82dd7f1847d297653a3e1efa3c4ef746.ppt

- Количество слайдов: 63

Defense Sustainment Consortium Project 6: Common Processes Phase 1 – Test Bed Demonstrations Program Review February 2, 2005 San Antonio, TX 1

Defense Sustainment Consortium Project 6: Common Processes Phase 1 – Test Bed Demonstrations Program Review February 2, 2005 San Antonio, TX 1

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 2

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 2

Problem - Solution Ø Future Logistics Enterprise (FLE) is Do. D’s vision to enhance support to the warfighter Ø FLE includes CBM+ Ø Enhanced prognostics / diagnostics Ø Failure trend analysis Ø Point of maintenance aids Ø Serial item tracking Ø Data-driven interactive maintenance training Ø Distance support Ø Integrated maintenance with other logistics functions 3

Problem - Solution Ø Future Logistics Enterprise (FLE) is Do. D’s vision to enhance support to the warfighter Ø FLE includes CBM+ Ø Enhanced prognostics / diagnostics Ø Failure trend analysis Ø Point of maintenance aids Ø Serial item tracking Ø Data-driven interactive maintenance training Ø Distance support Ø Integrated maintenance with other logistics functions 3

Army & Navy Targeted Solution Ø A practical system that can be integrated into any weapons platform. Ø A system that uses Commercial-Off-The-Shelf (COTS) applications. Ø The minimum of modifications to existing hardware. WBS 2. 5. 2 Common Processes – Phase 1 WBS 2. 5. 2. 1 Common Task Activities WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 3 AFDRAS Test Bed Demonstration WBS 2. 5. 2. 4 Project Management 4

Army & Navy Targeted Solution Ø A practical system that can be integrated into any weapons platform. Ø A system that uses Commercial-Off-The-Shelf (COTS) applications. Ø The minimum of modifications to existing hardware. WBS 2. 5. 2 Common Processes – Phase 1 WBS 2. 5. 2. 1 Common Task Activities WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 3 AFDRAS Test Bed Demonstration WBS 2. 5. 2. 4 Project Management 4

Common Processes Team Ø CVN Demonstration NGC: John Major, john. major@ngc. com NSWC: Walt Kostyk, kostykwj@nswccd. navy. mil Ø M 88 Demonstration UDLP: Andy Miller, andrew. miller@udlp. com PM M 88: Dave Boster, bosterd@tacom. army. mil Ø Integration & Project Management ATI: Curtis Holcomb, holcomb@aticorp. org Altarum: Ray Vander. Bok, ray. vanderbok@altarum. org 5

Common Processes Team Ø CVN Demonstration NGC: John Major, john. major@ngc. com NSWC: Walt Kostyk, kostykwj@nswccd. navy. mil Ø M 88 Demonstration UDLP: Andy Miller, andrew. miller@udlp. com PM M 88: Dave Boster, bosterd@tacom. army. mil Ø Integration & Project Management ATI: Curtis Holcomb, holcomb@aticorp. org Altarum: Ray Vander. Bok, ray. vanderbok@altarum. org 5

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 6

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 6

WBS 2. 5. 2. 1: Common Task Activities Ø WBS 2. 5. 2. 1. 1 Update common decision process Ø Common decision process documented in Phase-0 v Evaluate appropriate applications Ø Will work with OEM’s and PM’s for refining process Ø WBS 2. 5. 2. 1. 2 Promote common evaluation metrics Ø Primary role to support continued development Ø Build metrics from Phase-0 starting point Ø Share metrics and rationale across demonstrations 7

WBS 2. 5. 2. 1: Common Task Activities Ø WBS 2. 5. 2. 1. 1 Update common decision process Ø Common decision process documented in Phase-0 v Evaluate appropriate applications Ø Will work with OEM’s and PM’s for refining process Ø WBS 2. 5. 2. 1. 2 Promote common evaluation metrics Ø Primary role to support continued development Ø Build metrics from Phase-0 starting point Ø Share metrics and rationale across demonstrations 7

WBS 2. 5. 2. 1: Common Task Activities Ø WBS 2. 5. 2. 1. 3 Share metrics and lessons learned Ø Proactively share information across programs Ø Recruit DSC members to engage in program reviews Ø WBS 2. 5. 2. 1. 4 Plan for broad deployment Ø Work with OEM’s and PM offices to identify deployment path Ø Support deployment justification Ø WBS 2. 5. 2. 1. 5 Final report Ø System descriptions Ø Application description Ø System performance Ø Business impact (business & government) Ø Deployment plans 8

WBS 2. 5. 2. 1: Common Task Activities Ø WBS 2. 5. 2. 1. 3 Share metrics and lessons learned Ø Proactively share information across programs Ø Recruit DSC members to engage in program reviews Ø WBS 2. 5. 2. 1. 4 Plan for broad deployment Ø Work with OEM’s and PM offices to identify deployment path Ø Support deployment justification Ø WBS 2. 5. 2. 1. 5 Final report Ø System descriptions Ø Application description Ø System performance Ø Business impact (business & government) Ø Deployment plans 8

WBS 2. 5. 2. 1: Common Task Activities Ø Accomplishments Ø Assisted in capturing the core business cases for deployment Ø Developing metrics to support business cases Ø Next Quarter Ø Validate business cases and metrics with program offices Ø Status: 50% complete Ø Deliverables: Ø Updated Phase 0 Report – Dec 05 Ø Consolidated Final Report – Dec 05 9

WBS 2. 5. 2. 1: Common Task Activities Ø Accomplishments Ø Assisted in capturing the core business cases for deployment Ø Developing metrics to support business cases Ø Next Quarter Ø Validate business cases and metrics with program offices Ø Status: 50% complete Ø Deliverables: Ø Updated Phase 0 Report – Dec 05 Ø Consolidated Final Report – Dec 05 9

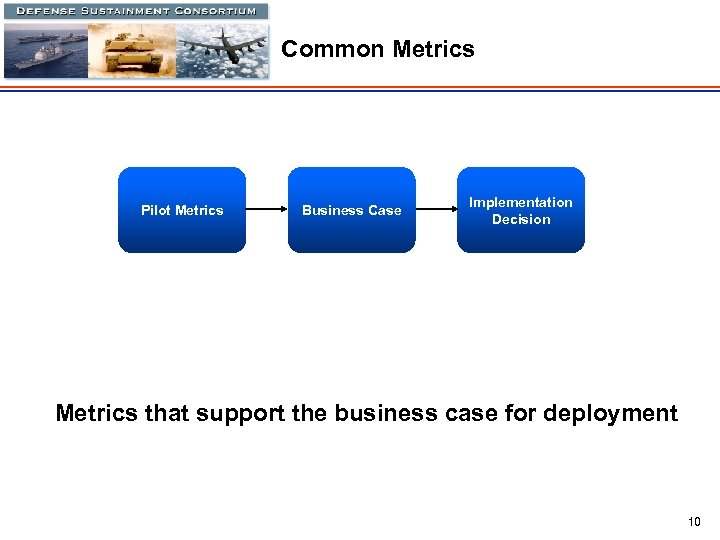

Common Metrics Pilot Metrics Business Case Implementation Decision Metrics that support the business case for deployment 10

Common Metrics Pilot Metrics Business Case Implementation Decision Metrics that support the business case for deployment 10

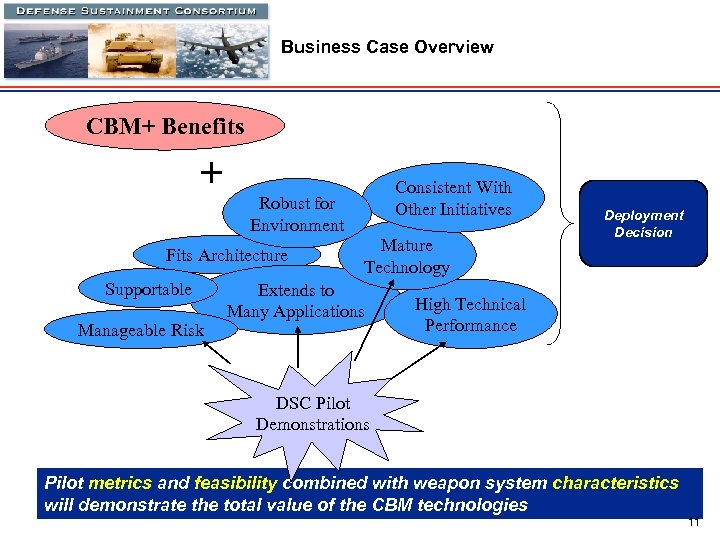

Business Case Overview CBM+ Benefits + Robust for Environment Fits Architecture Supportable Manageable Risk Consistent With Other Initiatives Mature Technology Extends to Many Applications Deployment Decision High Technical Performance DSC Pilot Demonstrations Pilot metrics and feasibility combined with weapon system characteristics will demonstrate the total value of the CBM technologies 11

Business Case Overview CBM+ Benefits + Robust for Environment Fits Architecture Supportable Manageable Risk Consistent With Other Initiatives Mature Technology Extends to Many Applications Deployment Decision High Technical Performance DSC Pilot Demonstrations Pilot metrics and feasibility combined with weapon system characteristics will demonstrate the total value of the CBM technologies 11

Core Business Case ØBenefits ØMeets the DOD policy that: “Condition Based Maintenance be implemented to improve maintenance agility and responsiveness, increase operational availability, and reduce life cycle total ownership costs” Ø In-line with DOD CBM+ Plan of Action and Milestones ØCost Ø Common approach that applies to multiple systems Ø Leverages existing hardware investments ØSupports Ø OSD-AT&L CBM+ Policy and Guidance Ø Navy’s CBM+ Initiatives & Integrated Condition Assessment System (ICAS) Ø Army’s CBM+ Plan 12

Core Business Case ØBenefits ØMeets the DOD policy that: “Condition Based Maintenance be implemented to improve maintenance agility and responsiveness, increase operational availability, and reduce life cycle total ownership costs” Ø In-line with DOD CBM+ Plan of Action and Milestones ØCost Ø Common approach that applies to multiple systems Ø Leverages existing hardware investments ØSupports Ø OSD-AT&L CBM+ Policy and Guidance Ø Navy’s CBM+ Initiatives & Integrated Condition Assessment System (ICAS) Ø Army’s CBM+ Plan 12

