05fb6ae9aa16753f18ad387a2818639e.ppt

- Количество слайдов: 15

Decorative Registers SMART-CME PACKAGING PROJECT

Decorative Registers SMART-CME PACKAGING PROJECT

COMPANY HISTORY • Ralph Oosterhuis and his wife, Tiki, began producing brass floor registers as an ancillary product in their former brass bed frame business. • After seven years of producing their signature “Decor Scroll” register in brass, they recognized that decorative floor registers had come of age and decided to drop their other product lines and focus solely on this niche market. • As a result, they incorporated Decor Grates in 1990.

COMPANY HISTORY • Ralph Oosterhuis and his wife, Tiki, began producing brass floor registers as an ancillary product in their former brass bed frame business. • After seven years of producing their signature “Decor Scroll” register in brass, they recognized that decorative floor registers had come of age and decided to drop their other product lines and focus solely on this niche market. • As a result, they incorporated Decor Grates in 1990.

COMPANY HISTORY • Consumers were looking for innovative enhancements for their homes. Decorative floor registers provided a unique finishing touch for the insightful home decorator. • Ralph and Tiki believed versatility was the key to success, developing new sizes and styles in a range of materials. • Decor Grates continues to develop decorative grates by exploring new materials and designs. • The Company has achieved its previous goal of becoming an innovative, entrepreneurial “One–Stop Shop” decorative register company. • The current objective is to become the destination for all floor and wall register needs.

COMPANY HISTORY • Consumers were looking for innovative enhancements for their homes. Decorative floor registers provided a unique finishing touch for the insightful home decorator. • Ralph and Tiki believed versatility was the key to success, developing new sizes and styles in a range of materials. • Decor Grates continues to develop decorative grates by exploring new materials and designs. • The Company has achieved its previous goal of becoming an innovative, entrepreneurial “One–Stop Shop” decorative register company. • The current objective is to become the destination for all floor and wall register needs.

PRODUCT SAMPLES

PRODUCT SAMPLES

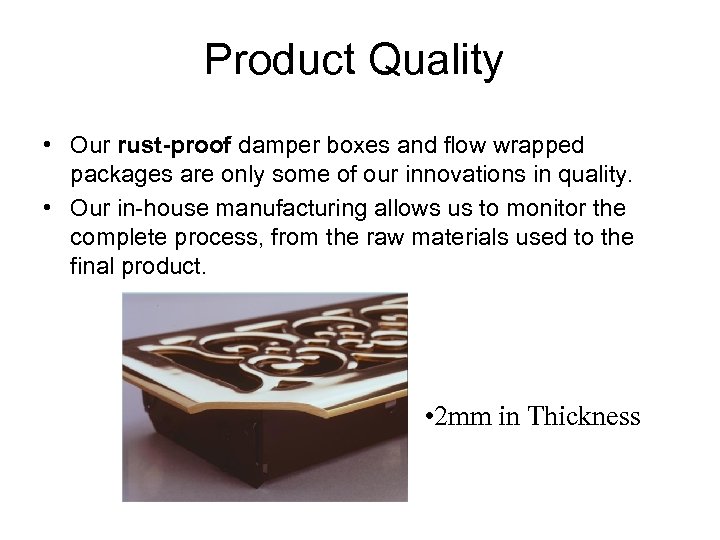

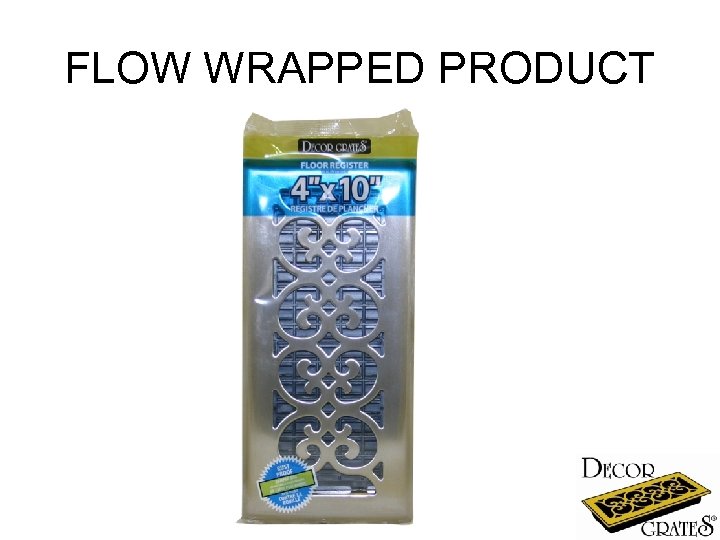

Product Quality • Our rust-proof damper boxes and flow wrapped packages are only some of our innovations in quality. • Our in-house manufacturing allows us to monitor the complete process, from the raw materials used to the final product. • 2 mm in Thickness

Product Quality • Our rust-proof damper boxes and flow wrapped packages are only some of our innovations in quality. • Our in-house manufacturing allows us to monitor the complete process, from the raw materials used to the final product. • 2 mm in Thickness

KEY EVENTS • 1990 - Decor Grates was incorporated to manage expanding demand for decorative floor registers • 1998 - Acquisition of Injection Moulding company provides the Company with capability of manufacturing plastic registers • 1999 - Listed in Canadian Business’ NEXT 100 ranking, placing it as one of the 200 fastest-growing companies in Canada • 2002 - Ralph and Tiki Oosterhuis nominated for Ernst & Young Entrepreneur of the Year Awards • 2003 - Decor Grates named in Profit 100 Canada’s Fastest Growing Companies by BMO Bank of Montreal

