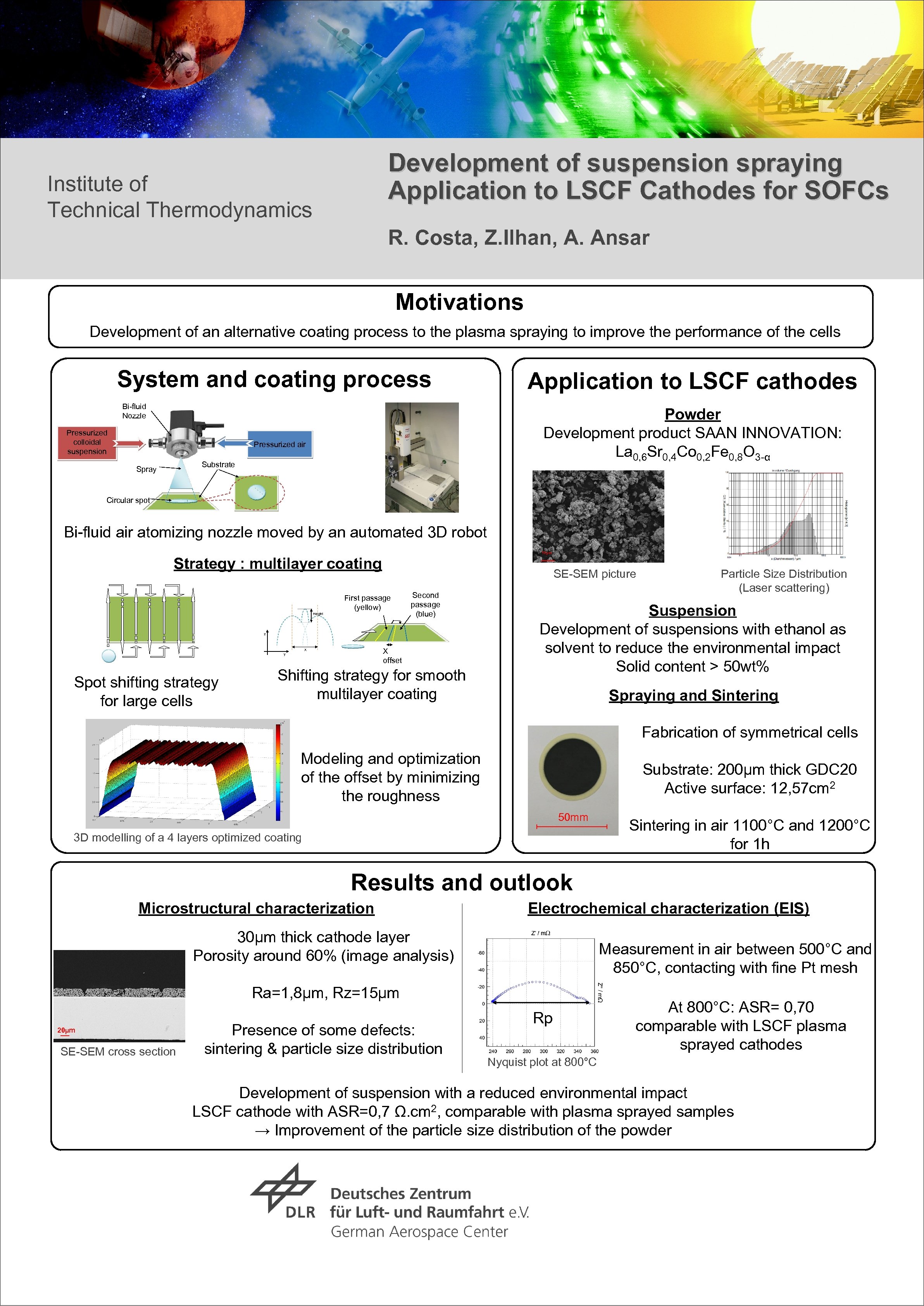

Development of suspension spraying Application to LSCF Cathodes for SOFCs Institute of Technical Thermodynamics R. Costa, Z. Ilhan, A. Ansar Motivations Development of an alternative coating process to the plasma spraying to improve the performance of the cells System and coating process Bi-fluid Nozzle Pressurized colloidal suspension Powder Development product SAAN INNOVATION: La 0, 6 Sr 0, 4 Co 0, 2 Fe 0, 8 O 3 -α Pressurized air Substrate Spray Application to LSCF cathodes Circular spot Bi-fluid air atomizing nozzle moved by an automated 3 D robot 10µm Strategy : multilayer coating SE-SEM picture First passage (yellow) Height Second passage (blue) z X offset X y Spot shifting strategy for large cells Shifting strategy for smooth multilayer coating Particle Size Distribution (Laser scattering) Suspension Development of suspensions with ethanol as solvent to reduce the environmental impact Solid content > 50 wt% Spraying and Sintering Fabrication of symmetrical cells Modeling and optimization of the offset by minimizing the roughness Substrate: 200µm thick GDC 20 Active surface: 12, 57 cm 2 50 mm 3 D modelling of a 4 layers optimized coating Sintering in air 1100°C and 1200°C for 1 h Results and outlook Microstructural characterization Electrochemical characterization (EIS) 30µm thick cathode layer Porosity around 60% (image analysis) Measurement in air between 500°C and 850°C, contacting with fine Pt mesh Ra=1, 8µm, Rz=15µm 20µm SE-SEM cross section Presence of some defects: sintering & particle size distribution Rp At 800°C: ASR= 0, 70 comparable with LSCF plasma sprayed cathodes Nyquist plot at 800°C Development of suspension with a reduced environmental impact LSCF cathode with ASR=0, 7 Ω. cm 2, comparable with plasma sprayed samples → Improvement of the particle size distribution of the powder

Development of suspension spraying Application to LSCF Cathodes for SOFCs Institute of Technical Thermodynamics R. Costa, Z. Ilhan, A. Ansar Motivations Development of an alternative coating process to the plasma spraying to improve the performance of the cells System and coating process Bi-fluid Nozzle Pressurized colloidal suspension Powder Development product SAAN INNOVATION: La 0, 6 Sr 0, 4 Co 0, 2 Fe 0, 8 O 3 -α Pressurized air Substrate Spray Application to LSCF cathodes Circular spot Bi-fluid air atomizing nozzle moved by an automated 3 D robot 10µm Strategy : multilayer coating SE-SEM picture First passage (yellow) Height Second passage (blue) z X offset X y Spot shifting strategy for large cells Shifting strategy for smooth multilayer coating Particle Size Distribution (Laser scattering) Suspension Development of suspensions with ethanol as solvent to reduce the environmental impact Solid content > 50 wt% Spraying and Sintering Fabrication of symmetrical cells Modeling and optimization of the offset by minimizing the roughness Substrate: 200µm thick GDC 20 Active surface: 12, 57 cm 2 50 mm 3 D modelling of a 4 layers optimized coating Sintering in air 1100°C and 1200°C for 1 h Results and outlook Microstructural characterization Electrochemical characterization (EIS) 30µm thick cathode layer Porosity around 60% (image analysis) Measurement in air between 500°C and 850°C, contacting with fine Pt mesh Ra=1, 8µm, Rz=15µm 20µm SE-SEM cross section Presence of some defects: sintering & particle size distribution Rp At 800°C: ASR= 0, 70 comparable with LSCF plasma sprayed cathodes Nyquist plot at 800°C Development of suspension with a reduced environmental impact LSCF cathode with ASR=0, 7 Ω. cm 2, comparable with plasma sprayed samples → Improvement of the particle size distribution of the powder

![]()