c6a172bc8fb0854bf491917aee611675.ppt

- Количество слайдов: 32

Design and Construction of the ATLAS Barrel TRT Chiho Wang Duke University 1 TRD Conference Bari, Sep. 2003

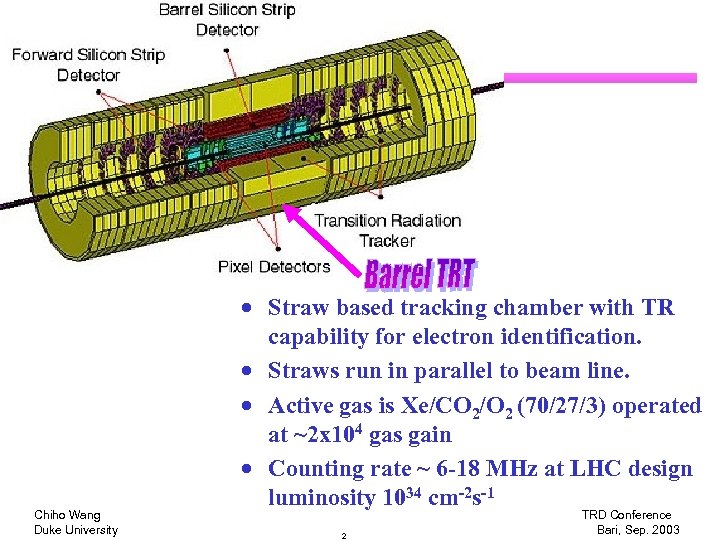

Design Parameters Chiho Wang Duke University · Straw based tracking chamber with TR capability for electron identification. · Straws run in parallel to beam line. · Active gas is Xe/CO 2/O 2 (70/27/3) operated at ~2 x 104 gas gain · Counting rate ~ 6 -18 MHz at LHC design luminosity 1034 cm-2 s-1 2 TRD Conference Bari, Sep. 2003

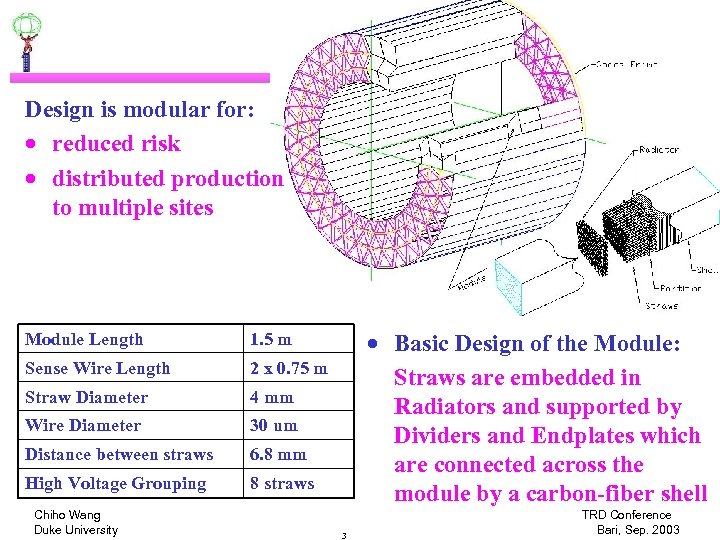

Design is modular for: · reduced risk · distributed production to multiple sites Module Length Sense Wire Length 2 x 0. 75 m Straw Diameter 4 mm Wire Diameter 30 um Distance between straws 6. 8 mm High Voltage Grouping · Basic Design of the Module: Straws are embedded in Radiators and supported by Dividers and Endplates which are connected across the module by a carbon-fiber shell 1. 5 m 8 straws Chiho Wang Duke University 3 TRD Conference Bari, Sep. 2003

