dimpled specimen The extration replica technique (a) polished

6782-tem_specimen_preparation_part_2.ppt

- Количество слайдов: 27

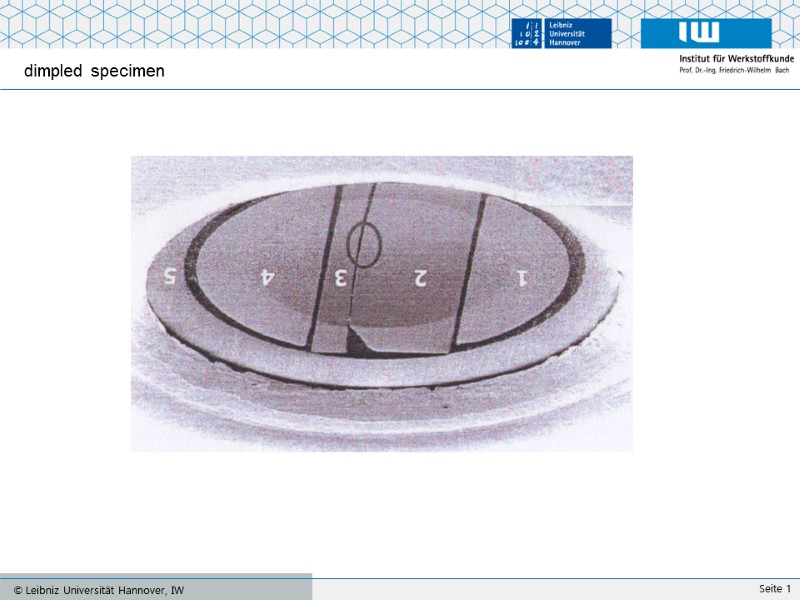

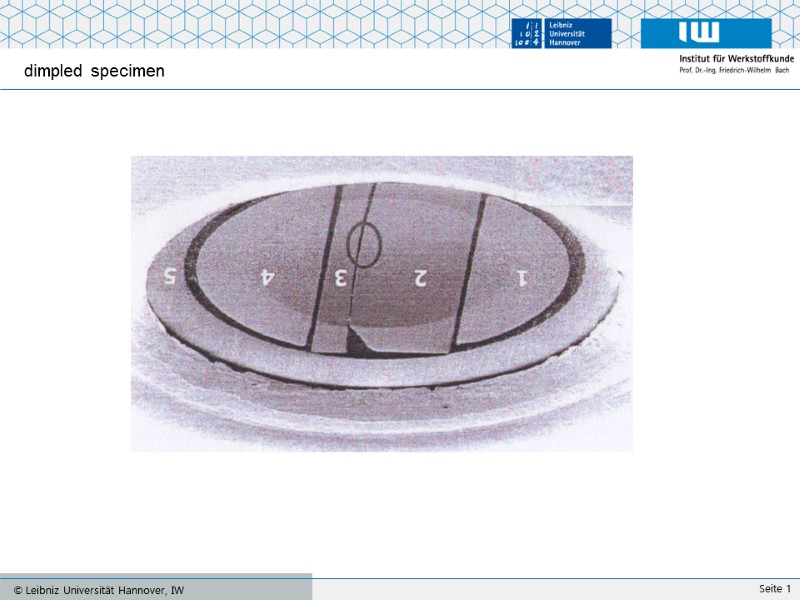

dimpled specimen

dimpled specimen

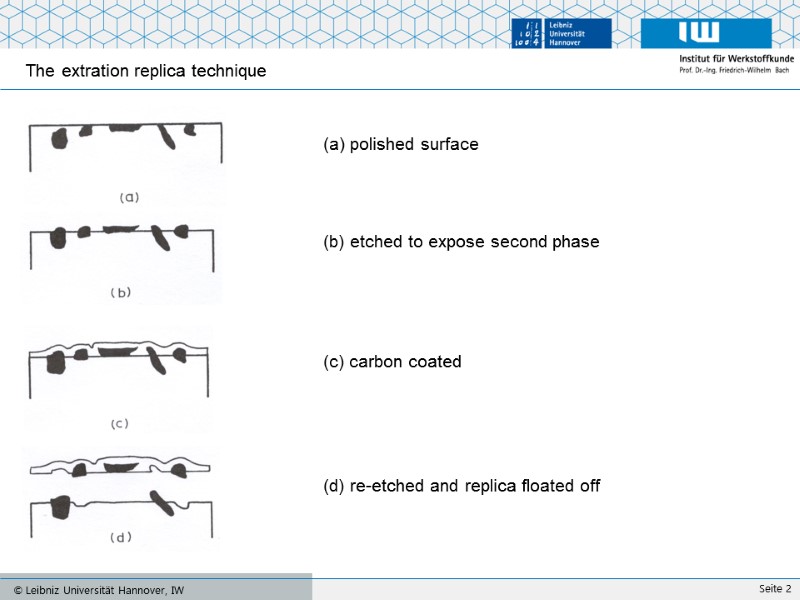

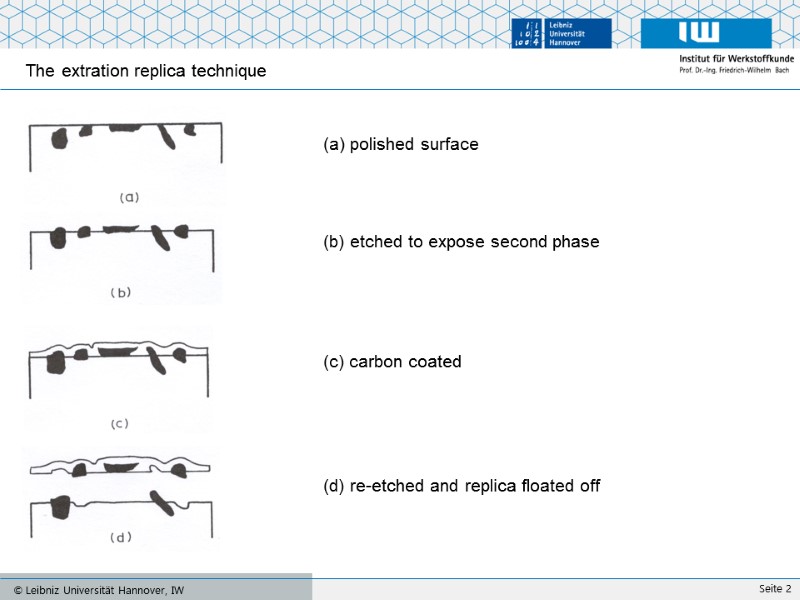

The extration replica technique (a) polished surface (b) etched to expose second phase (c) carbon coated (d) re-etched and replica floated off

The extration replica technique (a) polished surface (b) etched to expose second phase (c) carbon coated (d) re-etched and replica floated off

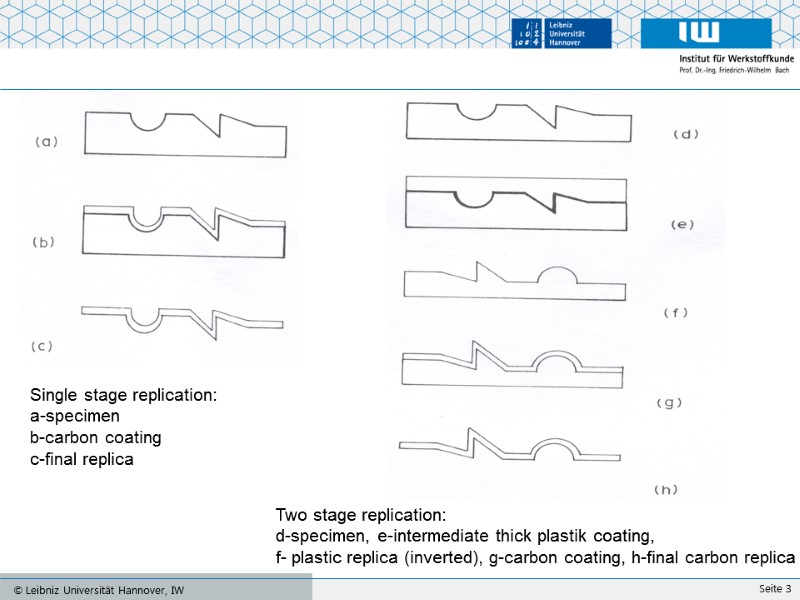

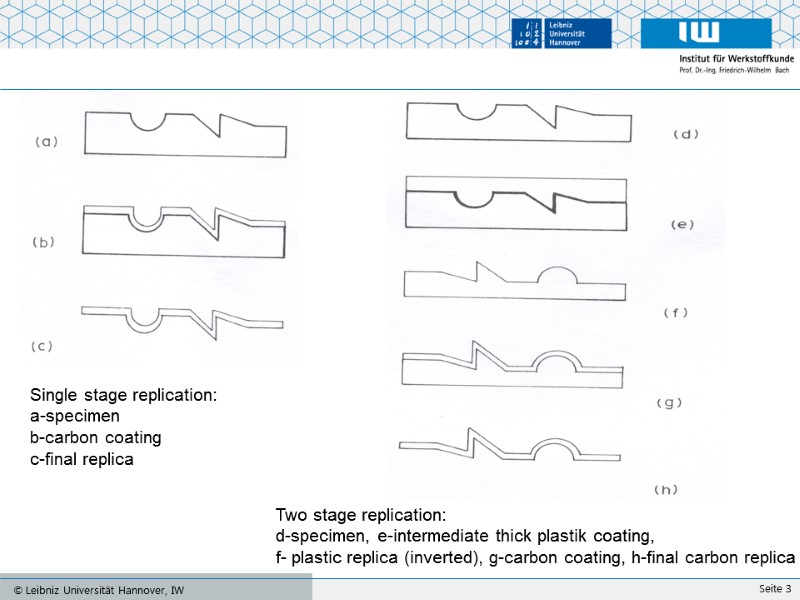

Single stage replication: a-specimen b-carbon coating c-final replica Two stage replication: d-specimen, e-intermediate thick plastik coating, f- plastic replica (inverted), g-carbon coating, h-final carbon replica

