c248c4af83de447227c74175101ae61e.ppt

- Количество слайдов: 75

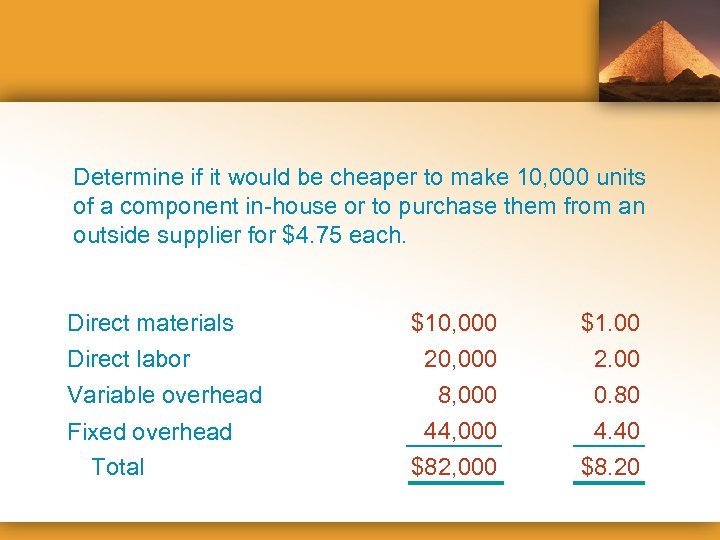

Determine if it would be cheaper to make 10, 000 units of a component in-house or to purchase them from an outside supplier for $4. 75 each. Direct materials Direct labor Variable overhead Fixed overhead Total $10, 000 20, 000 8, 000 44, 000 $82, 000 $1. 00 2. 00 0. 80 4. 40 $8. 20

Direct materials Direct labor Variable overhead $10, 000 20, 000 ------- $10, 000 20, 000 8, 000 ---- 8, 000 Purchase cost Fixed overhead is not included in the analysis. It will remain the same under either alternative.

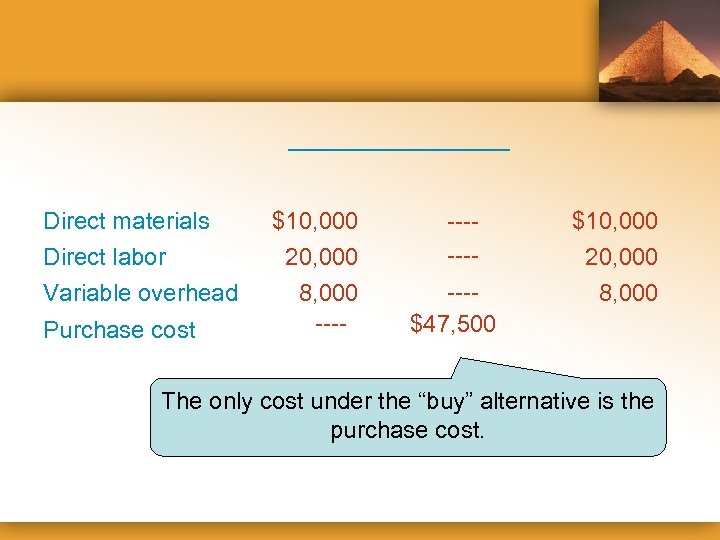

Direct materials Direct labor Variable overhead Purchase cost $10, 000 20, 000 8, 000 ---------$47, 500 $10, 000 20, 000 8, 000 The only cost under the “buy” alternative is the purchase cost.

