69ea236dc439c6345897e13eefe2d187.ppt

- Количество слайдов: 32

Designing Products and Processes with a Future

Designing Products and Processes with a Future

What does it take? l Involve the customer l Meet with the customer l Listen to customer l Educate the customer l Incorporate quality function deployment (QFD) l Design for robustness

What does it take? l Involve the customer l Meet with the customer l Listen to customer l Educate the customer l Incorporate quality function deployment (QFD) l Design for robustness

What is a customer? l l l l The person who buys the product? The federal regulator? The consumer reporter? The marketing and sales department? Engineering? Manufacturing? Suppliers?

What is a customer? l l l l The person who buys the product? The federal regulator? The consumer reporter? The marketing and sales department? Engineering? Manufacturing? Suppliers?

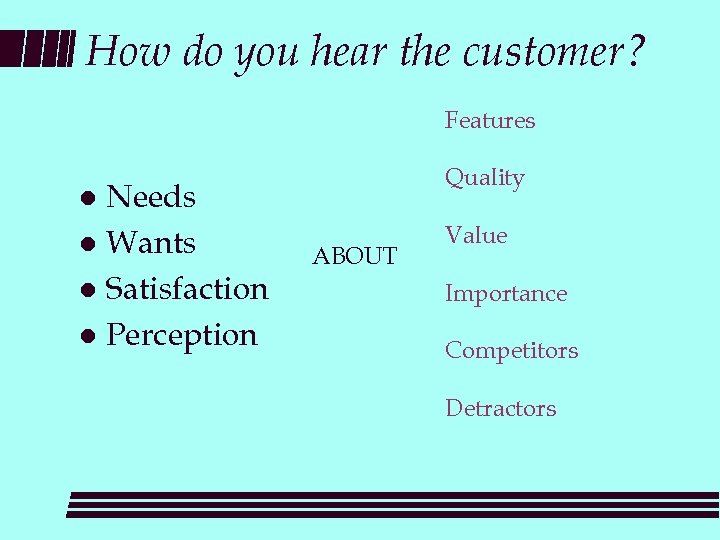

How do you hear the customer? Features Needs l Wants l Satisfaction l Perception Quality l ABOUT Value Importance Competitors Detractors

How do you hear the customer? Features Needs l Wants l Satisfaction l Perception Quality l ABOUT Value Importance Competitors Detractors

Product Design What the Customer wanted What Marketing described What Engineering designed What Manufacturing built

Product Design What the Customer wanted What Marketing described What Engineering designed What Manufacturing built

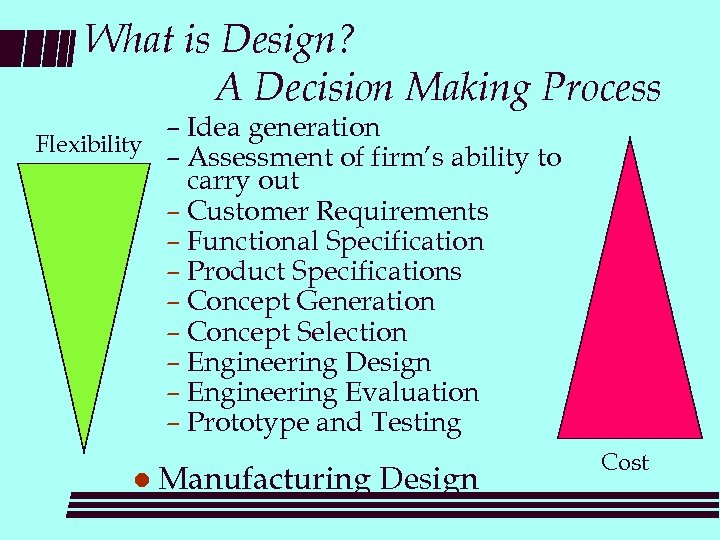

What is Design? A Decision Making Process – Idea generation Flexibility – Assessment of firm’s ability to carry out – Customer Requirements – Functional Specification – Product Specifications – Concept Generation – Concept Selection – Engineering Design – Engineering Evaluation – Prototype and Testing l Manufacturing Design Cost

What is Design? A Decision Making Process – Idea generation Flexibility – Assessment of firm’s ability to carry out – Customer Requirements – Functional Specification – Product Specifications – Concept Generation – Concept Selection – Engineering Design – Engineering Evaluation – Prototype and Testing l Manufacturing Design Cost