Single stage replication: a-specimen b-carbon coating c-final replica Two stage replication: d-specimen, e-intermediate thick plastik coating, f- plastic replica (inverted), g-carbon coating, h-final carbon replica

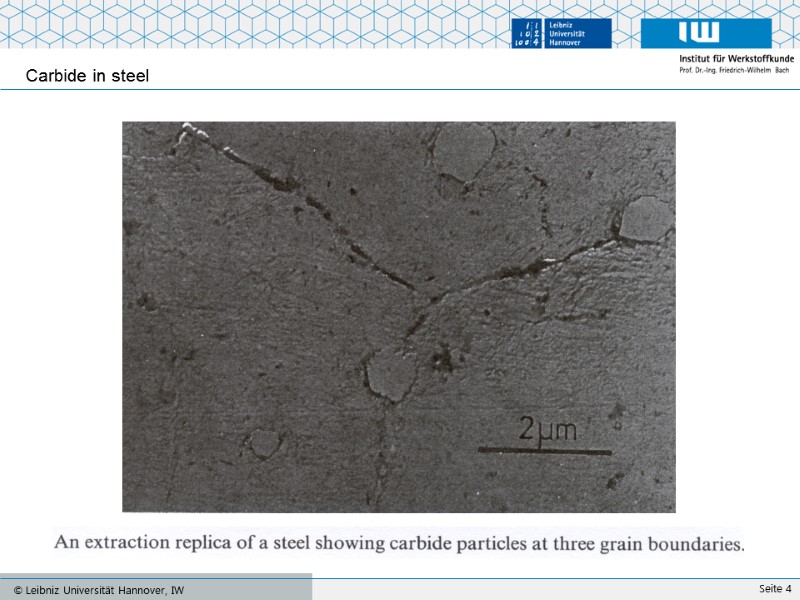

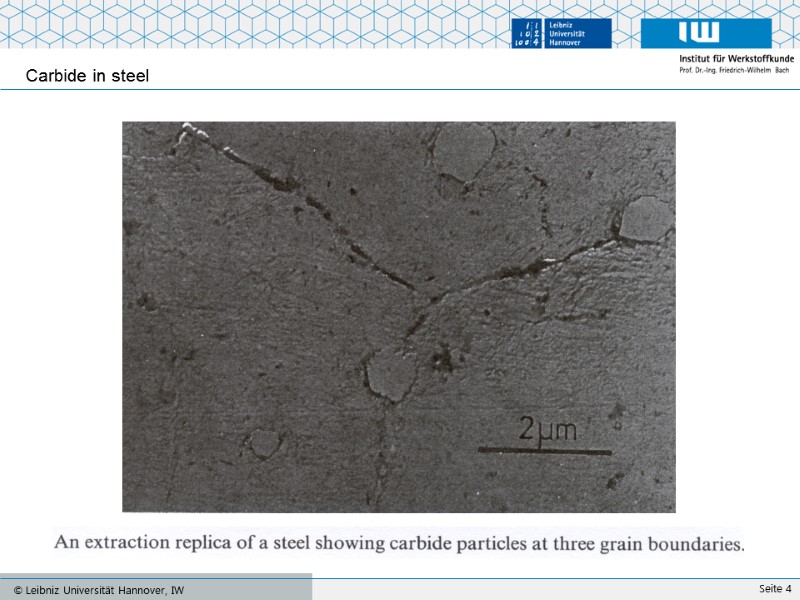

Carbide in steel

Carbide in steel

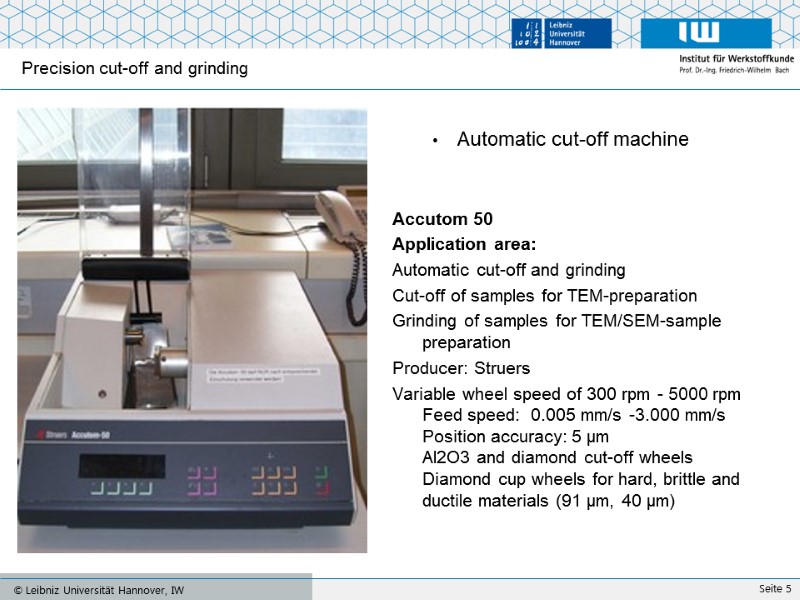

Precision cut-off and grinding Automatic cut-off machine Accutom 50 Application area: Automatic cut-off and grinding Cut-off of samples for TEM-preparation Grinding of samples for TEM/SEM-sample preparation Producer: Struers Variable wheel speed of 300 rpm - 5000 rpm Feed speed: 0.005 mm/s -3.000 mm/s Position accuracy: 5 µm Al2O3 and diamond cut-off wheels Diamond cup wheels for hard, brittle and ductile materials (91 µm, 40 µm)

Precision cut-off and grinding Automatic cut-off machine Accutom 50 Application area: Automatic cut-off and grinding Cut-off of samples for TEM-preparation Grinding of samples for TEM/SEM-sample preparation Producer: Struers Variable wheel speed of 300 rpm - 5000 rpm Feed speed: 0.005 mm/s -3.000 mm/s Position accuracy: 5 µm Al2O3 and diamond cut-off wheels Diamond cup wheels for hard, brittle and ductile materials (91 µm, 40 µm)

Wire saw A wire saw produces very fine slices from a material with just small stress to the sample. This procedure is applied to brittle materials, but also for cross section preparartions.

Wire saw A wire saw produces very fine slices from a material with just small stress to the sample. This procedure is applied to brittle materials, but also for cross section preparartions.

Duo Mill Ion mill Application area: ion milling of mechanically prepared specimens ion milling of electro polished specimens cooled ion milling of beam sensitive specimens Producer: GATAN Inc. Operation voltage: 1000 V - 4000 V Cathode: Octogun 2 coolable specimen stages (liquid nitrogen) Vacuum: 2 rotation pumps, 1 oildiffussion pump

Duo Mill Ion mill Application area: ion milling of mechanically prepared specimens ion milling of electro polished specimens cooled ion milling of beam sensitive specimens Producer: GATAN Inc. Operation voltage: 1000 V - 4000 V Cathode: Octogun 2 coolable specimen stages (liquid nitrogen) Vacuum: 2 rotation pumps, 1 oildiffussion pump

Precision Ion Polishing System (PIPS) Application area: ion milling of mechanically prepared specimens ion milling of electro polished specimens Producer: GATAN Inc. Operation voltage: 2000 V - 5000 V Vacuum: 1 membrane pump, 1 turbo molecular pump (oil free)

Precision Ion Polishing System (PIPS) Application area: ion milling of mechanically prepared specimens ion milling of electro polished specimens Producer: GATAN Inc. Operation voltage: 2000 V - 5000 V Vacuum: 1 membrane pump, 1 turbo molecular pump (oil free)

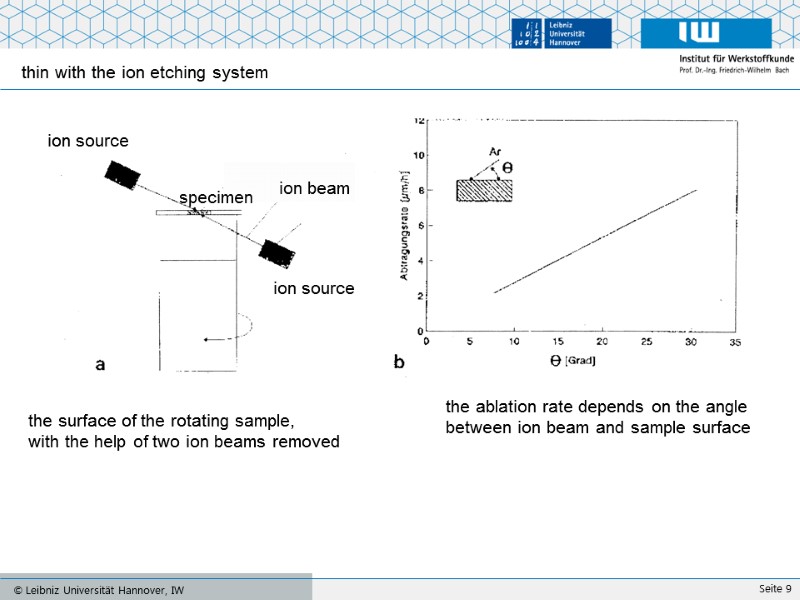

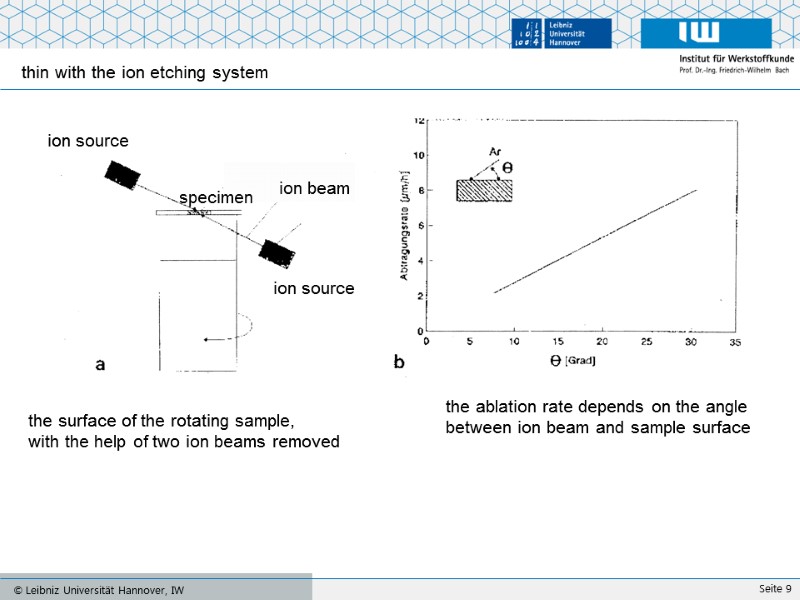

thin with the ion etching system ion source specimen ion beam ion source the surface of the rotating sample, with the help of two ion beams removed the ablation rate depends on the angle between ion beam and sample surface

