9e9b6b0ae6c2a46670c95418d6b71238.ppt

- Количество слайдов: 18

Design Automation for Aircraft Design – Micro Air Vehicle Application Ø David Lundström, Kristian Amadori Flygteknik 2010

Design Automation for Aircraft Design – Micro Air Vehicle Application Ø David Lundström, Kristian Amadori Flygteknik 2010

MAV – Micro Air Vehicle Ø DARPA definition: Physical size lesser than 15 cm Ø “General” definition: Size <0. 5 m, Weight <500 g Ø Unmanned aircraft small enough to easily be carried and operated by one person Ø Police, civil rescue, agriculture, meteorology, military 2 Flygteknik 2010

MAV – Micro Air Vehicle Ø DARPA definition: Physical size lesser than 15 cm Ø “General” definition: Size <0. 5 m, Weight <500 g Ø Unmanned aircraft small enough to easily be carried and operated by one person Ø Police, civil rescue, agriculture, meteorology, military 2 Flygteknik 2010

Department of Management and Engineering Department of Computer and Information Science Flu. Me. S Fluid & Mechatronic Systems 3 Flygteknik 2010

Department of Management and Engineering Department of Computer and Information Science Flu. Me. S Fluid & Mechatronic Systems 3 Flygteknik 2010

MAV Design Automation 5 Flygteknik 2010

MAV Design Automation 5 Flygteknik 2010

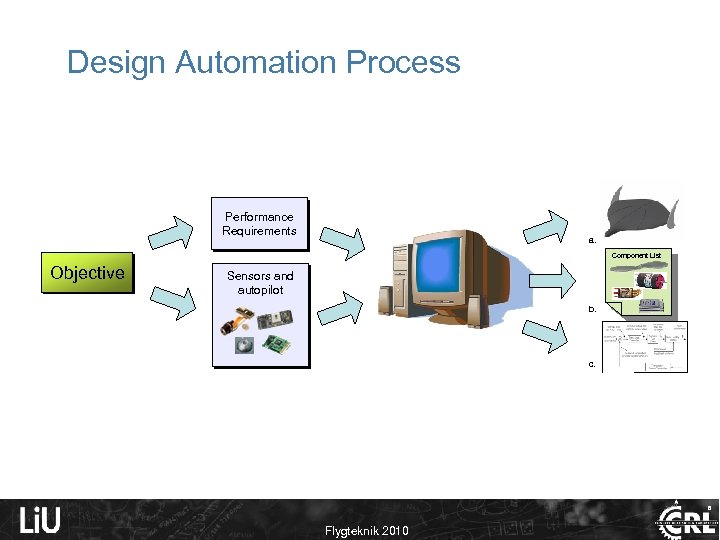

Design Automation Process Performance Requirements a. Component List Objective Sensors and autopilot b. c. 6 Flygteknik 2010

Design Automation Process Performance Requirements a. Component List Objective Sensors and autopilot b. c. 6 Flygteknik 2010

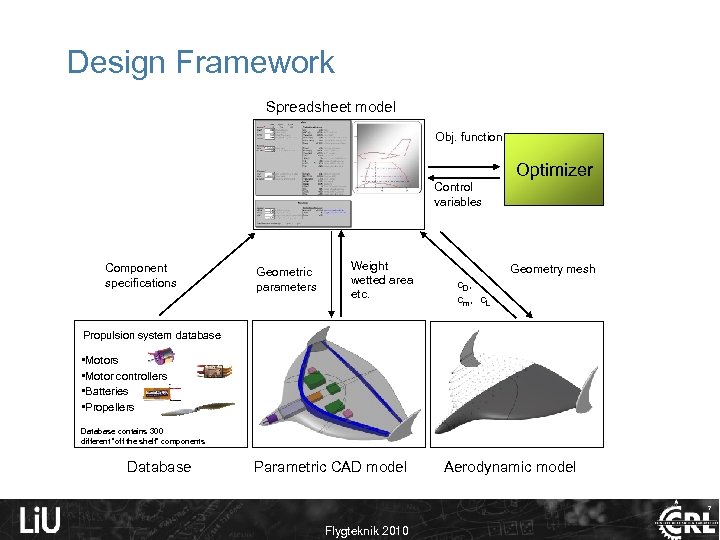

Design Framework Spreadsheet model Obj. function Optimizer Control variables Component specifications Geometric parameters Weight wetted area etc. Geometry mesh c. D, cm, c. L Propulsion system database • Motors • Motor controllers • Batteries • Propellers Database contains 300 different “off the shelf” components Database Parametric CAD model Aerodynamic model 7 Flygteknik 2010

