fd1ed17fd3b86024f9ce59fa4a91ba8a.ppt

- Количество слайдов: 66

DC & AC MACHINES

DC & AC MACHINES

Dc Machine CONTENTS – – – Overview of Direct Current Machines Construction Principle of Operation Types of DC Machine Power Flow Diagram Speed Control

Dc Machine CONTENTS – – – Overview of Direct Current Machines Construction Principle of Operation Types of DC Machine Power Flow Diagram Speed Control

Upon completion of the chapter the student should be able to: – State the principle by which machines convert mechanical energy to electrical energy. – Discuss the operating differences between different types of generators – Understand the principle of DC generator as it represents a logical behavior of dc motors.

Upon completion of the chapter the student should be able to: – State the principle by which machines convert mechanical energy to electrical energy. – Discuss the operating differences between different types of generators – Understand the principle of DC generator as it represents a logical behavior of dc motors.

Overview of Direct Current Machines • Direct-current (DC) machines are divided into dc generators and dc motors. • Most DC machines are similar to AC machines: i. e. they have AC voltages and current within them. • DC machines have DC outputs just because they have a mechanism converting AC voltages to DC voltages at their terminals. • This mechanism is called a commutator; therefore, DC machines are also called commutating machines. • DC generators are not as common as they used to be, because direct current, when required, is mainly produced by electronic rectifiers. • While dc motors are widely used, such automobile, aircraft, and portable electronics, in speed control applications…

Overview of Direct Current Machines • Direct-current (DC) machines are divided into dc generators and dc motors. • Most DC machines are similar to AC machines: i. e. they have AC voltages and current within them. • DC machines have DC outputs just because they have a mechanism converting AC voltages to DC voltages at their terminals. • This mechanism is called a commutator; therefore, DC machines are also called commutating machines. • DC generators are not as common as they used to be, because direct current, when required, is mainly produced by electronic rectifiers. • While dc motors are widely used, such automobile, aircraft, and portable electronics, in speed control applications…

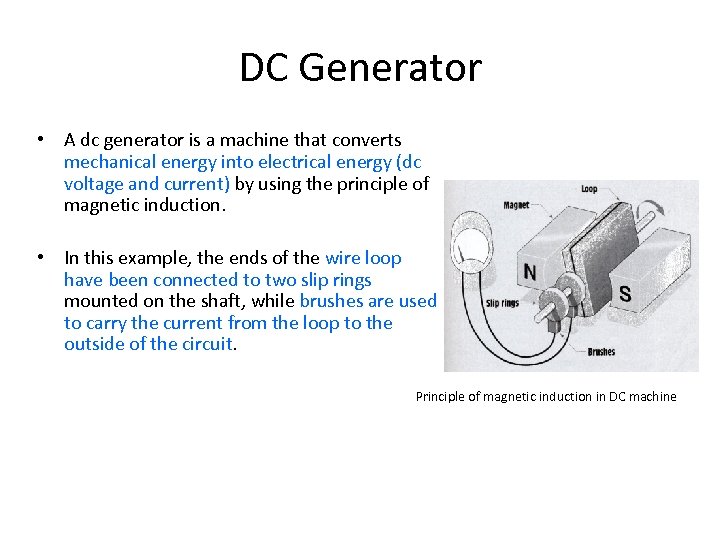

DC Generator • A dc generator is a machine that converts mechanical energy into electrical energy (dc voltage and current) by using the principle of magnetic induction. • In this example, the ends of the wire loop have been connected to two slip rings mounted on the shaft, while brushes are used to carry the current from the loop to the outside of the circuit. Principle of magnetic induction in DC machine

DC Generator • A dc generator is a machine that converts mechanical energy into electrical energy (dc voltage and current) by using the principle of magnetic induction. • In this example, the ends of the wire loop have been connected to two slip rings mounted on the shaft, while brushes are used to carry the current from the loop to the outside of the circuit. Principle of magnetic induction in DC machine

DC Motor • DC motors are everywhere! In a house, almost every mechanical movement that you see around you is caused by an DC (direct current) motor. • An dc motor is a machine that converts electrical energy into mechanical energy by supplying a dc power (voltage and current). • An advantage of DC motors is that it is easy to control their speed in a wide diapason.

DC Motor • DC motors are everywhere! In a house, almost every mechanical movement that you see around you is caused by an DC (direct current) motor. • An dc motor is a machine that converts electrical energy into mechanical energy by supplying a dc power (voltage and current). • An advantage of DC motors is that it is easy to control their speed in a wide diapason.

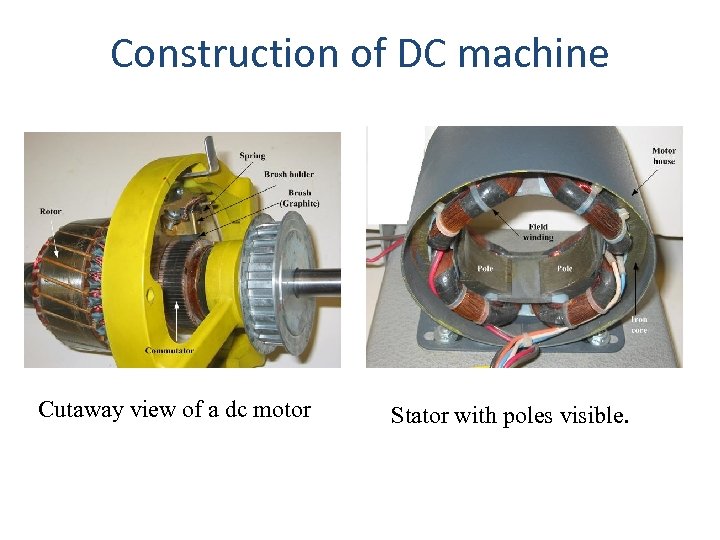

Construction of DC machine Cutaway view of a dc motor Stator with poles visible.

Construction of DC machine Cutaway view of a dc motor Stator with poles visible.

