87fad6b114468be96de1fa76e05bdf87.ppt

- Количество слайдов: 17

Dept. Physics & Astronomy Space Research Group GERB-4 Detector System Goldblack Coating Status Report 3 rd March 2004 Nick Nelms, John Dowson Space Research Group Dept. Physics & Astronomy University of Leicester UK

Goldblack Coating Dept. Physics & Astronomy Space Research Group What is goldblack coating? It is a very low density deposit of amorphous gold which appears black at both visible and IR wavelengths. Why is goldblack coating required? Applying a goldblack coating to thermal IR detectors improves spectral response and flatness and extends absorption range.

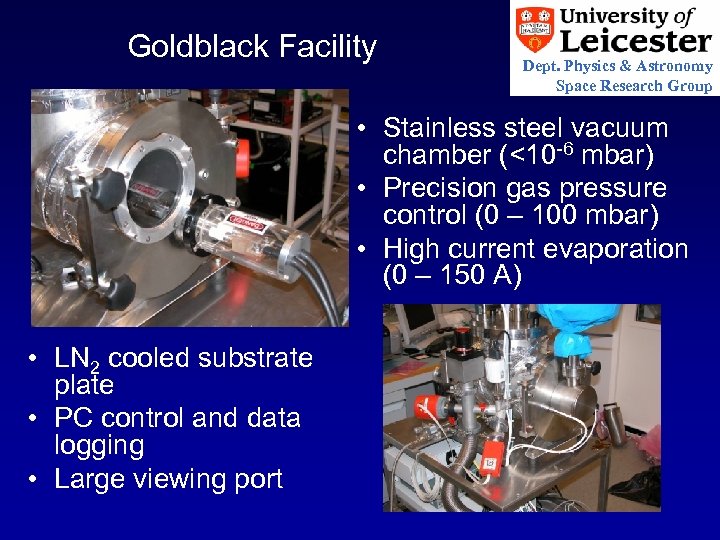

Goldblack Facility Dept. Physics & Astronomy Space Research Group • Stainless steel vacuum chamber (<10 -6 mbar) • Precision gas pressure control (0 – 100 mbar) • High current evaporation (0 – 150 A) • LN 2 cooled substrate plate • PC control and data logging • Large viewing port

Goldblack Deposition Dept. Physics & Astronomy Space Research Group Typical goldblacking procedure • Install substrate and gold metal • Evacuate chamber overnight • Cool substrate (typ. -55 deg. C) • Set chamber pressure (e. g. 10 mbar N 2) • Melt gold metal, hold for 60 sec • Increase current slowly to evaporation level • Allow gold to fully evaporate (10’s to 100’s sec) • Warm up substrate • Vent chamber to dry N 2 • Remove substrate

Goldblack Evaluation Variables under investigation • • • Gold quantity Chamber pressure Evaporation rate Substrate temperature Internal geometry Dept. Physics & Astronomy Space Research Group

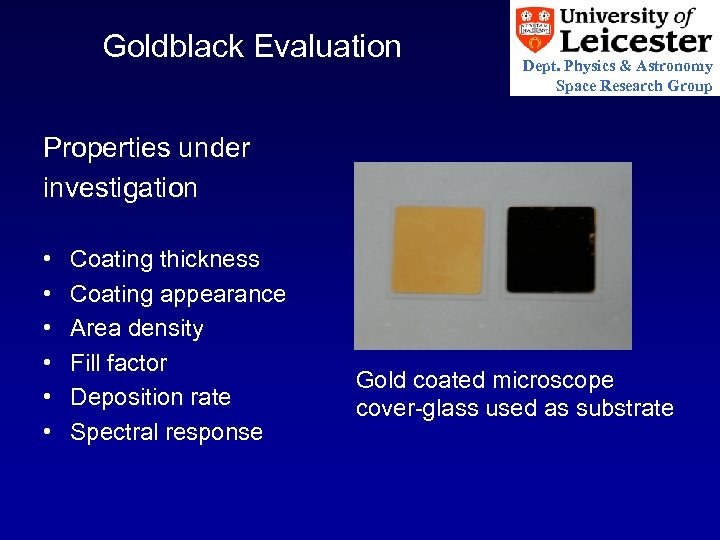

Goldblack Evaluation Dept. Physics & Astronomy Space Research Group Properties under investigation • • • Coating thickness Coating appearance Area density Fill factor Deposition rate Spectral response Gold coated microscope cover-glass used as substrate

Goldblack Evaluation Dept. Physics & Astronomy Space Research Group Parameter evaluation methods Thickness – Calibrated optical microscope Appearance – Optical microscope, SEM Area density - Gold coated substrate weighed before and after deposition Fill factor – Combination of thickness and area density Evaporation rate – Gold metal quantity and evaporation time measured

Goldblack Evaluation Dept. Physics & Astronomy Space Research Group Deposition rate – Deposition time (= evaporation time) measured and combined with sample weight measurements Spectral response – IR response measured with P-E Spectrum One (1. 2 – 27 um). Gold coated substrate gives 100% reflectance, absorption calculated as 1 - %R of goldblack measurement. Visible response measured using P-E Lambda 35 (0. 2 – 1. 1 um). Aluminium coated substrates used.