thin with the ion etching system ion source specimen ion beam ion source the surface of the rotating sample, with the help of two ion beams removed the ablation rate depends on the angle between ion beam and sample surface

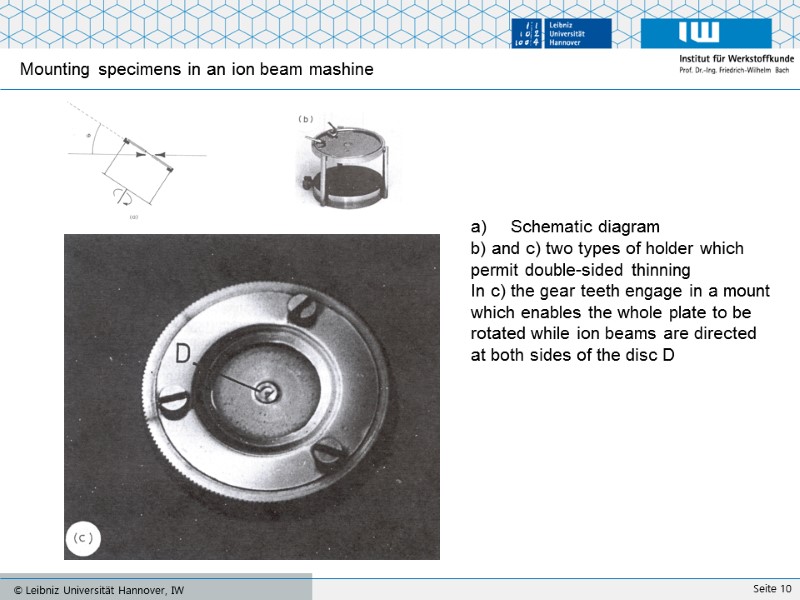

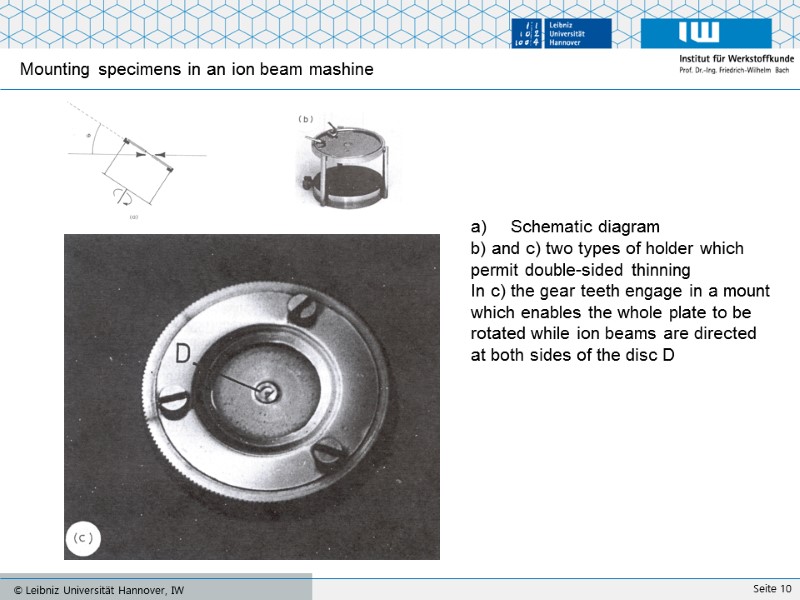

Schematic diagram b) and c) two types of holder which permit double-sided thinning In c) the gear teeth engage in a mount which enables the whole plate to be rotated while ion beams are directed at both sides of the disc D Mounting specimens in an ion beam mashine

Schematic diagram b) and c) two types of holder which permit double-sided thinning In c) the gear teeth engage in a mount which enables the whole plate to be rotated while ion beams are directed at both sides of the disc D Mounting specimens in an ion beam mashine

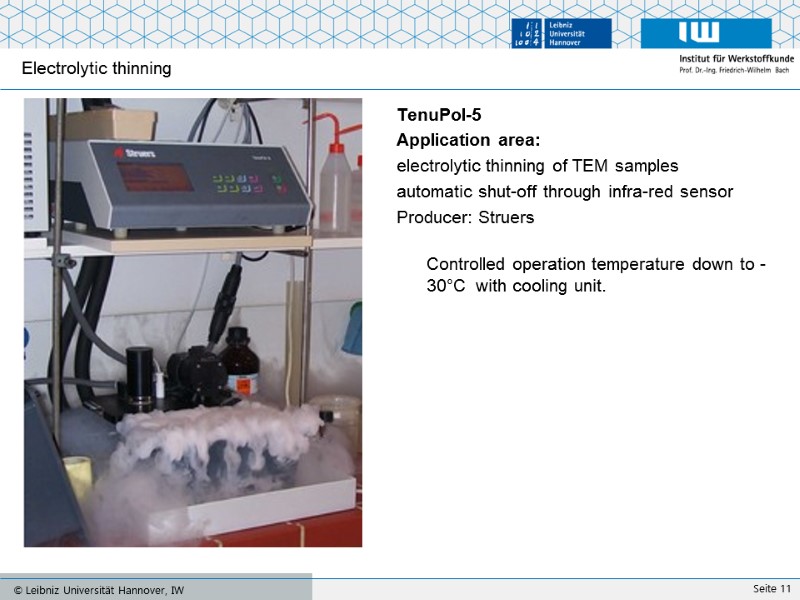

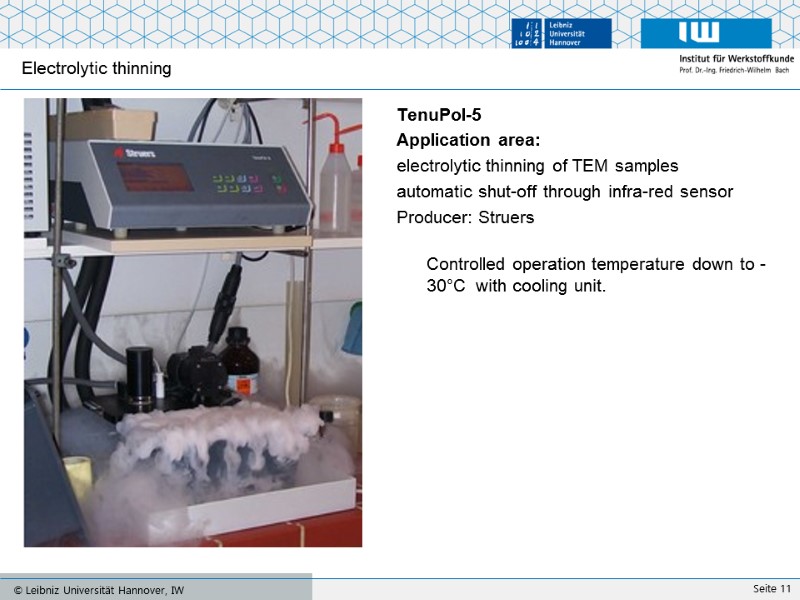

Electrolytic thinning TenuPol-5 Application area: electrolytic thinning of TEM samples automatic shut-off through infra-red sensor Producer: Struers Controlled operation temperature down to -30°C with cooling unit.

Electrolytic thinning TenuPol-5 Application area: electrolytic thinning of TEM samples automatic shut-off through infra-red sensor Producer: Struers Controlled operation temperature down to -30°C with cooling unit.