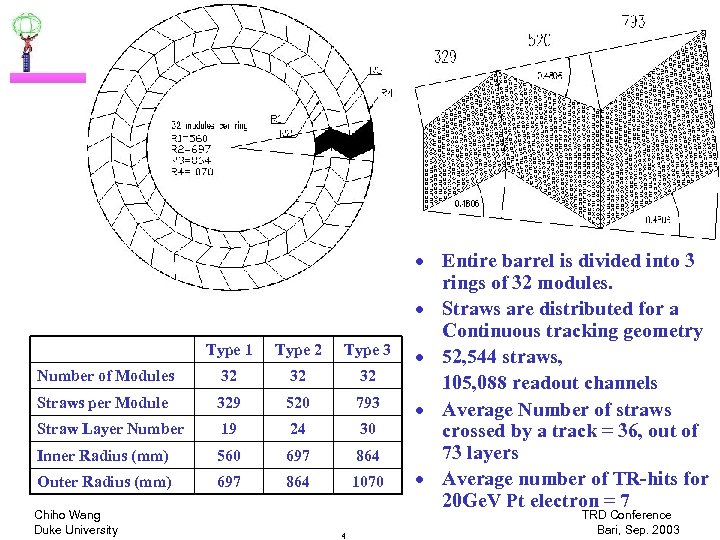

Type 1 Type 2 Type 3 Number of Modules 32 32 32 Straws per Module 329 520 793 Straw Layer Number 19 24 30 Inner Radius (mm) 560 697 864 Outer Radius (mm) 697 864 1070 Chiho Wang Duke University 4 · Entire barrel is divided into 3 rings of 32 modules. · Straws are distributed for a Continuous tracking geometry · 52, 544 straws, 105, 088 readout channels · Average Number of straws crossed by a track = 36, out of 73 layers · Average number of TR-hits for 20 Ge. V Pt electron = 7 TRD Conference Bari, Sep. 2003

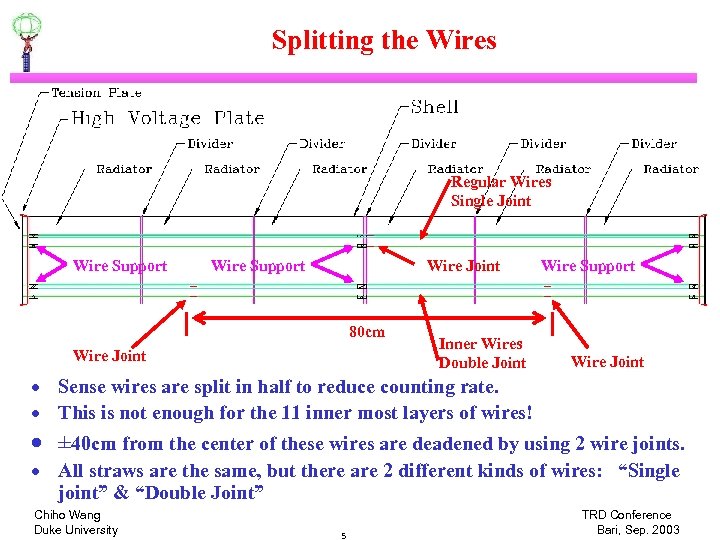

Splitting the Wires Regular Wires Single Joint Wire Support Wire Joint 80 cm Wire Joint Inner Wires Double Joint Wire Support Wire Joint · Sense wires are split in half to reduce counting rate. · This is not enough for the 11 inner most layers of wires! · ± 40 cm from the center of these wires are deadened by using 2 wire joints. · All straws are the same, but there are 2 different kinds of wires: “Single joint” & “Double Joint” Chiho Wang Duke University 5 TRD Conference Bari, Sep. 2003

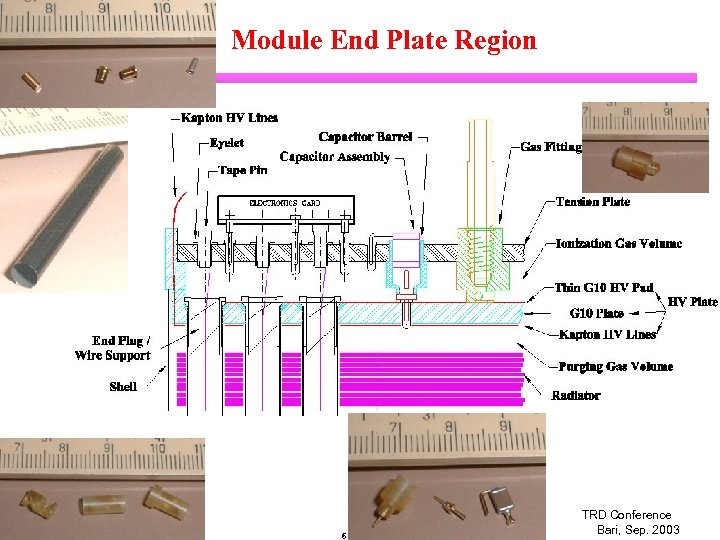

Module End Plate Region Chiho Wang Duke University 6 TRD Conference Bari, Sep. 2003

Components · Every component has its own QC process to go through when received from manufacturer, or when it’s prepared (pre-assembled) for installation Chiho Wang Duke University 7 TRD Conference Bari, Sep. 2003