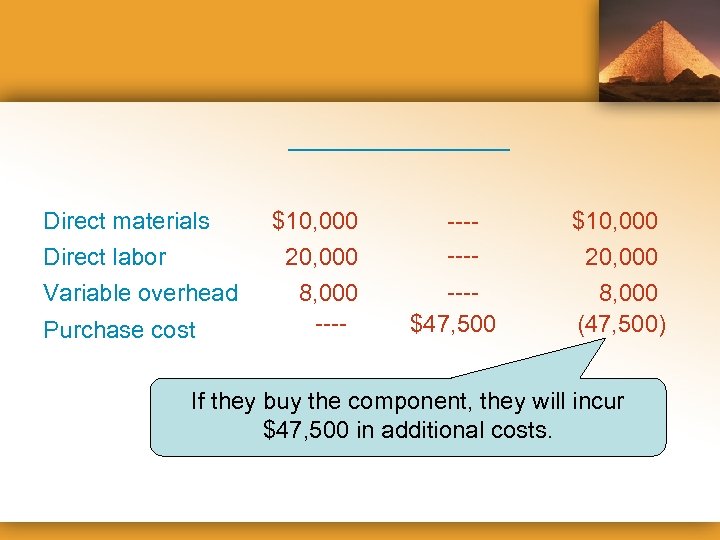

Direct materials Direct labor Variable overhead Purchase cost $10, 000 20, 000 8, 000 ---------$47, 500 $10, 000 20, 000 8, 000 (47, 500) If they buy the component, they will incur $47, 500 in additional costs.

Direct materials Direct labor Variable overhead Purchase cost Total $10, 000 20, 000 ------- $10, 000 20, 000 8, 000 ---- ---$47, 500 8, 000 (47, 500) $38, 000 $47, 500 $(9, 500) It is cheaper to make the component in-house. This alternative is better by $9, 500

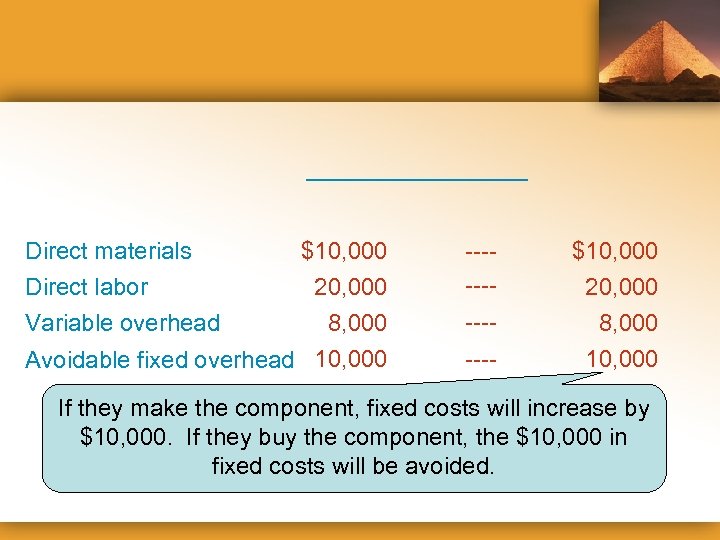

Direct materials Direct labor Variable overhead $10, 000 20, 000 8, 000 Avoidable fixed overhead 10, 000 ------- $10, 000 20, 000 8, 000 10, 000 If they make the component, fixed costs will increase by $10, 000. If they buy the component, the $10, 000 in fixed costs will be avoided.

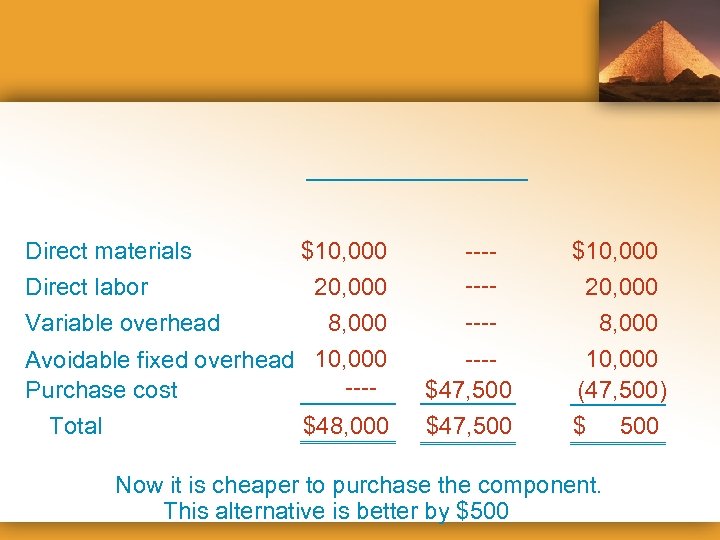

Direct materials Direct labor Variable overhead $10, 000 20, 000 8, 000 Avoidable fixed overhead 10, 000 ---Purchase cost Total $48, 000 ------$47, 500 $10, 000 20, 000 8, 000 10, 000 (47, 500) $ 500 Now it is cheaper to purchase the component. This alternative is better by $500

