fe13d6b1c314f4674131acd5b4628628.ppt

- Количество слайдов: 20

Define Phase Elements of Waste

Define Phase Elements of Waste

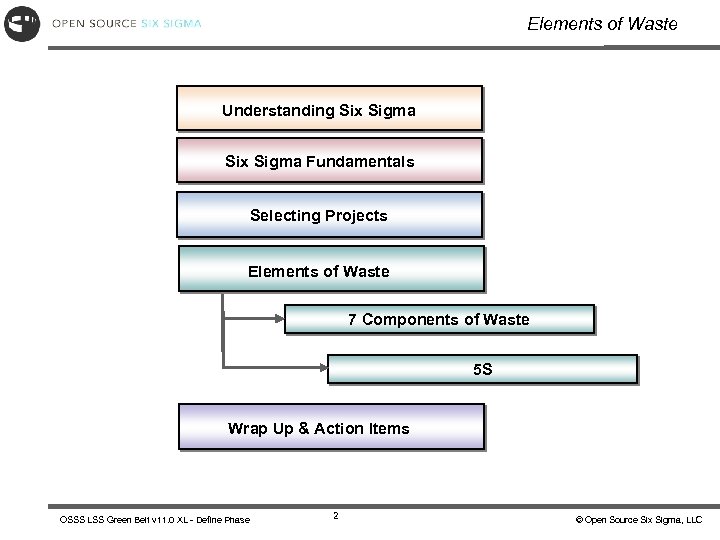

Elements of Waste Understanding Six Sigma Fundamentals Selecting Projects Elements of Waste 7 Components of Waste 5 S Wrap Up & Action Items OSSS LSS Green Belt v 11. 0 XL - Define Phase 2 © Open Source Six Sigma, LLC

Elements of Waste Understanding Six Sigma Fundamentals Selecting Projects Elements of Waste 7 Components of Waste 5 S Wrap Up & Action Items OSSS LSS Green Belt v 11. 0 XL - Define Phase 2 © Open Source Six Sigma, LLC

Definition of Lean “Lean Enterprise is based on the premise that anywhere work is being done, waste is being generated. The Lean Enterprise seeks to organize its processes to the optimum level, through the continual focus on the identification and elimination of waste. ” -- Barbara Wheat OSSS LSS Green Belt v 11. 0 XL - Define Phase 3 © Open Source Six Sigma, LLC

Definition of Lean “Lean Enterprise is based on the premise that anywhere work is being done, waste is being generated. The Lean Enterprise seeks to organize its processes to the optimum level, through the continual focus on the identification and elimination of waste. ” -- Barbara Wheat OSSS LSS Green Belt v 11. 0 XL - Define Phase 3 © Open Source Six Sigma, LLC

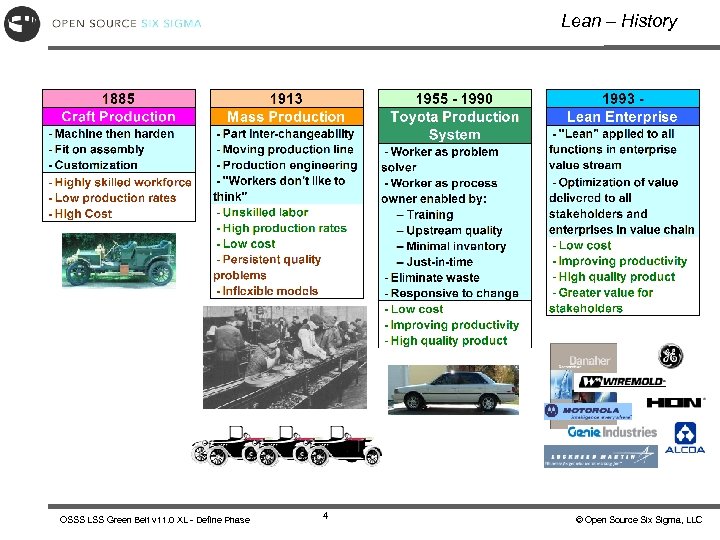

Lean – History OSSS LSS Green Belt v 11. 0 XL - Define Phase 4 © Open Source Six Sigma, LLC

Lean – History OSSS LSS Green Belt v 11. 0 XL - Define Phase 4 © Open Source Six Sigma, LLC