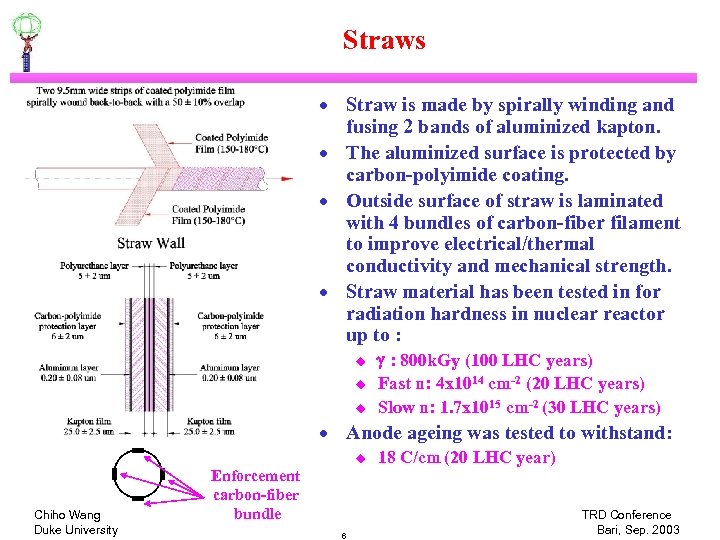

Straws · Straw is made by spirally winding and fusing 2 bands of aluminized kapton. · The aluminized surface is protected by carbon-polyimide coating. · Outside surface of straw is laminated with 4 bundles of carbon-fiber filament to improve electrical/thermal conductivity and mechanical strength. · Straw material has been tested in for radiation hardness in nuclear reactor up to : u u u g : 800 k. Gy (100 LHC years) Fast n: 4 x 1014 cm-2 (20 LHC years) Slow n: 1. 7 x 1015 cm-2 (30 LHC years) · Anode ageing was tested to withstand: u Chiho Wang Duke University Enforcement carbon-fiber bundle 8 18 C/cm (20 LHC year) TRD Conference Bari, Sep. 2003

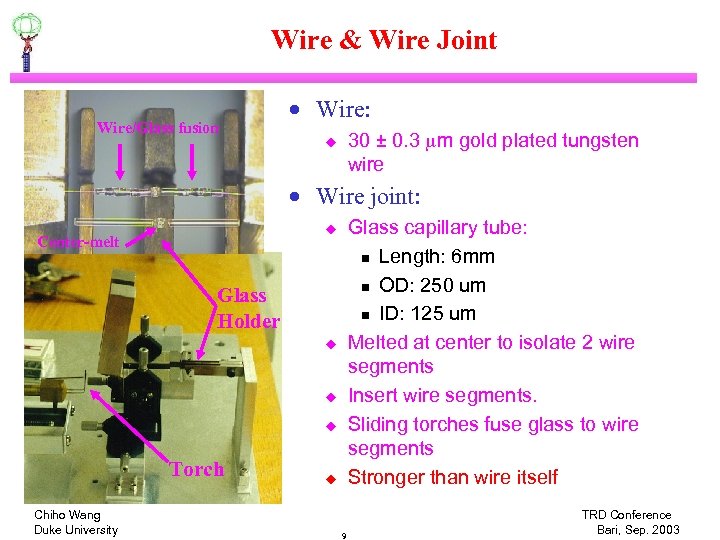

Wire & Wire Joint Wire/Glass fusion · Wire: 30 ± 0. 3 mm gold plated tungsten wire u · Wire joint: Glass capillary tube: n Length: 6 mm n OD: 250 um n ID: 125 um Melted at center to isolate 2 wire segments Insert wire segments. Sliding torches fuse glass to wire segments Stronger than wire itself u Center-melt Glass Holder u u u Torch Chiho Wang Duke University u 9 TRD Conference Bari, Sep. 2003

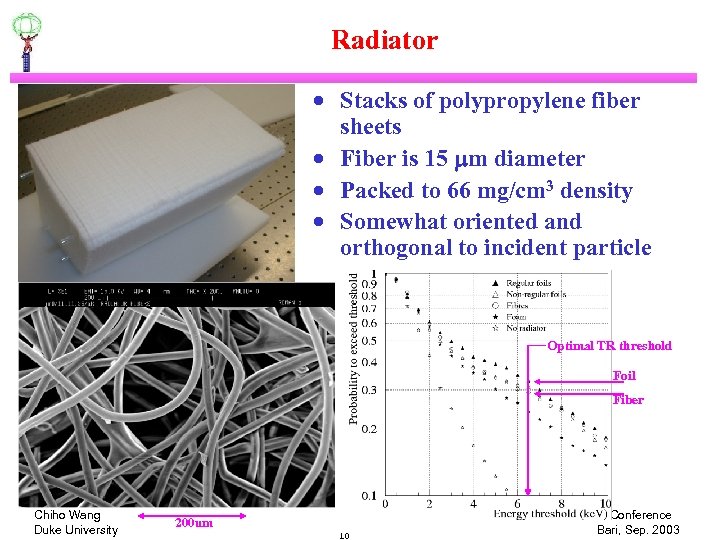

Radiator · Stacks of polypropylene fiber sheets · Fiber is 15 mm diameter · Packed to 66 mg/cm 3 density · Somewhat oriented and orthogonal to incident particle Optimal TR threshold Foil Fiber Chiho Wang Duke University 200 um 10 TRD Conference Bari, Sep. 2003