Goldblack Status Dept. Physics & Astronomy Space Research Group Coating thickness Typical thickness from previous work 10 – 100 um Coating thickness for GERBs 1 -3 ~20 um LU trial thickness results 5 – 70 um

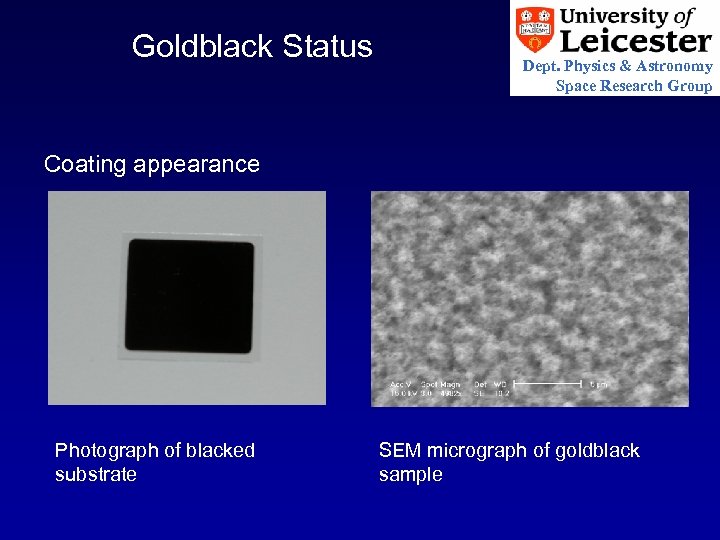

Goldblack Status Dept. Physics & Astronomy Space Research Group Coating appearance Photograph of blacked substrate SEM micrograph of goldblack sample

Goldblack Status Dept. Physics & Astronomy Space Research Group Area density Area densities from previous work 95 – 338 ug/cm^2 LU trial area densities 140 – 1380 ug/cm^2 Fill factors from previous work 0. 0015 – 0. 02 LU trial fill factors 0. 006 – 0. 04 Evaporation rate from previous work 0. 3 – 3. 3 mg/s LU trial evaporation rates 0. 1 – 1. 7 mg/s

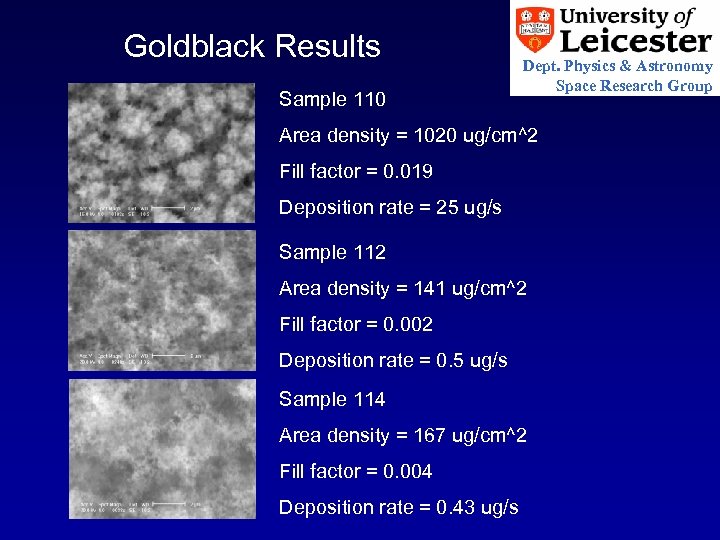

Goldblack Results Dept. Physics & Astronomy Space Research Group From previous work, good spectral response is given by low area density and low fill factor (fill factor is ratio of goldblack density to bulk gold density). Using LU goldblack facility, this indicates a requirement for cooled substrate, evaporation pressures of at least 10 mbar and low deposition rate.

Goldblack Reflectivity Measurements Dept. Physics & Astronomy Space Research Group

Goldblack Results Sample 110 Dept. Physics & Astronomy Space Research Group Area density = 1020 ug/cm^2 Fill factor = 0. 019 Deposition rate = 25 ug/s Sample 112 Area density = 141 ug/cm^2 Fill factor = 0. 002 Deposition rate = 0. 5 ug/s Sample 114 Area density = 167 ug/cm^2 Fill factor = 0. 004 Deposition rate = 0. 43 ug/s

Goldblack Reflectivity Measurements Dept. Physics & Astronomy Space Research Group GERB 4 Spec

Goldblack Issues Dept. Physics & Astronomy Space Research Group Aging effects Most previously reported goldblacks undergo some aging resulting in a degradation of spectral performance. This can be countered by introducing 1 -2% Cu into the gold melt as in the case of GERB 1 -3. The aging may be dependent upon water content during deposition. Initial investigations show no degradation due to aging but further work is required.

Goldblack Issues Dept. Physics & Astronomy Space Research Group Reticulated blacking The aim of this work is to produce reticulated blacking – a goldblack deposit on each individual pixel only. The method uses a custom bi-metal mask and alignment tool. The alignment tool is in house and has been tested successfully – it allows sub-micron alignment of detector and mask. The photo-masks are also in-house. An initial blacking trial using the photo-mask and a silicon substrate has had partial success with goldblack being deposited through the 50 x 45 um holes.

87fad6b114468be96de1fa76e05bdf87.ppt