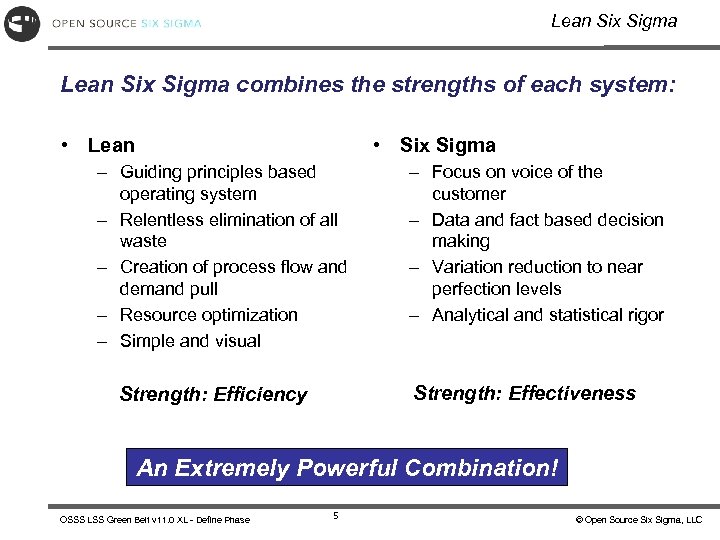

Lean Six Sigma combines the strengths of each system: • Lean • Six Sigma – Guiding principles based operating system – Relentless elimination of all waste – Creation of process flow and demand pull – Resource optimization – Simple and visual – Focus on voice of the customer – Data and fact based decision making – Variation reduction to near perfection levels – Analytical and statistical rigor Strength: Effectiveness Strength: Efficiency An Extremely Powerful Combination! OSSS LSS Green Belt v 11. 0 XL - Define Phase 5 © Open Source Six Sigma, LLC

Lean Six Sigma combines the strengths of each system: • Lean • Six Sigma – Guiding principles based operating system – Relentless elimination of all waste – Creation of process flow and demand pull – Resource optimization – Simple and visual – Focus on voice of the customer – Data and fact based decision making – Variation reduction to near perfection levels – Analytical and statistical rigor Strength: Effectiveness Strength: Efficiency An Extremely Powerful Combination! OSSS LSS Green Belt v 11. 0 XL - Define Phase 5 © Open Source Six Sigma, LLC

Project Requirements for Lean • Perhaps one of the most criminal employee performance issues in today’s organizations is generated not by a desire to cheat one’s employer but rather by a lack of regard to waste. • In every work environment there are multiple opportunities for reducing the non-value added activities that have (over time) become an ingrained part of the standard operating procedure. • These non-value added activities have become so ingrained in our process that they are no longer recognized for what they are, WASTE. • waste (v. ) Anything other than the minimum amount of time, material, people, space, energy, etc needed to add value to the product or service you are providing. • The Japanese word for waste is muda. Get that stuff outta here! OSSS LSS Green Belt v 11. 0 XL - Define Phase 6 © Open Source Six Sigma, LLC

Project Requirements for Lean • Perhaps one of the most criminal employee performance issues in today’s organizations is generated not by a desire to cheat one’s employer but rather by a lack of regard to waste. • In every work environment there are multiple opportunities for reducing the non-value added activities that have (over time) become an ingrained part of the standard operating procedure. • These non-value added activities have become so ingrained in our process that they are no longer recognized for what they are, WASTE. • waste (v. ) Anything other than the minimum amount of time, material, people, space, energy, etc needed to add value to the product or service you are providing. • The Japanese word for waste is muda. Get that stuff outta here! OSSS LSS Green Belt v 11. 0 XL - Define Phase 6 © Open Source Six Sigma, LLC

Seven Components of Waste Muda is classified into seven components: – – – – Overproduction Correction (defects) Inventory Motion Overprocessing Conveyance Waiting Sometimes additional forms of muda are added: – Under use of talent – Lack of safety Being Lean means eliminating waste. OSSS LSS Green Belt v 11. 0 XL - Define Phase 7 © Open Source Six Sigma, LLC

Seven Components of Waste Muda is classified into seven components: – – – – Overproduction Correction (defects) Inventory Motion Overprocessing Conveyance Waiting Sometimes additional forms of muda are added: – Under use of talent – Lack of safety Being Lean means eliminating waste. OSSS LSS Green Belt v 11. 0 XL - Define Phase 7 © Open Source Six Sigma, LLC