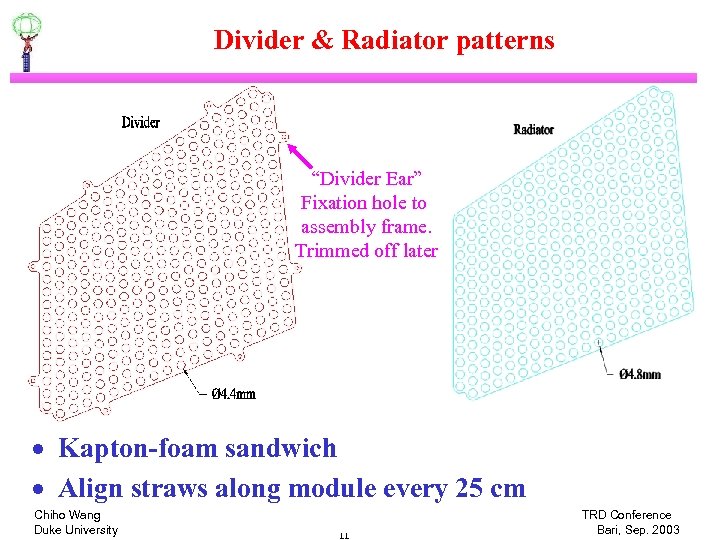

Divider & Radiator patterns “Divider Ear” Fixation hole to assembly frame. Trimmed off later · Kapton-foam sandwich · Align straws along module every 25 cm Chiho Wang Duke University 11 TRD Conference Bari, Sep. 2003

Carbon-Fiber Shell Cooling Tubes · Structural support for module. · Heat exchanger for module cooling Kapton lamination Chiho Wang Duke University Holes for Divider ears 12 TRD Conference Bari, Sep. 2003

High Voltage Plate · Made of 3 parts: u u u · · Precision machined FR 4 tray Kapton circuit in the back Thin HV circuit pattern in the front Bring HV to straws Position straws in the module Mount module to support structure Individual traces tested to 3 k. V Chiho Wang Duke University 13 TRD Conference Bari, Sep. 2003

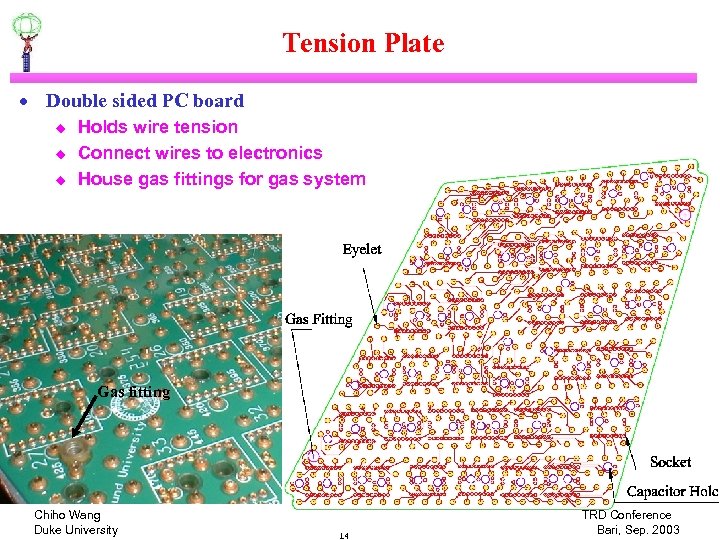

Tension Plate · Double sided PC board u u u Holds wire tension Connect wires to electronics House gas fittings for gas system Gas fitting Chiho Wang Duke University 14 TRD Conference Bari, Sep. 2003