Design Framework Spreadsheet model Obj. function Optimizer Control variables Component specifications Geometric parameters Weight wetted area etc. Geometry mesh c. D, cm, c. L Propulsion system database • Motors • Motor controllers • Batteries • Propellers Database contains 300 different “off the shelf” components Database Parametric CAD model Aerodynamic model 7 Flygteknik 2010

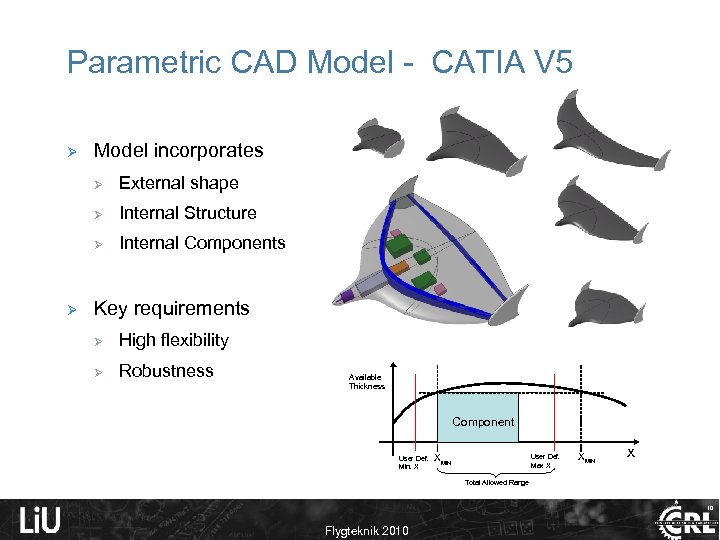

Parametric CAD Model - CATIA V 5 Ø Model incorporates Ø Ø Internal Structure Ø Ø External shape Internal Components Key requirements Ø High flexibility Ø Robustness Available Thickness Component User Def. Min. X XMIN User Def. Max X XMIN x Total Allowed Range 10 Flygteknik 2010

Parametric CAD Model - CATIA V 5 Ø Model incorporates Ø Ø Internal Structure Ø Ø External shape Internal Components Key requirements Ø High flexibility Ø Robustness Available Thickness Component User Def. Min. X XMIN User Def. Max X XMIN x Total Allowed Range 10 Flygteknik 2010

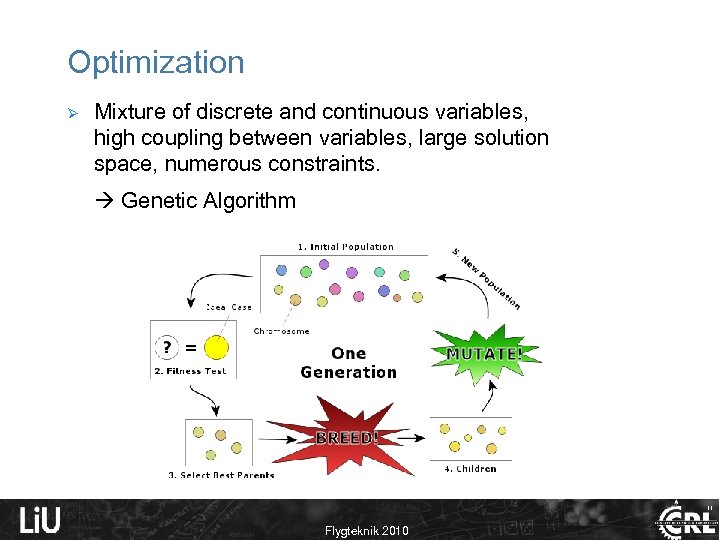

Optimization Ø Mixture of discrete and continuous variables, high coupling between variables, large solution space, numerous constraints. Genetic Algorithm 11 Flygteknik 2010