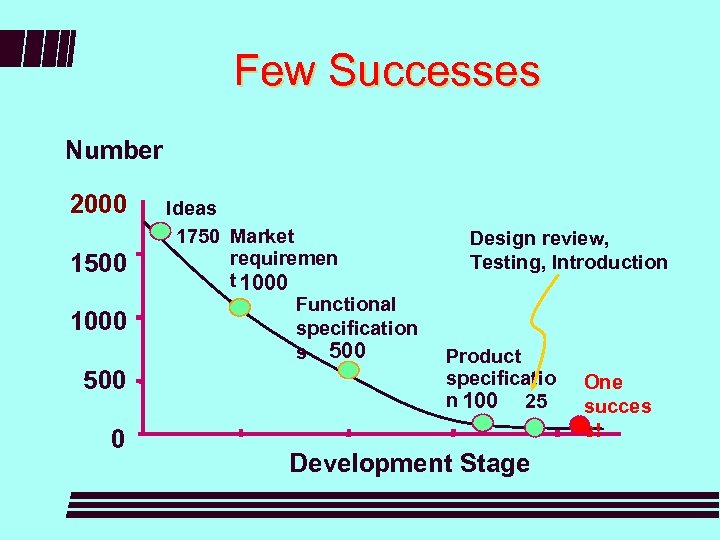

Few Successes Number 2000 1500 1000 500 0 Ideas 1750 Market requiremen t 1000 Functional specification s 500 Design review, Testing, Introduction Product specificatio n 100 25 Development Stage One succes s!

Few Successes Number 2000 1500 1000 500 0 Ideas 1750 Market requiremen t 1000 Functional specification s 500 Design review, Testing, Introduction Product specificatio n 100 25 Development Stage One succes s!

QUALITY FUNCTION DEPLOYMENT l Quality Function Deployment – Uses the voice of the customer to build a design tool: » House of quality QFD: An approach that integrates the “voice of the customer” into the product and service development process.

QUALITY FUNCTION DEPLOYMENT l Quality Function Deployment – Uses the voice of the customer to build a design tool: » House of quality QFD: An approach that integrates the “voice of the customer” into the product and service development process.

Quality Function Deployment l Identify customer wants l Identify how the good/service will satisfy customer wants l Relate customer wants to product hows l Identify relationships between the firm’s hows l Develop importance ratings l Evaluate competing products

Quality Function Deployment l Identify customer wants l Identify how the good/service will satisfy customer wants l Relate customer wants to product hows l Identify relationships between the firm’s hows l Develop importance ratings l Evaluate competing products

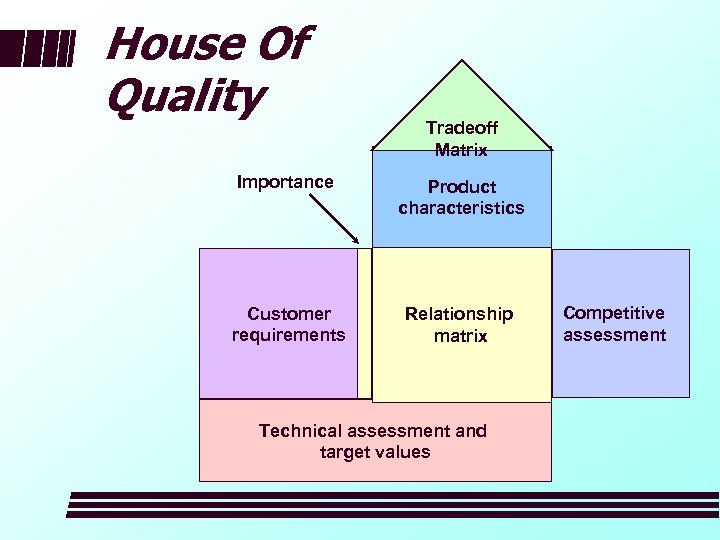

House Of Quality Tradeoff Matrix Importance Product characteristics Customer requirements Relationship matrix Technical assessment and target values Competitive assessment

House Of Quality Tradeoff Matrix Importance Product characteristics Customer requirements Relationship matrix Technical assessment and target values Competitive assessment