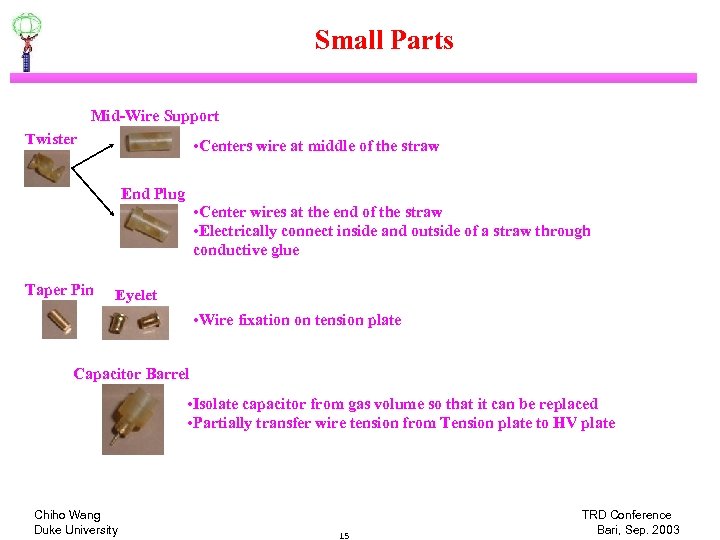

Small Parts Mid-Wire Support Twister • Centers wire at middle of the straw End Plug Taper Pin • Center wires at the end of the straw • Electrically connect inside and outside of a straw through conductive glue Eyelet • Wire fixation on tension plate Capacitor Barrel • Isolate capacitor from gas volume so that it can be replaced • Partially transfer wire tension from Tension plate to HV plate Chiho Wang Duke University 15 TRD Conference Bari, Sep. 2003

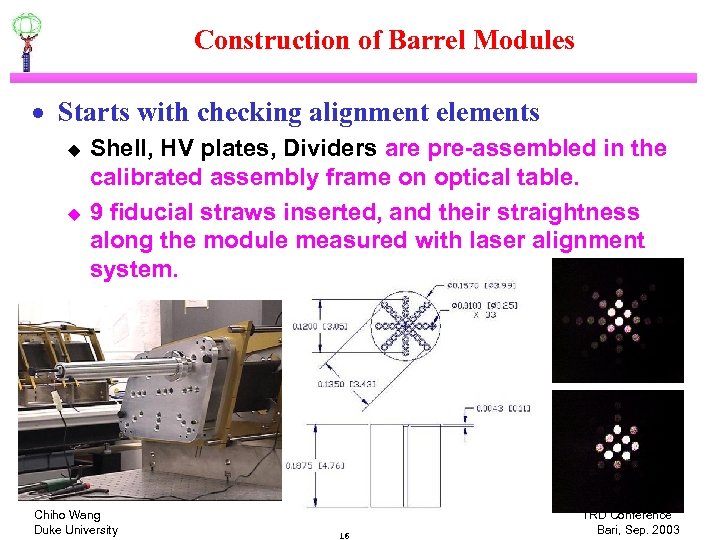

Construction of Barrel Modules · Starts with checking alignment elements u u Shell, HV plates, Dividers are pre-assembled in the calibrated assembly frame on optical table. 9 fiducial straws inserted, and their straightness along the module measured with laser alignment system. Chiho Wang Duke University 16 TRD Conference Bari, Sep. 2003

Laser alignment data Chiho Wang Duke University 17 TRD Conference Bari, Sep. 2003

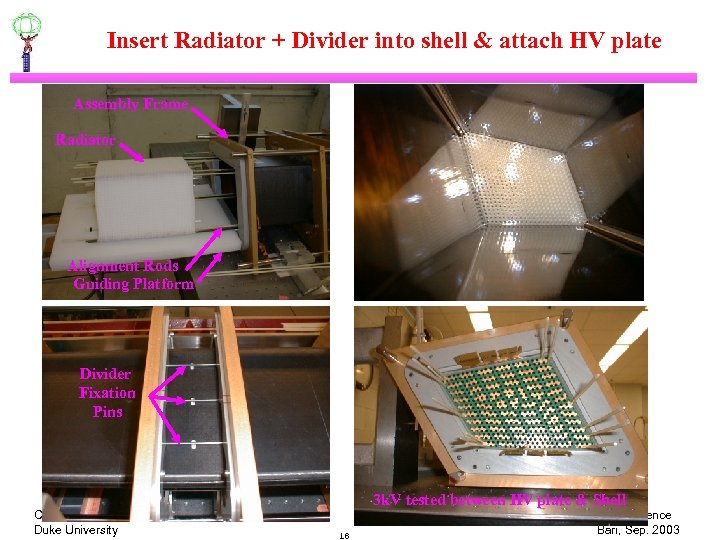

Insert Radiator + Divider into shell & attach HV plate Assembly Frame Radiator Alignment Rods Guiding Platform Divider Fixation Pins Chiho Wang Duke University 3 k. V tested between HV plate & Shell 18 TRD Conference Bari, Sep. 2003