Common Task Activities Ø Next Steps Ø Briefings for support of DSC CBM+ Efforts v OSD, NAVSEA, NAVSUP, FCS. . . Ø Broad exposure in the Navy and Army Ø Identify a weapon system to continue Common Processes Efforts (Future) Ø Identify specific metrics for pilot demonstrations 13

Common Task Activities Ø Next Steps Ø Briefings for support of DSC CBM+ Efforts v OSD, NAVSEA, NAVSUP, FCS. . . Ø Broad exposure in the Navy and Army Ø Identify a weapon system to continue Common Processes Efforts (Future) Ø Identify specific metrics for pilot demonstrations 13

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 14

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 14

WBS 2. 5. 2. 2: Automated Diagnostic / Prognostic (ADP) System - Test Bed Demonstration Ø Goals: Ø Install, test, and demonstrate a commercial ADP system connected to ICAS through the existing ship network. Ø The ADP will communicate to ICAS through an Open System Architecture – Condition Based Maintenance (OSACBM) commercial standard Ø The integrated ADP/ICAS/Network will align with CBM+ Ø The integrated ADP/ICAS/Network will align with OPNAV Instruction 4700. 7 k (11 JUL 2003) 15

WBS 2. 5. 2. 2: Automated Diagnostic / Prognostic (ADP) System - Test Bed Demonstration Ø Goals: Ø Install, test, and demonstrate a commercial ADP system connected to ICAS through the existing ship network. Ø The ADP will communicate to ICAS through an Open System Architecture – Condition Based Maintenance (OSACBM) commercial standard Ø The integrated ADP/ICAS/Network will align with CBM+ Ø The integrated ADP/ICAS/Network will align with OPNAV Instruction 4700. 7 k (11 JUL 2003) 15

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Expected Tangible Benefits: Ø Reusable “core” can be modified to be used on many different ship systems Ø Represents the “how-to” link between a commercial vendor and ICAS Ø Allows embedded diagnostic and maintenance expertise from the vendor/manufacturer to be applied Ø Show vendors create individual ADPs that send CBM information to ICAS Ø Reduced workload on NSWCCD to develop and maintain: v the equipment system data bases v equipment expert systems v equipment prognostic systems v ADP interfaces (for each individual ADP/ICAS interface) Ø Ø Reduced maintenance workload on the Ship’s Force Measurable “availability” of ship’s systems Performance of maintenance only “as required” Detect, Diagnose, and be provided “what action to take” concerning system faults 16

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Expected Tangible Benefits: Ø Reusable “core” can be modified to be used on many different ship systems Ø Represents the “how-to” link between a commercial vendor and ICAS Ø Allows embedded diagnostic and maintenance expertise from the vendor/manufacturer to be applied Ø Show vendors create individual ADPs that send CBM information to ICAS Ø Reduced workload on NSWCCD to develop and maintain: v the equipment system data bases v equipment expert systems v equipment prognostic systems v ADP interfaces (for each individual ADP/ICAS interface) Ø Ø Reduced maintenance workload on the Ship’s Force Measurable “availability” of ship’s systems Performance of maintenance only “as required” Detect, Diagnose, and be provided “what action to take” concerning system faults 16

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Process for Deployment of Results Ø Hold Symposium for ADP and ICAS Development and Integration Ø Demonstrate ADP / ICAS to OSD (CBM+) Ø Demonstrate ADP / ICAS capabilities to NAVSEA Ø Demonstrate ADP / ICAS capabilities to PEO Carriers Ø Demonstrate ADP / ICAS capabilities to Army Ø Present Technical Papers at ASNE and MFPT Conferences 17

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Process for Deployment of Results Ø Hold Symposium for ADP and ICAS Development and Integration Ø Demonstrate ADP / ICAS to OSD (CBM+) Ø Demonstrate ADP / ICAS capabilities to NAVSEA Ø Demonstrate ADP / ICAS capabilities to PEO Carriers Ø Demonstrate ADP / ICAS capabilities to Army Ø Present Technical Papers at ASNE and MFPT Conferences 17

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Progress Relative to Schedule Ø Progress is noted in each WBS section in following slides. Ø Regrouping after NSWC brought back online. Ø Project will be back on schedule by March ’ 05. Ø No problems foreseen in meeting deliverables after that date. 18

WBS 2. 5. 2. 2: ADP Test Bed Demonstration Ø Progress Relative to Schedule Ø Progress is noted in each WBS section in following slides. Ø Regrouping after NSWC brought back online. Ø Project will be back on schedule by March ’ 05. Ø No problems foreseen in meeting deliverables after that date. 18

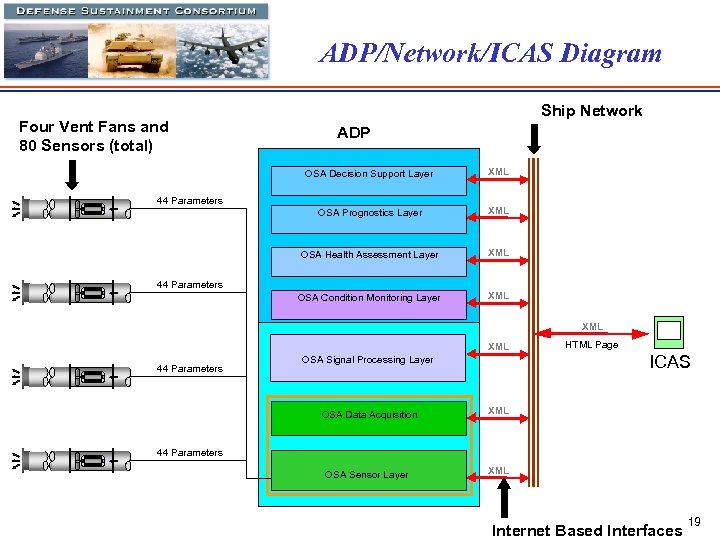

ADP/Network/ICAS Diagram Four Vent Fans and 80 Sensors (total) Ship Network ADP OSA Decision Support Layer XML OSA Prognostics Layer XML OSA Health Assessment Layer XML OSA Condition Monitoring Layer XML 44 Parameters OSA Signal Processing Layer OSA Data Acquisition ICAS XML OSA Sensor Layer HTML Page XML 44 Parameters Internet Based Interfaces 19

ADP/Network/ICAS Diagram Four Vent Fans and 80 Sensors (total) Ship Network ADP OSA Decision Support Layer XML OSA Prognostics Layer XML OSA Health Assessment Layer XML OSA Condition Monitoring Layer XML 44 Parameters OSA Signal Processing Layer OSA Data Acquisition ICAS XML OSA Sensor Layer HTML Page XML 44 Parameters Internet Based Interfaces 19

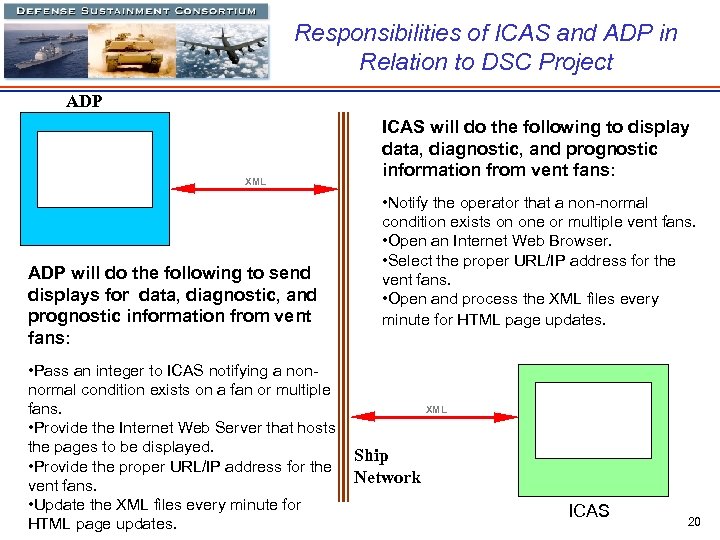

Responsibilities of ICAS and ADP in Relation to DSC Project ADP XML ADP will do the following to send displays for data, diagnostic, and prognostic information from vent fans: • Pass an integer to ICAS notifying a nonnormal condition exists on a fan or multiple fans. • Provide the Internet Web Server that hosts the pages to be displayed. • Provide the proper URL/IP address for the vent fans. • Update the XML files every minute for HTML page updates. ICAS will do the following to display data, diagnostic, and prognostic information from vent fans: • Notify the operator that a non-normal condition exists on one or multiple vent fans. • Open an Internet Web Browser. • Select the proper URL/IP address for the vent fans. • Open and process the XML files every minute for HTML page updates. XML Ship Network ICAS 20

Responsibilities of ICAS and ADP in Relation to DSC Project ADP XML ADP will do the following to send displays for data, diagnostic, and prognostic information from vent fans: • Pass an integer to ICAS notifying a nonnormal condition exists on a fan or multiple fans. • Provide the Internet Web Server that hosts the pages to be displayed. • Provide the proper URL/IP address for the vent fans. • Update the XML files every minute for HTML page updates. ICAS will do the following to display data, diagnostic, and prognostic information from vent fans: • Notify the operator that a non-normal condition exists on one or multiple vent fans. • Open an Internet Web Browser. • Select the proper URL/IP address for the vent fans. • Open and process the XML files every minute for HTML page updates. XML Ship Network ICAS 20