Optimization Ø Mixture of discrete and continuous variables, high coupling between variables, large solution space, numerous constraints. Genetic Algorithm 11 Flygteknik 2010

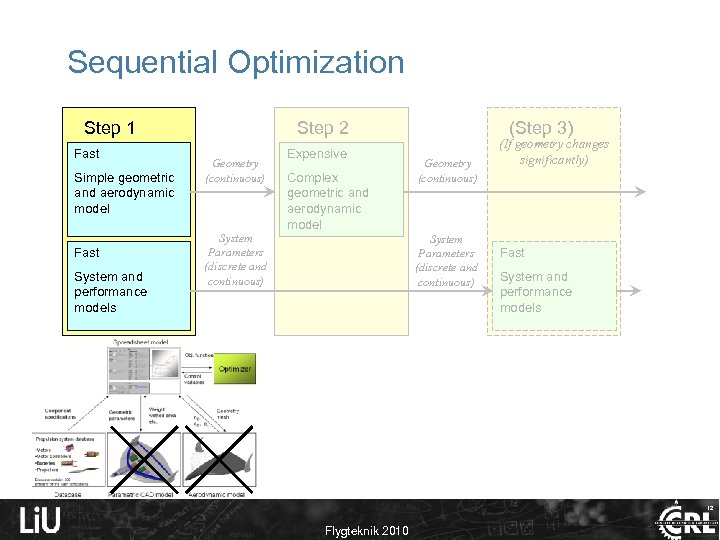

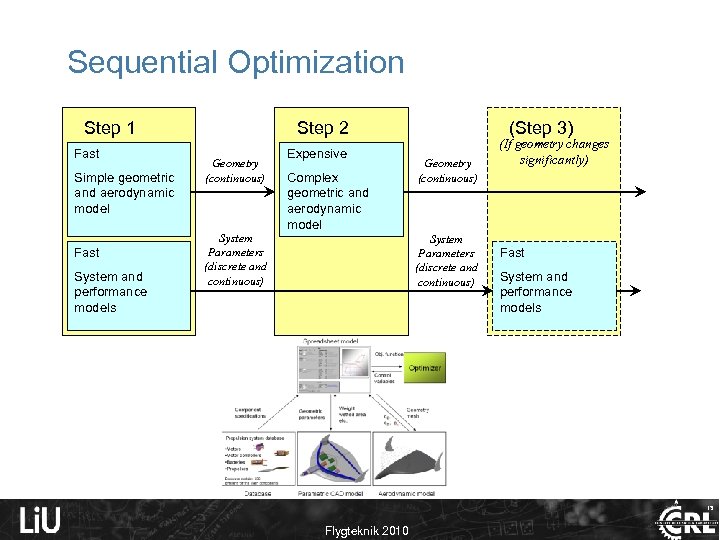

Sequential Optimization Step 1 Fast Simple geometric and aerodynamic model Fast System and performance models Step 2 Geometry (continuous) System Parameters (discrete and continuous) Expensive Complex geometric and aerodynamic model (Step 3) Geometry (continuous) System Parameters (discrete and continuous) (If geometry changes significantly) Fast System and performance models 12 Flygteknik 2010

Sequential Optimization Step 1 Fast Simple geometric and aerodynamic model Fast System and performance models Step 2 Geometry (continuous) System Parameters (discrete and continuous) Expensive Complex geometric and aerodynamic model (Step 3) Geometry (continuous) System Parameters (discrete and continuous) (If geometry changes significantly) Fast System and performance models 12 Flygteknik 2010

Sequential Optimization Step 1 Fast Simple geometric and aerodynamic model Fast System and performance models Step 2 Geometry (continuous) System Parameters (discrete and continuous) Expensive Complex geometric and aerodynamic model (Step 3) Geometry (continuous) System Parameters (discrete and continuous) (If geometry changes significantly) Fast System and performance models 13 Flygteknik 2010

Sequential Optimization Step 1 Fast Simple geometric and aerodynamic model Fast System and performance models Step 2 Geometry (continuous) System Parameters (discrete and continuous) Expensive Complex geometric and aerodynamic model (Step 3) Geometry (continuous) System Parameters (discrete and continuous) (If geometry changes significantly) Fast System and performance models 13 Flygteknik 2010