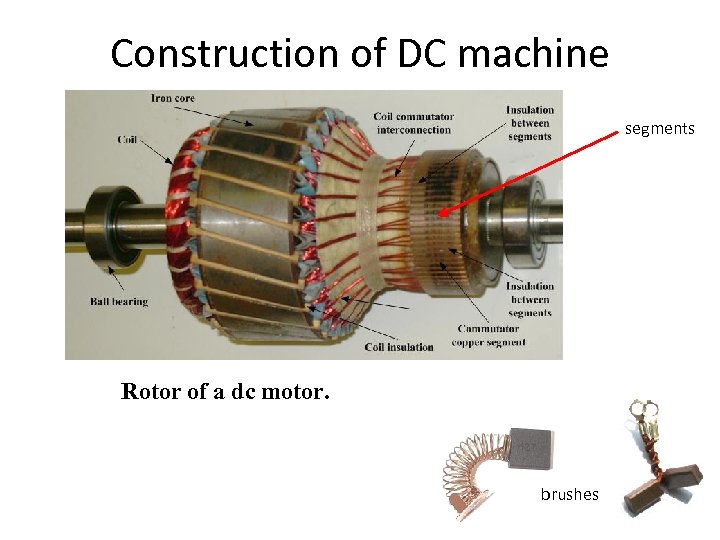

Construction of DC machine segments Rotor of a dc motor. brushes

Construction of DC machine segments Rotor of a dc motor. brushes

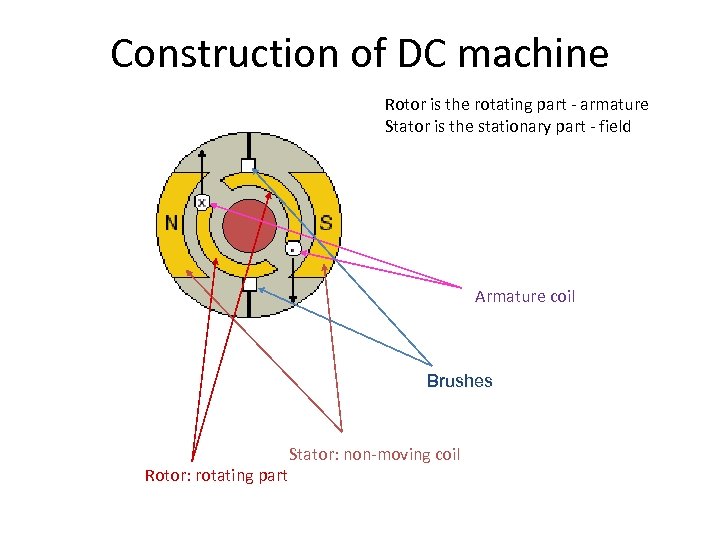

Construction of DC machine Rotor is the rotating part - armature Stator is the stationary part - field Armature coil Brushes Rotor: rotating part Stator: non-moving coil

Construction of DC machine Rotor is the rotating part - armature Stator is the stationary part - field Armature coil Brushes Rotor: rotating part Stator: non-moving coil

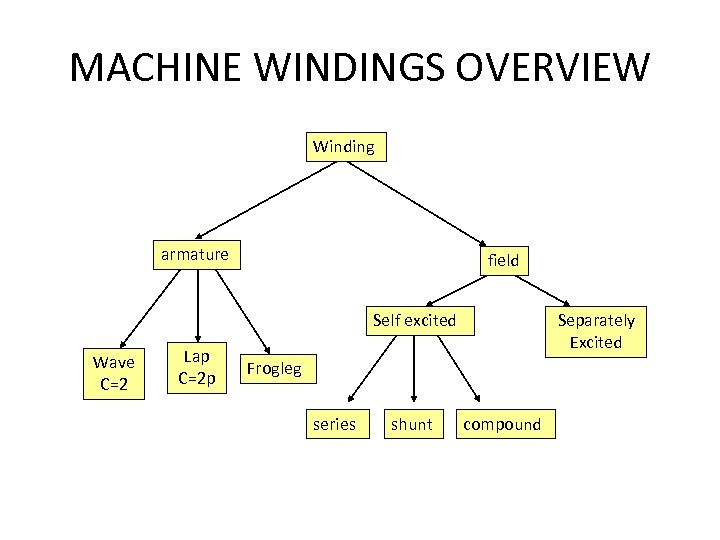

MACHINE WINDINGS OVERVIEW Winding armature field Self excited Wave C=2 Lap C=2 p Separately Excited Frogleg series shunt compound

MACHINE WINDINGS OVERVIEW Winding armature field Self excited Wave C=2 Lap C=2 p Separately Excited Frogleg series shunt compound

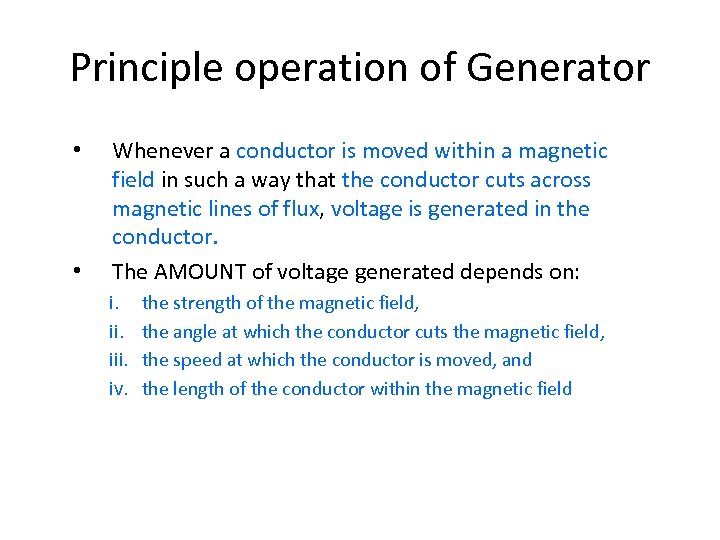

Principle operation of Generator • • Whenever a conductor is moved within a magnetic field in such a way that the conductor cuts across magnetic lines of flux, voltage is generated in the conductor. The AMOUNT of voltage generated depends on: i. iii. iv. the strength of the magnetic field, the angle at which the conductor cuts the magnetic field, the speed at which the conductor is moved, and the length of the conductor within the magnetic field

Principle operation of Generator • • Whenever a conductor is moved within a magnetic field in such a way that the conductor cuts across magnetic lines of flux, voltage is generated in the conductor. The AMOUNT of voltage generated depends on: i. iii. iv. the strength of the magnetic field, the angle at which the conductor cuts the magnetic field, the speed at which the conductor is moved, and the length of the conductor within the magnetic field

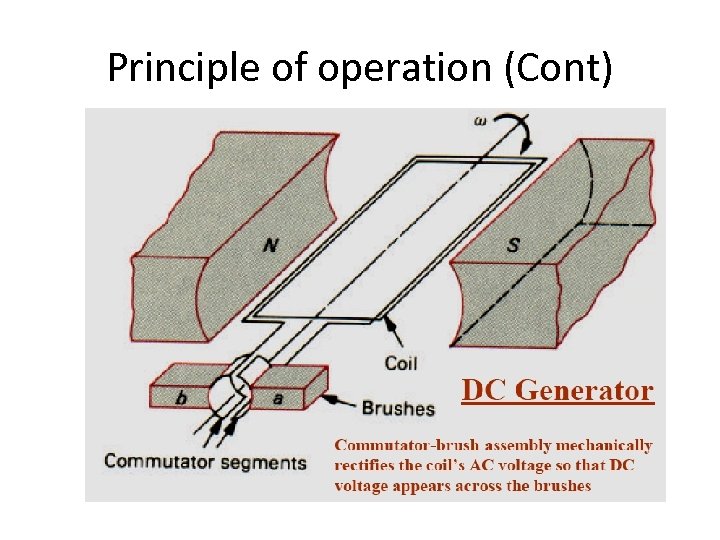

Principle of operation (Cont)

Principle of operation (Cont)