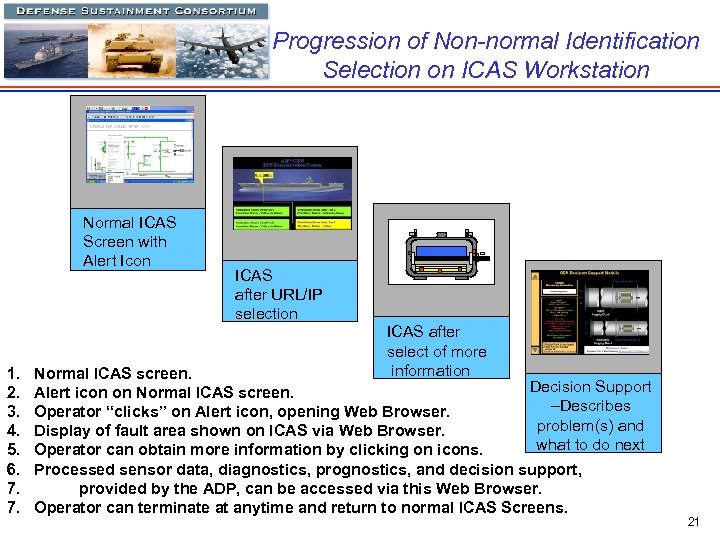

Progression of Non-normal Identification Selection on ICAS Workstation Normal ICAS Screen with Alert Icon 1. 2. 3. 4. 5. 6. 7. 7. ICAS after URL/IP selection ICAS after select of more information Normal ICAS screen. Decision Support Alert icon on Normal ICAS screen. –Describes Operator “clicks” on Alert icon, opening Web Browser. problem(s) and Display of fault area shown on ICAS via Web Browser. what to do next Operator can obtain more information by clicking on icons. Processed sensor data, diagnostics, prognostics, and decision support, provided by the ADP, can be accessed via this Web Browser. Operator can terminate at anytime and return to normal ICAS Screens. 21

Progression of Non-normal Identification Selection on ICAS Workstation Normal ICAS Screen with Alert Icon 1. 2. 3. 4. 5. 6. 7. 7. ICAS after URL/IP selection ICAS after select of more information Normal ICAS screen. Decision Support Alert icon on Normal ICAS screen. –Describes Operator “clicks” on Alert icon, opening Web Browser. problem(s) and Display of fault area shown on ICAS via Web Browser. what to do next Operator can obtain more information by clicking on icons. Processed sensor data, diagnostics, prognostics, and decision support, provided by the ADP, can be accessed via this Web Browser. Operator can terminate at anytime and return to normal ICAS Screens. 21

WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 2. 1 Selected System General Maintenance and Time Frequency Analysis Objective: Review maintenance reports and determine potential impact of ADP on maintenance cost for ventilation systems Ø Accomplishments Ø Target Demonstration Platform v v v Evaluated CVN 73 existing network and ICAS infrastructures Performed a ship check on CVN 73 Located four ventilation fans for test Located area for ADP system Determined that we will use temporary shore power Ø Failure Mode Analysis v NSWC has completed the Fan Failure Analysis Report v Targeted ventilation systems on the O 3 level on forward end of ship. v Reviewing the NSWC Fan Failure Analysis Report Ø Next Quarter Ø Prepare a Test and Evaluation (T&E) Report for AIRLANT and obtain necessary approvals Ø Preparing initial Drawings to submit to AIRLANT for approval and insertion into the Availability Work Package Ø Status: 75% complete Ø Deliverable: Fan Failure Analysis Report – Jan 05 22

WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 2. 1 Selected System General Maintenance and Time Frequency Analysis Objective: Review maintenance reports and determine potential impact of ADP on maintenance cost for ventilation systems Ø Accomplishments Ø Target Demonstration Platform v v v Evaluated CVN 73 existing network and ICAS infrastructures Performed a ship check on CVN 73 Located four ventilation fans for test Located area for ADP system Determined that we will use temporary shore power Ø Failure Mode Analysis v NSWC has completed the Fan Failure Analysis Report v Targeted ventilation systems on the O 3 level on forward end of ship. v Reviewing the NSWC Fan Failure Analysis Report Ø Next Quarter Ø Prepare a Test and Evaluation (T&E) Report for AIRLANT and obtain necessary approvals Ø Preparing initial Drawings to submit to AIRLANT for approval and insertion into the Availability Work Package Ø Status: 75% complete Ø Deliverable: Fan Failure Analysis Report – Jan 05 22

WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 2. 2 CBM System Development Objective: Develop ADP for ventilation system onboard CVN 68 class aircraft carrier. Ø Accomplishments Ø Developed interface between ADP and ICAS using OSA - MIMOSA standards Ø Integrated the ADP system with the NSWCCD developed Integrated Condition Assessment System (ICAS) via an open systems interface standard on January 19, 2005 Ø Completed and tested integration of ADP with ICAS. Ø Next Quarter Ø Adapting NGNN ADP system for target systems based on the NSWCCD Fan Failure Analysis Report. Ø Developing Test Plan and Procedure for the ADP System. Ø Complete test of ADP SYSTEM Ø Status: 80% Ø Deliverable: ADP System Documentation – March 05 23

WBS 2. 5. 2. 2 ADP Test Bed Demonstration WBS 2. 5. 2. 2. 2 CBM System Development Objective: Develop ADP for ventilation system onboard CVN 68 class aircraft carrier. Ø Accomplishments Ø Developed interface between ADP and ICAS using OSA - MIMOSA standards Ø Integrated the ADP system with the NSWCCD developed Integrated Condition Assessment System (ICAS) via an open systems interface standard on January 19, 2005 Ø Completed and tested integration of ADP with ICAS. Ø Next Quarter Ø Adapting NGNN ADP system for target systems based on the NSWCCD Fan Failure Analysis Report. Ø Developing Test Plan and Procedure for the ADP System. Ø Complete test of ADP SYSTEM Ø Status: 80% Ø Deliverable: ADP System Documentation – March 05 23

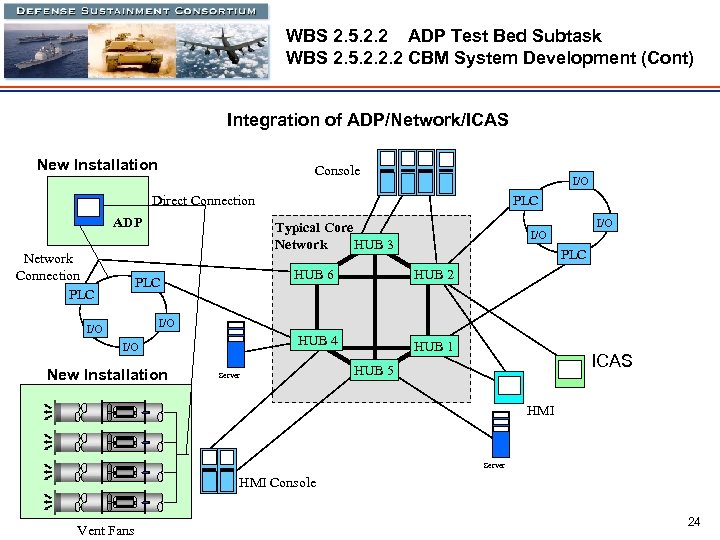

WBS 2. 5. 2. 2 ADP Test Bed Subtask WBS 2. 5. 2. 2. 2 CBM System Development (Cont) Integration of ADP/Network/ICAS New Installation Console I/O PLC Direct Connection ADP Network Connection PLC Typical Core HUB 3 Network PLC HUB 6 HUB 2 HUB 4 PLC I/O HUB 1 I/O I/O New Installation Server ICAS HUB 5 HMI Server HMI Console Vent Fans 24

WBS 2. 5. 2. 2 ADP Test Bed Subtask WBS 2. 5. 2. 2. 2 CBM System Development (Cont) Integration of ADP/Network/ICAS New Installation Console I/O PLC Direct Connection ADP Network Connection PLC Typical Core HUB 3 Network PLC HUB 6 HUB 2 HUB 4 PLC I/O HUB 1 I/O I/O New Installation Server ICAS HUB 5 HMI Server HMI Console Vent Fans 24

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 3 Laboratory Testing Lab Testing Description (Sept’ 04 -Mar’ 05) Ø Accomplishments Ø Target Demonstration Platform Ø Identified, procured, and have tested fan sensors and data acquisition software to ensure reliability Ø Developed test plans and procedures and have tested the ADP sensors and support equipment. Ø Developed test plans and procedures and have tested the integration of the ADP with ICAS and the network infrastructure Ø Next Quarter Ø Adapting NGNN ADP system for target systems based on the NSWCCD Implementing the findings of the NSWC Fan Failure Analysis Report in the ADP code Ø Demonstrate / test the ADP diagnostics/prognostics capabilities 25

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 3 Laboratory Testing Lab Testing Description (Sept’ 04 -Mar’ 05) Ø Accomplishments Ø Target Demonstration Platform Ø Identified, procured, and have tested fan sensors and data acquisition software to ensure reliability Ø Developed test plans and procedures and have tested the ADP sensors and support equipment. Ø Developed test plans and procedures and have tested the integration of the ADP with ICAS and the network infrastructure Ø Next Quarter Ø Adapting NGNN ADP system for target systems based on the NSWCCD Implementing the findings of the NSWC Fan Failure Analysis Report in the ADP code Ø Demonstrate / test the ADP diagnostics/prognostics capabilities 25

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 3 Laboratory Testing Lab Testing Description (continued) Ø Next Quarter Ø Documentation of test results Ø Status: 75% complete Ø Deliverable: ADP Lab Demonstration – March 05 26

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 3 Laboratory Testing Lab Testing Description (continued) Ø Next Quarter Ø Documentation of test results Ø Status: 75% complete Ø Deliverable: ADP Lab Demonstration – March 05 26

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 4 Ship Installation and Testing Ø Shipboard Installation and Initial Testing (Jan’ 05 -Jul’ 05) Ø Overview The ADP will acquire data from four representative vane-axial fans in relatively close proximity to each other to minimize installation costs for the project. Installation will be accomplished on CVN 73 during the January-December scheduled availability. The ADP will be connected via the shipboard network to ICAS where diagnostic and prognostic vent fan information will be displayed to the operator. We are expecting installation to be completed in the June – July time frame. 27

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 4 Ship Installation and Testing Ø Shipboard Installation and Initial Testing (Jan’ 05 -Jul’ 05) Ø Overview The ADP will acquire data from four representative vane-axial fans in relatively close proximity to each other to minimize installation costs for the project. Installation will be accomplished on CVN 73 during the January-December scheduled availability. The ADP will be connected via the shipboard network to ICAS where diagnostic and prognostic vent fan information will be displayed to the operator. We are expecting installation to be completed in the June – July time frame. 27