Overproduction is producing more than the next step needs or more than the customer buys. – It may be the worst form of waste because it contributes to all the others. Examples are: üPreparing extra reports üReports not acted upon or even read üMultiple copies in data storage üOver-ordering materials üDuplication of effort/reports Waste of Overproduction relates to the excessive accumulation of work-in-process (WIP) or finished goods inventory. OSSS LSS Green Belt v 11. 0 XL - Define Phase 8 © Open Source Six Sigma, LLC

Overproduction is producing more than the next step needs or more than the customer buys. – It may be the worst form of waste because it contributes to all the others. Examples are: üPreparing extra reports üReports not acted upon or even read üMultiple copies in data storage üOver-ordering materials üDuplication of effort/reports Waste of Overproduction relates to the excessive accumulation of work-in-process (WIP) or finished goods inventory. OSSS LSS Green Belt v 11. 0 XL - Define Phase 8 © Open Source Six Sigma, LLC

Correction of defects is as obvious as it sounds. Examples are: üIncorrect data entry üPaying the wrong vendor üMisspelled words in communications üMaking bad product üMaterials or labor discarded during production Eliminate erors!! OSSS LSS Green Belt v 11. 0 XL - Define Phase Waste of Correction includes the waste of handling and fixing mistakes. This is common in both manufacturing and transactional settings. 9 © Open Source Six Sigma, LLC

Correction of defects is as obvious as it sounds. Examples are: üIncorrect data entry üPaying the wrong vendor üMisspelled words in communications üMaking bad product üMaterials or labor discarded during production Eliminate erors!! OSSS LSS Green Belt v 11. 0 XL - Define Phase Waste of Correction includes the waste of handling and fixing mistakes. This is common in both manufacturing and transactional settings. 9 © Open Source Six Sigma, LLC

Inventory is the liability of materials that are bought, invested in and not immediately sold or used. Examples are: üTransactions not processed üBigger “in box” than “out box” üOver-ordering materials consumed in-house üOver-ordering raw materials – just in case Waste of Inventory is identical to overproduction except that it refers to the waste of acquiring raw material before the exact moment that it is needed. OSSS LSS Green Belt v 11. 0 XL - Define Phase 10 © Open Source Six Sigma, LLC

Inventory is the liability of materials that are bought, invested in and not immediately sold or used. Examples are: üTransactions not processed üBigger “in box” than “out box” üOver-ordering materials consumed in-house üOver-ordering raw materials – just in case Waste of Inventory is identical to overproduction except that it refers to the waste of acquiring raw material before the exact moment that it is needed. OSSS LSS Green Belt v 11. 0 XL - Define Phase 10 © Open Source Six Sigma, LLC

Motion is the unnecessary movement of people and equipment. – This includes looking for things like documents or parts as well as movement that is straining. Examples are: üExtra steps üExtra data entry üHaving to look for something Waste of Motion examines how people move to ensure that value is added. OSSS LSS Green Belt v 11. 0 XL - Define Phase 11 © Open Source Six Sigma, LLC

Motion is the unnecessary movement of people and equipment. – This includes looking for things like documents or parts as well as movement that is straining. Examples are: üExtra steps üExtra data entry üHaving to look for something Waste of Motion examines how people move to ensure that value is added. OSSS LSS Green Belt v 11. 0 XL - Define Phase 11 © Open Source Six Sigma, LLC

Overprocessing is tasks, activities and materials that don’t add value. – Can be caused by poor product or tool design as well as from not understanding what the customer wants. Examples are: üSign-offs üReports that contain more information than the customer wants or needs Waste of Overprocessing relates to overprocessing anything that may not be adding value in the eyes of the customer. OSSS LSS Green Belt v 11. 0 XL - Define Phase 12 üCommunications, reports, emails, contracts, etc that contain more than the necessary points (briefer is better) üVoice mails that are too long © Open Source Six Sigma, LLC

Overprocessing is tasks, activities and materials that don’t add value. – Can be caused by poor product or tool design as well as from not understanding what the customer wants. Examples are: üSign-offs üReports that contain more information than the customer wants or needs Waste of Overprocessing relates to overprocessing anything that may not be adding value in the eyes of the customer. OSSS LSS Green Belt v 11. 0 XL - Define Phase 12 üCommunications, reports, emails, contracts, etc that contain more than the necessary points (briefer is better) üVoice mails that are too long © Open Source Six Sigma, LLC