Price $9. 00 Direct Materials (3. 00) --- (3. 00) Direct Labor (2. 80) --- (2. 80) Variable Overhead (1. 50) --- (1. 50) Increase in operating income $1. 70 $ --- $ 0 $9. 00 $1. 70

Sales Less: Variable Expenses Contribution Margin Less: Advertising Cost of supervision Total relevant benefit (loss) $150, 000 140, 000 $ 10, 000 (10, 000) (35, 000) $ -----$ 0 $150, 000 140, 000 $ 10, 000 (10, 000) (35, 000) $(35, 000)

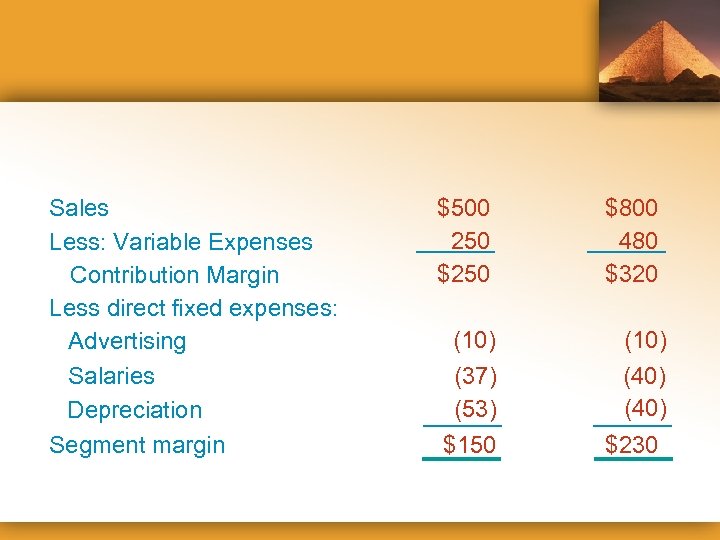

Sales Less: Variable Expenses Contribution Margin Less direct fixed expenses: Advertising Salaries Depreciation Segment margin $500 250 $250 (10) (37) (53) $150 $800 480 $320 (10) (40) $230

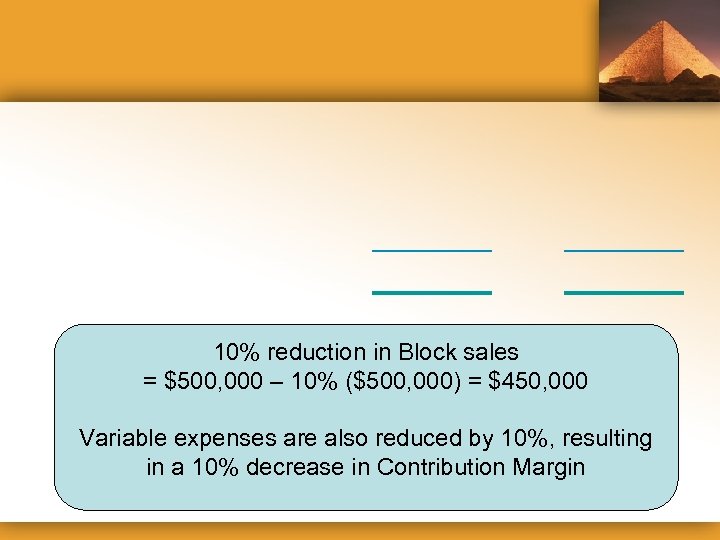

10% reduction in Block sales = $500, 000 – 10% ($500, 000) = $450, 000 Variable expenses are also reduced by 10%, resulting in a 10% decrease in Contribution Margin

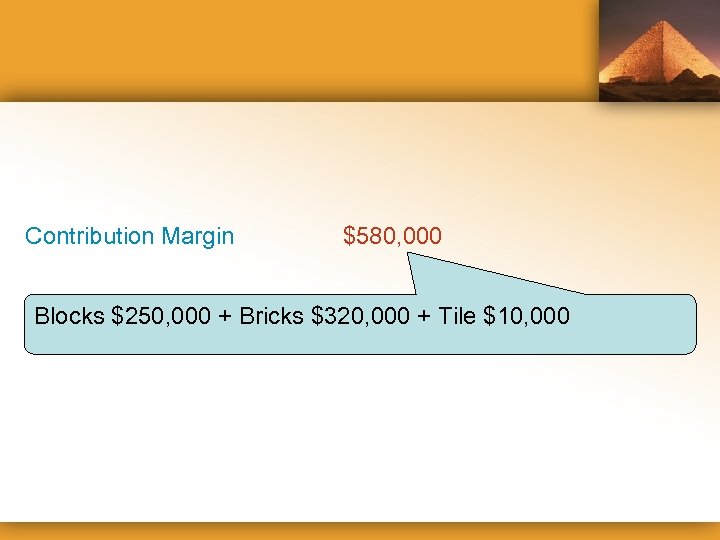

Contribution Margin $580, 000 Blocks $250, 000 + Bricks $320, 000 + Tile $10, 000