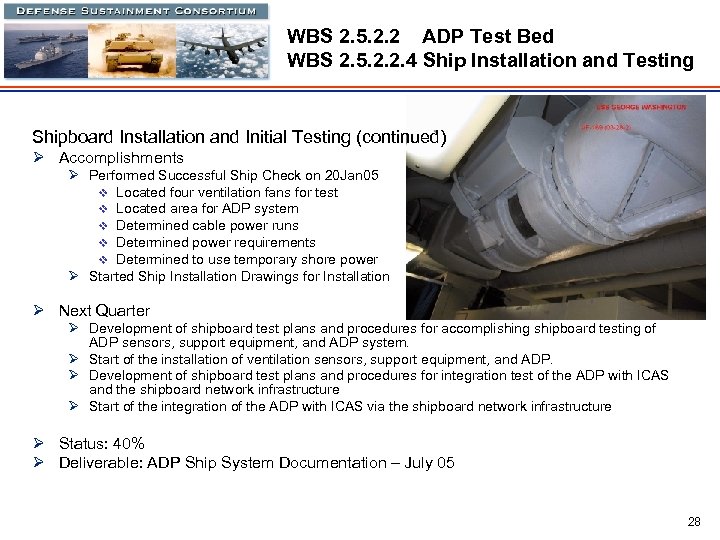

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 4 Ship Installation and Testing Shipboard Installation and Initial Testing (continued) Ø Accomplishments Ø Performed Successful Ship Check on 20 Jan 05 v Located four ventilation fans for test v Located area for ADP system v Determined cable power runs v Determined power requirements v Determined to use temporary shore power Ø Started Ship Installation Drawings for Installation Ø Next Quarter Ø Development of shipboard test plans and procedures for accomplishing shipboard testing of ADP sensors, support equipment, and ADP system. Ø Start of the installation of ventilation sensors, support equipment, and ADP. Ø Development of shipboard test plans and procedures for integration test of the ADP with ICAS and the shipboard network infrastructure Ø Start of the integration of the ADP with ICAS via the shipboard network infrastructure Ø Status: 40% Ø Deliverable: ADP Ship System Documentation – July 05 28

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 4 Ship Installation and Testing Shipboard Installation and Initial Testing (continued) Ø Accomplishments Ø Performed Successful Ship Check on 20 Jan 05 v Located four ventilation fans for test v Located area for ADP system v Determined cable power runs v Determined power requirements v Determined to use temporary shore power Ø Started Ship Installation Drawings for Installation Ø Next Quarter Ø Development of shipboard test plans and procedures for accomplishing shipboard testing of ADP sensors, support equipment, and ADP system. Ø Start of the installation of ventilation sensors, support equipment, and ADP. Ø Development of shipboard test plans and procedures for integration test of the ADP with ICAS and the shipboard network infrastructure Ø Start of the integration of the ADP with ICAS via the shipboard network infrastructure Ø Status: 40% Ø Deliverable: ADP Ship System Documentation – July 05 28

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 5 Demonstration Ship Board Demonstration (June 05 – Dec 05) Ø Monitor the ability of the system to pass any maintenance conditions to ICAS. Ø After 3 months visit the ship and examine ADP/ICAS. Ø After 6 month period v review data to confirm the existence or non-existence of failures or problems v determine if fan parts usage aligns with ADP fault identification v In the event of no failures or problems with the selected fans, implement failure simulation test procedures Ø Simulation Plan Ø Development of test plans and procedures for accomplishing shipboard simulation testing of ADP sensors, support equipment, and ADP system. Ø Stimulate maintenance faults/problems through sensor stimulation and/or through software and determine the ability of the system to pass these maintenance conditions to ICAS. Ø Document demonstration results. Ø Status: 0% Not started 29

WBS 2. 5. 2. 2 ADP Test Bed WBS 2. 5. 2. 2. 5 Demonstration Ship Board Demonstration (June 05 – Dec 05) Ø Monitor the ability of the system to pass any maintenance conditions to ICAS. Ø After 3 months visit the ship and examine ADP/ICAS. Ø After 6 month period v review data to confirm the existence or non-existence of failures or problems v determine if fan parts usage aligns with ADP fault identification v In the event of no failures or problems with the selected fans, implement failure simulation test procedures Ø Simulation Plan Ø Development of test plans and procedures for accomplishing shipboard simulation testing of ADP sensors, support equipment, and ADP system. Ø Stimulate maintenance faults/problems through sensor stimulation and/or through software and determine the ability of the system to pass these maintenance conditions to ICAS. Ø Document demonstration results. Ø Status: 0% Not started 29

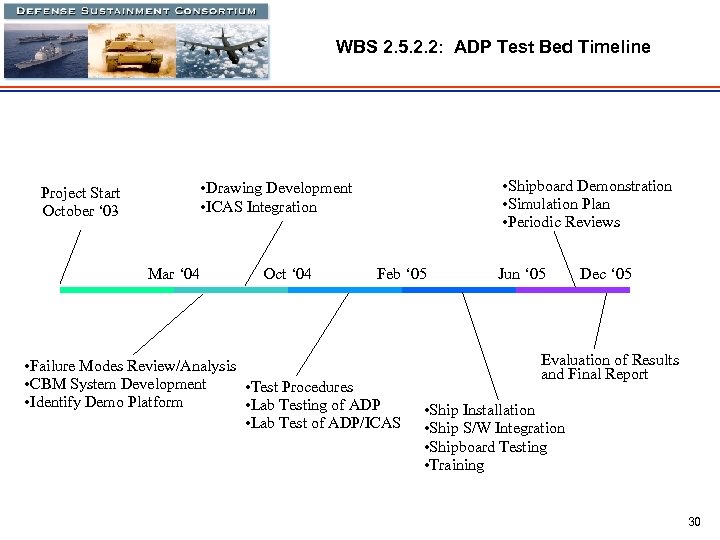

WBS 2. 5. 2. 2: ADP Test Bed Timeline • Shipboard Demonstration • Simulation Plan • Periodic Reviews • Drawing Development • ICAS Integration Project Start October ‘ 03 Mar ‘ 04 Oct ‘ 04 Feb ‘ 05 • Failure Modes Review/Analysis • CBM System Development • Test Procedures • Identify Demo Platform • Lab Testing of ADP • Lab Test of ADP/ICAS Jun ‘ 05 Dec ‘ 05 Evaluation of Results and Final Report • Ship Installation • Ship S/W Integration • Shipboard Testing • Training 30

WBS 2. 5. 2. 2: ADP Test Bed Timeline • Shipboard Demonstration • Simulation Plan • Periodic Reviews • Drawing Development • ICAS Integration Project Start October ‘ 03 Mar ‘ 04 Oct ‘ 04 Feb ‘ 05 • Failure Modes Review/Analysis • CBM System Development • Test Procedures • Identify Demo Platform • Lab Testing of ADP • Lab Test of ADP/ICAS Jun ‘ 05 Dec ‘ 05 Evaluation of Results and Final Report • Ship Installation • Ship S/W Integration • Shipboard Testing • Training 30

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 31

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 31

Task 3: Test Bed Demonstration 2 – Automated Fault Data Reporting Assessment System (AFDRAS) Ø Goals: Ø Construct a demonstrator to show the ability to collect, interpret, and store data acquired during weapon system (HERCULES) diagnostics and maintenance. Ø Show that stored data is useful for off-system assessment databases or other logistical support functions (CBM+). Ø Integrate data acquisition with the troubleshooting process so that data is collected during maintenance and formatted for transmission to a central database. 32

Task 3: Test Bed Demonstration 2 – Automated Fault Data Reporting Assessment System (AFDRAS) Ø Goals: Ø Construct a demonstrator to show the ability to collect, interpret, and store data acquired during weapon system (HERCULES) diagnostics and maintenance. Ø Show that stored data is useful for off-system assessment databases or other logistical support functions (CBM+). Ø Integrate data acquisition with the troubleshooting process so that data is collected during maintenance and formatted for transmission to a central database. 32

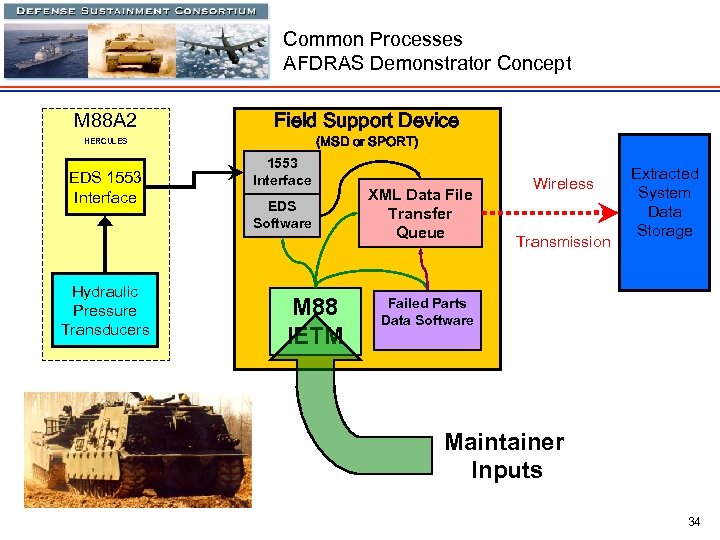

Common Processes AFDRAS Demonstrator Concept Ø Use current IETM software. Ø Use current Enhanced Diagnostic System (EDS) hardware and software. The EDS software will require some changes to record the necessary data. Ø Develop additional software to enable maintainer to record parts information data. Ø Develop software to format data into an XML tagged format for wireless transmission from the field support device. 33

Common Processes AFDRAS Demonstrator Concept Ø Use current IETM software. Ø Use current Enhanced Diagnostic System (EDS) hardware and software. The EDS software will require some changes to record the necessary data. Ø Develop additional software to enable maintainer to record parts information data. Ø Develop software to format data into an XML tagged format for wireless transmission from the field support device. 33

Common Processes AFDRAS Demonstrator Concept M 88 A 2 Field Support Device (MSD or SPORT) HERCULES EDS 1553 Interface Hydraulic Pressure Transducers 1553 Interface EDS Software M 88 IETM XML Data File Transfer Queue Wireless Transmission Extracted System Data Storage Failed Parts Data Software Maintainer Inputs 34

