6b2e333b0218332a68536e73e3d292e5.ppt

- Количество слайдов: 33

Designing an Internal Corrosion Program NACE Eastern Area Conference Roy D. Fultineer Jr.

Designing an Internal Corrosion Program NACE Eastern Area Conference Roy D. Fultineer Jr.

Introduction • • • Plans and Procedures Training Know the system When do we get involved Understand Corrosion Mechanisms Identify the right monitoring locations Monitor and Trend data Possible Mitigation Follow-up

Introduction • • • Plans and Procedures Training Know the system When do we get involved Understand Corrosion Mechanisms Identify the right monitoring locations Monitor and Trend data Possible Mitigation Follow-up

Plans and Procedures • Internal Corrosion Plans – Generic • Potential Treats – Acid Gases, Bacteria, Erosion, etc. • Types of monitoring – Gas samples – Liquid samples – Coupons • Requirements for internal corrosion monitoring • Parameters to monitor and trend

Plans and Procedures • Internal Corrosion Plans – Generic • Potential Treats – Acid Gases, Bacteria, Erosion, etc. • Types of monitoring – Gas samples – Liquid samples – Coupons • Requirements for internal corrosion monitoring • Parameters to monitor and trend

Plans and Procedures • Internal Corrosion Plans – Generic • Basic Decision Criteria – If indications are found, what is the next step.

Plans and Procedures • Internal Corrosion Plans – Generic • Basic Decision Criteria – If indications are found, what is the next step.

Plans and Procedures • Internal Corrosion Plans – Specific • Location of facility • Specific location of monitoring locations • Specific timing of monitoring • Specific water control methods – Pigging – Drips – Dehydration • Schedule of these control methods • What action has been taken?

Plans and Procedures • Internal Corrosion Plans – Specific • Location of facility • Specific location of monitoring locations • Specific timing of monitoring • Specific water control methods – Pigging – Drips – Dehydration • Schedule of these control methods • What action has been taken?

Plans and Procedures • Internal Corrosion Plans – Specific • What action is planned? • How will action be evaluated?

Plans and Procedures • Internal Corrosion Plans – Specific • What action is planned? • How will action be evaluated?

Plans and Procedures • Procedures – Procedures go into specific action of how to conduct sampling and monitoring – Important aspect of internal corrosion plan – Procedures go hand-in–hand with training

Plans and Procedures • Procedures – Procedures go into specific action of how to conduct sampling and monitoring – Important aspect of internal corrosion plan – Procedures go hand-in–hand with training

Training • Properly trained personnel is critical to the success of any internal corrosion program – In house training – On the job training – NACE and other professional organizations • Collecting accurate data is critical • The better the data, the better the decisions

Training • Properly trained personnel is critical to the success of any internal corrosion program – In house training – On the job training – NACE and other professional organizations • Collecting accurate data is critical • The better the data, the better the decisions

When do we get involved • Internal corrosion should be considered in the • initial design phase of any project Things to consider: – Water content and water removal – Elevation profile – Inlets and outlets to the system – Gas Quality – Flow regimes

When do we get involved • Internal corrosion should be considered in the • initial design phase of any project Things to consider: – Water content and water removal – Elevation profile – Inlets and outlets to the system – Gas Quality – Flow regimes

Know your system • Operation Factors – Direction of flow – Flow rates – Flow regime – Pressures – Product – Upsets – Elevation Profile

Know your system • Operation Factors – Direction of flow – Flow rates – Flow regime – Pressures – Product – Upsets – Elevation Profile

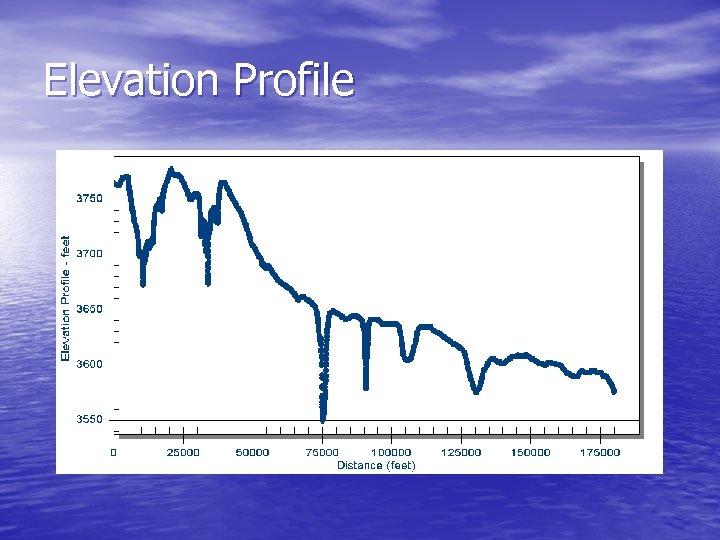

Elevation Profile

Elevation Profile

Understand Corrosion Mechanisms • Causes – Water – CO 2 Influenced – H 2 S Influenced – MIC – O 2 – Velocity/Flow Related