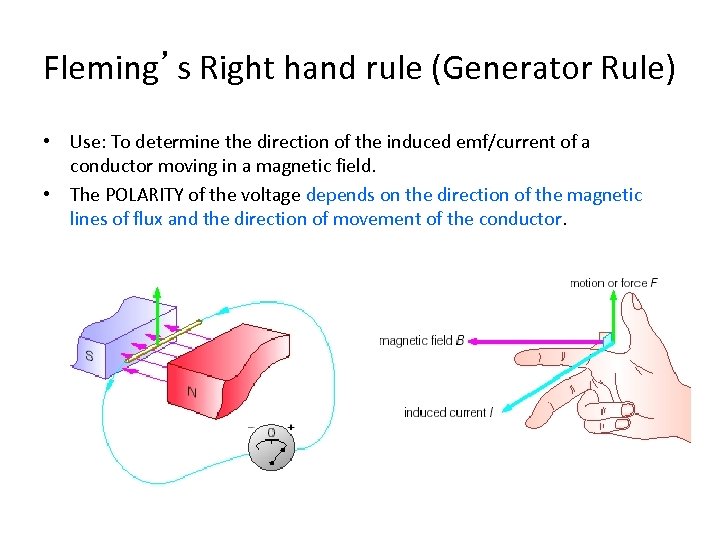

Fleming’s Right hand rule (Generator Rule) • Use: To determine the direction of the induced emf/current of a conductor moving in a magnetic field. • The POLARITY of the voltage depends on the direction of the magnetic lines of flux and the direction of movement of the conductor.

Fleming’s Right hand rule (Generator Rule) • Use: To determine the direction of the induced emf/current of a conductor moving in a magnetic field. • The POLARITY of the voltage depends on the direction of the magnetic lines of flux and the direction of movement of the conductor.

DC Machine Equivalent Circuit • The magnetic field produced by the stator poles induces a voltage in the rotor (or armature) coils when the generator is rotated. • This induced voltage is represented by a voltage source. • The stator coil has resistance, which is connected in series. • The pole flux is produced by the DC excitation/field current, which is magnetically coupled to the rotor • The field circuit has resistance and a source • The voltage drop on the brushes represented by a battery

DC Machine Equivalent Circuit • The magnetic field produced by the stator poles induces a voltage in the rotor (or armature) coils when the generator is rotated. • This induced voltage is represented by a voltage source. • The stator coil has resistance, which is connected in series. • The pole flux is produced by the DC excitation/field current, which is magnetically coupled to the rotor • The field circuit has resistance and a source • The voltage drop on the brushes represented by a battery

DC Machine Equivalent Circuit 1. Permanent magnet 2. Separately excited 3. Self-excited

DC Machine Equivalent Circuit 1. Permanent magnet 2. Separately excited 3. Self-excited

DC Machine Equivalent Circuit 1. Permanent magnet • The poles are made of permanent magnets. • No field winding required. • Small size. • Disadvantage is low flux density, so low torque.

DC Machine Equivalent Circuit 1. Permanent magnet • The poles are made of permanent magnets. • No field winding required. • Small size. • Disadvantage is low flux density, so low torque.

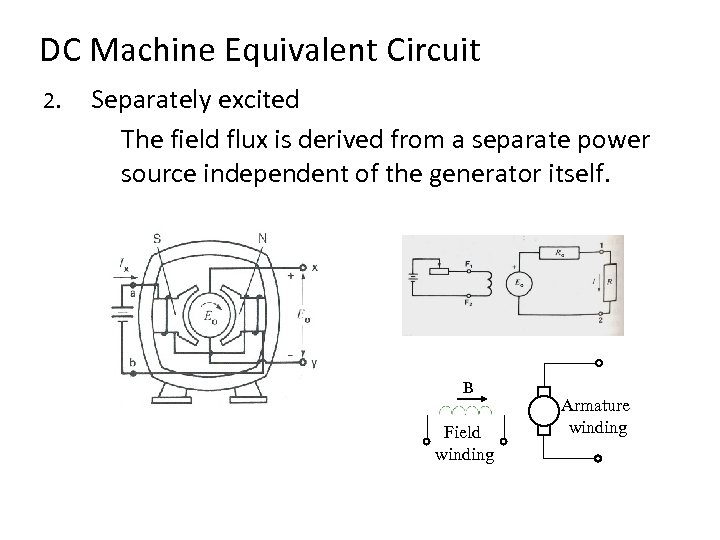

DC Machine Equivalent Circuit 2. Separately excited The field flux is derived from a separate power source independent of the generator itself. B Field winding Armature winding

DC Machine Equivalent Circuit 2. Separately excited The field flux is derived from a separate power source independent of the generator itself. B Field winding Armature winding

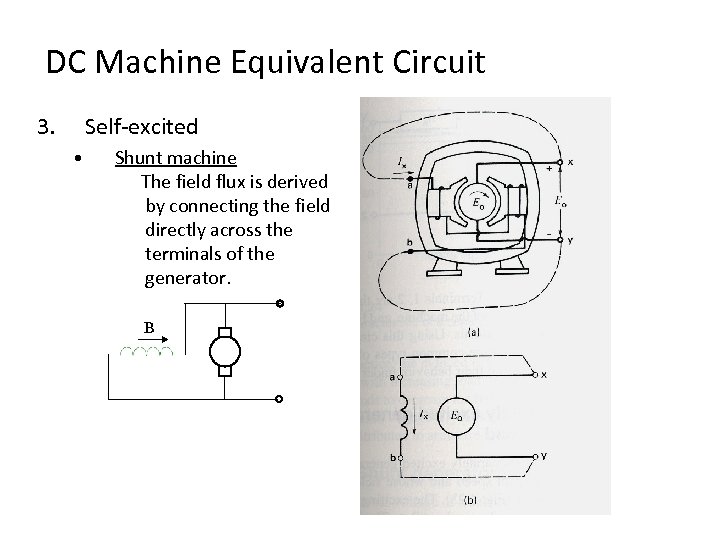

DC Machine Equivalent Circuit 3. Self-excited • Shunt machine The field flux is derived by connecting the field directly across the terminals of the generator. B

DC Machine Equivalent Circuit 3. Self-excited • Shunt machine The field flux is derived by connecting the field directly across the terminals of the generator. B

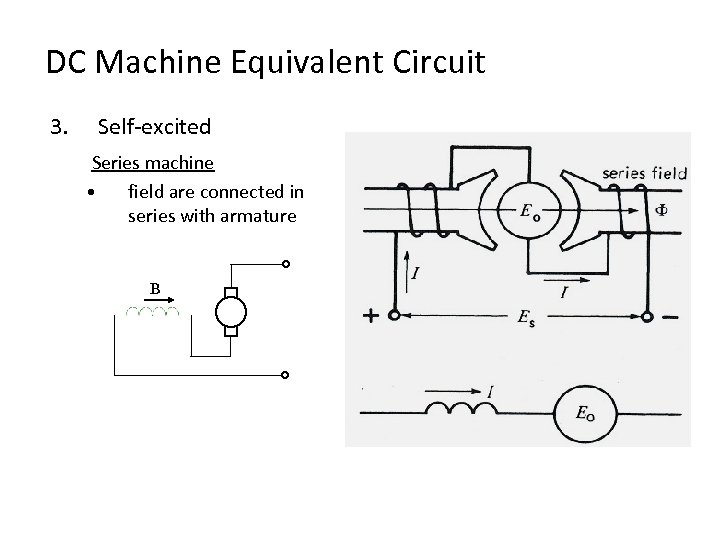

DC Machine Equivalent Circuit 3. Self-excited Series machine • field are connected in series with armature B