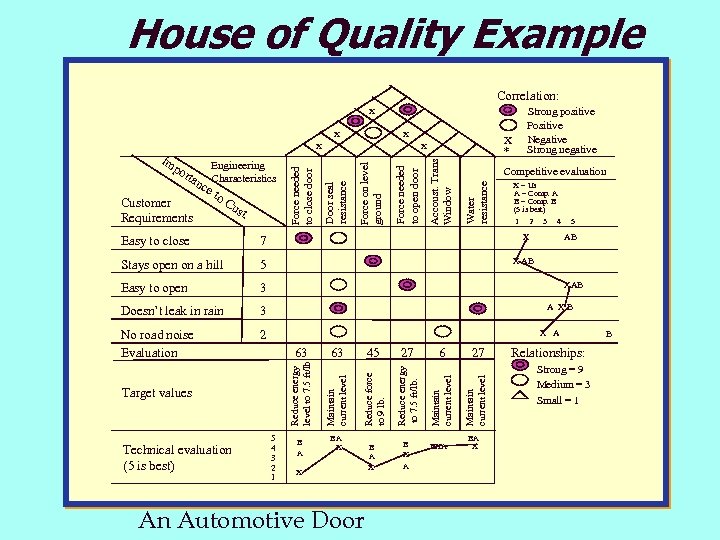

House of Quality Example Correlation: X X X * Competitive evaluation Water resistance ust. Accoust. Trans. Window o. C Force needed to open door et Force on level ground Customer Requirements Engineering nc Characteristics Door seal resistance po rta Force needed to close door Im X X X Strong positive Positive Negative Strong negative X = Us A = Comp. A B = Comp. B (5 is best) 1 2 3 4 Easy to close 7 5 X AB Easy to open 3 Doesn’t leak in rain 3 No road noise Evaluation 2 AB X Stays open on a hill 5 XAB A XB X A Technical evaluation (5 is best) 5 4 3 2 1 B A BA X X An Automotive Door B A X B X A BXA 27 Maintain current level 6 Maintain current level 27 Reduce energy to 7. 5 ft/lb. 45 Reduce force to 9 lb. Target values 63 Maintain current level Reduce energy level to 7. 5 ft/lb 63 BA X Relationships: Strong = 9 Medium = 3 Small = 1 B

House of Quality Example Correlation: X X X * Competitive evaluation Water resistance ust. Accoust. Trans. Window o. C Force needed to open door et Force on level ground Customer Requirements Engineering nc Characteristics Door seal resistance po rta Force needed to close door Im X X X Strong positive Positive Negative Strong negative X = Us A = Comp. A B = Comp. B (5 is best) 1 2 3 4 Easy to close 7 5 X AB Easy to open 3 Doesn’t leak in rain 3 No road noise Evaluation 2 AB X Stays open on a hill 5 XAB A XB X A Technical evaluation (5 is best) 5 4 3 2 1 B A BA X X An Automotive Door B A X B X A BXA 27 Maintain current level 6 Maintain current level 27 Reduce energy to 7. 5 ft/lb. 45 Reduce force to 9 lb. Target values 63 Maintain current level Reduce energy level to 7. 5 ft/lb 63 BA X Relationships: Strong = 9 Medium = 3 Small = 1 B

Idea Generation Stage Provides basis for entry into market l Sources of ideas l – Market need (60 -80%); engineering & operations (20%); technology; competitors; inventions; employees l Follows from marketing strategy – Identifies, defines, & selects best market opportunities

Idea Generation Stage Provides basis for entry into market l Sources of ideas l – Market need (60 -80%); engineering & operations (20%); technology; competitors; inventions; employees l Follows from marketing strategy – Identifies, defines, & selects best market opportunities

Customer Requirements Stage Identifies & positions key product benefits – Stated in core benefits proposition (CBP) – Example: Long lasting with more power (Sears’ Die Hard Battery) House of Quality Identifies detailed list of product attributes desired Product by customer Characteristics – Focus groups or Customer 1 -on-1 interviews Requirements l l

Customer Requirements Stage Identifies & positions key product benefits – Stated in core benefits proposition (CBP) – Example: Long lasting with more power (Sears’ Die Hard Battery) House of Quality Identifies detailed list of product attributes desired Product by customer Characteristics – Focus groups or Customer 1 -on-1 interviews Requirements l l

Functional Specification Stage l l Defines product in terms of how the product would meet desired attributes Identifies product’s engineering characteristics – Example: printer noise (d. B) l l Prioritizes engineering characteristics May rate product compared to competitors’ House of Quality Product Characteristics Customer Requirements