Common Processes AFDRAS Demonstrator Concept M 88 A 2 Field Support Device (MSD or SPORT) HERCULES EDS 1553 Interface Hydraulic Pressure Transducers 1553 Interface EDS Software M 88 IETM XML Data File Transfer Queue Wireless Transmission Extracted System Data Storage Failed Parts Data Software Maintainer Inputs 34

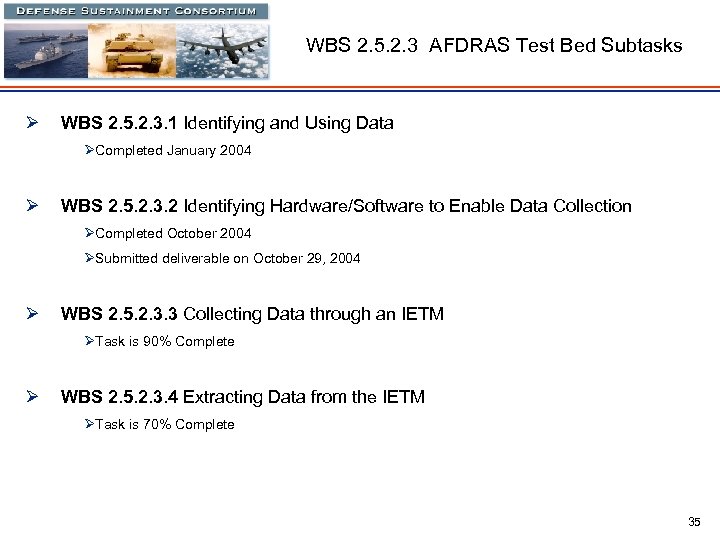

WBS 2. 5. 2. 3 AFDRAS Test Bed Subtasks Ø WBS 2. 5. 2. 3. 1 Identifying and Using Data ØCompleted January 2004 Ø WBS 2. 5. 2. 3. 2 Identifying Hardware/Software to Enable Data Collection ØCompleted October 2004 ØSubmitted deliverable on October 29, 2004 Ø WBS 2. 5. 2. 3. 3 Collecting Data through an IETM ØTask is 90% Complete Ø WBS 2. 5. 2. 3. 4 Extracting Data from the IETM ØTask is 70% Complete 35

WBS 2. 5. 2. 3 AFDRAS Test Bed Subtasks Ø WBS 2. 5. 2. 3. 1 Identifying and Using Data ØCompleted January 2004 Ø WBS 2. 5. 2. 3. 2 Identifying Hardware/Software to Enable Data Collection ØCompleted October 2004 ØSubmitted deliverable on October 29, 2004 Ø WBS 2. 5. 2. 3. 3 Collecting Data through an IETM ØTask is 90% Complete Ø WBS 2. 5. 2. 3. 4 Extracting Data from the IETM ØTask is 70% Complete 35

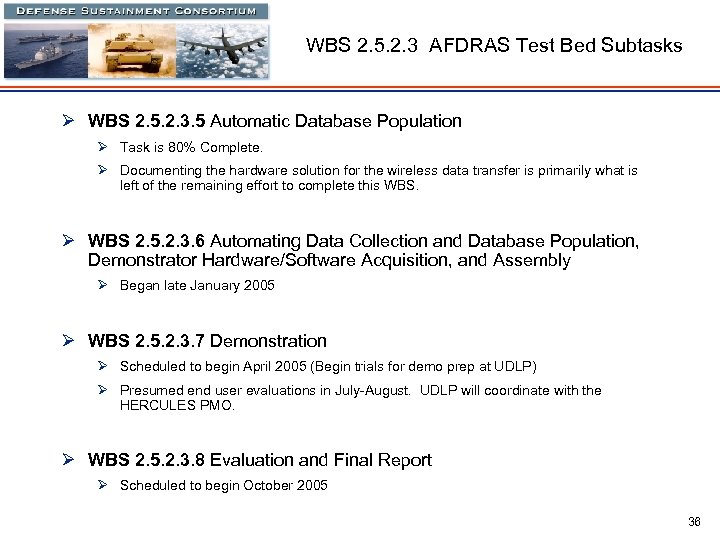

WBS 2. 5. 2. 3 AFDRAS Test Bed Subtasks Ø WBS 2. 5. 2. 3. 5 Automatic Database Population Ø Task is 80% Complete. Ø Documenting the hardware solution for the wireless data transfer is primarily what is left of the remaining effort to complete this WBS. Ø WBS 2. 5. 2. 3. 6 Automating Data Collection and Database Population, Demonstrator Hardware/Software Acquisition, and Assembly Ø Began late January 2005 Ø WBS 2. 5. 2. 3. 7 Demonstration Ø Scheduled to begin April 2005 (Begin trials for demo prep at UDLP) Ø Presumed end user evaluations in July-August. UDLP will coordinate with the HERCULES PMO. Ø WBS 2. 5. 2. 3. 8 Evaluation and Final Report Ø Scheduled to begin October 2005 36

WBS 2. 5. 2. 3 AFDRAS Test Bed Subtasks Ø WBS 2. 5. 2. 3. 5 Automatic Database Population Ø Task is 80% Complete. Ø Documenting the hardware solution for the wireless data transfer is primarily what is left of the remaining effort to complete this WBS. Ø WBS 2. 5. 2. 3. 6 Automating Data Collection and Database Population, Demonstrator Hardware/Software Acquisition, and Assembly Ø Began late January 2005 Ø WBS 2. 5. 2. 3. 7 Demonstration Ø Scheduled to begin April 2005 (Begin trials for demo prep at UDLP) Ø Presumed end user evaluations in July-August. UDLP will coordinate with the HERCULES PMO. Ø WBS 2. 5. 2. 3. 8 Evaluation and Final Report Ø Scheduled to begin October 2005 36

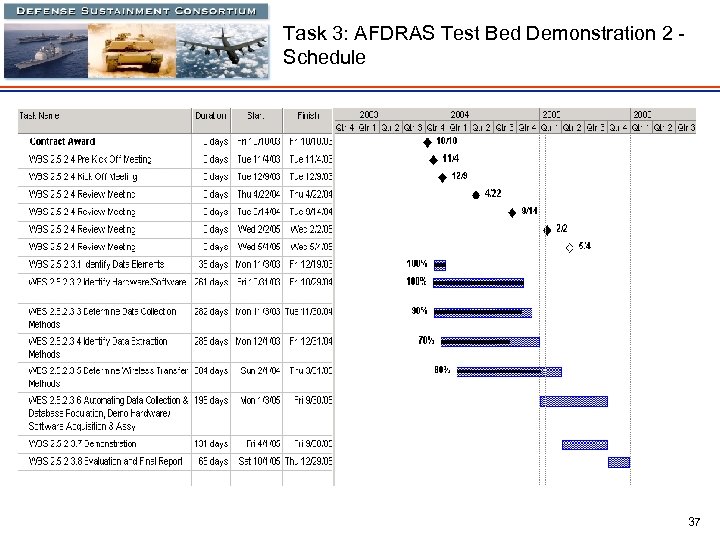

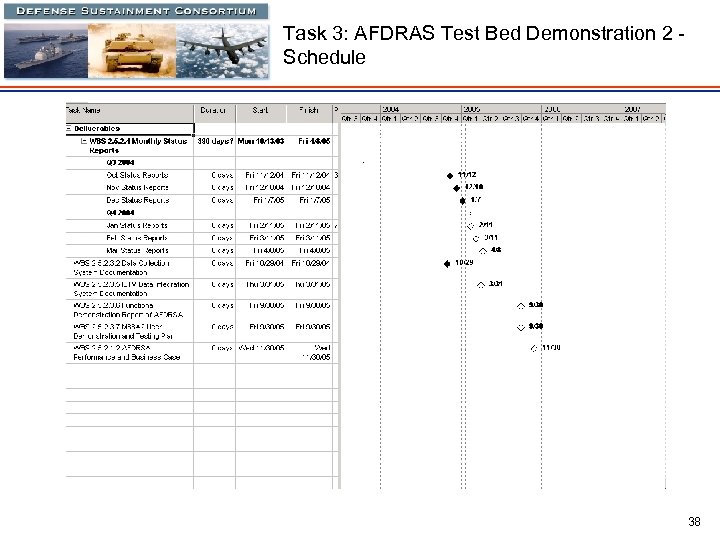

Task 3: AFDRAS Test Bed Demonstration 2 Schedule 37

Task 3: AFDRAS Test Bed Demonstration 2 Schedule 37

Task 3: AFDRAS Test Bed Demonstration 2 Schedule 38

Task 3: AFDRAS Test Bed Demonstration 2 Schedule 38

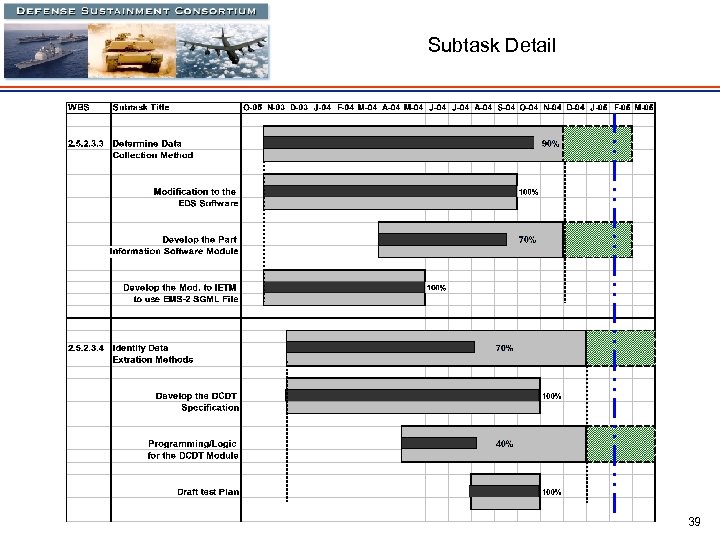

Subtask Detail 39

Subtask Detail 39

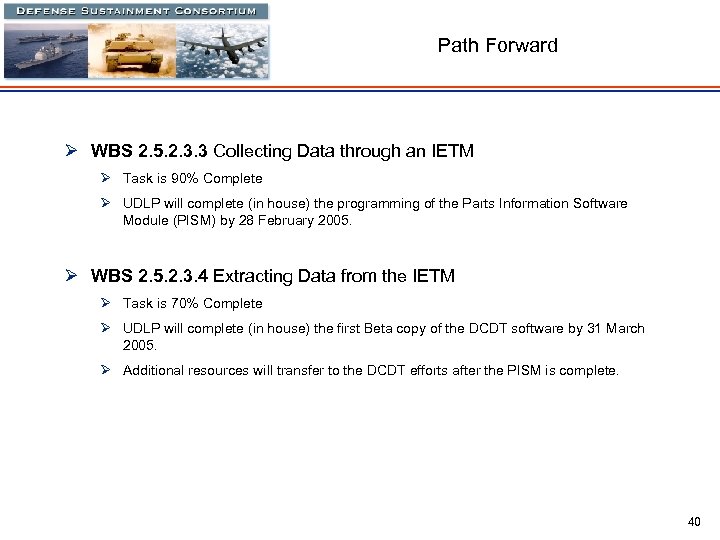

Path Forward Ø WBS 2. 5. 2. 3. 3 Collecting Data through an IETM Ø Task is 90% Complete Ø UDLP will complete (in house) the programming of the Parts Information Software Module (PISM) by 28 February 2005. Ø WBS 2. 5. 2. 3. 4 Extracting Data from the IETM Ø Task is 70% Complete Ø UDLP will complete (in house) the first Beta copy of the DCDT software by 31 March 2005. Ø Additional resources will transfer to the DCDT efforts after the PISM is complete. 40

