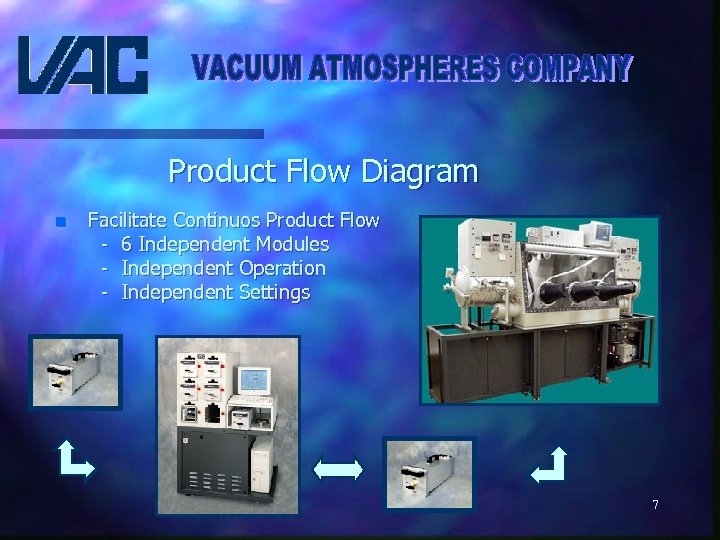

Product Flow Diagram n Facilitate Continuos Product Flow - 6 Independent Modules - Independent Operation - Independent Settings 7

Performance - Multiple Module Vacuum Oven n n Temperature - Ambient to 125° Celsius Accuracy - Ambient to 100°C ± 2°C, 100 - 125°C ± 3°C Temperature Overshoot - Less Than 2°C Setting Range - Each Module; 40 - 125°C in 5°C Increments Heat Cycle - Ambient to 100°C in less than 20 Minutes Cool Down - By Convection Approx. 1°C per Minute above 50 °C Diagnostics - Initial Vacuum, Time to Temp. , Ultimate Vacuum Ultimate Module Vacuum - Less than 1 Torr Data Logging - Sample#, 2 Shelf Temp. , Bake Time, Vacuum Alarm - Displayed on Monitor, Available as Single SSR Output Vacuum Pump - Oil-Free Scroll 7. 9 ft³/min (134 m³/hr) 8

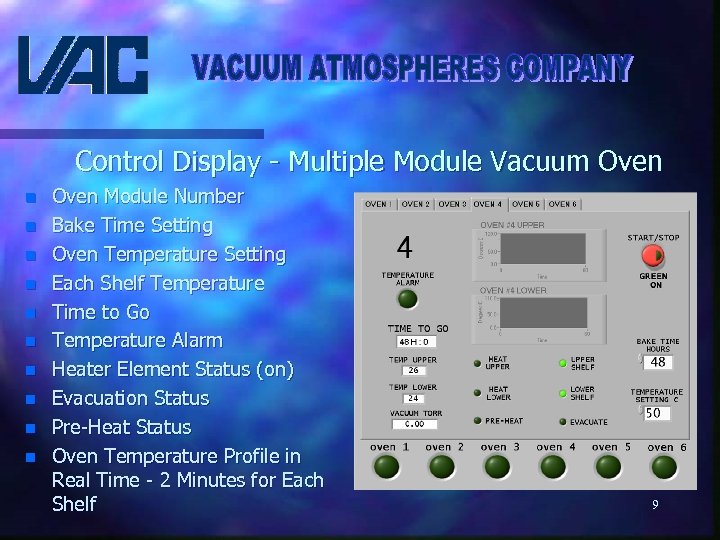

Control Display - Multiple Module Vacuum Oven n n Oven Module Number Bake Time Setting Oven Temperature Setting Each Shelf Temperature Time to Go Temperature Alarm Heater Element Status (on) Evacuation Status Pre-Heat Status Oven Temperature Profile in Real Time - 2 Minutes for Each Shelf 9