Functional Specification Stage l l Defines product in terms of how the product would meet desired attributes Identifies product’s engineering characteristics – Example: printer noise (d. B) l l Prioritizes engineering characteristics May rate product compared to competitors’ House of Quality Product Characteristics Customer Requirements

Product Specification Stage l l Determines how product will be made Gives product’s physical specifications – Example: Dimensions, material etc. Defined by engineering House of Quality drawing Done often on computer Component – Computer-Aided Design (CAD) Specifications Product Characteristics

Product Specification Stage l l Determines how product will be made Gives product’s physical specifications – Example: Dimensions, material etc. Defined by engineering House of Quality drawing Done often on computer Component – Computer-Aided Design (CAD) Specifications Product Characteristics

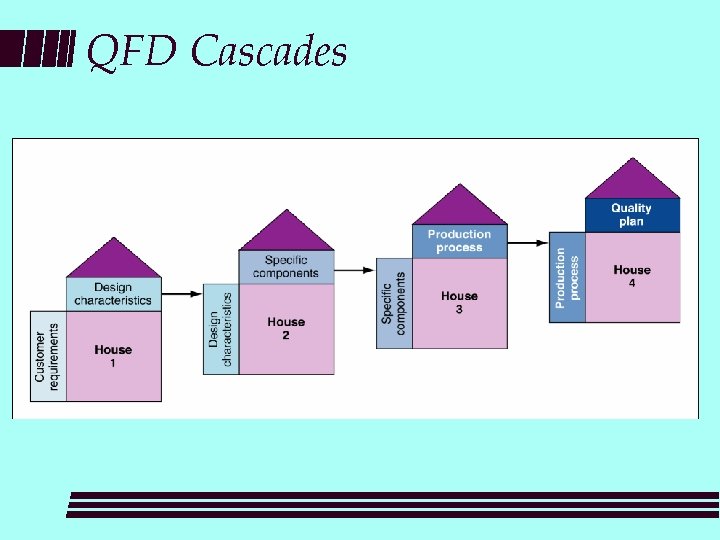

Quality Function Deployment l Product design process using cross-functional teams – Marketing, engineering, manufacturing Translates customer preferences into specific product characteristics l Involves creating 4 tabular ‘Matrices’ or ‘Houses’ l – Breakdown product design into increasing levels of detail

Quality Function Deployment l Product design process using cross-functional teams – Marketing, engineering, manufacturing Translates customer preferences into specific product characteristics l Involves creating 4 tabular ‘Matrices’ or ‘Houses’ l – Breakdown product design into increasing levels of detail

To Build House of Quality l Identify customer wants l Identify how the good/service will satisfy customer wants. l Relate the customer’s wants to the product’s hows. l Develop importance ratings l Evaluate competing ideas and concepts Ultimately you choose the design Not the customer!

To Build House of Quality l Identify customer wants l Identify how the good/service will satisfy customer wants. l Relate the customer’s wants to the product’s hows. l Develop importance ratings l Evaluate competing ideas and concepts Ultimately you choose the design Not the customer!

House of Quality Example You’ve been assigned temporarily to a QFD team. The goal of the team is to develop a new camera design. Build a House of Quality. © 1984 -1994 T/Maker Co.

House of Quality Example You’ve been assigned temporarily to a QFD team. The goal of the team is to develop a new camera design. Build a House of Quality. © 1984 -1994 T/Maker Co.