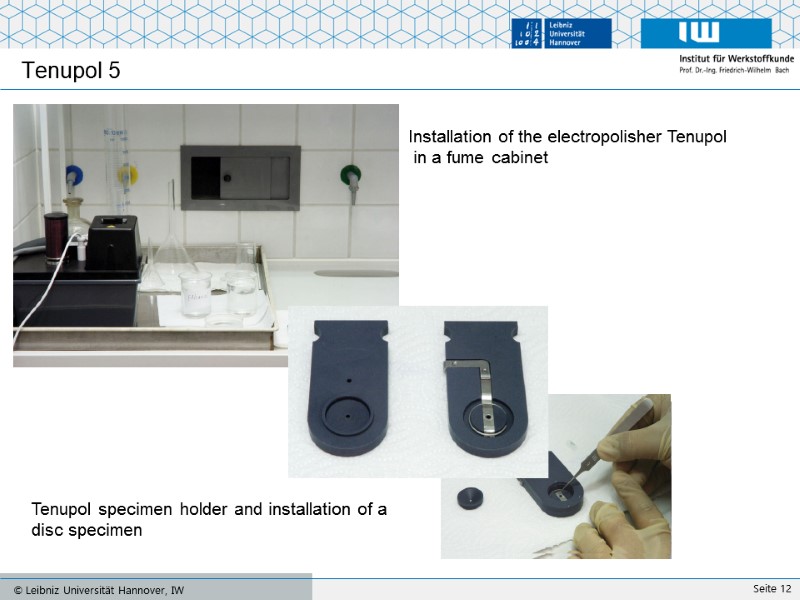

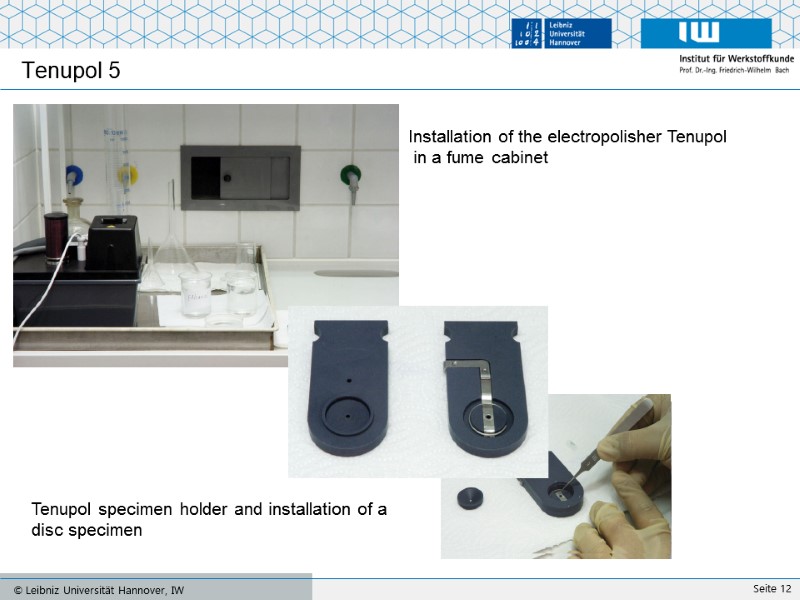

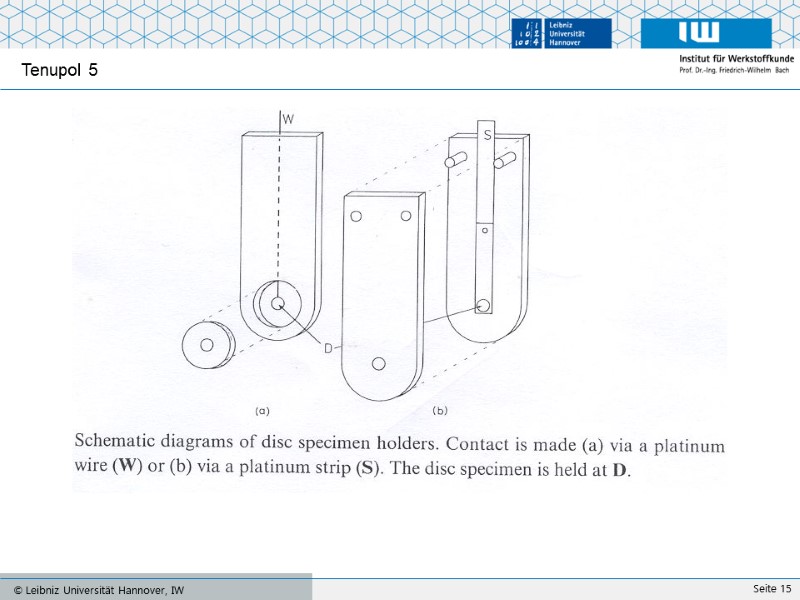

Tenupol 5 Tenupol specimen holder and installation of a disc specimen Installation of the electropolisher Tenupol in a fume cabinet

Tenupol 5 Tenupol specimen holder and installation of a disc specimen Installation of the electropolisher Tenupol in a fume cabinet

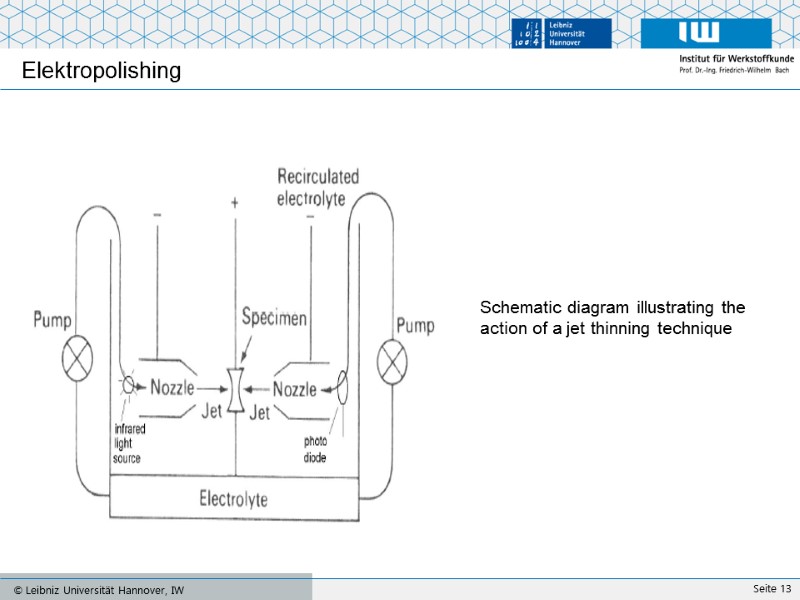

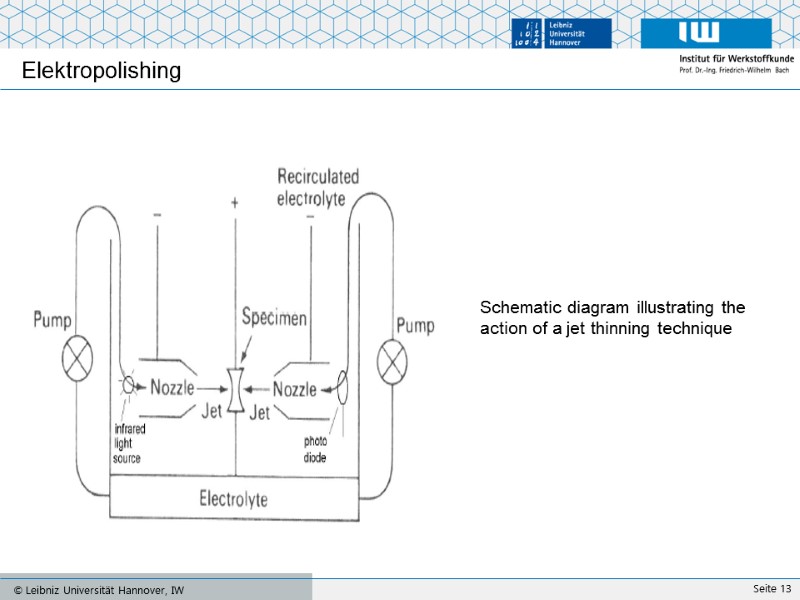

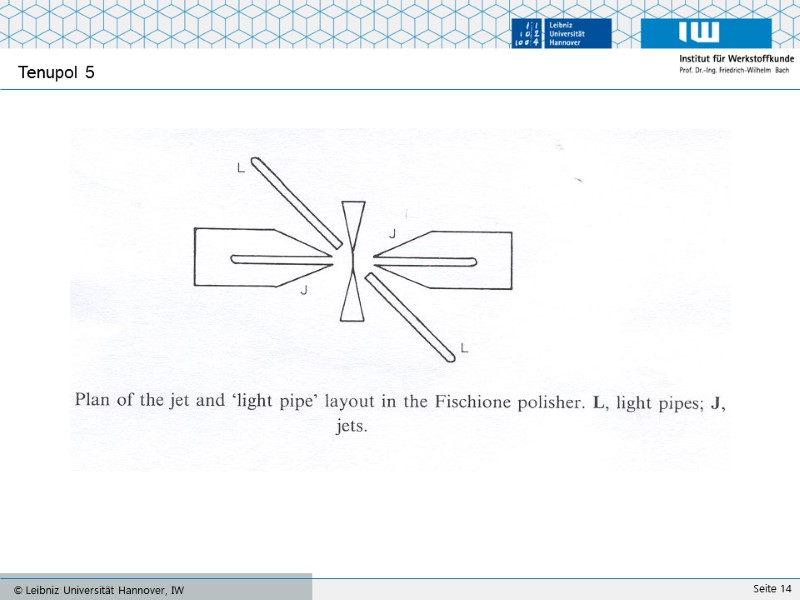

Elektropolishing Schematic diagram illustrating the action of a jet thinning technique

Elektropolishing Schematic diagram illustrating the action of a jet thinning technique