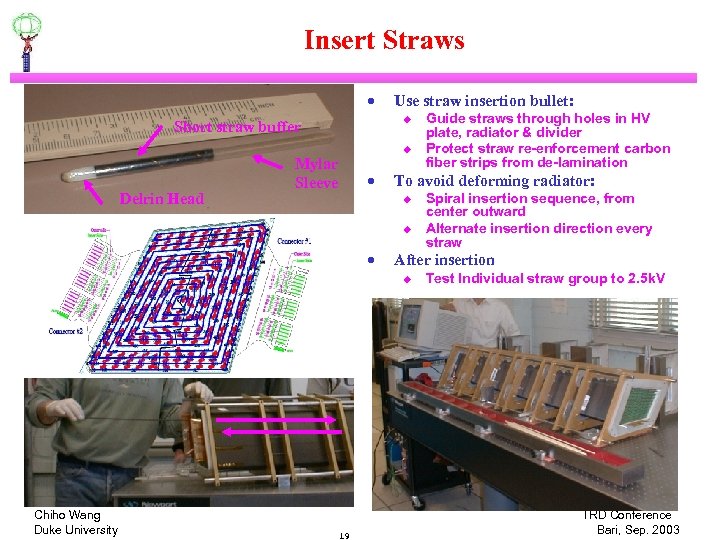

Insert Straws · u Short straw buffer Delrin Head Use straw insertion bullet: u Mylar Sleeve · To avoid deforming radiator: u u · 19 Spiral insertion sequence, from center outward Alternate insertion direction every straw After insertion u Chiho Wang Duke University Guide straws through holes in HV plate, radiator & divider Protect straw re-enforcement carbon fiber strips from de-lamination Test Individual straw group to 2. 5 k. V TRD Conference Bari, Sep. 2003

Conductive Glue dispenser Rotor A ring of Conductive glue End Plug End plug holder Chiho Wang Duke University · Use endplug to glue straws from inside to outside and to HV plate · Measure straw resistance after gluing each side · HV test each straw group to 2. 5 k. V before and after gluing each side After gluing one side 20 After gluing both sides TRD Conference Bari, Sep. 2003

Seal between High Voltage Plate and Straws 3” plastic syringe tip Glue Divider · Seal around straw end-plug and HV plate surface with AY 103 Chiho Wang Duke University · Pot back side of HV plate 2. 4 mm thick with Stycast 1266. 21 TRD Conference Bari, Sep. 2003

End of “Mechanical Assembly” Leak test system · Clean up: u u u HV Tester Gas seal plate & fitting for leak test u Check cooling tube holes with gauge rod (rim/clean as needed). Clean capacitor socket for blockage Clean excessive glue on HV plate walls Clean gas fitting seats on HV plate · Check: u HV Relay box u Chiho Wang Duke University 22 HV test (last at 2. 5 k. V): n 2. 5 k. V through each individual straw group Module leak test: n < 1 m. Bar / min TRD Conference Bari, Sep. 2003

Assemble/Attach Tension Plate · Tension plate assembly: u u HV trace Capacitor barrel pin Thousands of components assembled each plate = thousands of possible leak n Eyelets, Sockets, Capacitor barrels, Gas fittings. Seal inner surface with a layer of glue (AY 103) for gas tightness · After tension plate attached, check HV paths continuity between Kapton traces and Capacitor pins. Chiho Wang Duke University 23 TRD Conference Bari, Sep. 2003

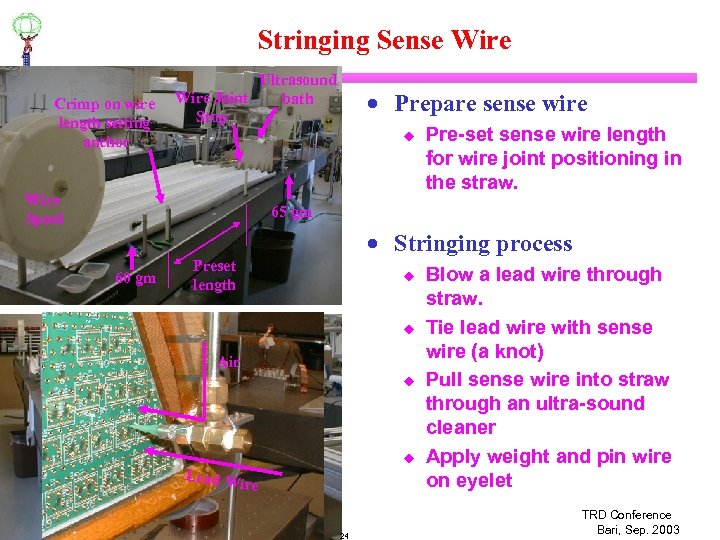

Stringing Sense Wire Crimp on wire length setting anchor Ultrasound Wire Joint bath Stop · Prepare sense wire u Wire Spool Pre-set sense wire length for wire joint positioning in the straw. 65 gm · Stringing process 60 gm Preset length u u Air u Chiho Wang Duke University Motorized Lead Wire Weight Spool L applyingead Wire pulley u 24 Blow a lead wire through straw. Tie lead wire with sense wire (a knot) Pull sense wire into straw through an ultra-sound cleaner Apply weight and pin wire on eyelet TRD Conference Bari, Sep. 2003