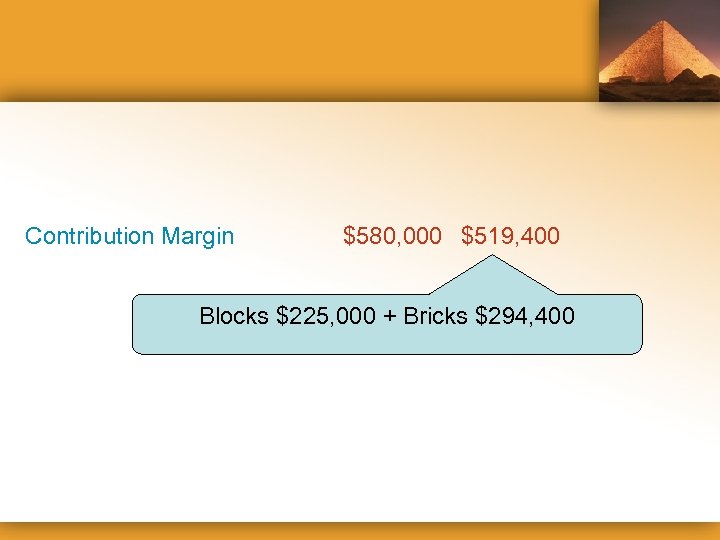

Contribution Margin $580, 000 $519, 400 Blocks $225, 000 + Bricks $294, 400

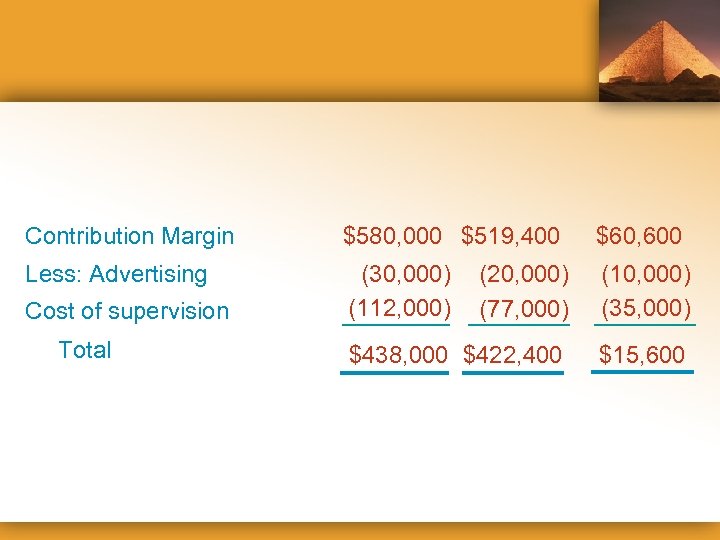

Contribution Margin $580, 000 $519, 400 $60, 600 Less: Advertising (30, 000) (112, 000) (20, 000) (77, 000) (10, 000) (35, 000) $438, 000 $422, 400 $15, 600 Cost of supervision Total

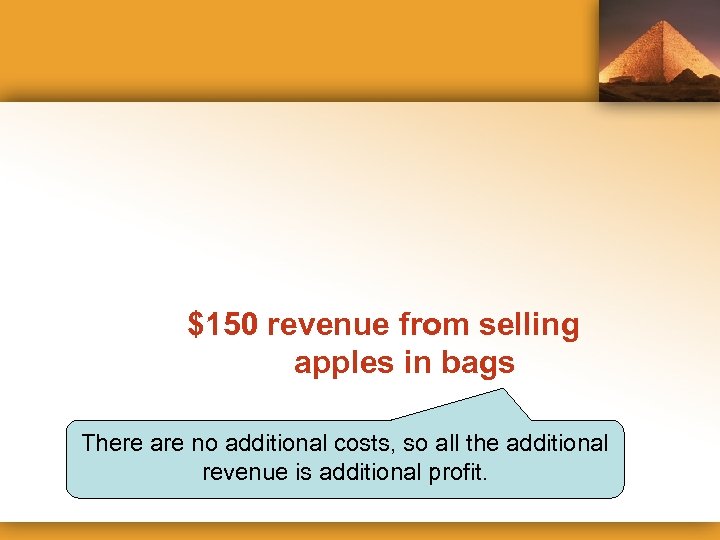

$150 revenue from selling apples in bags There are no additional costs, so all the additional revenue is additional profit.