KEY EVENTS • 1990 - Decor Grates was incorporated to manage expanding demand for decorative floor registers • 1998 - Acquisition of Injection Moulding company provides the Company with capability of manufacturing plastic registers • 1999 - Listed in Canadian Business’ NEXT 100 ranking, placing it as one of the 200 fastest-growing companies in Canada • 2002 - Ralph and Tiki Oosterhuis nominated for Ernst & Young Entrepreneur of the Year Awards • 2003 - Decor Grates named in Profit 100 Canada’s Fastest Growing Companies by BMO Bank of Montreal

INJECTION MOULDING EQUIPMENT

INJECTION MOULDING EQUIPMENT

ARMAGEDDON • 2005 – Largest customer decides to go offshore with cheaper imported product. • 2007 – Next largest customer changes buying direction and leaves us with huge amount of unlisted inventory. • 2008 – The worst recession since the 1930 s hits the global economy • 2008 - The banks compound the difficulties by putting the squeeze on anyone with debt.

ARMAGEDDON • 2005 – Largest customer decides to go offshore with cheaper imported product. • 2007 – Next largest customer changes buying direction and leaves us with huge amount of unlisted inventory. • 2008 – The worst recession since the 1930 s hits the global economy • 2008 - The banks compound the difficulties by putting the squeeze on anyone with debt.

IMPOSSIBLE TO RECOVER? • Money was in short supply and credit facilities were shrinking. • Sales were declining. • We looked at sourcing cheaper product overseas, but we didn’t want to lose control of our manufacturing and assembly. • We decided instead to look at ways to reduce our manufacturing and assembly costs.

IMPOSSIBLE TO RECOVER? • Money was in short supply and credit facilities were shrinking. • Sales were declining. • We looked at sourcing cheaper product overseas, but we didn’t want to lose control of our manufacturing and assembly. • We decided instead to look at ways to reduce our manufacturing and assembly costs.

SOLUTION • The whole Reduce, Reuse, Recycle movement gave us the idea to not only reduce packaging, but to reduce costs as well. • Our old packaging consisted of shrink wrap, a retail box per unit, 4 retail boxes in a display carton, 2 display cartons in a shipping carton. • We asked our packaging consultant to suggest solutions to reduce both the materials and labour involved in our packaging process. • The most interesting solution was to go with a flow wrap process, but the cost was more than we could afford at that time. • Then we spoke to the good people running the SMARTCME Program.

SOLUTION • The whole Reduce, Reuse, Recycle movement gave us the idea to not only reduce packaging, but to reduce costs as well. • Our old packaging consisted of shrink wrap, a retail box per unit, 4 retail boxes in a display carton, 2 display cartons in a shipping carton. • We asked our packaging consultant to suggest solutions to reduce both the materials and labour involved in our packaging process. • The most interesting solution was to go with a flow wrap process, but the cost was more than we could afford at that time. • Then we spoke to the good people running the SMARTCME Program.

BUSINESS TRANSFORMED • We had our application approved and were able to lease the balance not funded. • The results were incredible! • We went from 3 shrink wrap lines, producing 9, 000 units per day, to 1 flow wrap line, producing 15, 000 units per day. • The packaging now consisted of 100% recyclable pre-printed flow wrap packaging using a thermal printer to print specific sku information with 8 flow wrapped units in a dual shipping and display carton. • We were now able to compete with cheaper overseas imports and went from a money losing operation to being once again profitable. • Even without the funding, the payback was less than 6 months.

BUSINESS TRANSFORMED • We had our application approved and were able to lease the balance not funded. • The results were incredible! • We went from 3 shrink wrap lines, producing 9, 000 units per day, to 1 flow wrap line, producing 15, 000 units per day. • The packaging now consisted of 100% recyclable pre-printed flow wrap packaging using a thermal printer to print specific sku information with 8 flow wrapped units in a dual shipping and display carton. • We were now able to compete with cheaper overseas imports and went from a money losing operation to being once again profitable. • Even without the funding, the payback was less than 6 months.

FLOW WRAPPER

FLOW WRAPPER

FLOW WRAPPED PRODUCT

FLOW WRAPPED PRODUCT

ALMOST 2 YEARS LATER • We’ve just purchased a second flow wrap machine, which doubles our assembly and packaging capacity. • We’re well positioned to take advantage of new opportunities as the global economy slowly recovers. • We’re upgrading our ERP software to provide further efficiencies and hope to receive additional funding to offset some of the costs.

ALMOST 2 YEARS LATER • We’ve just purchased a second flow wrap machine, which doubles our assembly and packaging capacity. • We’re well positioned to take advantage of new opportunities as the global economy slowly recovers. • We’re upgrading our ERP software to provide further efficiencies and hope to receive additional funding to offset some of the costs.

CONCLUSION • There was a good possibility that we might not have survived without the changes made possible by the funding we received from the SMART-CME Program. • For $50, 000 of funding over 60 local jobs were safeguarded. • This was a WIN-WIN situation for Decor Grates, the provincial and federal governments and, of course, the employees. • This is the best kind of government stimulus since the payback is measurable and sustainable. • Well done to the SMART-CME Program.

CONCLUSION • There was a good possibility that we might not have survived without the changes made possible by the funding we received from the SMART-CME Program. • For $50, 000 of funding over 60 local jobs were safeguarded. • This was a WIN-WIN situation for Decor Grates, the provincial and federal governments and, of course, the employees. • This is the best kind of government stimulus since the payback is measurable and sustainable. • Well done to the SMART-CME Program.