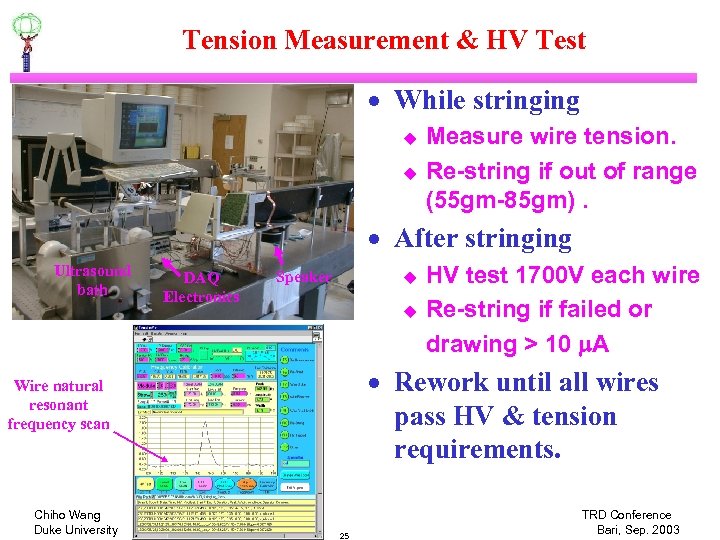

Tension Measurement & HV Test · While stringing u u Measure wire tension. Re-string if out of range (55 gm-85 gm). · After stringing Ultrasound bath DAQ Electronics Speaker u u · Rework until all wires pass HV & tension requirements. Wire natural resonant frequency scan Chiho Wang Duke University HV test 1700 V each wire Re-string if failed or drawing > 10 m. A 25 TRD Conference Bari, Sep. 2003

Mobile 16 -Channel Tension Tester · After re-work u u u Measure wire tensions on both sides. Re-work if low tension (<50 gm ) Re-work if |front – back| > 5 gm (wire joint hits mid-wire support) Front side Back side Chiho Wang Duke University 26 TRD Conference Bari, Sep. 2003

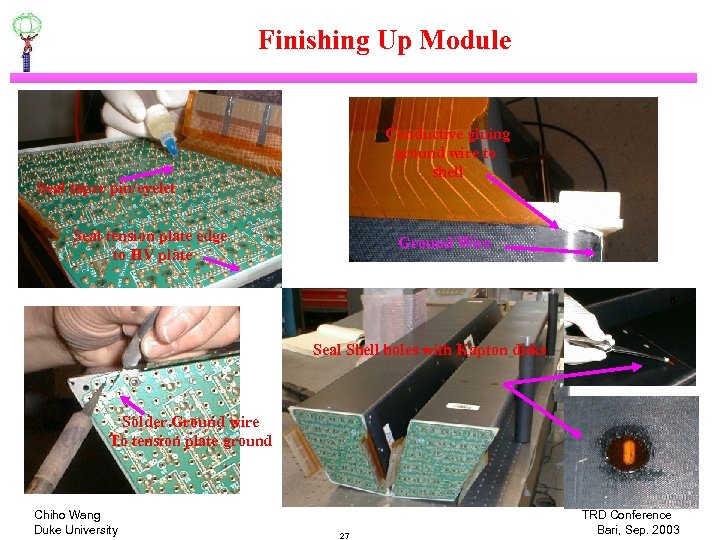

Finishing Up Module Conductive gluing ground wire to shell Seal taper pin/eyelet Seal tension plate edge to HV plate Ground Wire Seal Shell holes with Kapton disks Solder Ground wire To tension plate ground Chiho Wang Duke University 27 TRD Conference Bari, Sep. 2003