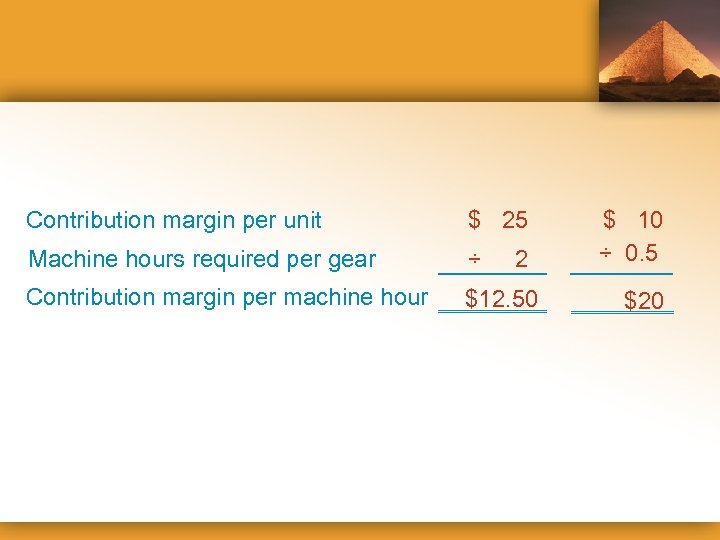

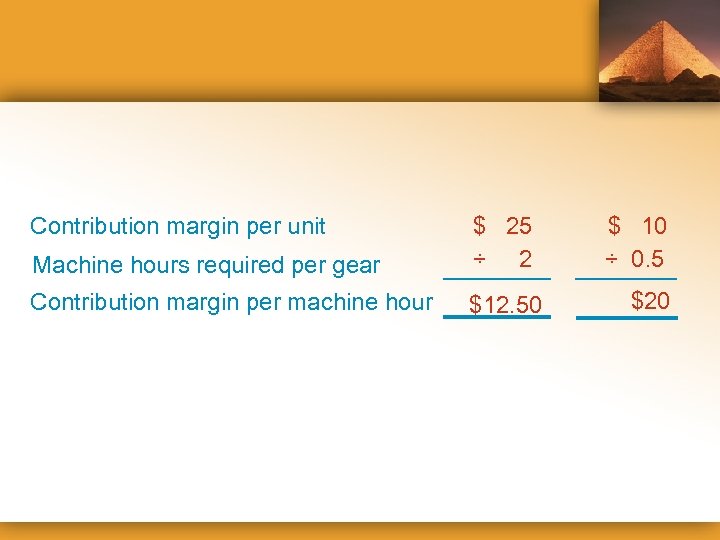

Contribution margin per unit $ 25 Machine hours required per gear ÷ Contribution margin per machine hour $12. 50 2 $ 10 ÷ 0. 5 $20

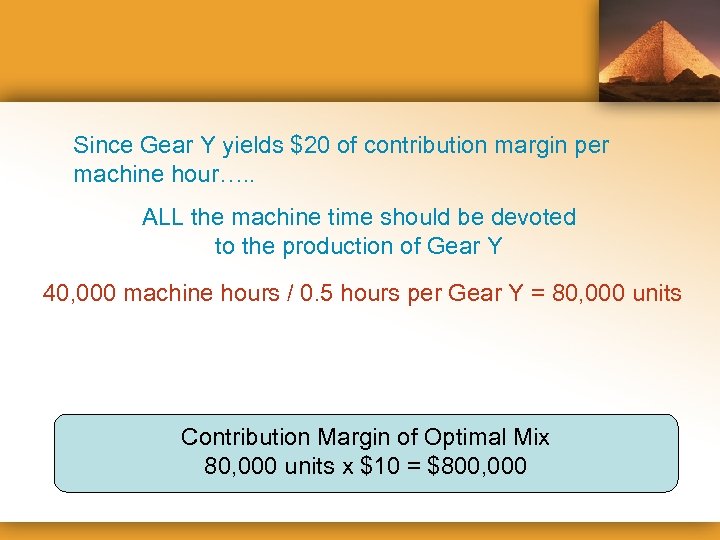

Since Gear Y yields $20 of contribution margin per machine hour…. . ALL the machine time should be devoted to the production of Gear Y 40, 000 machine hours / 0. 5 hours per Gear Y = 80, 000 units Contribution Margin of Optimal Mix 80, 000 units x $10 = $800, 000