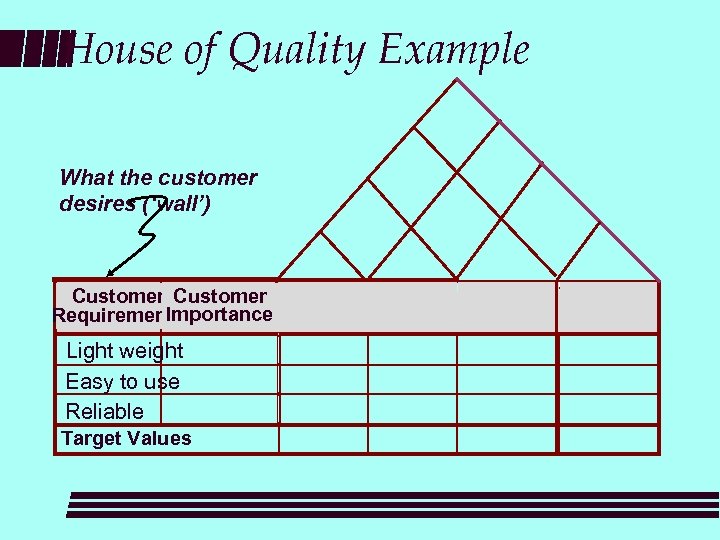

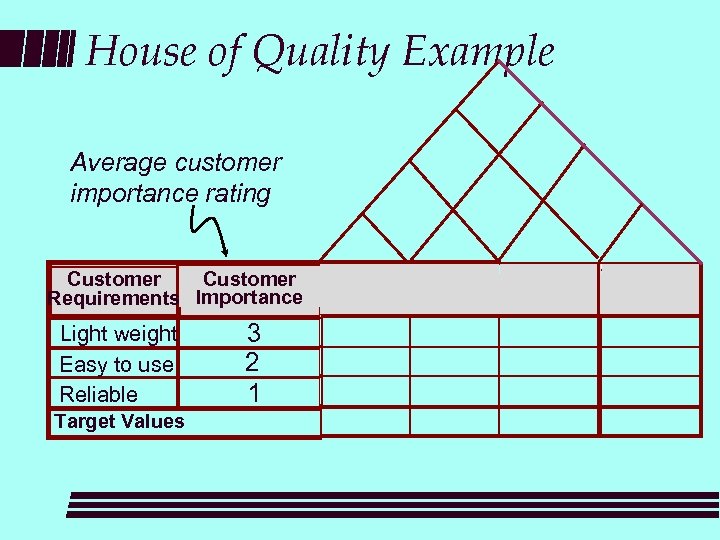

House of Quality Example What the customer desires (‘wall’) Customer Importance Requirements Light weight Easy to use Reliable Target Values

House of Quality Example What the customer desires (‘wall’) Customer Importance Requirements Light weight Easy to use Reliable Target Values

House of Quality Example Average customer importance rating Customer Requirements Importance Light weight Easy to use Reliable Target Values 3 2 1

House of Quality Example Average customer importance rating Customer Requirements Importance Light weight Easy to use Reliable Target Values 3 2 1

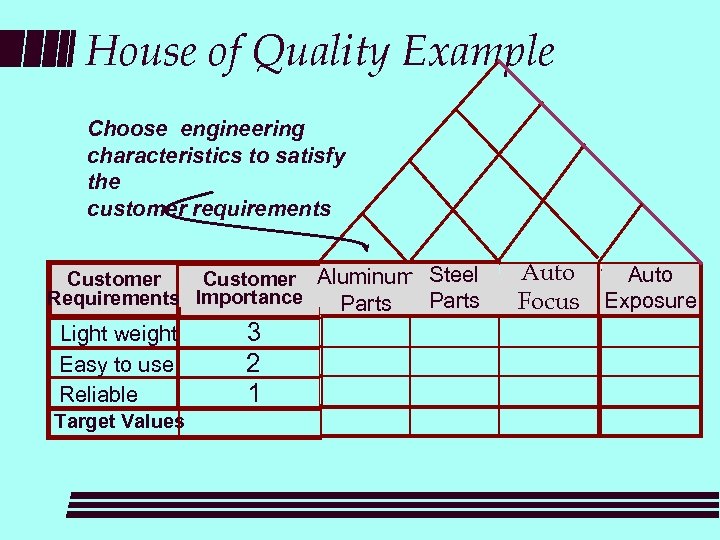

House of Quality Example Choose engineering characteristics to satisfy the customer requirements Customer Aluminum Steel Requirements Importance Parts Light weight Easy to use Reliable Target Values 3 2 1 Auto Focus Auto Exposure

House of Quality Example Choose engineering characteristics to satisfy the customer requirements Customer Aluminum Steel Requirements Importance Parts Light weight Easy to use Reliable Target Values 3 2 1 Auto Focus Auto Exposure