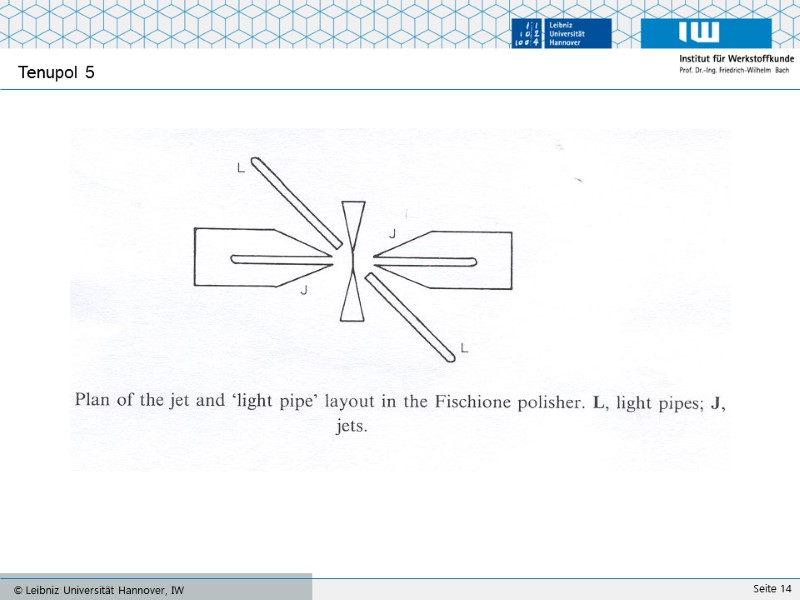

Tenupol 5

Tenupol 5

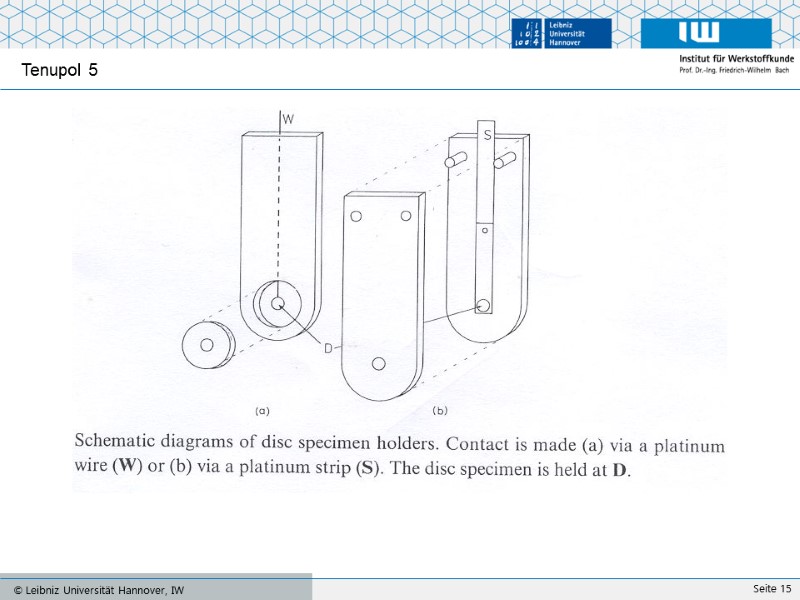

Tenupol 5

Tenupol 5

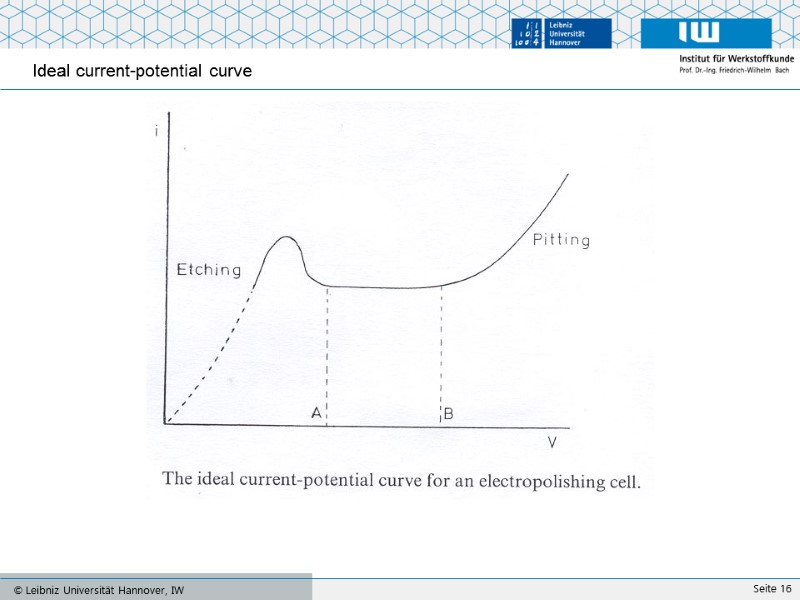

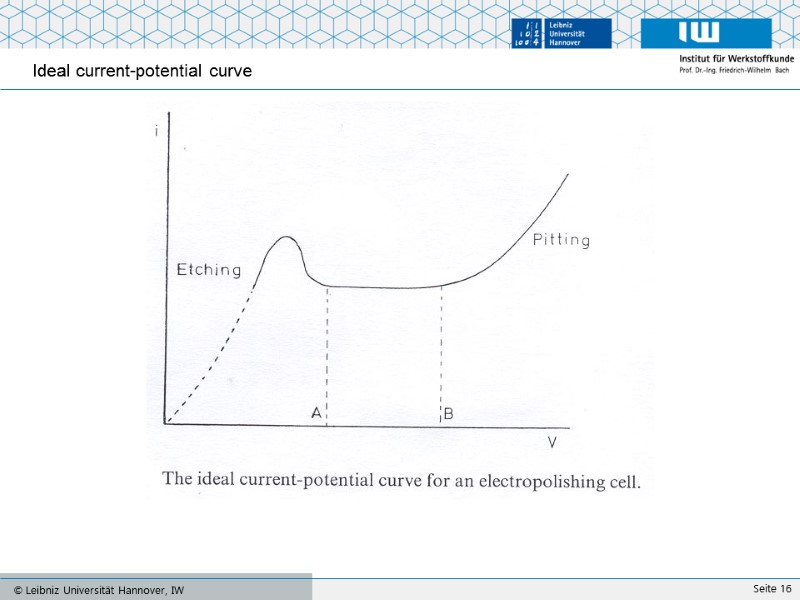

Ideal current-potential curve

Ideal current-potential curve

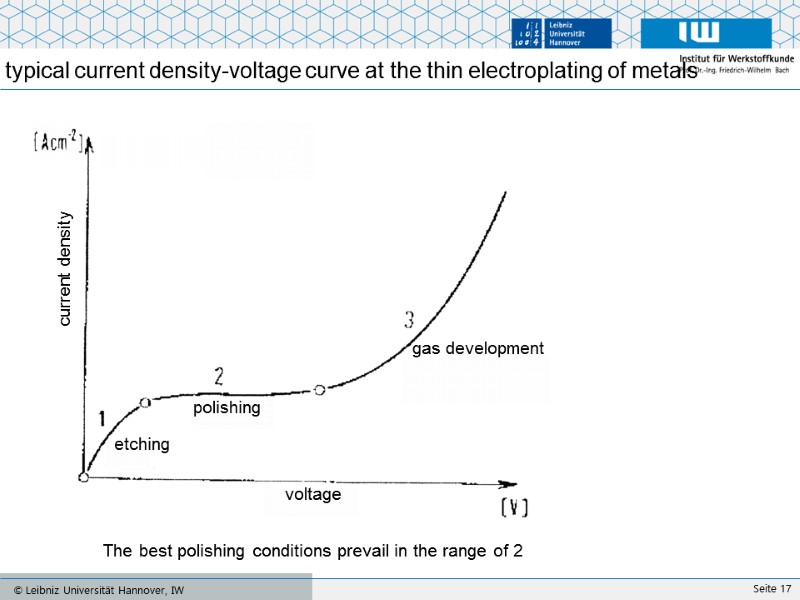

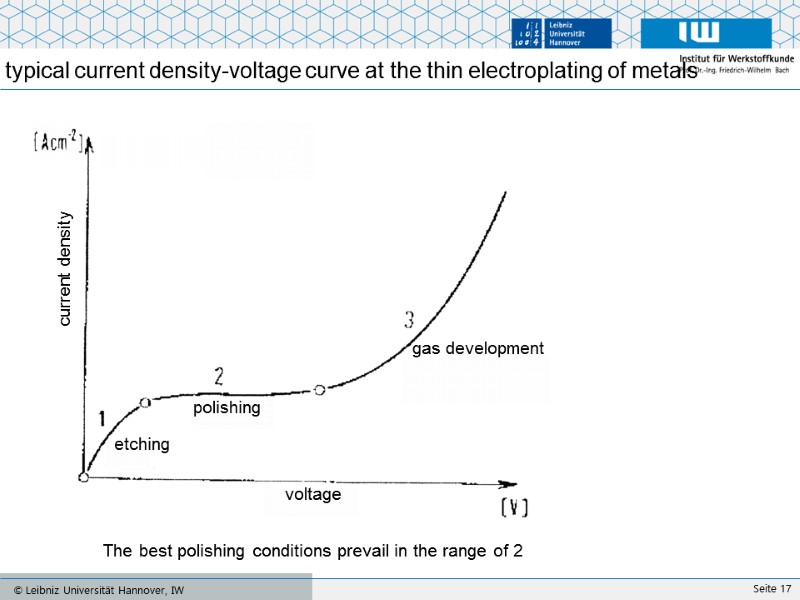

typical current density-voltage curve at the thin electroplating of metals etching current density gas development polishing voltage The best polishing conditions prevail in the range of 2

typical current density-voltage curve at the thin electroplating of metals etching current density gas development polishing voltage The best polishing conditions prevail in the range of 2