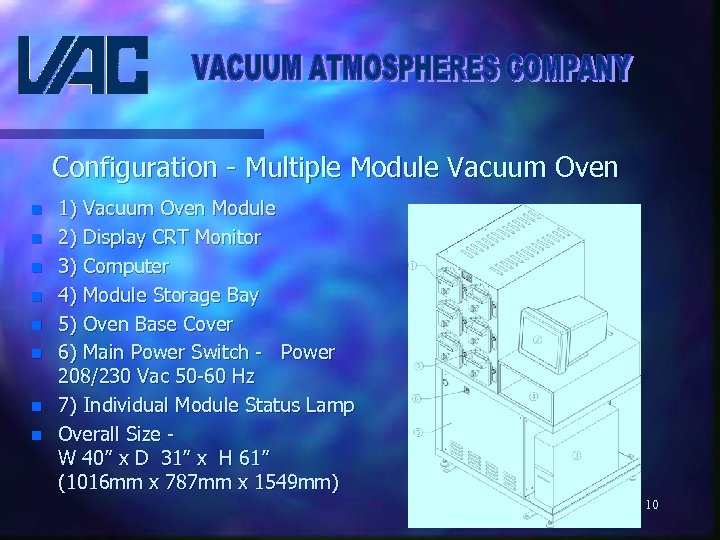

Configuration - Multiple Module Vacuum Oven n n n n 1) Vacuum Oven Module 2) Display CRT Monitor 3) Computer 4) Module Storage Bay 5) Oven Base Cover 6) Main Power Switch - Power 208/230 Vac 50 -60 Hz 7) Individual Module Status Lamp Overall Size W 40” x D 31” x H 61” (1016 mm x 787 mm x 1549 mm) 10

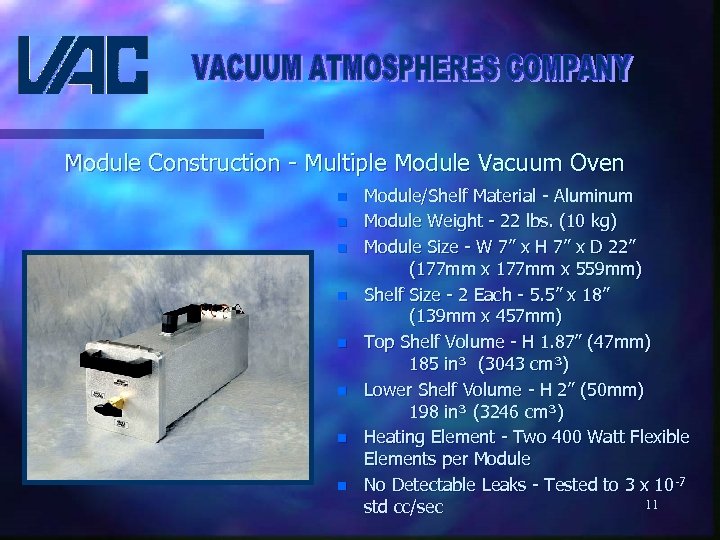

Module Construction - Multiple Module Vacuum Oven n n n n Module/Shelf Material - Aluminum Module Weight - 22 lbs. (10 kg) Module Size - W 7” x H 7” x D 22” (177 mm x 559 mm) Shelf Size - 2 Each - 5. 5” x 18” (139 mm x 457 mm) Top Shelf Volume - H 1. 87” (47 mm) 185 in³ (3043 cm³) Lower Shelf Volume - H 2” (50 mm) 198 in³ (3246 cm³) Heating Element - Two 400 Watt Flexible Elements per Module No Detectable Leaks - Tested to 3 x 10 -7 11 std cc/sec

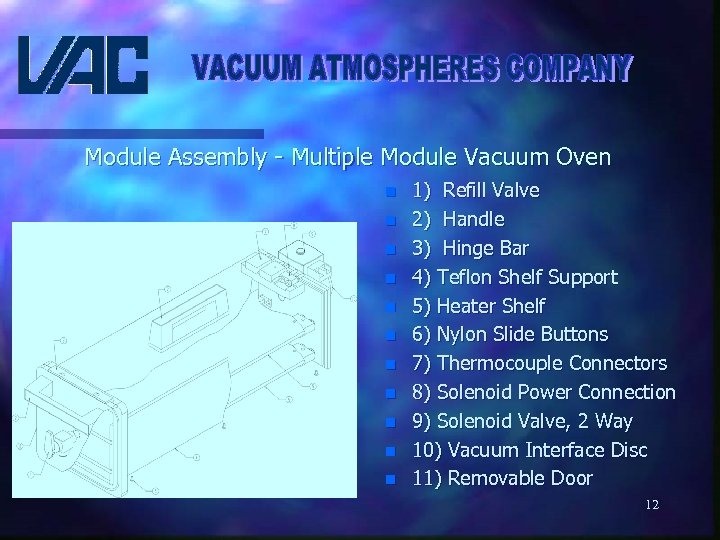

Module Assembly - Multiple Module Vacuum Oven n n 1) Refill Valve 2) Handle 3) Hinge Bar 4) Teflon Shelf Support 5) Heater Shelf 6) Nylon Slide Buttons 7) Thermocouple Connectors 8) Solenoid Power Connection 9) Solenoid Valve, 2 Way 10) Vacuum Interface Disc 11) Removable Door 12

0224333e80f815df6038fc9b2bdbb994.ppt