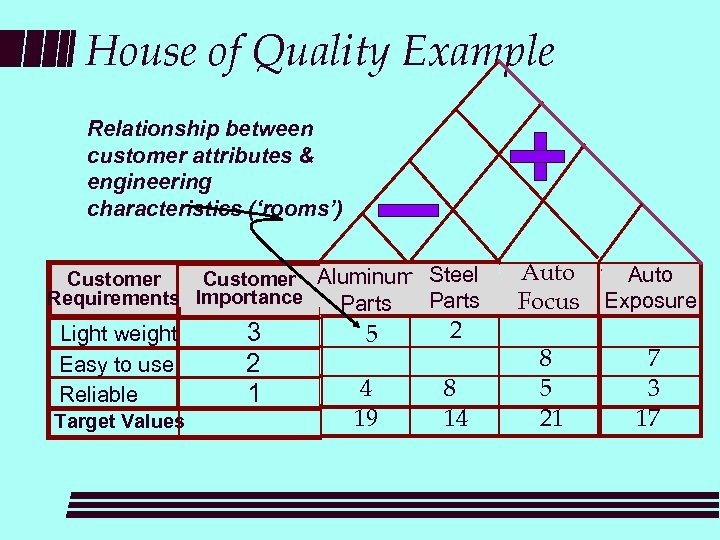

House of Quality Example Relationship between customer attributes & engineering characteristics (‘rooms’) Customer Aluminum Steel Requirements Importance Parts Light weight Easy to use Reliable Target Values 3 2 1 5 2 4 19 8 14 Auto Focus Auto Exposure 8 5 21 7 3 17

House of Quality Example Relationship between customer attributes & engineering characteristics (‘rooms’) Customer Aluminum Steel Requirements Importance Parts Light weight Easy to use Reliable Target Values 3 2 1 5 2 4 19 8 14 Auto Focus Auto Exposure 8 5 21 7 3 17

QFD Cascades

QFD Cascades

ROBUST DESIGN Design that results in products or services that can function over a broad range of conditions

ROBUST DESIGN Design that results in products or services that can function over a broad range of conditions

What does Robust Design mean? l l l Plan for variability Assess your capabilities Design for Manufacturing Reduce Costs Practice! Improve RAM-D

What does Robust Design mean? l l l Plan for variability Assess your capabilities Design for Manufacturing Reduce Costs Practice! Improve RAM-D

Variability: The Taguchi Approach to ROBUST DESIGN i Design a robust product − Insensitive to environmental factors either in manufacturing or in use. i Central feature is Parameter Design i Determines − factors that are controllable and those not controllable − their optimal levels relative to major product advances

Variability: The Taguchi Approach to ROBUST DESIGN i Design a robust product − Insensitive to environmental factors either in manufacturing or in use. i Central feature is Parameter Design i Determines − factors that are controllable and those not controllable − their optimal levels relative to major product advances

ASSESS CAPABILITIES l Identify Core Strengths l Match Products To Processing Capabilities – Design for Manufacturing (DFM)

ASSESS CAPABILITIES l Identify Core Strengths l Match Products To Processing Capabilities – Design for Manufacturing (DFM)

DESIGN FOR MANUFACTURING The designers’ consideration of the organization’s manufacturing capabilities when designing a product. Materials Processes Assembly

DESIGN FOR MANUFACTURING The designers’ consideration of the organization’s manufacturing capabilities when designing a product. Materials Processes Assembly

REDUCE COSTS l Focus on simplification & standardization − Design for Assembly (DFA) − Increase emphasis on component commonality l Study how products are designed & built l Eliminate duplicate design & processes l Strategically control capital spending

REDUCE COSTS l Focus on simplification & standardization − Design for Assembly (DFA) − Increase emphasis on component commonality l Study how products are designed & built l Eliminate duplicate design & processes l Strategically control capital spending

INVOLVE OPERATIONS l Practice concurrent engineering l Establish technical exchange programs l Use collaborative styles l Look for continual improvement

INVOLVE OPERATIONS l Practice concurrent engineering l Establish technical exchange programs l Use collaborative styles l Look for continual improvement

IMPROVE DURABILITY, RELIABILITY, & SAFETY 1) Improve component design 2) Use redundancy 3) Improve production and/or 4) 5) 6) 7) 8) assembly techniques Improve testing Use robust design Use modular design Improve preventive maintenance Educate customers

IMPROVE DURABILITY, RELIABILITY, & SAFETY 1) Improve component design 2) Use redundancy 3) Improve production and/or 4) 5) 6) 7) 8) assembly techniques Improve testing Use robust design Use modular design Improve preventive maintenance Educate customers

Good Luck with your designs!

Good Luck with your designs!