Defense Logistics Agency Latin America Mercury Storage Project Inception Workshop April 22, 2009 Dennis M. Lynch, Environmental Protection Specialist Defense National Stockpile Center Warfighter Support Stewardship Improvements Business Process Refinements Workforce Development

Defense Logistics Agency Latin America Mercury Storage Project Inception Workshop April 22, 2009 Dennis M. Lynch, Environmental Protection Specialist Defense National Stockpile Center Warfighter Support Stewardship Improvements Business Process Refinements Workforce Development

AGENDA • • • DNSC Mercury Inventory DNSC Mercury Sales History DNSC Mercury Stockpile Stewardship Program Former Storage Method Mercury Safety Initiatives – 2002 & 2007 Reaching a Mercury Decision Storage Preparations at Hawthorne Army Depot Storage Costs Transport to Nevada

AGENDA • • • DNSC Mercury Inventory DNSC Mercury Sales History DNSC Mercury Stockpile Stewardship Program Former Storage Method Mercury Safety Initiatives – 2002 & 2007 Reaching a Mercury Decision Storage Preparations at Hawthorne Army Depot Storage Costs Transport to Nevada

Defense National Stockpile Center Mercury Inventory Commodity grade elemental mercury 4, 436 metric tons stockpiled – Somerville, New Jersey – Warren, Ohio – New Haven, Indiana 2, 617 MT 1, 262 MT 557 MT Safely stored for over 50 years – Sales discontinued in 1994 ISO 14001: 2004 certificate

Defense National Stockpile Center Mercury Inventory Commodity grade elemental mercury 4, 436 metric tons stockpiled – Somerville, New Jersey – Warren, Ohio – New Haven, Indiana 2, 617 MT 1, 262 MT 557 MT Safely stored for over 50 years – Sales discontinued in 1994 ISO 14001: 2004 certificate

Defense National Stockpile Center Mercury Sales History • DNSC sold more than 50, 000 flasks of mercury during period 1979 – 1994. • Sales were suspended in 1994 after concerns were expressed by members of Congress and the US Environmental Protection Agency. • Mercury was sold to brokers and metals dealers, and was transferred as payment-in-kind for companies involved in upgrading other stockpile commodities.

Defense National Stockpile Center Mercury Sales History • DNSC sold more than 50, 000 flasks of mercury during period 1979 – 1994. • Sales were suspended in 1994 after concerns were expressed by members of Congress and the US Environmental Protection Agency. • Mercury was sold to brokers and metals dealers, and was transferred as payment-in-kind for companies involved in upgrading other stockpile commodities.

DNSC Mercury Stockpile Stewardship Program • The services of Oak Ridge National Laboratory (ORNL) obtained in 2007. – Very respected science and technology laboratory with a great mercury knowledge base. • ORNL’s research produced quality recommendations for the safe storage of elemental mercury for up to 40 years – Technology included ultrasonic testing, radiography, and flask weld inspections. – Developed a protocol for periodic drum inspections – Evaluated the expected integrity of the existing flasks over the extended storage period – Evaluated the expected integrity over-pack drums over the extended storage period

DNSC Mercury Stockpile Stewardship Program • The services of Oak Ridge National Laboratory (ORNL) obtained in 2007. – Very respected science and technology laboratory with a great mercury knowledge base. • ORNL’s research produced quality recommendations for the safe storage of elemental mercury for up to 40 years – Technology included ultrasonic testing, radiography, and flask weld inspections. – Developed a protocol for periodic drum inspections – Evaluated the expected integrity of the existing flasks over the extended storage period – Evaluated the expected integrity over-pack drums over the extended storage period