Conveyance is the unnecessary movement of material and goods. – Steps in a process should be located close to each other so movement is minimized. Examples are: üExtra steps in the process üDistance traveled üMoving paper from place to place Waste of Conveyance is the movement of material. OSSS LSS Green Belt v 11. 0 XL - Define Phase 13 © Open Source Six Sigma, LLC

Conveyance is the unnecessary movement of material and goods. – Steps in a process should be located close to each other so movement is minimized. Examples are: üExtra steps in the process üDistance traveled üMoving paper from place to place Waste of Conveyance is the movement of material. OSSS LSS Green Belt v 11. 0 XL - Define Phase 13 © Open Source Six Sigma, LLC

Waiting is nonproductive time due to lack of material, people, or equipment. – Can be due to slow or broken machines, material not arriving on time, etc. Examples are: üProcessing once each month instead of as the work comes in üShowing up on time for a meeting that starts late üDelayed work due to lack of communication from another internal group Waste of Waiting is the cost of an idle resource. OSSS LSS Green Belt v 11. 0 XL - Define Phase 14 © Open Source Six Sigma, LLC

Waiting is nonproductive time due to lack of material, people, or equipment. – Can be due to slow or broken machines, material not arriving on time, etc. Examples are: üProcessing once each month instead of as the work comes in üShowing up on time for a meeting that starts late üDelayed work due to lack of communication from another internal group Waste of Waiting is the cost of an idle resource. OSSS LSS Green Belt v 11. 0 XL - Define Phase 14 © Open Source Six Sigma, LLC

Exercise objective: To identify waste that occurs in your processes. Write an example of each type of Muda below: – – – – OSSS LSS Green Belt v 11. 0 XL - Define Phase Overproduction Correction Inventory Motion Overprocessing Conveyance Waiting 15 ___________________ ___________________ © Open Source Six Sigma, LLC

Exercise objective: To identify waste that occurs in your processes. Write an example of each type of Muda below: – – – – OSSS LSS Green Belt v 11. 0 XL - Define Phase Overproduction Correction Inventory Motion Overprocessing Conveyance Waiting 15 ___________________ ___________________ © Open Source Six Sigma, LLC

5 S – The Basics 5 S is a process designed to organize the workplace, keep it neat and clean, maintain standardized conditions and instill the discipline required to enable each individual to achieve and maintain a world class work environment. • • • Seiri - Put things in order Seiton - Proper Arrangement Seiso – Clean Seiketsu – Purity Shitsuke - Commitment OSSS LSS Green Belt v 11. 0 XL - Define Phase 16 © Open Source Six Sigma, LLC

5 S – The Basics 5 S is a process designed to organize the workplace, keep it neat and clean, maintain standardized conditions and instill the discipline required to enable each individual to achieve and maintain a world class work environment. • • • Seiri - Put things in order Seiton - Proper Arrangement Seiso – Clean Seiketsu – Purity Shitsuke - Commitment OSSS LSS Green Belt v 11. 0 XL - Define Phase 16 © Open Source Six Sigma, LLC

