3e3fadc4e0e9050518a3c8d79f1947a9.ppt

- Количество слайдов: 11

DCS 370 18 V Band Saw

DCS 370 18 V Band Saw End Users Electricians, Plumbers, HVAC, Sprinkler Conduit Unistrut Threaded Rod Core 18 V DEWALT Users now have a Lightweight, Compact, Cordless Solution!

DCS 370 18 V Band Saw Why DEWALT 18 V Band Saw? Portability Durability Performance System

DCS 370 18 V Band Saw 18 V Cordless Band Saw 2 1/2” Cut Capacity for common materials Cuts up to 2” SCH 40 Pipe Balanced Design Centered handle enables end user to cut in all orientations including overhead Compact & Lightweight 9. 0 lbs (Li-Ion) & 15” Length Hang Hook Allows the saw to hung from lifts, ladders, carts and tripod vices 18 V Battery System Compatible with all 18 V batteries DCF 885 C 2 DCS 370 L

DCS 370 18 V Band Saw Ergonomics DEWALT Milwaukee Stout DCS 370 2629 -22 X-250 15” 18 -3/4” 15” Weight – Li-Ion 9. 2 lbs 10. 5 lbs n/a Weight - Ni. Cd 10. 0 lbs n/a 9. 6 lbs User Need Length

DCS 370 18 V Band Saw Durability Drop / Life • Survives Repeated Drops • Proven Drive Train • Hang Hook Composite Base

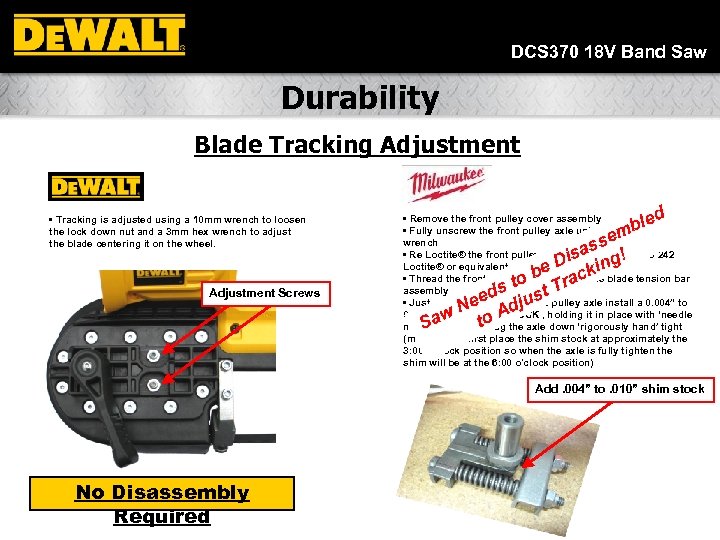

DCS 370 18 V Band Saw Durability Blade Tracking Adjustment • Tracking is adjusted using a 10 mm wrench to loosen the lock down nut and a 3 mm hex wrench to adjust the blade centering it on the wheel. Adjustment Screws d ble m • Remove the front pulley cover assembly • Fully unscrew the front pulley axle using a 5/8" open end wrench • Re Loctite® the front pulley axle threads using Blue 242 Loctite® or equivalent • Thread the front pulley axle back into the blade tension bar assembly • Just prior to seating the front pulley axle install a 0. 004” to 0. 010” piece of SHIM STOCK , holding it in place with ‘needle nose’ pliers and snug the axle down ‘rigorously hand’ tight (may need to first place the shim stock at approximately the 3: 00 o'clock position so when the axle is fully tighten the shim will be at the 6: 00 o'clock position) sse a Dis king! e o b Trac t eds just Ne Ad w to Sa Add. 004” to. 010” shim stock No Disassembly Required

DCS 370 18 V Band Saw Performance Speed of Cut • Speed = 570 FPM • Blade = 14/18 Tooth Cuts / Charge 100+ 3/4” Conduit = to M 18 40+ = to Deep Cut 1 5/8” Unistrut

DCS 370 18 V Band Saws & Blades DCS 370 B Sugg. Retail $219. 00 DCS 370 K Sugg. Retail $299. 00 DCS 370 L Sugg. Retail $379. 00 Includes: DCS 370 Cordless Band Saw – Bare Tool Only Includes: DCS 370 Cordless Band Saw, (1) DC 9096 Battery, DW 9116 Charger, and Bag. Includes: DCS 370 Cordless Band Saw, (1) DC 9180 XRP Li-Ion Battery, DC 9310 Charger, and Bag. Replacement Accessory Blades Orders can be placed: Orders begin shipping: Now 6/20/11

DCS 370 18 V Band Saw Merchandising Sell Sheet – DCS 370 SS Rack – ICDCS 370 RK Channel Card for Rack – ICDCS 370 RKCS

DCS 370 18 V Band Saw FAQ’s 1. This saw looks similar to the Stout 18 V band saw. Have we partnered with them? Did we buy Stout Tool Corporation? The band saw design is the result of spending time on job sites with end users that have a need for a more portable metal cutting solution. We found that a majority of applications for mechanical trades could be cut with the capacity of our saw. We recognized that Stout had developed a portable cutting solution that met our performance criteria for ease of use, durability and cut quality. For these reasons DEWALT is working collaboratively with Stout Tool to develop a band saw that meets the requirement of our most demanding end users. 2. Are all DEWALT 18 V batteries compatible with the saw? Yes. All 18 V batteries are compatible. However to satisfy end user run time needs it is recommended they use the DC 9096 or DC 9180. 3. What length is the blade? It looks shorter than a corded band saw. Where will I be able to purchase replacements? The band saw blade is 32 – 7/8” long. It will be available from the same retailers that sell the saw. 4. Why no work light on the saw? Although work lights have become common for most cordless tools we determined for this first generation of 18 V band saw to not include a light. This decision was based on end user feedback and our focus on delivering the most critical needs of the end user – ease of use, durability and cut quality.

3e3fadc4e0e9050518a3c8d79f1947a9.ppt