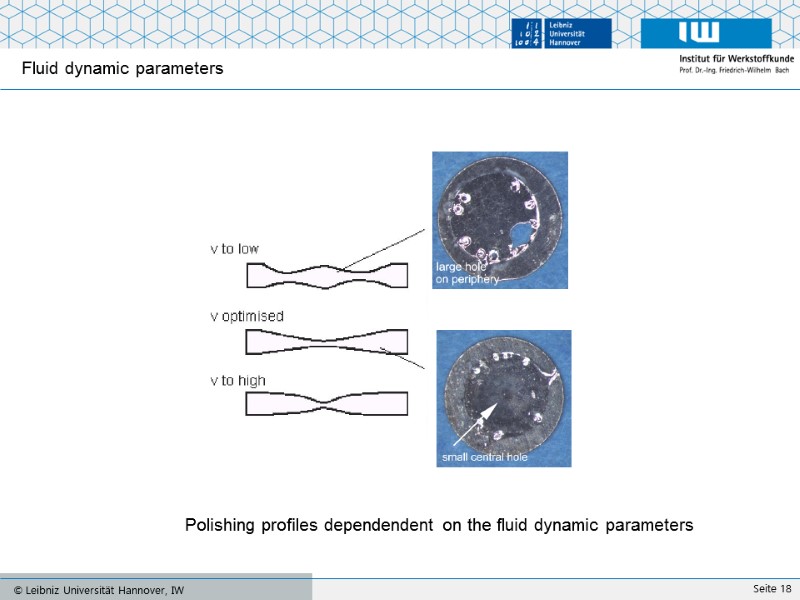

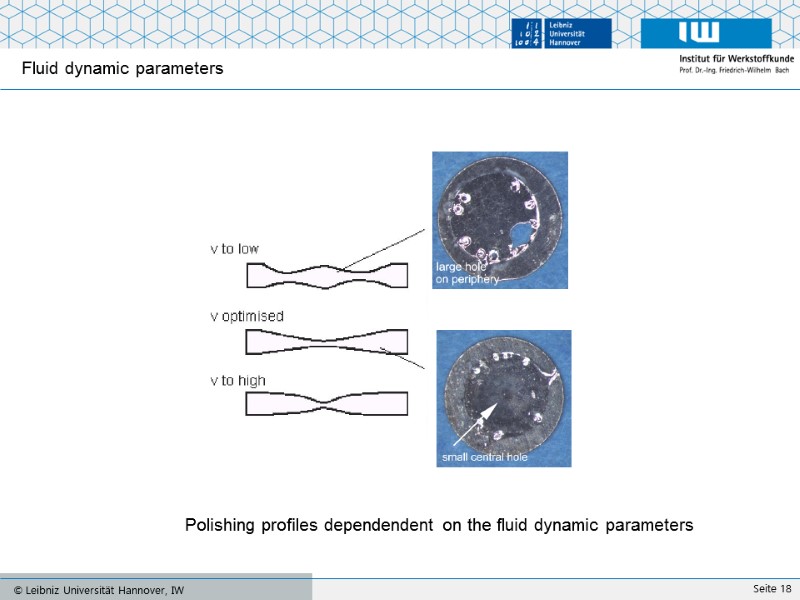

Fluid dynamic parameters Polishing profiles dependendent on the fluid dynamic parameters

Fluid dynamic parameters Polishing profiles dependendent on the fluid dynamic parameters

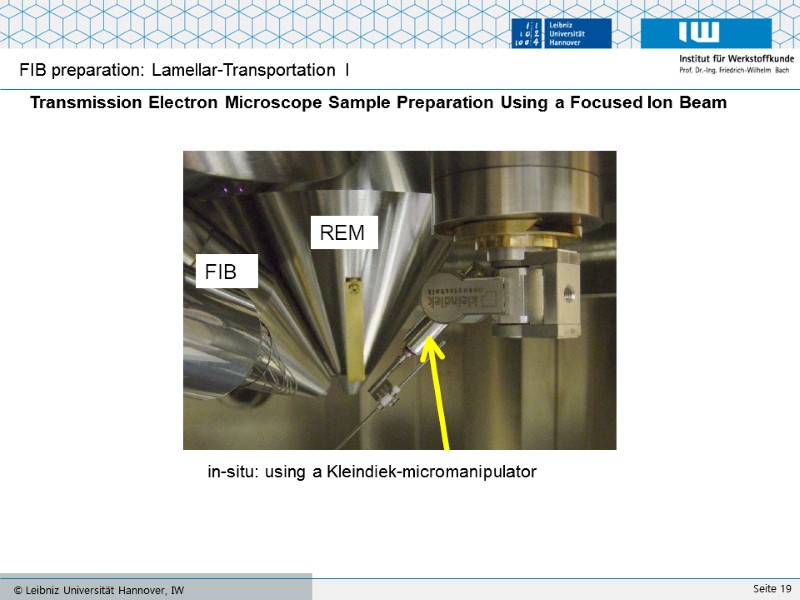

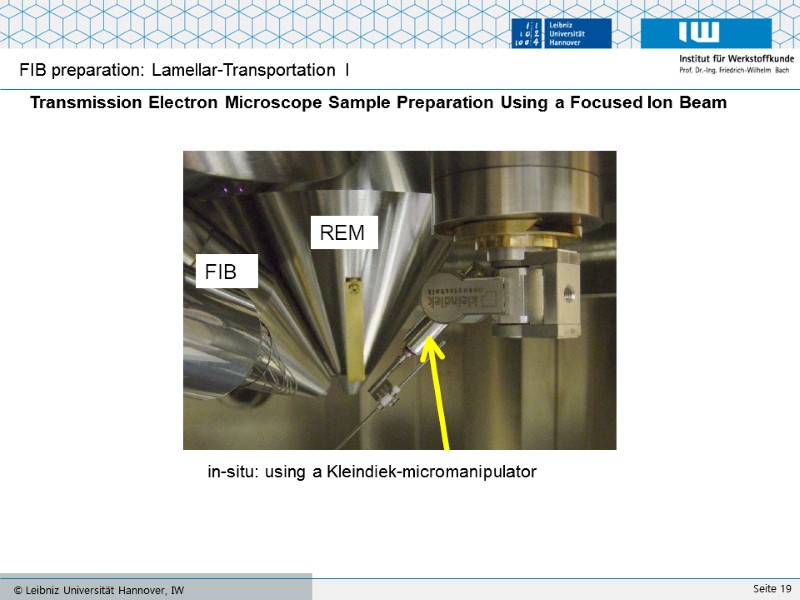

in-situ: using a Kleindiek-micromanipulator FIB preparation: Lamellar-Transportation I Transmission Electron Microscope Sample Preparation Using a Focused Ion Beam

in-situ: using a Kleindiek-micromanipulator FIB preparation: Lamellar-Transportation I Transmission Electron Microscope Sample Preparation Using a Focused Ion Beam