DC Machine Equivalent Circuit 3. Self-excited Series machine • field are connected in series with armature B

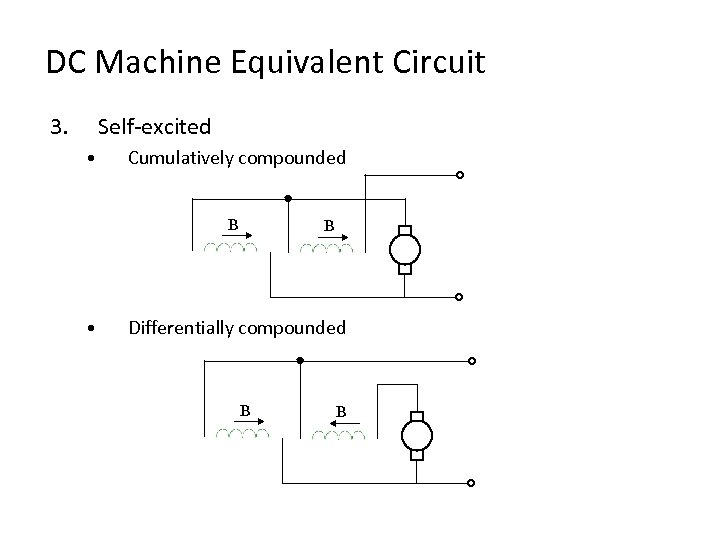

DC Machine Equivalent Circuit 3. Self-excited • Cumulatively compounded B • B Differentially compounded B B

DC Machine Equivalent Circuit 3. Self-excited • Cumulatively compounded B • B Differentially compounded B B

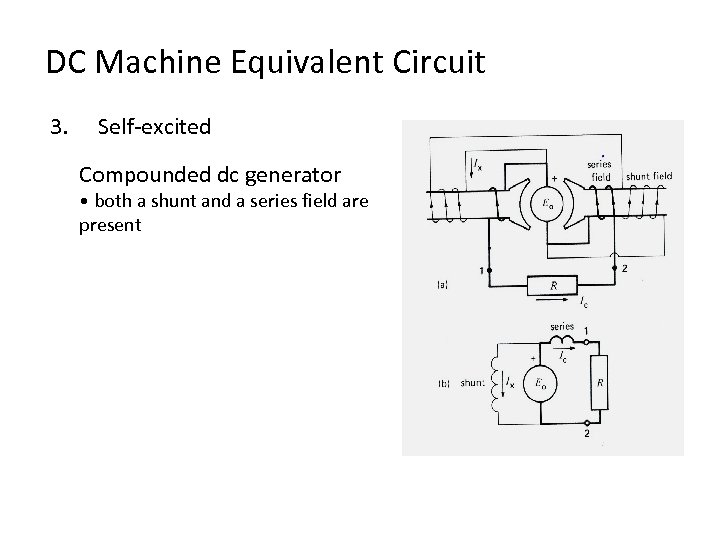

DC Machine Equivalent Circuit 3. Self-excited Compounded dc generator • both a shunt and a series field are present

DC Machine Equivalent Circuit 3. Self-excited Compounded dc generator • both a shunt and a series field are present

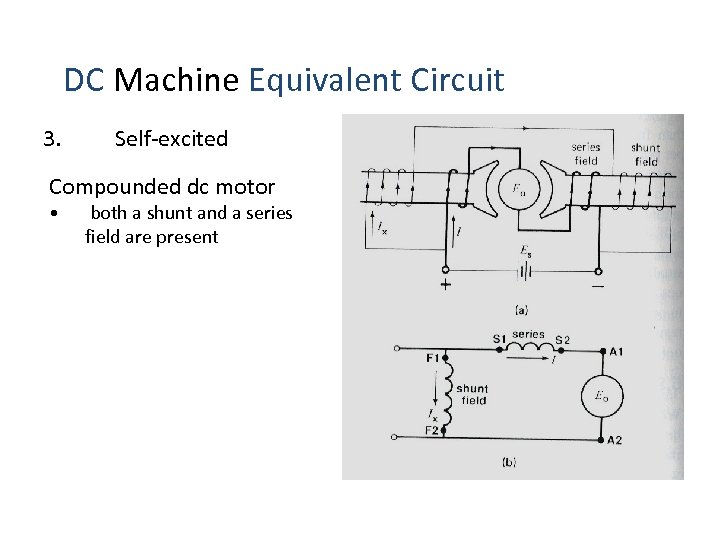

DC Machine Equivalent Circuit 3. Self-excited Compounded dc motor • both a shunt and a series field are present

DC Machine Equivalent Circuit 3. Self-excited Compounded dc motor • both a shunt and a series field are present

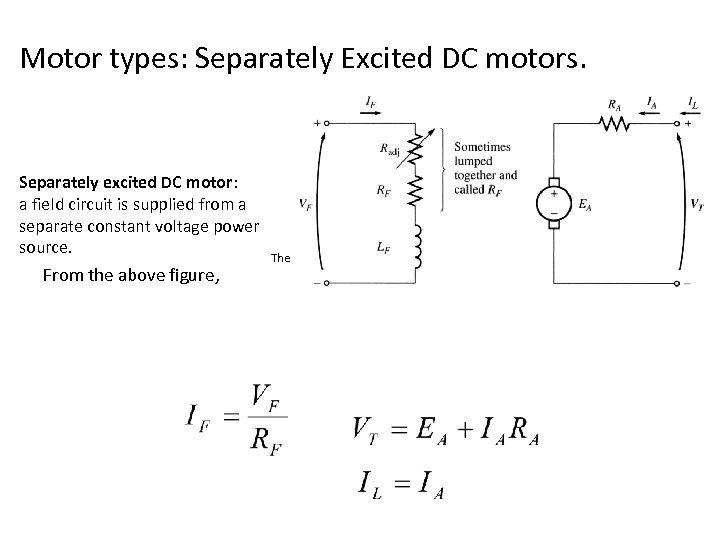

Motor types: Separately Excited DC motors. Separately excited DC motor: a field circuit is supplied from a separate constant voltage power source. The Equivalent Circuit of Separately Excited dc Motor. From the above figure,

Motor types: Separately Excited DC motors. Separately excited DC motor: a field circuit is supplied from a separate constant voltage power source. The Equivalent Circuit of Separately Excited dc Motor. From the above figure,