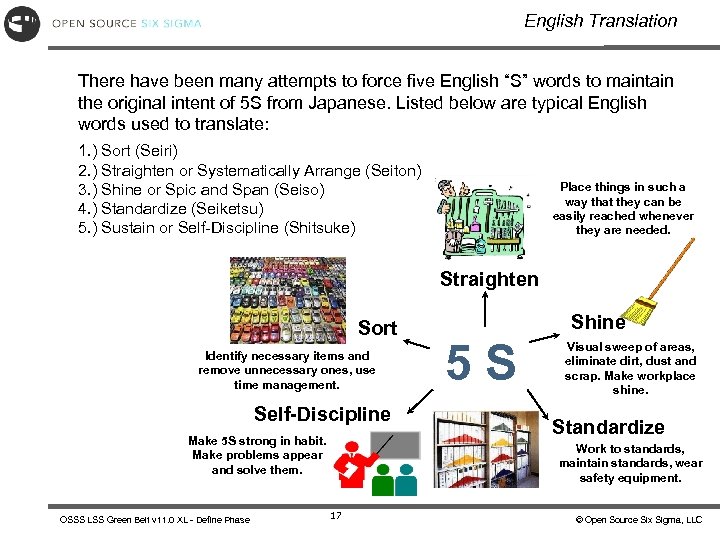

English Translation There have been many attempts to force five English “S” words to maintain the original intent of 5 S from Japanese. Listed below are typical English words used to translate: 1. ) Sort (Seiri) 2. ) Straighten or Systematically Arrange (Seiton) 3. ) Shine or Spic and Span (Seiso) 4. ) Standardize (Seiketsu) 5. ) Sustain or Self-Discipline (Shitsuke) Place things in such a way that they can be easily reached whenever they are needed. Straighten Sort Identify necessary items and remove unnecessary ones, use time management. Self-Discipline Make 5 S strong in habit. Make problems appear and solve them. OSSS LSS Green Belt v 11. 0 XL - Define Phase Shine 5 S Visual sweep of areas, eliminate dirt, dust and scrap. Make workplace shine. Standardize Work to standards, maintain standards, wear safety equipment. 17 © Open Source Six Sigma, LLC

English Translation There have been many attempts to force five English “S” words to maintain the original intent of 5 S from Japanese. Listed below are typical English words used to translate: 1. ) Sort (Seiri) 2. ) Straighten or Systematically Arrange (Seiton) 3. ) Shine or Spic and Span (Seiso) 4. ) Standardize (Seiketsu) 5. ) Sustain or Self-Discipline (Shitsuke) Place things in such a way that they can be easily reached whenever they are needed. Straighten Sort Identify necessary items and remove unnecessary ones, use time management. Self-Discipline Make 5 S strong in habit. Make problems appear and solve them. OSSS LSS Green Belt v 11. 0 XL - Define Phase Shine 5 S Visual sweep of areas, eliminate dirt, dust and scrap. Make workplace shine. Standardize Work to standards, maintain standards, wear safety equipment. 17 © Open Source Six Sigma, LLC

Exercise objective: : To identify elements of 5 S in your workplace. Write an example for each of the 5 S’s below: • • • OSSS LSS Green Belt v 11. 0 XL - Define Phase Sort Straighten Shine Standardize Self-Discipline 18 ____________________ __________ © Open Source Six Sigma, LLC

Exercise objective: : To identify elements of 5 S in your workplace. Write an example for each of the 5 S’s below: • • • OSSS LSS Green Belt v 11. 0 XL - Define Phase Sort Straighten Shine Standardize Self-Discipline 18 ____________________ __________ © Open Source Six Sigma, LLC

Summary At this point, you should be able to: • Identify and describe the 7 Elements of Waste • Describe 5 S • Provide examples of how Lean Principles can affect your area OSSS LSS Green Belt v 11. 0 XL - Define Phase 19 © Open Source Six Sigma, LLC

Summary At this point, you should be able to: • Identify and describe the 7 Elements of Waste • Describe 5 S • Provide examples of how Lean Principles can affect your area OSSS LSS Green Belt v 11. 0 XL - Define Phase 19 © Open Source Six Sigma, LLC

The Certified Lean Six Sigma Green Belt Assessment The Certified Lean Six Sigma Green Belt (CLSSGB) tests are useful for assessing Green Belt’s knowledge of Lean Six Sigma. The CLSSGB can be used in preparation for the ASQ or IASSC Certified Six Sigma Green Belt (CSSGB) exam or for any number of other certifications, including private company certifications. The Lean Six Sigma Green Belt Course Manual Open Source Six Sigma Course Manuals are professionally designed and formatted manuals used by Belt’s during training and for reference guides afterwards. The OSSS manuals complement the OSSS Training Materials and consist of slide content, instructional notes data sets and templates. Get the latest products at… www. opensourcesixsigma. com OSSS LSS Green Belt v 11. 0 XL - Define Phase © Open Source Six Sigma, LLC

The Certified Lean Six Sigma Green Belt Assessment The Certified Lean Six Sigma Green Belt (CLSSGB) tests are useful for assessing Green Belt’s knowledge of Lean Six Sigma. The CLSSGB can be used in preparation for the ASQ or IASSC Certified Six Sigma Green Belt (CSSGB) exam or for any number of other certifications, including private company certifications. The Lean Six Sigma Green Belt Course Manual Open Source Six Sigma Course Manuals are professionally designed and formatted manuals used by Belt’s during training and for reference guides afterwards. The OSSS manuals complement the OSSS Training Materials and consist of slide content, instructional notes data sets and templates. Get the latest products at… www. opensourcesixsigma. com OSSS LSS Green Belt v 11. 0 XL - Define Phase © Open Source Six Sigma, LLC