Path Forward Ø WBS 2. 5. 2. 3. 3 Collecting Data through an IETM Ø Task is 90% Complete Ø UDLP will complete (in house) the programming of the Parts Information Software Module (PISM) by 28 February 2005. Ø WBS 2. 5. 2. 3. 4 Extracting Data from the IETM Ø Task is 70% Complete Ø UDLP will complete (in house) the first Beta copy of the DCDT software by 31 March 2005. Ø Additional resources will transfer to the DCDT efforts after the PISM is complete. 40

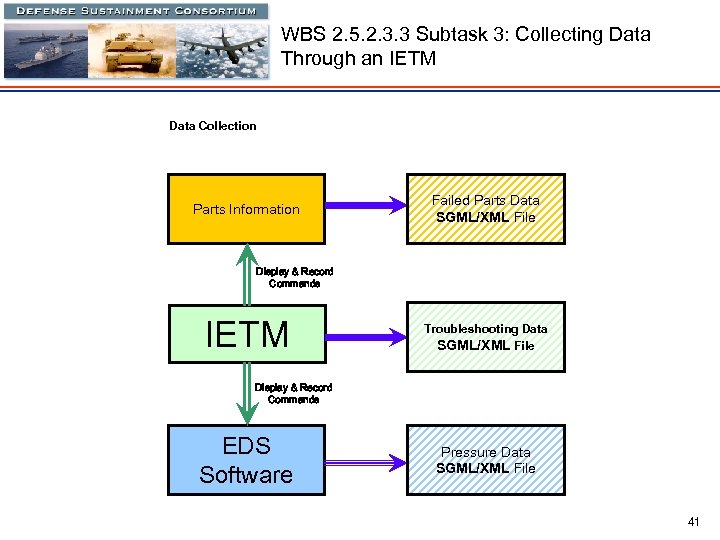

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Data Collection Parts Information Failed Parts Data SGML/XML File Display & Record Commands IETM Troubleshooting Data SGML/XML File Display & Record Commands EDS Software Pressure Data SGML/XML File 41

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Data Collection Parts Information Failed Parts Data SGML/XML File Display & Record Commands IETM Troubleshooting Data SGML/XML File Display & Record Commands EDS Software Pressure Data SGML/XML File 41

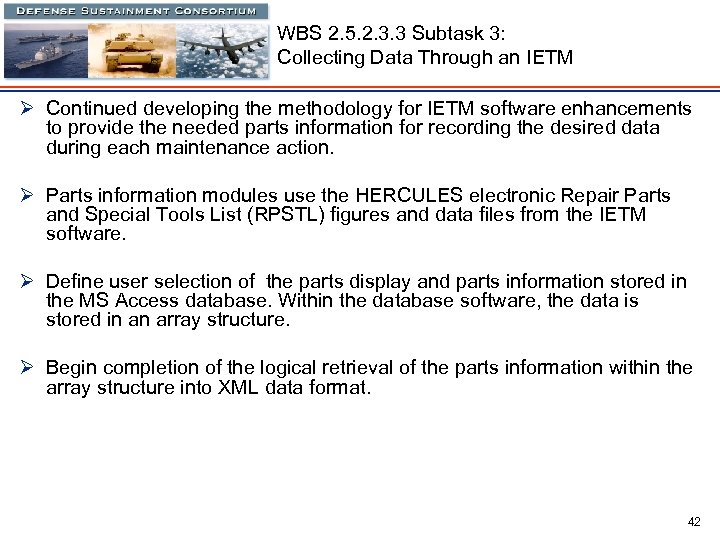

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Ø Continued developing the methodology for IETM software enhancements to provide the needed parts information for recording the desired data during each maintenance action. Ø Parts information modules use the HERCULES electronic Repair Parts and Special Tools List (RPSTL) figures and data files from the IETM software. Ø Define user selection of the parts display and parts information stored in the MS Access database. Within the database software, the data is stored in an array structure. Ø Begin completion of the logical retrieval of the parts information within the array structure into XML data format. 42

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Ø Continued developing the methodology for IETM software enhancements to provide the needed parts information for recording the desired data during each maintenance action. Ø Parts information modules use the HERCULES electronic Repair Parts and Special Tools List (RPSTL) figures and data files from the IETM software. Ø Define user selection of the parts display and parts information stored in the MS Access database. Within the database software, the data is stored in an array structure. Ø Begin completion of the logical retrieval of the parts information within the array structure into XML data format. 42

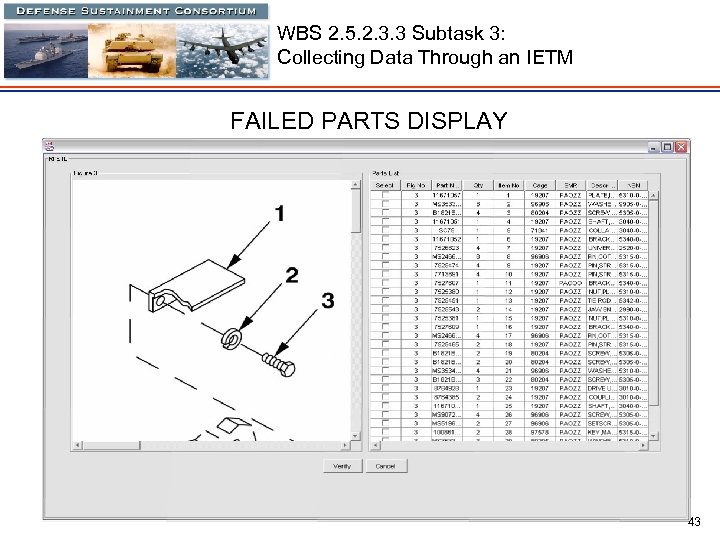

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DISPLAY 43

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DISPLAY 43

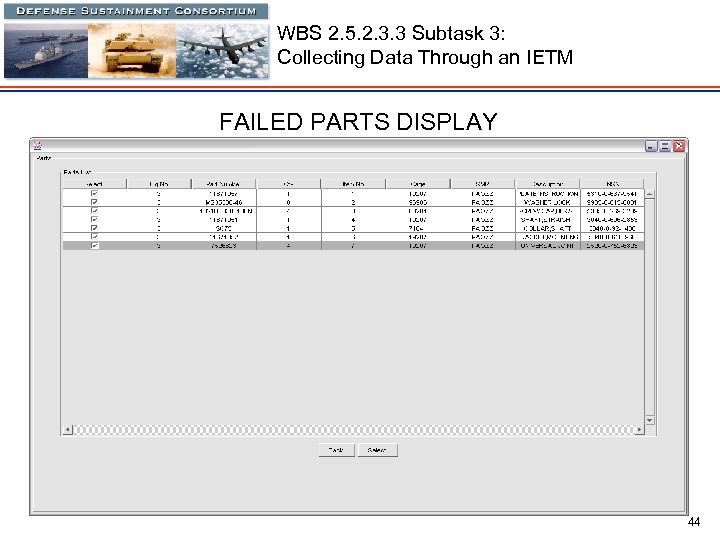

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DISPLAY 44

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DISPLAY 44

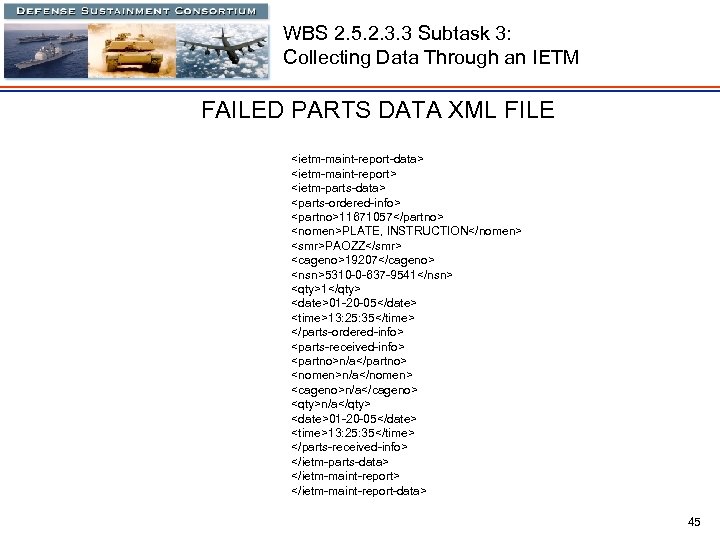

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DATA XML FILE

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM FAILED PARTS DATA XML FILE