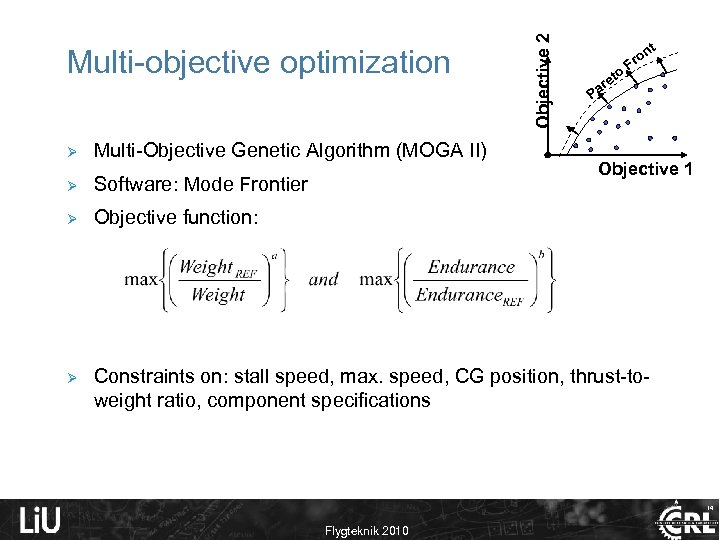

Objective 2 Multi-objective optimization o et n ro t F r Pa Ø Multi-Objective Genetic Algorithm (MOGA II) Ø Software: Mode Frontier Ø Objective function: Ø Constraints on: stall speed, max. speed, CG position, thrust-toweight ratio, component specifications Objective 1 14 Flygteknik 2010

Objective 2 Multi-objective optimization o et n ro t F r Pa Ø Multi-Objective Genetic Algorithm (MOGA II) Ø Software: Mode Frontier Ø Objective function: Ø Constraints on: stall speed, max. speed, CG position, thrust-toweight ratio, component specifications Objective 1 14 Flygteknik 2010

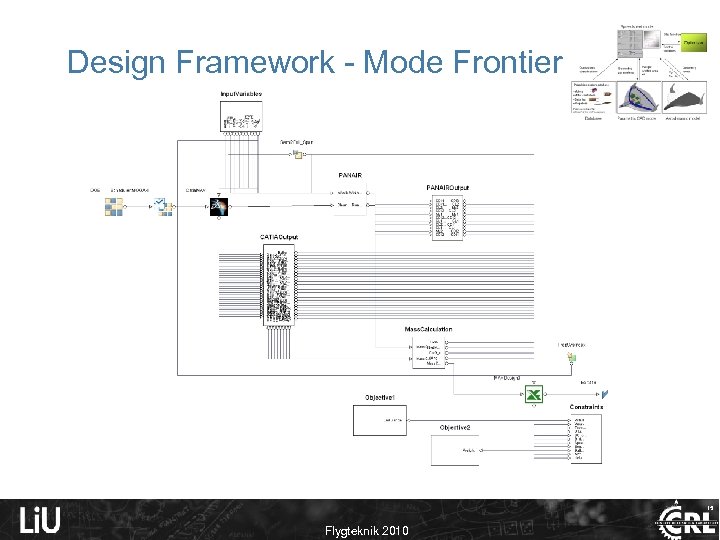

Design Framework - Mode Frontier 15 Flygteknik 2010

Design Framework - Mode Frontier 15 Flygteknik 2010

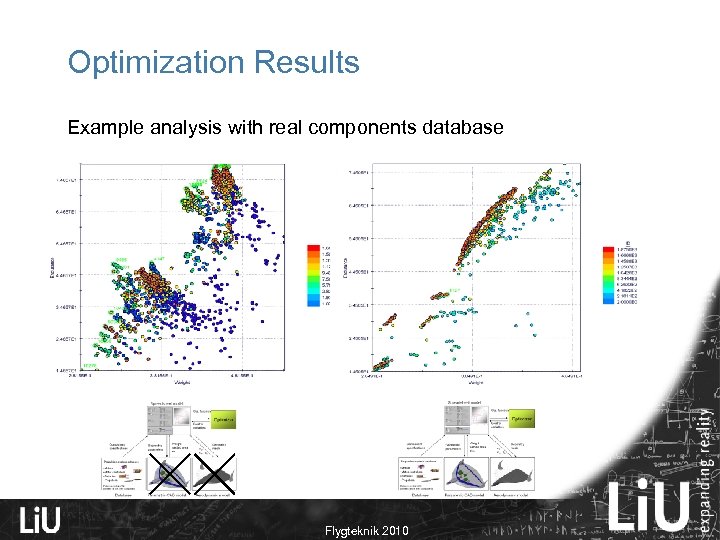

Optimization Results Example analysis with real components database 16 Flygteknik 2010