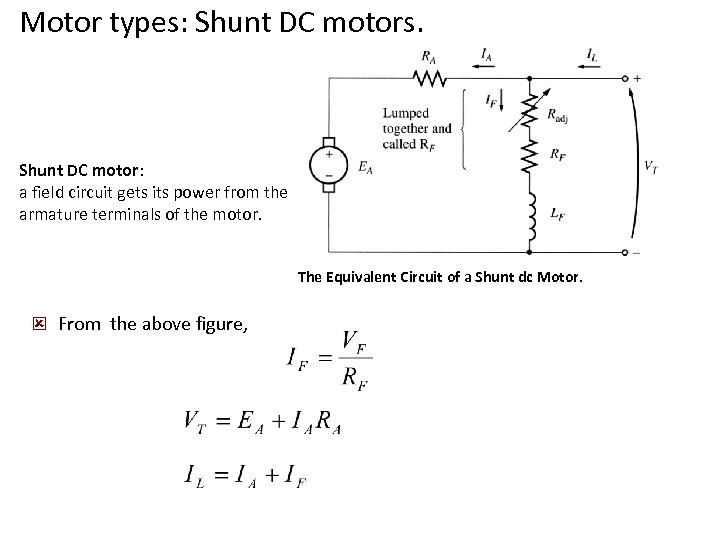

Motor types: Shunt DC motors. Shunt DC motor: a field circuit gets its power from the armature terminals of the motor. The Equivalent Circuit of a Shunt dc Motor. ý From the above figure,

Motor types: Shunt DC motors. Shunt DC motor: a field circuit gets its power from the armature terminals of the motor. The Equivalent Circuit of a Shunt dc Motor. ý From the above figure,

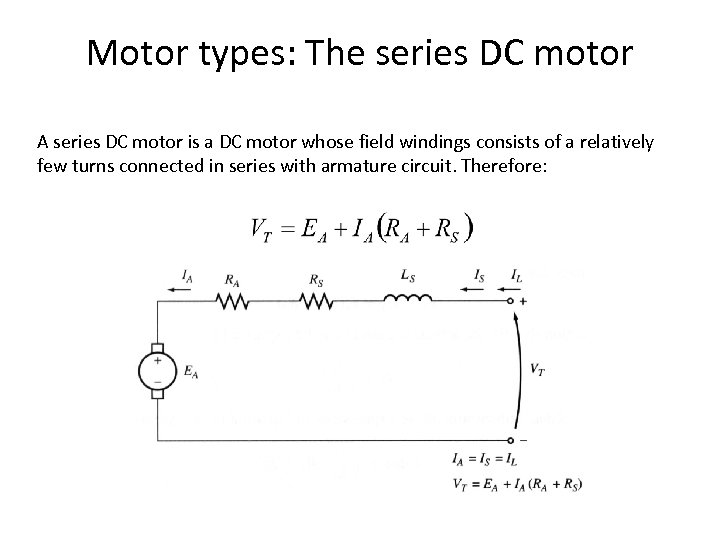

Motor types: The series DC motor A series DC motor is a DC motor whose field windings consists of a relatively few turns connected in series with armature circuit. Therefore:

Motor types: The series DC motor A series DC motor is a DC motor whose field windings consists of a relatively few turns connected in series with armature circuit. Therefore:

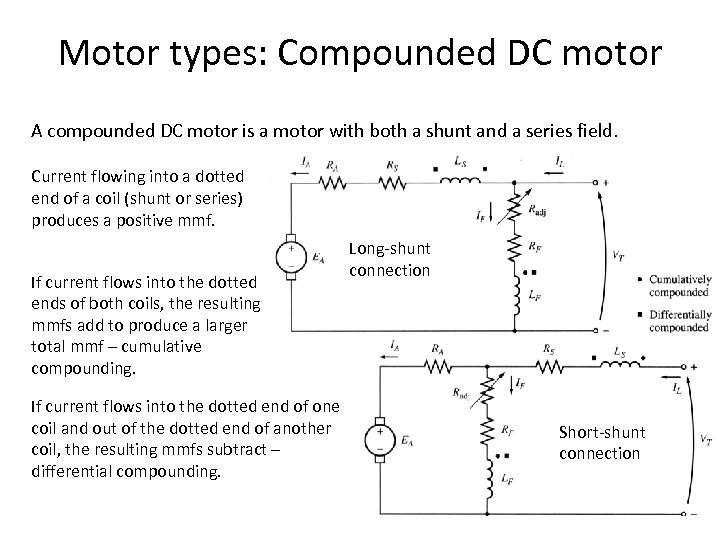

Motor types: Compounded DC motor A compounded DC motor is a motor with both a shunt and a series field. Current flowing into a dotted end of a coil (shunt or series) produces a positive mmf. If current flows into the dotted ends of both coils, the resulting mmfs add to produce a larger total mmf – cumulative compounding. If current flows into the dotted end of one coil and out of the dotted end of another coil, the resulting mmfs subtract – differential compounding. Long-shunt connection Short-shunt connection

Motor types: Compounded DC motor A compounded DC motor is a motor with both a shunt and a series field. Current flowing into a dotted end of a coil (shunt or series) produces a positive mmf. If current flows into the dotted ends of both coils, the resulting mmfs add to produce a larger total mmf – cumulative compounding. If current flows into the dotted end of one coil and out of the dotted end of another coil, the resulting mmfs subtract – differential compounding. Long-shunt connection Short-shunt connection

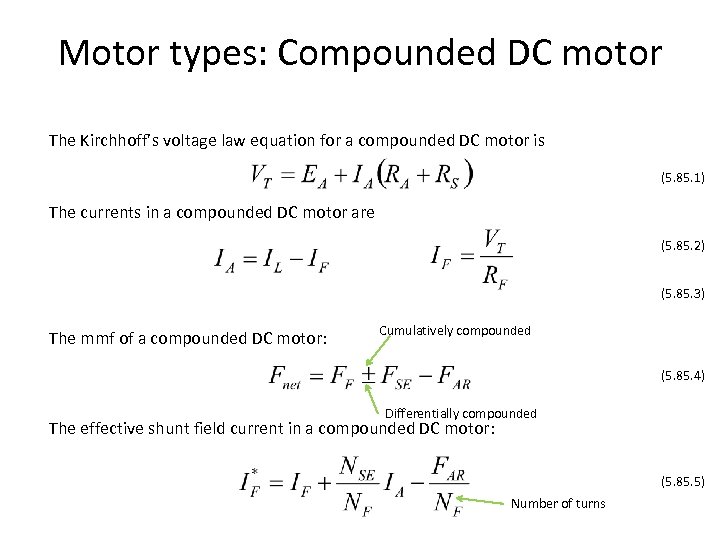

Motor types: Compounded DC motor The Kirchhoff’s voltage law equation for a compounded DC motor is (5. 85. 1) The currents in a compounded DC motor are (5. 85. 2) (5. 85. 3) The mmf of a compounded DC motor: Cumulatively compounded (5. 85. 4) Differentially compounded The effective shunt field current in a compounded DC motor: (5. 85. 5) Number of turns