Understand Corrosion Mechanisms • Causes – Water – CO 2 Influenced – H 2 S Influenced – MIC – O 2 – Velocity/Flow Related

Understand Corrosion Mechanisms • Water – Necessary for internal corrosion – Temperature • Reaction rates double for every 10 degree Celsius rise – p. H • Less then 5 can result in increased corrosion – Carbonates • Acts as a acid buffer

Understand Corrosion Mechanisms • Water – Necessary for internal corrosion – Temperature • Reaction rates double for every 10 degree Celsius rise – p. H • Less then 5 can result in increased corrosion – Carbonates • Acts as a acid buffer

Understand Corrosion Mechanisms • CO 2 Corrosion – Carbon Dioxide + water = Carbonic Acid – Carbonic Acid + iron = iron carbonate + hydrogen – Carbon dioxide is in the gas – Carbonic acid creates corrosion – Generally mild corrosion except when with other corrodents

Understand Corrosion Mechanisms • CO 2 Corrosion – Carbon Dioxide + water = Carbonic Acid – Carbonic Acid + iron = iron carbonate + hydrogen – Carbon dioxide is in the gas – Carbonic acid creates corrosion – Generally mild corrosion except when with other corrodents

Understand Corrosion Mechanisms • H 2 S Corrosion – Hydrogen Sulfide + iron + water = – Iron Sulfide + water + hydrogen – From sour gas operations or from SRB’s (MIC) – Corrosion pitting occurs where Fe. S forms on the metal surface and creates a local corrosion cell

Understand Corrosion Mechanisms • H 2 S Corrosion – Hydrogen Sulfide + iron + water = – Iron Sulfide + water + hydrogen – From sour gas operations or from SRB’s (MIC) – Corrosion pitting occurs where Fe. S forms on the metal surface and creates a local corrosion cell

Understand Corrosion Mechanisms • MIC – Acid Producers - APB’s – Sulfate Reducing Bacteria - SRB’s – Controlled with a clean system and bacteriacides/biocides

Understand Corrosion Mechanisms • MIC – Acid Producers - APB’s – Sulfate Reducing Bacteria - SRB’s – Controlled with a clean system and bacteriacides/biocides

Understand Corrosion Mechanisms • Oxygen – Oxygen + iron + water = Iron oxide + water – Oxygen creates an oxidizing effect and with other corrodents = accelerated corrosion – Oxygen concentration cells create corrosion due to oxygen depletion areas

Understand Corrosion Mechanisms • Oxygen – Oxygen + iron + water = Iron oxide + water – Oxygen creates an oxidizing effect and with other corrodents = accelerated corrosion – Oxygen concentration cells create corrosion due to oxygen depletion areas

Understand Corrosion Mechanisms • Velocity/Flow related attacks – High surface fluid or particle velocities – Erosion • High Energy with or without particles • Removes metal • Leaves smooth surface – Erosion Corrosion • Erosion removes protective film or scale • Exposes metal surface to environment

Understand Corrosion Mechanisms • Velocity/Flow related attacks – High surface fluid or particle velocities – Erosion • High Energy with or without particles • Removes metal • Leaves smooth surface – Erosion Corrosion • Erosion removes protective film or scale • Exposes metal surface to environment

Pick the right monitoring locations • Representative of system • Right location – Know what your looking for and put monitoring devices in right location. – Top of the line versus bottom of line corrosion • Right device – Pick the monitoring device that is designed for the application

Pick the right monitoring locations • Representative of system • Right location – Know what your looking for and put monitoring devices in right location. – Top of the line versus bottom of line corrosion • Right device – Pick the monitoring device that is designed for the application

Monitor and trend data • Collect the data you need and compare it to all • • other data Be careful not to add to much weight to any one data set Determine if action is required