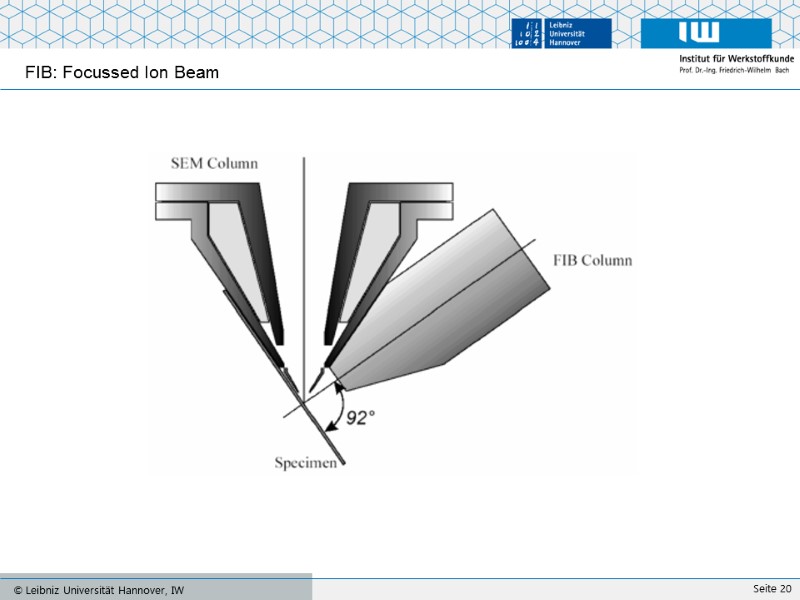

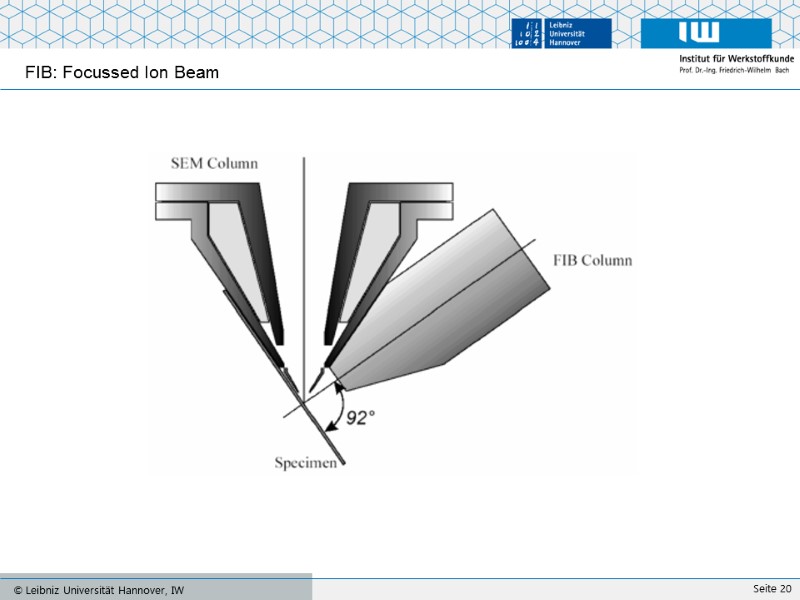

FIB: Focussed Ion Beam

FIB: Focussed Ion Beam

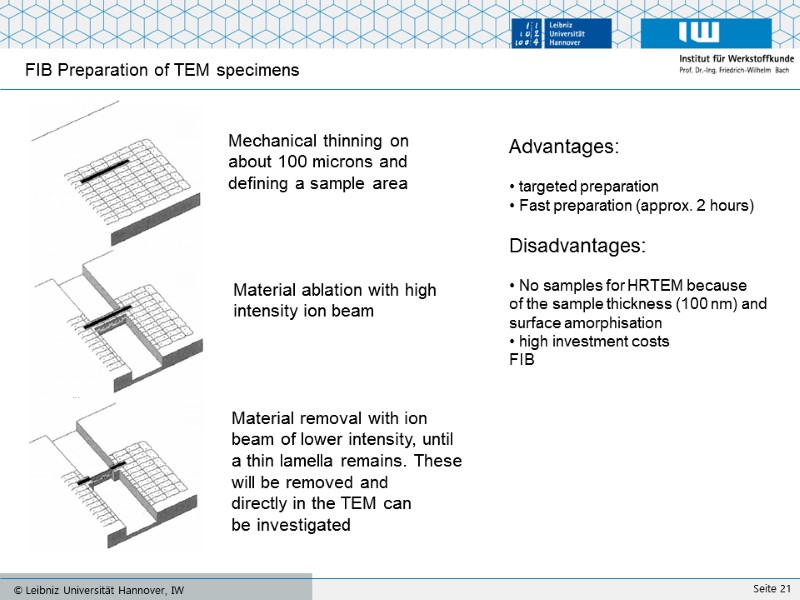

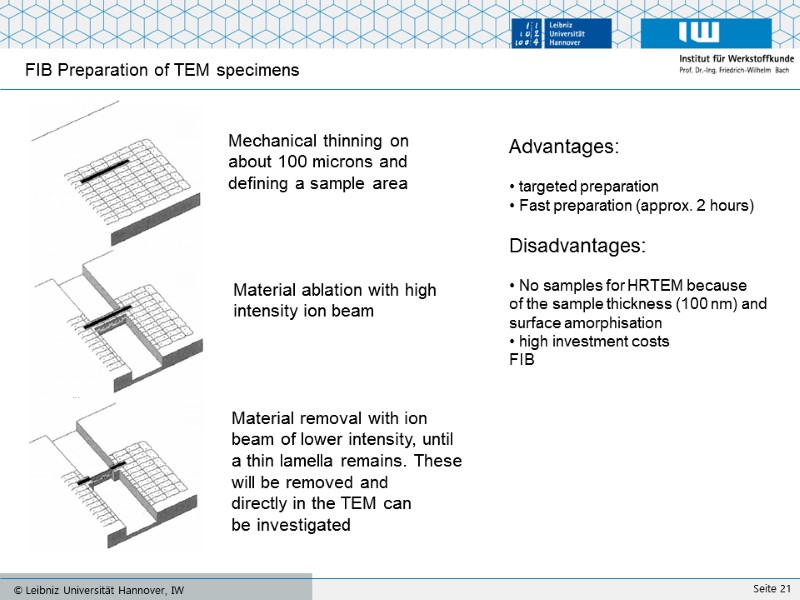

Mechanical thinning on about 100 microns and defining a sample area Material ablation with high intensity ion beam Material removal with ion beam of lower intensity, until a thin lamella remains. These will be removed and directly in the TEM can be investigated FIB Preparation of TEM specimens

Mechanical thinning on about 100 microns and defining a sample area Material ablation with high intensity ion beam Material removal with ion beam of lower intensity, until a thin lamella remains. These will be removed and directly in the TEM can be investigated FIB Preparation of TEM specimens

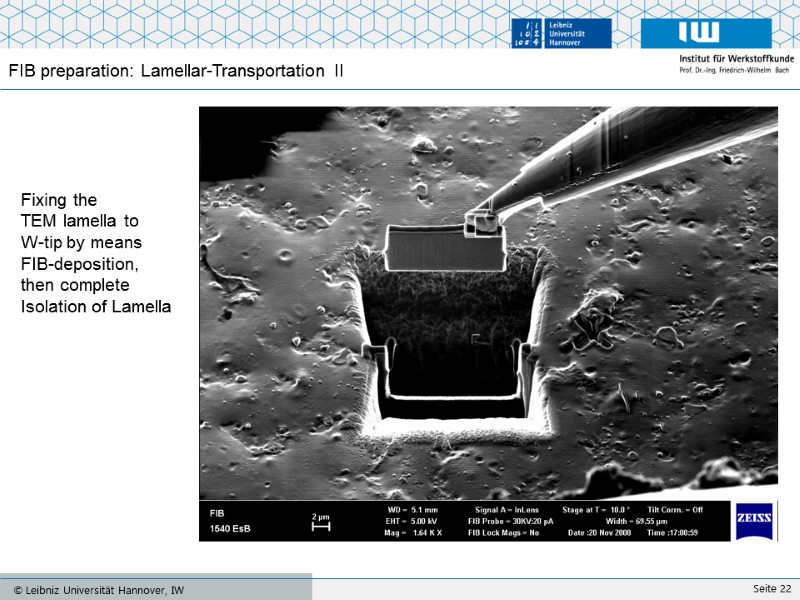

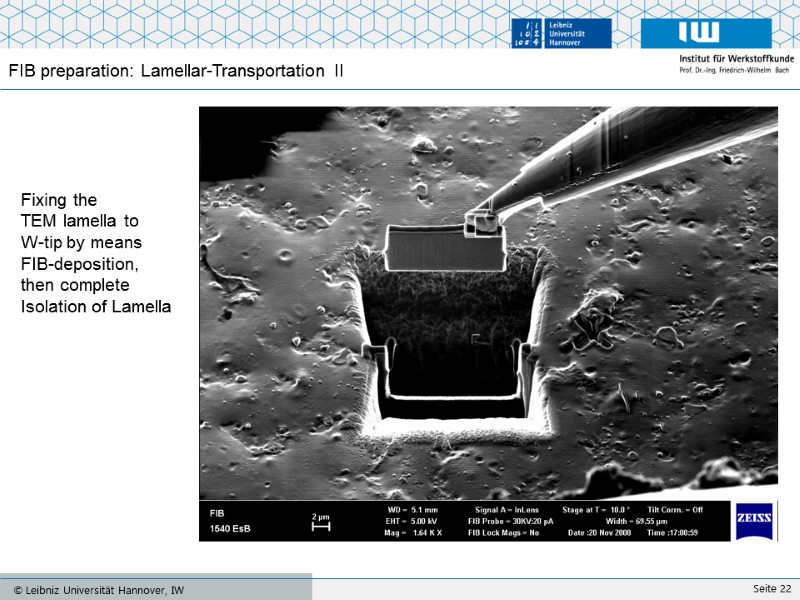

Fixing the TEM lamella to W-tip by means FIB-deposition, then complete Isolation of Lamella FIB preparation: Lamellar-Transportation II

Fixing the TEM lamella to W-tip by means FIB-deposition, then complete Isolation of Lamella FIB preparation: Lamellar-Transportation II