Motor types: Compounded DC motor The Kirchhoff’s voltage law equation for a compounded DC motor is (5. 85. 1) The currents in a compounded DC motor are (5. 85. 2) (5. 85. 3) The mmf of a compounded DC motor: Cumulatively compounded (5. 85. 4) Differentially compounded The effective shunt field current in a compounded DC motor: (5. 85. 5) Number of turns

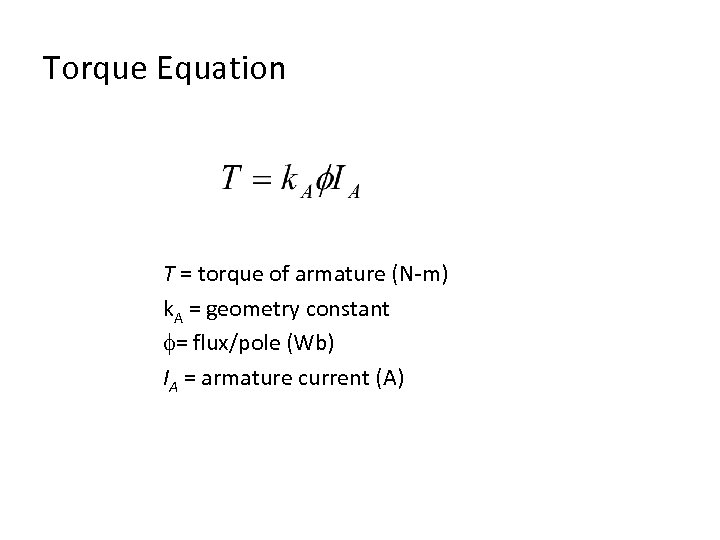

Torque Equation T = torque of armature (N-m) k. A = geometry constant = flux/pole (Wb) IA = armature current (A)

Torque Equation T = torque of armature (N-m) k. A = geometry constant = flux/pole (Wb) IA = armature current (A)

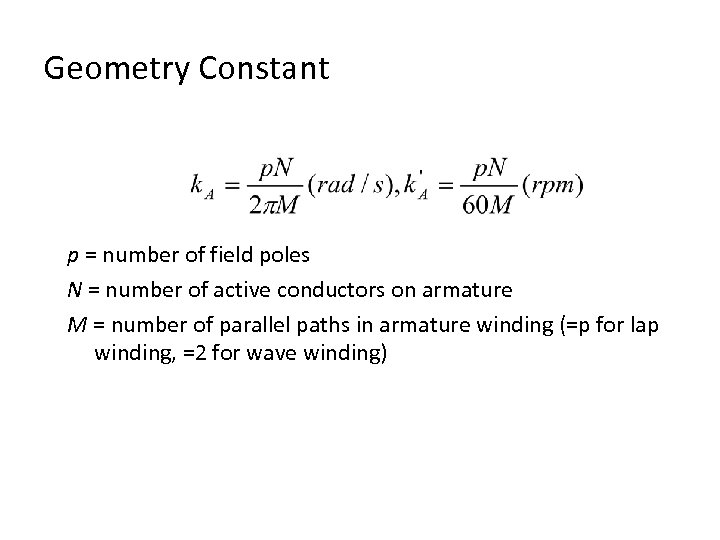

Geometry Constant p = number of field poles N = number of active conductors on armature M = number of parallel paths in armature winding (=p for lap winding, =2 for wave winding)

Geometry Constant p = number of field poles N = number of active conductors on armature M = number of parallel paths in armature winding (=p for lap winding, =2 for wave winding)

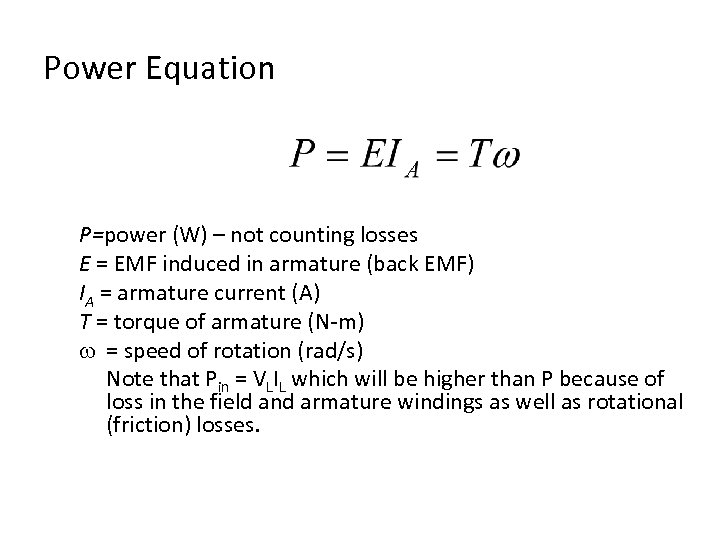

Power Equation P=power (W) – not counting losses E = EMF induced in armature (back EMF) IA = armature current (A) T = torque of armature (N-m) = speed of rotation (rad/s) Note that Pin = VLIL which will be higher than P because of loss in the field and armature windings as well as rotational (friction) losses.

Power Equation P=power (W) – not counting losses E = EMF induced in armature (back EMF) IA = armature current (A) T = torque of armature (N-m) = speed of rotation (rad/s) Note that Pin = VLIL which will be higher than P because of loss in the field and armature windings as well as rotational (friction) losses.

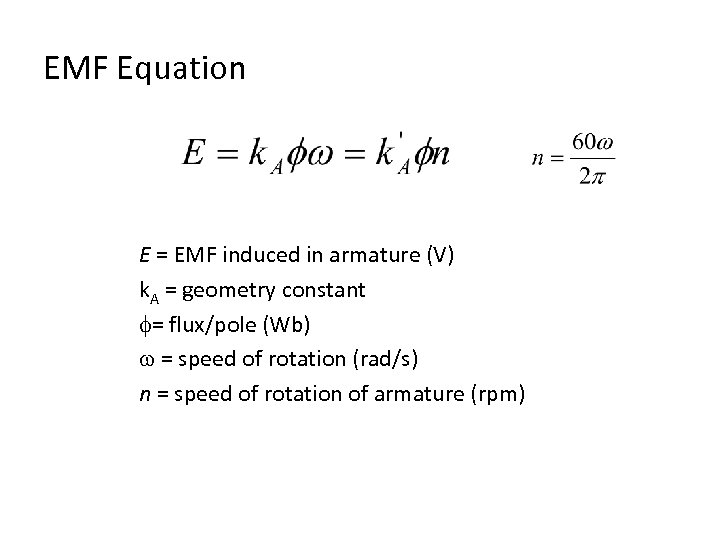

EMF Equation E = EMF induced in armature (V) k. A = geometry constant = flux/pole (Wb) = speed of rotation (rad/s) n = speed of rotation of armature (rpm)