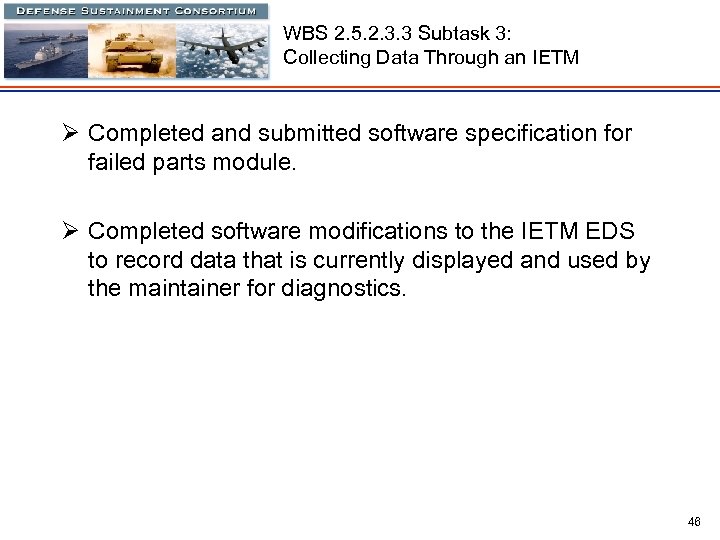

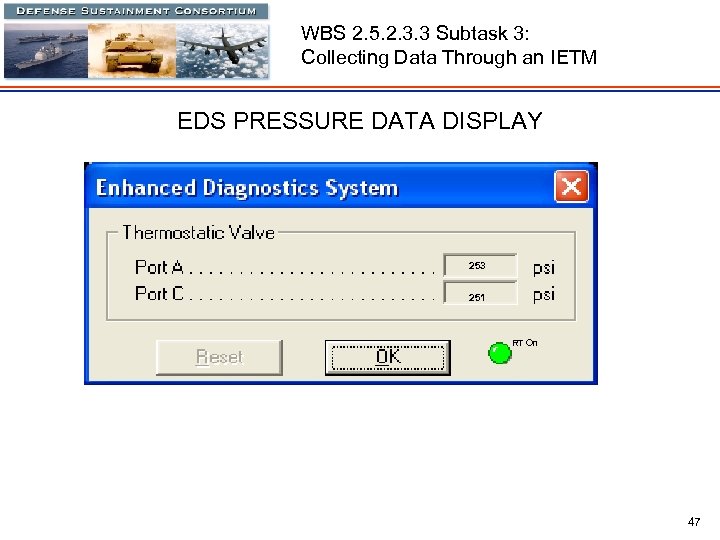

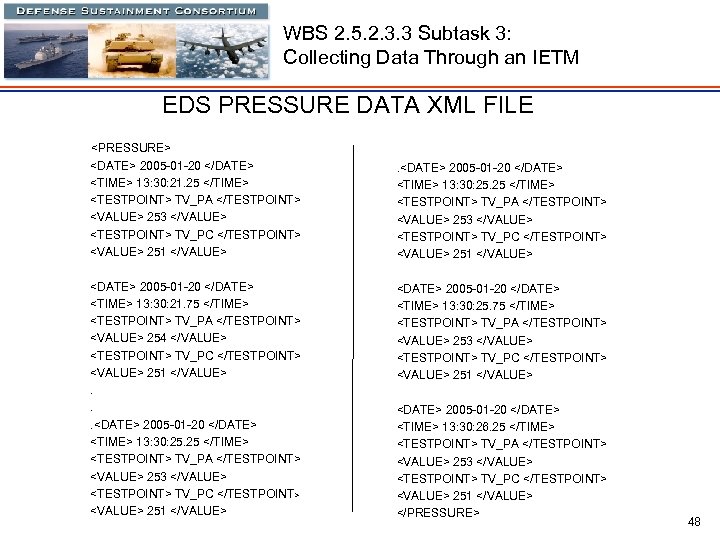

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Ø Completed and submitted software specification for failed parts module. Ø Completed software modifications to the IETM EDS to record data that is currently displayed and used by the maintainer for diagnostics. 46

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM Ø Completed and submitted software specification for failed parts module. Ø Completed software modifications to the IETM EDS to record data that is currently displayed and used by the maintainer for diagnostics. 46

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM EDS PRESSURE DATA DISPLAY 253 251 RT On 47

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM EDS PRESSURE DATA DISPLAY 253 251 RT On 47

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM EDS PRESSURE DATA XML FILE

WBS 2. 5. 2. 3. 3 Subtask 3: Collecting Data Through an IETM EDS PRESSURE DATA XML FILE

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing(Extracting) Data Through an IETM Ø Completed software development that extracts troubleshooting and maintenance action information using the SGML file produced by the IETM. Ø Completed specification for the DCDT software which was submitted as part of the UDLP Common Processes Phase 1 Data Collection System Documentation on October 29, 2004. 49

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing(Extracting) Data Through an IETM Ø Completed software development that extracts troubleshooting and maintenance action information using the SGML file produced by the IETM. Ø Completed specification for the DCDT software which was submitted as part of the UDLP Common Processes Phase 1 Data Collection System Documentation on October 29, 2004. 49

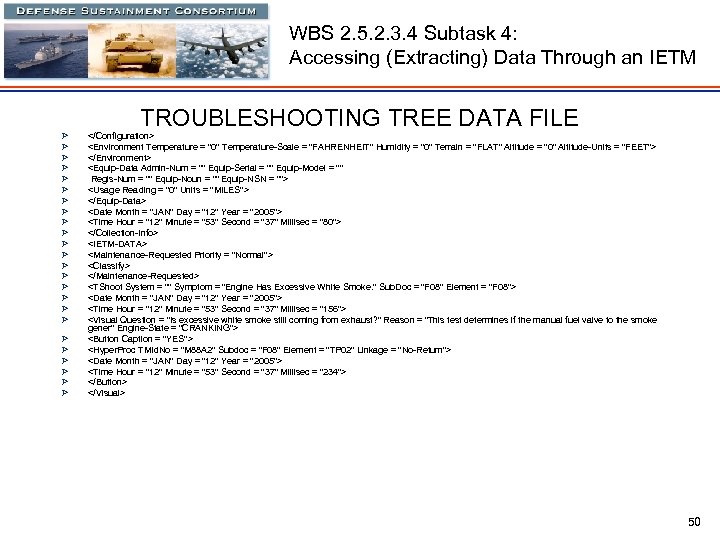

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM Ø Ø Ø Ø Ø Ø TROUBLESHOOTING TREE DATA FILE

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM Ø Ø Ø Ø Ø Ø TROUBLESHOOTING TREE DATA FILE

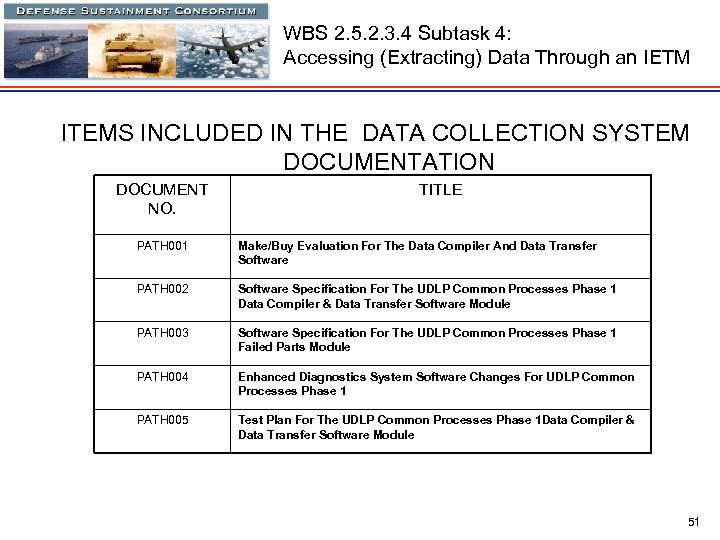

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM ITEMS INCLUDED IN THE DATA COLLECTION SYSTEM DOCUMENTATION DOCUMENT NO. TITLE PATH 001 Make/Buy Evaluation For The Data Compiler And Data Transfer Software PATH 002 Software Specification For The UDLP Common Processes Phase 1 Data Compiler & Data Transfer Software Module PATH 003 Software Specification For The UDLP Common Processes Phase 1 Failed Parts Module PATH 004 Enhanced Diagnostics System Software Changes For UDLP Common Processes Phase 1 PATH 005 Test Plan For The UDLP Common Processes Phase 1 Data Compiler & Data Transfer Software Module 51

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM ITEMS INCLUDED IN THE DATA COLLECTION SYSTEM DOCUMENTATION DOCUMENT NO. TITLE PATH 001 Make/Buy Evaluation For The Data Compiler And Data Transfer Software PATH 002 Software Specification For The UDLP Common Processes Phase 1 Data Compiler & Data Transfer Software Module PATH 003 Software Specification For The UDLP Common Processes Phase 1 Failed Parts Module PATH 004 Enhanced Diagnostics System Software Changes For UDLP Common Processes Phase 1 PATH 005 Test Plan For The UDLP Common Processes Phase 1 Data Compiler & Data Transfer Software Module 51

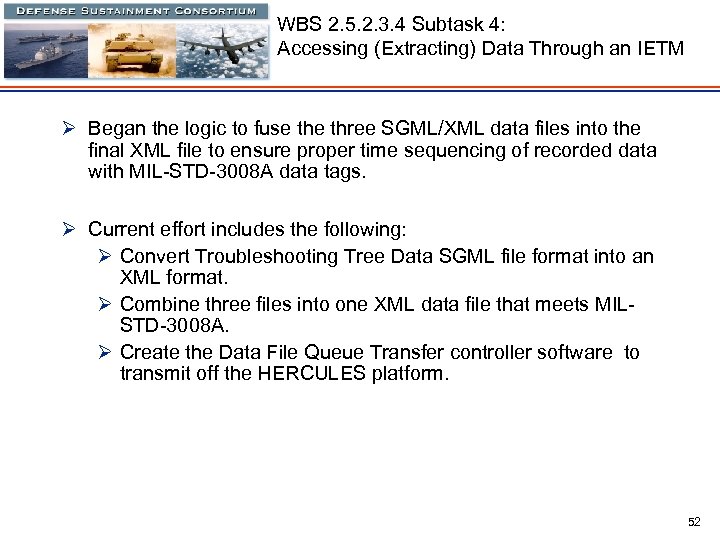

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM Ø Began the logic to fuse three SGML/XML data files into the final XML file to ensure proper time sequencing of recorded data with MIL-STD-3008 A data tags. Ø Current effort includes the following: Ø Convert Troubleshooting Tree Data SGML file format into an XML format. Ø Combine three files into one XML data file that meets MILSTD-3008 A. Ø Create the Data File Queue Transfer controller software to transmit off the HERCULES platform. 52