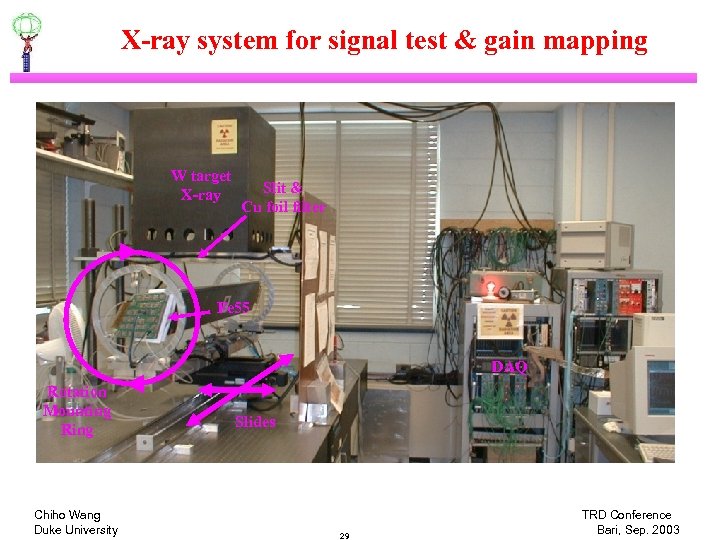

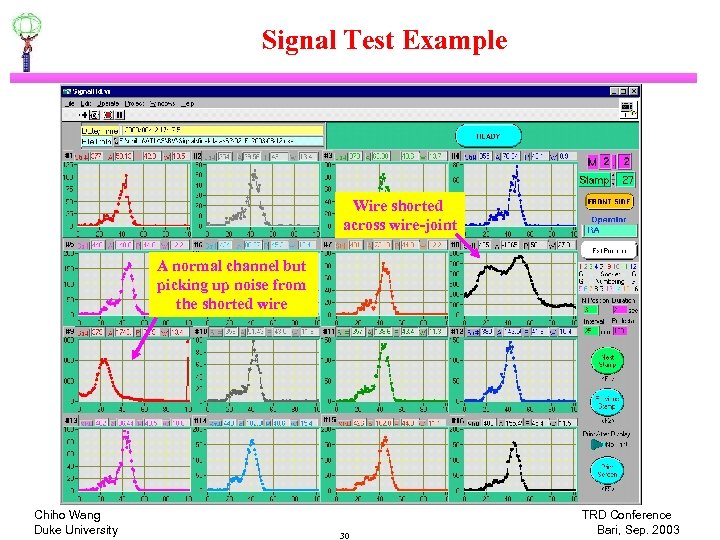

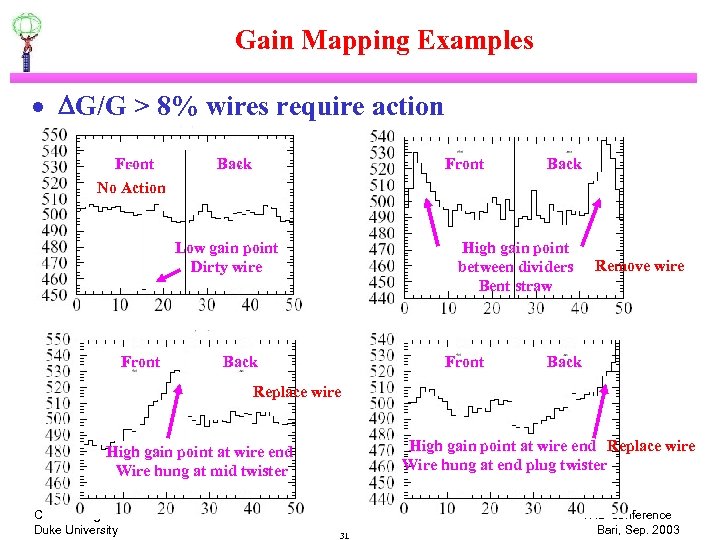

Module Passport Verification · On X-ray Scanner u u · · · Signal test: to ensure every channel functional, or documented if otherwise. Gain map: 25 positions each wire segment. Gain variation < 5% or documented HV soaking during signal test & gain mapping (2 -3 days) identifies/remove unstable wires & record current draw Re-work wires if removed wires > 1%. Chiho Wang Duke University 28 Measure ionization volume leak rate Measure purging volume leak rate Measure wire tensions. Check Dimension & Envelope Test module mounting TRD Conference Bari, Sep. 2003

X-ray system for signal test & gain mapping W target X-ray Slit & Cu foil filter Fe 55 DAQ Rotation Mounting Ring Chiho Wang Duke University Slides 29 TRD Conference Bari, Sep. 2003

Signal Test Example Wire shorted across wire-joint A normal channel but picking up noise from the shorted wire Chiho Wang Duke University 30 TRD Conference Bari, Sep. 2003

Gain Mapping Examples · DG/G > 8% wires require action Front No Action Back Front Low gain point Dirty wire Front Back High gain point between dividers Bent straw Back Front Remove wire Back Replace wire High gain point at wire end Replace wire Wire hung at end plug twister High gain point at wire end Wire hung at mid twister Chiho Wang Duke University 31 TRD Conference Bari, Sep. 2003

Summary · QC procedures are in every step of production procedures. · A QC “passport” is generated before a module leaves production site. · Module production is near its completion. ~ 10 modules have been completed and shipped to CERN in the past month or so. · In early 2004, modules will begin to assemble into barrel support structure. Chiho Wang Duke University 32 TRD Conference Bari, Sep. 2003

c6a172bc8fb0854bf491917aee611675.ppt