Monitor and trend data • Collect the data you need and compare it to all • • other data Be careful not to add to much weight to any one data set Determine if action is required

Possible Mitigation Methods • Do nothing – Sometimes the best answer is to continue to monitor and study – More information will lead to better decisions – More technical or sophisticated analysis may be appropriate – Chemicals can actually make the situation worse

Possible Mitigation Methods • Do nothing – Sometimes the best answer is to continue to monitor and study – More information will lead to better decisions – More technical or sophisticated analysis may be appropriate – Chemicals can actually make the situation worse

Possible Mitigation Methods • Liquid removal – Drip Blowing • Drip should be monitored and blown on frequencies that ensure no free liquids • Used to monitor for corrosion parameters – Pigging • Ran on frequencies that ensure no free liquids • Thought should be given to the type of pigs used • Speed of pigging can influence

Possible Mitigation Methods • Liquid removal – Drip Blowing • Drip should be monitored and blown on frequencies that ensure no free liquids • Used to monitor for corrosion parameters – Pigging • Ran on frequencies that ensure no free liquids • Thought should be given to the type of pigs used • Speed of pigging can influence

Possible Mitigation Methods • Dehydration – Removal of water through dehydration can greatly reduces possibility of internal corrosion – High initial cost and added O&M cost – Does not necessarily remove the need for chemical

Possible Mitigation Methods • Dehydration – Removal of water through dehydration can greatly reduces possibility of internal corrosion – High initial cost and added O&M cost – Does not necessarily remove the need for chemical

Possible Mitigation Methods • Control Inlet Product Quality – Monitor product quality entering system – Have control to shut in suppliers

Possible Mitigation Methods • Control Inlet Product Quality – Monitor product quality entering system – Have control to shut in suppliers

Possible Mitigation Methods • Chemical Treating – Batch – Slug – Continuous – Squeeze

Possible Mitigation Methods • Chemical Treating – Batch – Slug – Continuous – Squeeze

Possible Mitigation Methods • Design – One of the most effective means of control • Use of proper materials • Size pipeline properly (oversized = liquid hold-up) • Modeling and/or flow regime will dictate location and/or need for drips, pigging, etc. • Material selection can be key – Steel is not always the best solution – Example: Fiberglass piping in acid gas environment

Possible Mitigation Methods • Design – One of the most effective means of control • Use of proper materials • Size pipeline properly (oversized = liquid hold-up) • Modeling and/or flow regime will dictate location and/or need for drips, pigging, etc. • Material selection can be key – Steel is not always the best solution – Example: Fiberglass piping in acid gas environment

Follow-up (Did it Work? ) • • • Coupons Liquid Sampling Residuals Monitoring In Line Inspection (ILI) Gas Monitoring

Follow-up (Did it Work? ) • • • Coupons Liquid Sampling Residuals Monitoring In Line Inspection (ILI) Gas Monitoring

Coupons • Weight Loss – Compare previous rates to new rates – Compare pretreated versus post-treatment – CID – Copper Ion Displacement – monitoring chemical distribution

Coupons • Weight Loss – Compare previous rates to new rates – Compare pretreated versus post-treatment – CID – Copper Ion Displacement – monitoring chemical distribution

Liquid Sampling • Monitor effects on water chemistry – p. H (increasing or decreasing) • Increase – Scaling • Decrease – Corrosion – Metals (increasing decreasing) • Mn/Fe ratio • Trending – Bacteria levels

Liquid Sampling • Monitor effects on water chemistry – p. H (increasing or decreasing) • Increase – Scaling • Decrease – Corrosion – Metals (increasing decreasing) • Mn/Fe ratio • Trending – Bacteria levels

Residual Monitoring • Are chemicals getting where you need them • Are the residuals adequate • If not, – Adjust existing facilities – Add new injection points – Change application (continuous to pigging)

Residual Monitoring • Are chemicals getting where you need them • Are the residuals adequate • If not, – Adjust existing facilities – Add new injection points – Change application (continuous to pigging)

ILI Inspection • Need base line • Follow-ups – Monitor corrosion growth – Monitor for new corrosion.

ILI Inspection • Need base line • Follow-ups – Monitor corrosion growth – Monitor for new corrosion.

Gas Monitoring • Monitor Quality – CO 2 – H 2 S – Water – O 2 • Monitor for changes

Gas Monitoring • Monitor Quality – CO 2 – H 2 S – Water – O 2 • Monitor for changes

Questions?

Questions?