Optimization Results Example analysis with real components database 16 Flygteknik 2010

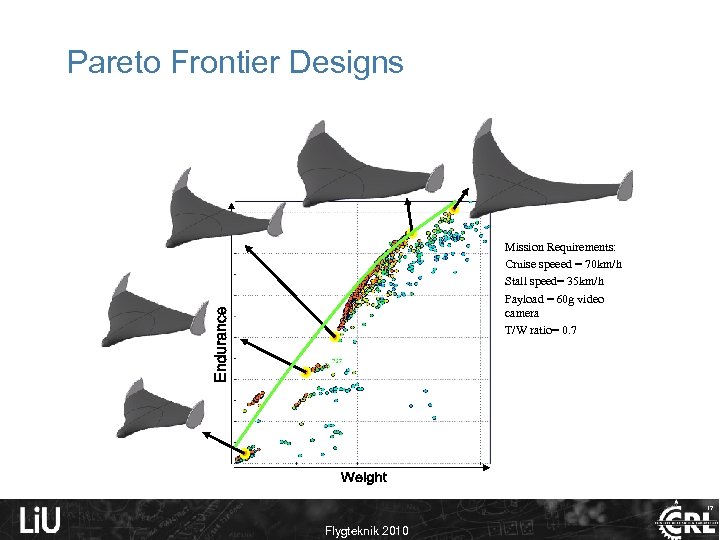

Pareto Frontier Designs Mission Requirements: Cruise speeed = 70 km/h Stall speed= 35 km/h Payload = 60 g video camera T/W ratio= 0. 7 17 Flygteknik 2010

Pareto Frontier Designs Mission Requirements: Cruise speeed = 70 km/h Stall speed= 35 km/h Payload = 60 g video camera T/W ratio= 0. 7 17 Flygteknik 2010

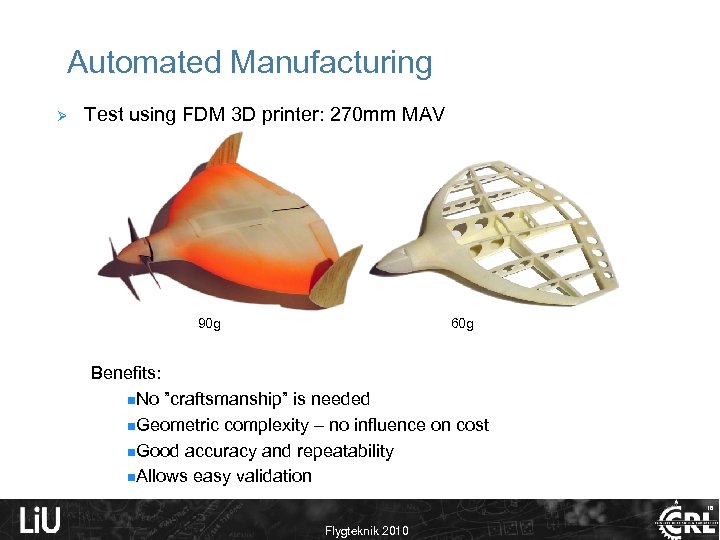

Automated Manufacturing Ø Test using FDM 3 D printer: 270 mm MAV 90 g 60 g Benefits: n. No ”craftsmanship” is needed n. Geometric complexity – no influence on cost n. Good accuracy and repeatability n. Allows easy validation 18 Flygteknik 2010

Automated Manufacturing Ø Test using FDM 3 D printer: 270 mm MAV 90 g 60 g Benefits: n. No ”craftsmanship” is needed n. Geometric complexity – no influence on cost n. Good accuracy and repeatability n. Allows easy validation 18 Flygteknik 2010