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM Ø Began the logic to fuse three SGML/XML data files into the final XML file to ensure proper time sequencing of recorded data with MIL-STD-3008 A data tags. Ø Current effort includes the following: Ø Convert Troubleshooting Tree Data SGML file format into an XML format. Ø Combine three files into one XML data file that meets MILSTD-3008 A. Ø Create the Data File Queue Transfer controller software to transmit off the HERCULES platform. 52

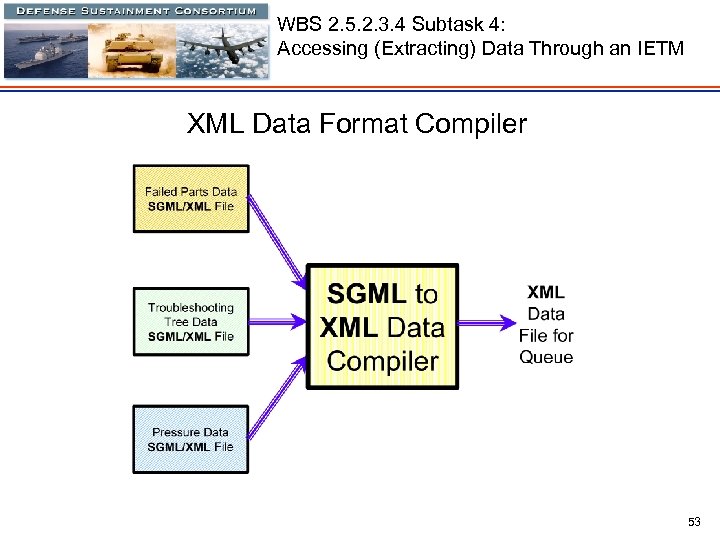

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM XML Data Format Compiler 53

WBS 2. 5. 2. 3. 4 Subtask 4: Accessing (Extracting) Data Through an IETM XML Data Format Compiler 53

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Continued development of alternative solutions to the contract requirements for the trade study evaluation. This trade study will be used to determine the optimal solution to automatically transfer the data to populate a database. Some options are: v Cellular Data Link. v 802. 11 b Wireless Ethernet. Ø Developed software plan for implementation of automated data transfer requirements that is addressed in the DCDT specification Ø Submitted software test plan as part of the UDLP Common Processes Phase 1 Data Collection System Documentation. 54

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Continued development of alternative solutions to the contract requirements for the trade study evaluation. This trade study will be used to determine the optimal solution to automatically transfer the data to populate a database. Some options are: v Cellular Data Link. v 802. 11 b Wireless Ethernet. Ø Developed software plan for implementation of automated data transfer requirements that is addressed in the DCDT specification Ø Submitted software test plan as part of the UDLP Common Processes Phase 1 Data Collection System Documentation. 54

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Cellular Data Link Ø Reviewed the Wireless Application Protocol (WAP) specification WAP-210 WAPArch. 20010712 and Wireless Application Environment Specification WAP -25 -WAEspec-20020207. Ø Architecture and standards created for wireless communication. Ø Architecture and standards enable data transport primarily aimed at wireless telecommunication industry but include other wireless applications. Ø The architecture optimizes the content and air-link protocols. Utilizes HTTP servers and standard XML mark up language technology. Ø The architecture can be achieved by using Java language, ASP or any scripting language. Ø Issues: v Architecture is immature in evolving wireless technology. v No architecture and or system requirements are available from the Army. v Integrity/Reliability/Portability. v Wireless Network Types. 55

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Cellular Data Link Ø Reviewed the Wireless Application Protocol (WAP) specification WAP-210 WAPArch. 20010712 and Wireless Application Environment Specification WAP -25 -WAEspec-20020207. Ø Architecture and standards created for wireless communication. Ø Architecture and standards enable data transport primarily aimed at wireless telecommunication industry but include other wireless applications. Ø The architecture optimizes the content and air-link protocols. Utilizes HTTP servers and standard XML mark up language technology. Ø The architecture can be achieved by using Java language, ASP or any scripting language. Ø Issues: v Architecture is immature in evolving wireless technology. v No architecture and or system requirements are available from the Army. v Integrity/Reliability/Portability. v Wireless Network Types. 55

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø 802. 11 b Wireless Ethernet Ø Architecture with respect to range and capability is adequate for the demonstration. Ø Technology is mature and readily available. Ø DCDT software and hardware solutions and cost are favorable to the program budget. 56

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø 802. 11 b Wireless Ethernet Ø Architecture with respect to range and capability is adequate for the demonstration. Ø Technology is mature and readily available. Ø DCDT software and hardware solutions and cost are favorable to the program budget. 56

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Next Quarter: Ø Subtask 3: v Complete development of information retrieval within the software data array structure for the parts information module. Ø Subtask 4: v Complete the DCDT software Ø Subtask 5: v Finalize and verify DCDT software and test plan v Finalize hardware solutions 57

WBS 2. 5. 2. 3. 5 Subtask 5: Automatic Database Population Ø Next Quarter: Ø Subtask 3: v Complete development of information retrieval within the software data array structure for the parts information module. Ø Subtask 4: v Complete the DCDT software Ø Subtask 5: v Finalize and verify DCDT software and test plan v Finalize hardware solutions 57

Path Forward – Business Opportunities Ø Target Customer Support and Commitment Ø HERCULES PMO Assistance v The HERCULES PM has designated the ILS Manager to support the AFDRAS efforts. HERCULES – Heavy Equipment Recovery Combat Utility and Lift Evacuation System Ø FCS Technology Insertion v Identify opportunities where the AFDRAS can be applied to FCS Spirals for current or future force technology insertion. 58

Path Forward – Business Opportunities Ø Target Customer Support and Commitment Ø HERCULES PMO Assistance v The HERCULES PM has designated the ILS Manager to support the AFDRAS efforts. HERCULES – Heavy Equipment Recovery Combat Utility and Lift Evacuation System Ø FCS Technology Insertion v Identify opportunities where the AFDRAS can be applied to FCS Spirals for current or future force technology insertion. 58

HERCULES PMO Assistance Ø Actively participates in key AFDRAS decisions (eg. Assisted in identification of recorded fields) Ø Designate an M 88 A 2 equipped with an EDS for the demonstration and test trials. Ø Provide customer evaluation and user feedback on demonstration results. Arrange end user test at Fort Knox. Ø Evaluate benefits of future fielding of the AFDRAS system embedded with HERCULES IETMs. 59

HERCULES PMO Assistance Ø Actively participates in key AFDRAS decisions (eg. Assisted in identification of recorded fields) Ø Designate an M 88 A 2 equipped with an EDS for the demonstration and test trials. Ø Provide customer evaluation and user feedback on demonstration results. Arrange end user test at Fort Knox. Ø Evaluate benefits of future fielding of the AFDRAS system embedded with HERCULES IETMs. 59

FCS Technology Insertion Ø AFDRAS can be used to add capability to current or future force vehicles through the FCS Logistic Decision Support System (LDSS) or similar system. Ø Conducted discussions with Boeing in St. Louis, the Lead System Integrators (LSI), regarding possible applications with current force upgrades. Ø UDLP personnel actively participate in a number of IPTs involved with the development of the FCS Support Systems to provide opportunities for us to offer AFDRAS compatibility and portability for future customer applications. 60

FCS Technology Insertion Ø AFDRAS can be used to add capability to current or future force vehicles through the FCS Logistic Decision Support System (LDSS) or similar system. Ø Conducted discussions with Boeing in St. Louis, the Lead System Integrators (LSI), regarding possible applications with current force upgrades. Ø UDLP personnel actively participate in a number of IPTs involved with the development of the FCS Support Systems to provide opportunities for us to offer AFDRAS compatibility and portability for future customer applications. 60

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 61

Common Processes Agenda Description Presenter Introduction – Objectives Holcomb Metrics/Common Tasks Vander. Bok ADP Test Bed Demonstration Major AFDRAS Test Bed Demonstration Miller Project Financials Holcomb 61

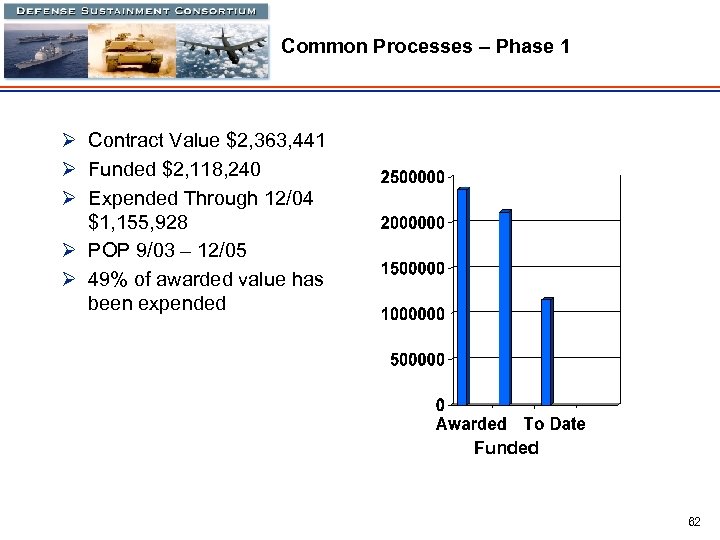

Common Processes – Phase 1 Ø Contract Value $2, 363, 441 Ø Funded $2, 118, 240 Ø Expended Through 12/04 $1, 155, 928 Ø POP 9/03 – 12/05 Ø 49% of awarded value has been expended Funded 62

Common Processes – Phase 1 Ø Contract Value $2, 363, 441 Ø Funded $2, 118, 240 Ø Expended Through 12/04 $1, 155, 928 Ø POP 9/03 – 12/05 Ø 49% of awarded value has been expended Funded 62

Defense Sustainment Consortium Project 6: Common Processes Discussion 63

Defense Sustainment Consortium Project 6: Common Processes Discussion 63