EMF Equation E = EMF induced in armature (V) k. A = geometry constant = flux/pole (Wb) = speed of rotation (rad/s) n = speed of rotation of armature (rpm)

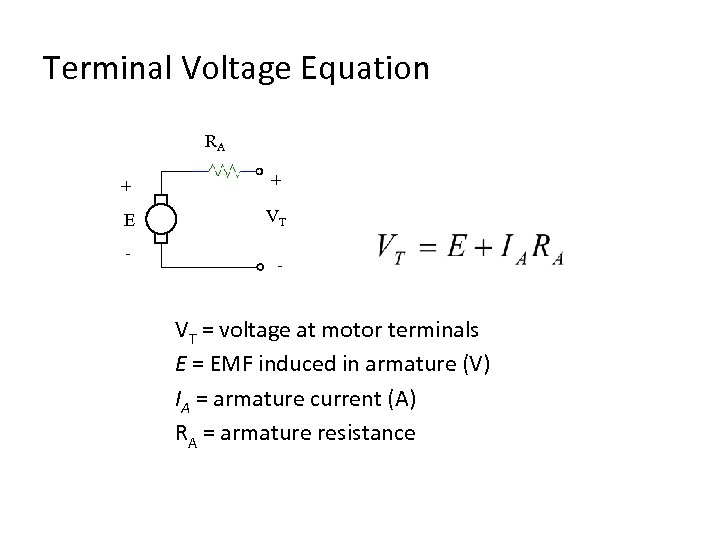

Terminal Voltage Equation RA + + E VT - - VT = voltage at motor terminals E = EMF induced in armature (V) IA = armature current (A) RA = armature resistance

Terminal Voltage Equation RA + + E VT - - VT = voltage at motor terminals E = EMF induced in armature (V) IA = armature current (A) RA = armature resistance

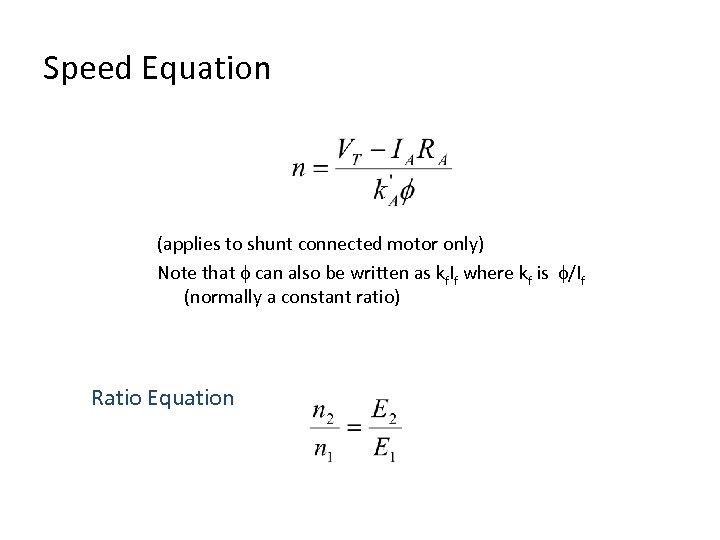

Speed Equation (applies to shunt connected motor only) Note that can also be written as kf. If where kf is /If (normally a constant ratio) Ratio Equation

Speed Equation (applies to shunt connected motor only) Note that can also be written as kf. If where kf is /If (normally a constant ratio) Ratio Equation

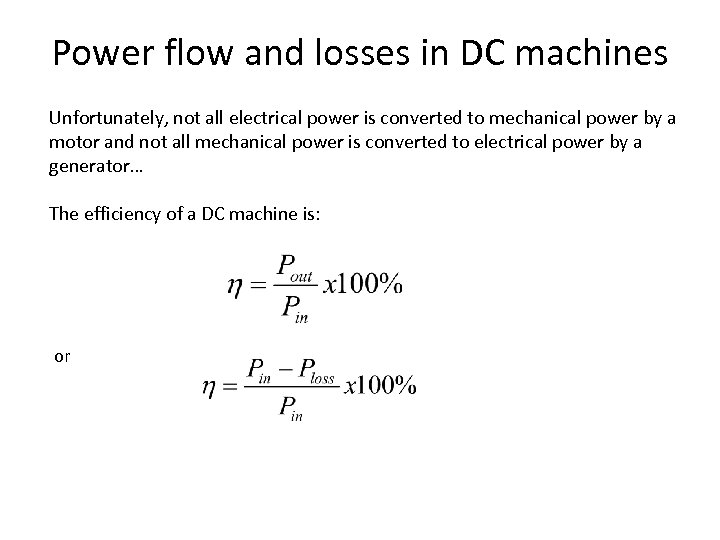

Power flow and losses in DC machines Unfortunately, not all electrical power is converted to mechanical power by a motor and not all mechanical power is converted to electrical power by a generator… The efficiency of a DC machine is: or

Power flow and losses in DC machines Unfortunately, not all electrical power is converted to mechanical power by a motor and not all mechanical power is converted to electrical power by a generator… The efficiency of a DC machine is: or

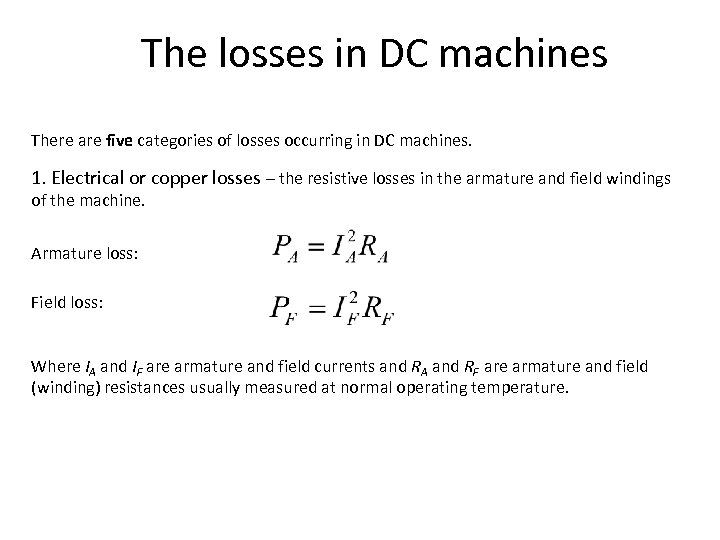

The losses in DC machines There are five categories of losses occurring in DC machines. 1. Electrical or copper losses – the resistive losses in the armature and field windings of the machine. Armature loss: Field loss: Where IA and IF are armature and field currents and RA and RF are armature and field (winding) resistances usually measured at normal operating temperature.

The losses in DC machines There are five categories of losses occurring in DC machines. 1. Electrical or copper losses – the resistive losses in the armature and field windings of the machine. Armature loss: Field loss: Where IA and IF are armature and field currents and RA and RF are armature and field (winding) resistances usually measured at normal operating temperature.