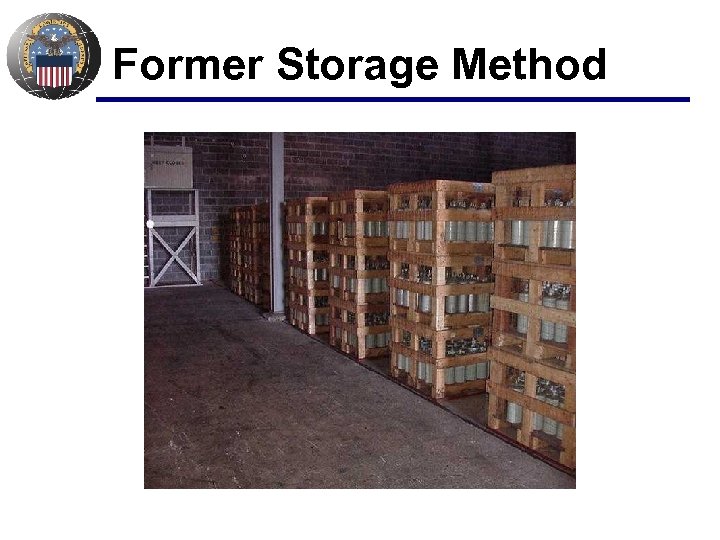

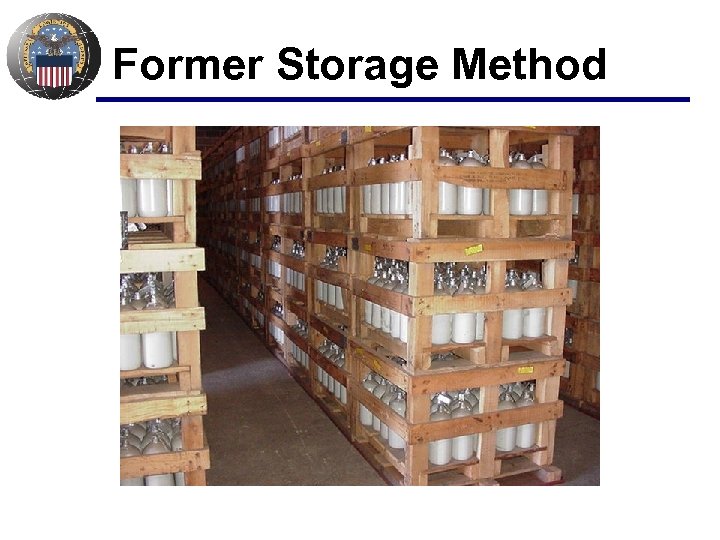

Former Storage Method

Former Storage Method

Former Storage Method

Former Storage Method

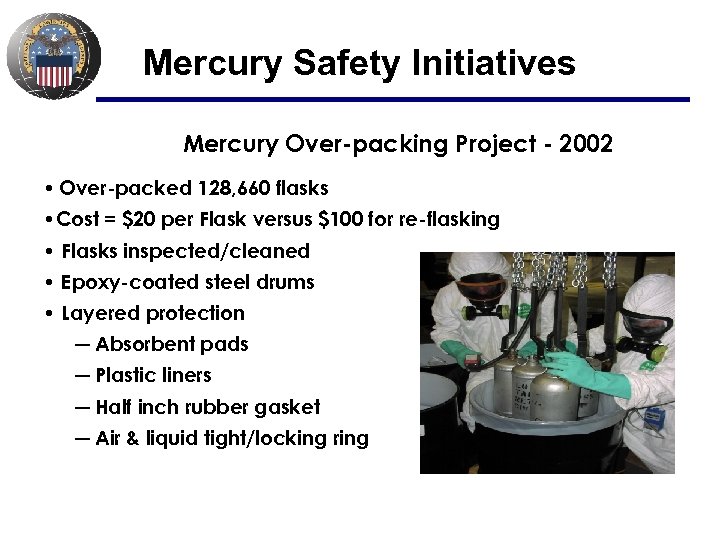

Mercury Safety Initiatives Mercury Over-packing Project - 2002 • Over-packed 128, 660 flasks • Cost = $20 per Flask versus $100 for re-flasking • Flasks inspected/cleaned • Epoxy-coated steel drums • Layered protection ─ Absorbent pads ─ Plastic liners ─ Half inch rubber gasket ─ Air & liquid tight/locking ring

Mercury Safety Initiatives Mercury Over-packing Project - 2002 • Over-packed 128, 660 flasks • Cost = $20 per Flask versus $100 for re-flasking • Flasks inspected/cleaned • Epoxy-coated steel drums • Layered protection ─ Absorbent pads ─ Plastic liners ─ Half inch rubber gasket ─ Air & liquid tight/locking ring

Mercury Safety Initiatives Mercury Flask Inspection Project (Nevada) - 2007 • Inspected 128, 660 flasks • Tightened 100 stoppers • Applied Lock-Tite to stoppers

Mercury Safety Initiatives Mercury Flask Inspection Project (Nevada) - 2007 • Inspected 128, 660 flasks • Tightened 100 stoppers • Applied Lock-Tite to stoppers

Reaching a Mercury Decision • 2001 – DNSC initiated an Environmental Impact Statement (EIS) – Evaluated alternatives for long-term management of the mercury • 2002 – Conducted visits to potential storage sites – Selected three for analysis in EIS • 2004 – Issued Final EIS – Determined no effective mercury treatment technology available – Identified preferred alternative – long term storage • 2004 – A Record of Decision reached for the EIS – Announced the decision to consolidate the mercury at one location – Did not identify specific location at that time

Reaching a Mercury Decision • 2001 – DNSC initiated an Environmental Impact Statement (EIS) – Evaluated alternatives for long-term management of the mercury • 2002 – Conducted visits to potential storage sites – Selected three for analysis in EIS • 2004 – Issued Final EIS – Determined no effective mercury treatment technology available – Identified preferred alternative – long term storage • 2004 – A Record of Decision reached for the EIS – Announced the decision to consolidate the mercury at one location – Did not identify specific location at that time

Reaching a Mercury Decision • 2006 – Hawthorne Army Depot (Hawthorne, Nev. ) was chosen as the consolidation site

Reaching a Mercury Decision • 2006 – Hawthorne Army Depot (Hawthorne, Nev. ) was chosen as the consolidation site