Contribution margin per unit Machine hours required per gear $ 25 ÷ 2 Contribution margin per machine hour $12. 50 $ 10 ÷ 0. 5 $20

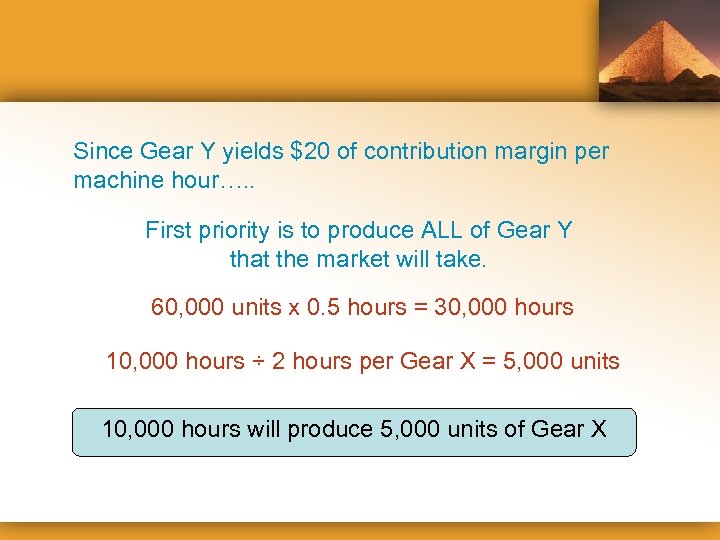

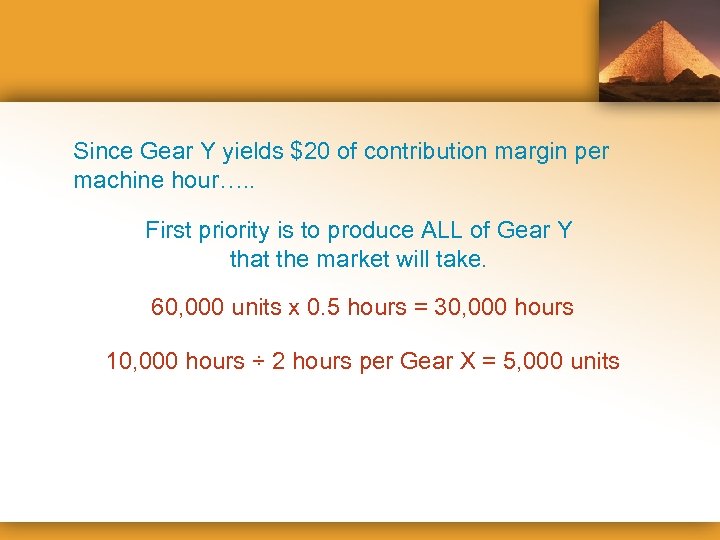

Since Gear Y yields $20 of contribution margin per machine hour…. . First priority is to produce ALL of Gear Y that the market will take. 60, 000 units x 0. 5 hours = 30, 000 hours 60, 000 is the maximum sales for any gear. 60, 000 units use 30, 000 machine hours. This leaves 10, 000 hours of production time.

Since Gear Y yields $20 of contribution margin per machine hour…. . First priority is to produce ALL of Gear Y that the market will take. 60, 000 units x 0. 5 hours = 30, 000 hours 10, 000 hours ÷ 2 hours per Gear X = 5, 000 units 10, 000 hours will produce 5, 000 units of Gear X

Since Gear Y yields $20 of contribution margin per machine hour…. . First priority is to produce ALL of Gear Y that the market will take. 60, 000 units x 0. 5 hours = 30, 000 hours 10, 000 hours ÷ 2 hours per Gear X = 5, 000 units

Price = $82, 800

c248c4af83de447227c74175101ae61e.ppt