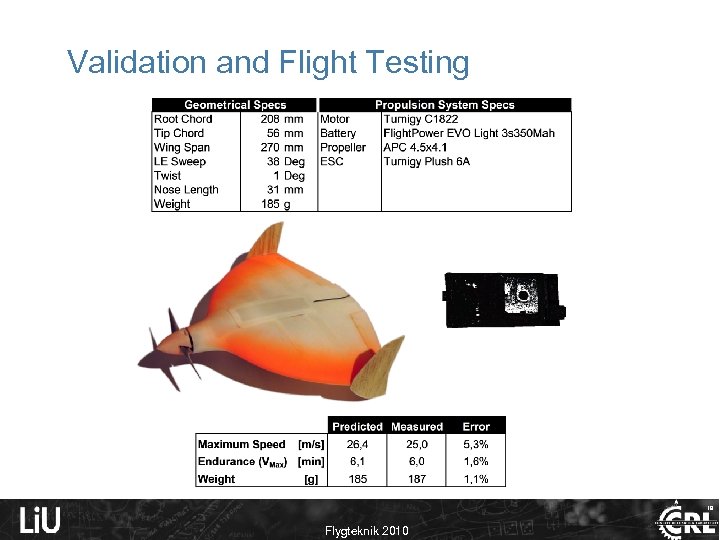

Validation and Flight Testing 19 Flygteknik 2010

Validation and Flight Testing 19 Flygteknik 2010

Conclusions Ø Automated MAV design has been demonstrated and proven to be realistic. Ø Current modeling is a balance of accuracy and calculation speed. Propulsion system has highest impact on performance Ø Method can be seen as a stepping stone for improving conceptual design methods for larger UAVs and manned aircraft. Key innovations to achieve automated design is: Ø Discrete propulsion system optimization using COTS-components Ø Unique composition of design framework Ø Sequential optimization process with increased model fidelity Ø Usage of Multi-objective optimization Ø Efficient method for internal component placement and balancing Ø 3 D printing for fabrication 20 Flygteknik 2010

Conclusions Ø Automated MAV design has been demonstrated and proven to be realistic. Ø Current modeling is a balance of accuracy and calculation speed. Propulsion system has highest impact on performance Ø Method can be seen as a stepping stone for improving conceptual design methods for larger UAVs and manned aircraft. Key innovations to achieve automated design is: Ø Discrete propulsion system optimization using COTS-components Ø Unique composition of design framework Ø Sequential optimization process with increased model fidelity Ø Usage of Multi-objective optimization Ø Efficient method for internal component placement and balancing Ø 3 D printing for fabrication 20 Flygteknik 2010

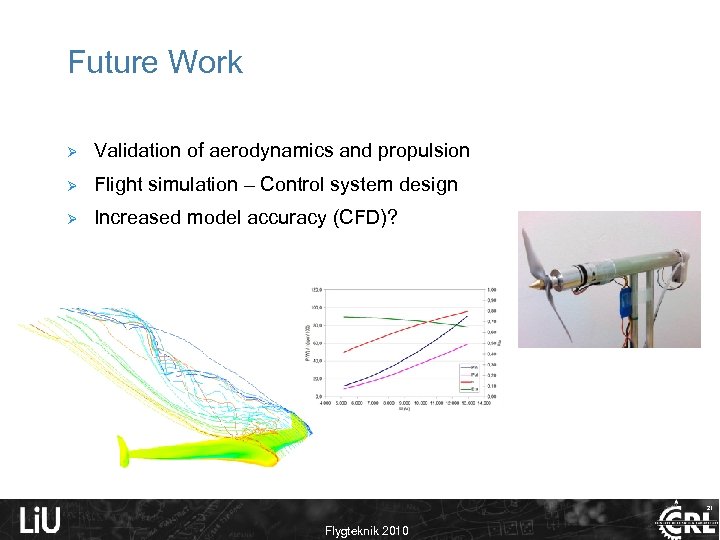

Future Work Ø Validation of aerodynamics and propulsion Ø Flight simulation – Control system design Ø Increased model accuracy (CFD)? 21 Flygteknik 2010

Future Work Ø Validation of aerodynamics and propulsion Ø Flight simulation – Control system design Ø Increased model accuracy (CFD)? 21 Flygteknik 2010