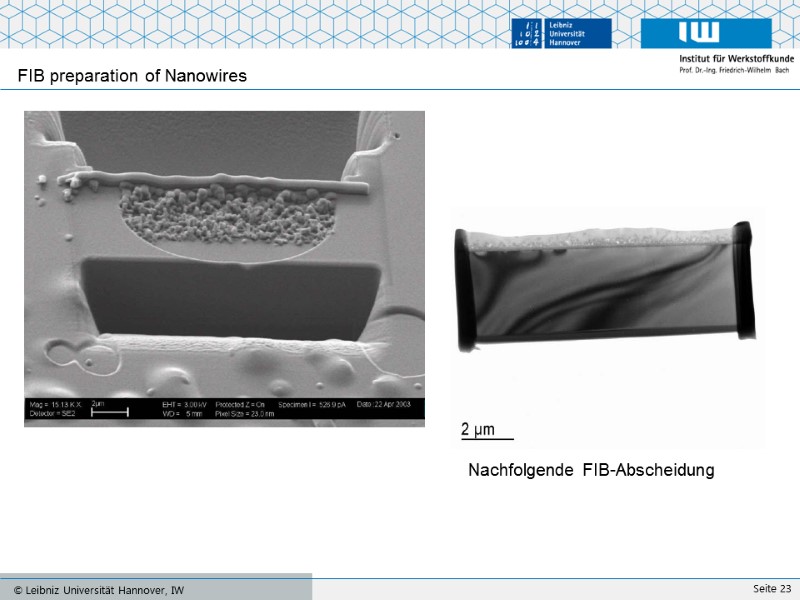

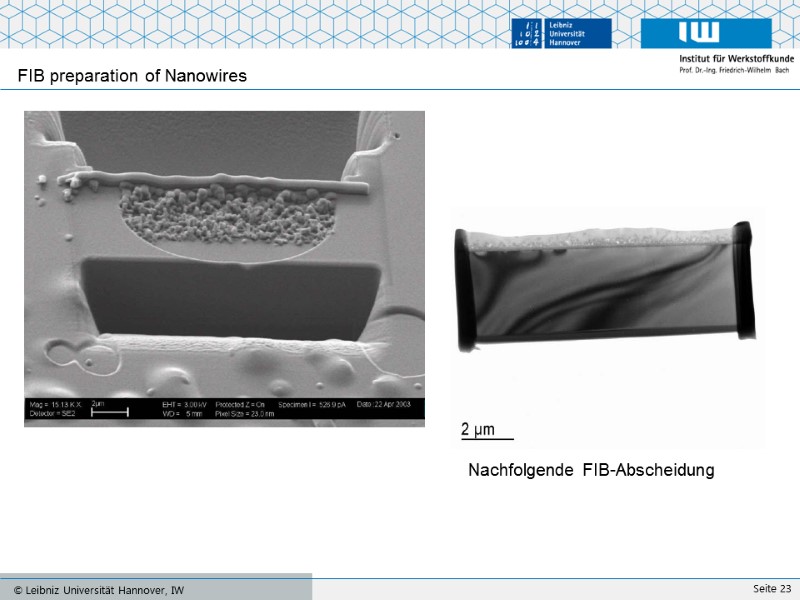

FIB preparation of Nanowires Nachfolgende FIB-Abscheidung

FIB preparation of Nanowires Nachfolgende FIB-Abscheidung

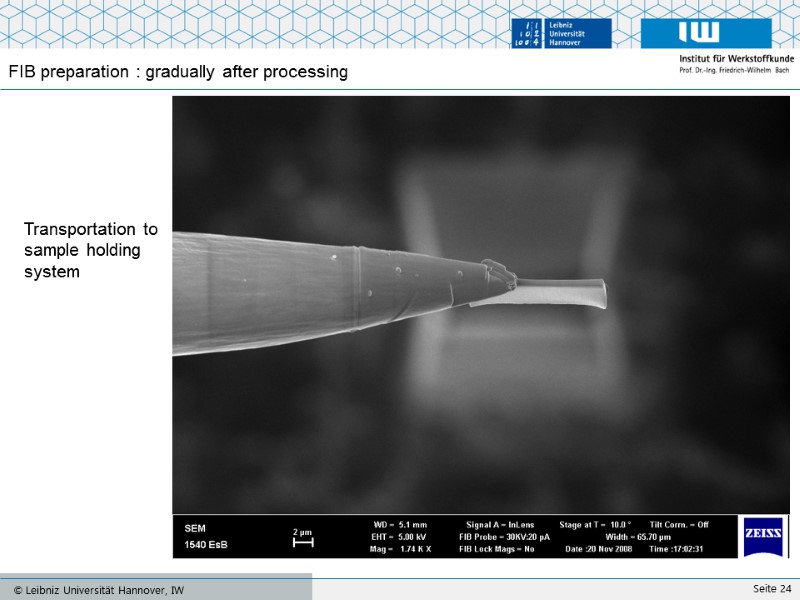

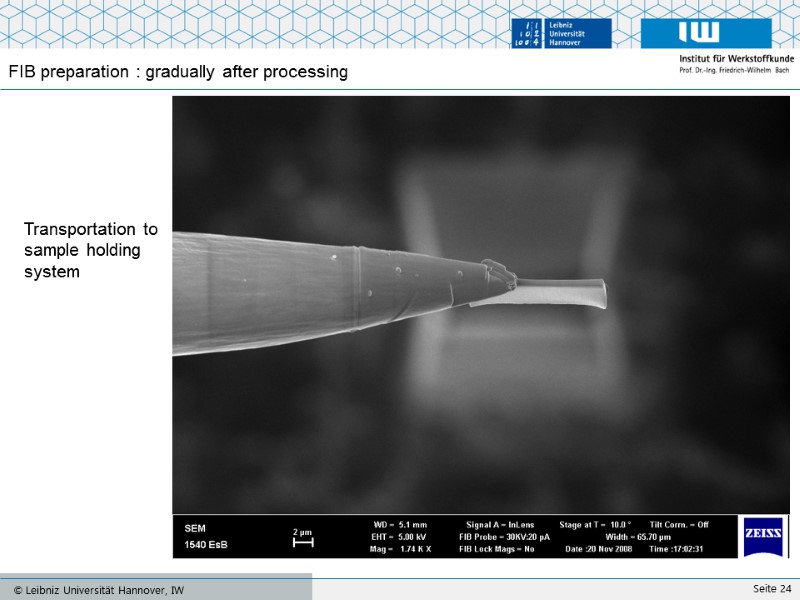

Transportation to sample holding system FIB preparation : gradually after processing

Transportation to sample holding system FIB preparation : gradually after processing

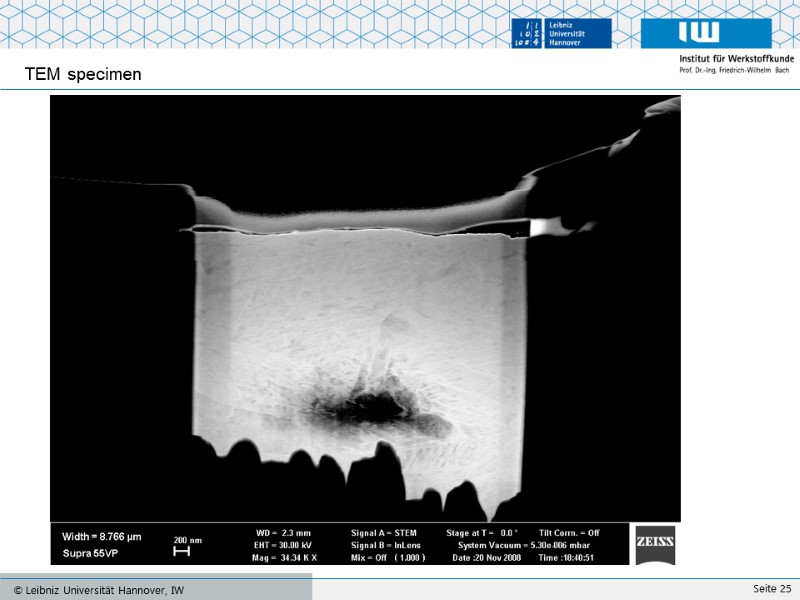

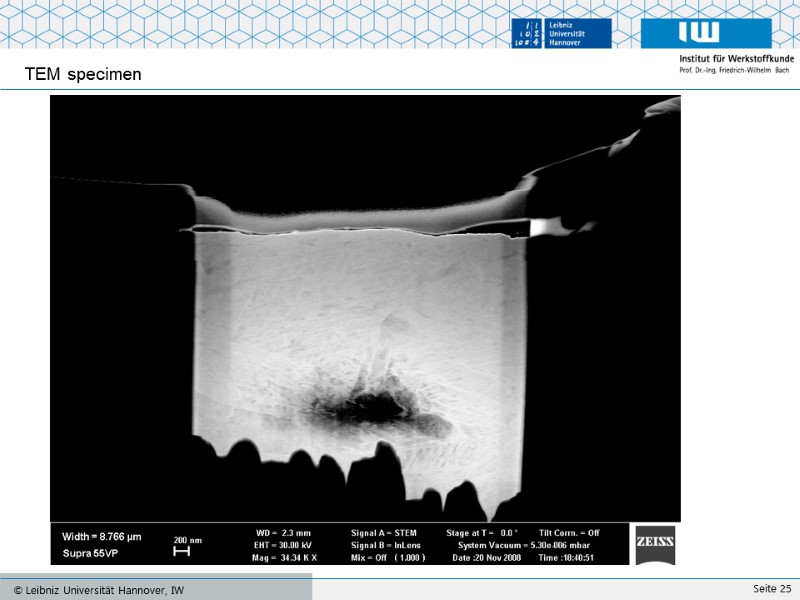

TEM specimen

TEM specimen

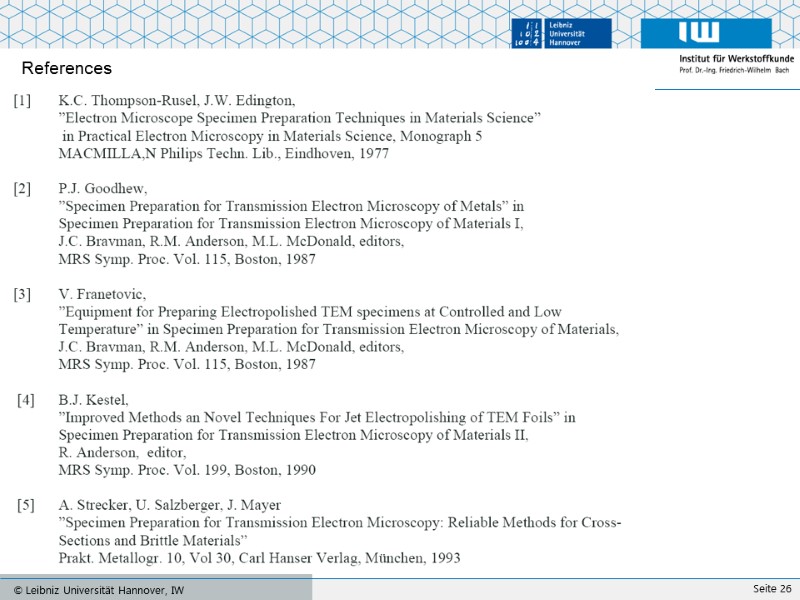

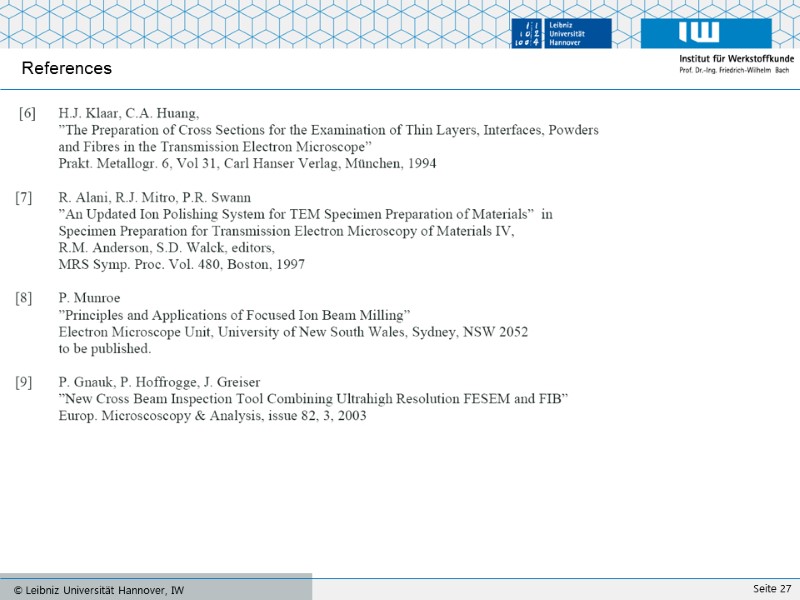

References

References

References

References