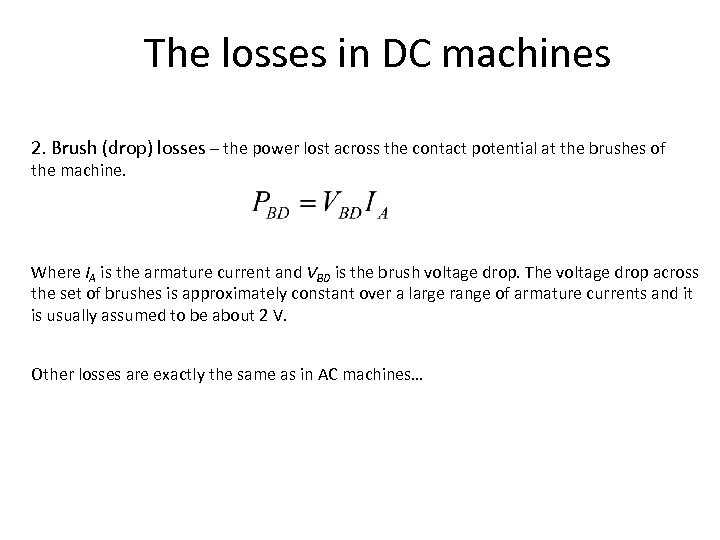

The losses in DC machines 2. Brush (drop) losses – the power lost across the contact potential at the brushes of the machine. Where IA is the armature current and VBD is the brush voltage drop. The voltage drop across the set of brushes is approximately constant over a large range of armature currents and it is usually assumed to be about 2 V. Other losses are exactly the same as in AC machines…

The losses in DC machines 2. Brush (drop) losses – the power lost across the contact potential at the brushes of the machine. Where IA is the armature current and VBD is the brush voltage drop. The voltage drop across the set of brushes is approximately constant over a large range of armature currents and it is usually assumed to be about 2 V. Other losses are exactly the same as in AC machines…

The losses in DC machines 3. Core losses – hysteresis losses and eddy current losses. They vary as B 2 (square of flux density) and as n 1. 5 (speed of rotation of the magnetic field). 4. Mechanical losses – losses associated with mechanical effects: friction (friction of the bearings) and windage (friction between the moving parts of the machine and the air inside the casing). These losses vary as the cube of rotation speed n 3. 5. Stray (Miscellaneous) losses – losses that cannot be classified in any of the previous categories. They are usually due to inaccuracies in modeling. For many machines, stray losses are assumed as 1% of full load.

The losses in DC machines 3. Core losses – hysteresis losses and eddy current losses. They vary as B 2 (square of flux density) and as n 1. 5 (speed of rotation of the magnetic field). 4. Mechanical losses – losses associated with mechanical effects: friction (friction of the bearings) and windage (friction between the moving parts of the machine and the air inside the casing). These losses vary as the cube of rotation speed n 3. 5. Stray (Miscellaneous) losses – losses that cannot be classified in any of the previous categories. They are usually due to inaccuracies in modeling. For many machines, stray losses are assumed as 1% of full load.

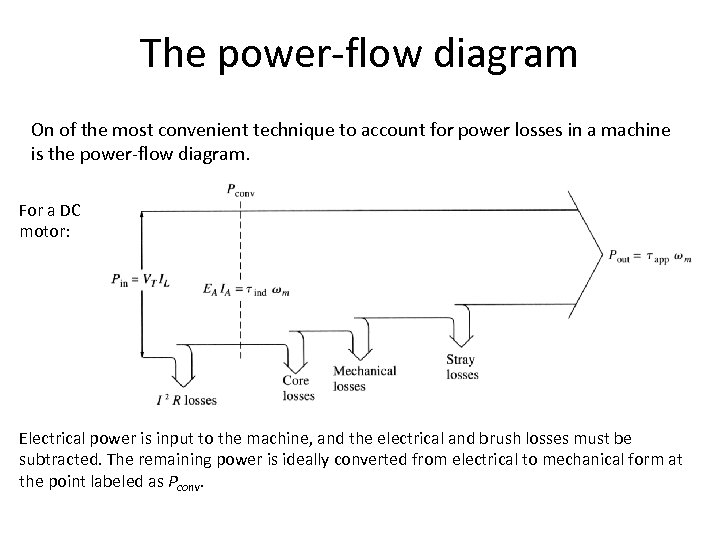

The power-flow diagram On of the most convenient technique to account for power losses in a machine is the power-flow diagram. For a DC motor: Electrical power is input to the machine, and the electrical and brush losses must be subtracted. The remaining power is ideally converted from electrical to mechanical form at the point labeled as Pconv.

The power-flow diagram On of the most convenient technique to account for power losses in a machine is the power-flow diagram. For a DC motor: Electrical power is input to the machine, and the electrical and brush losses must be subtracted. The remaining power is ideally converted from electrical to mechanical form at the point labeled as Pconv.

The power-flow diagram The electrical power that is converted is And the resulting mechanical power is After the power is converted to mechanical form, the stray losses, mechanical losses, and core losses are subtracted, and the remaining mechanical power is output to the load.

The power-flow diagram The electrical power that is converted is And the resulting mechanical power is After the power is converted to mechanical form, the stray losses, mechanical losses, and core losses are subtracted, and the remaining mechanical power is output to the load.

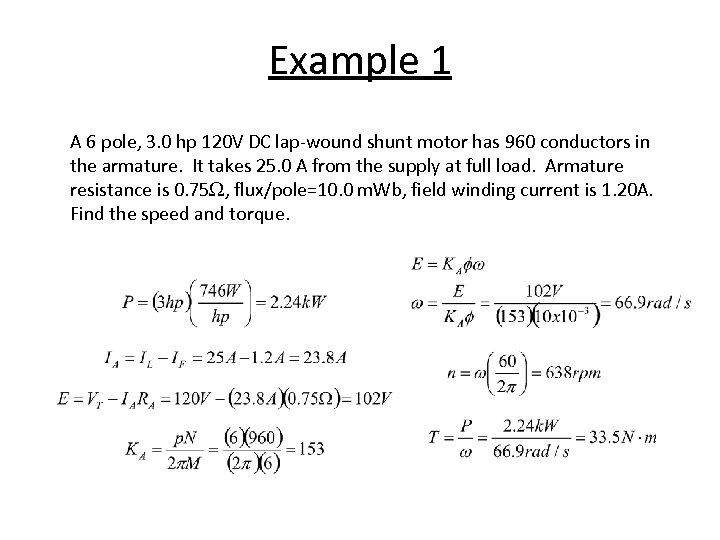

Example 1 A 6 pole, 3. 0 hp 120 V DC lap-wound shunt motor has 960 conductors in the armature. It takes 25. 0 A from the supply at full load. Armature resistance is 0. 75 , flux/pole=10. 0 m. Wb, field winding current is 1. 20 A. Find the speed and torque.

Example 1 A 6 pole, 3. 0 hp 120 V DC lap-wound shunt motor has 960 conductors in the armature. It takes 25. 0 A from the supply at full load. Armature resistance is 0. 75 , flux/pole=10. 0 m. Wb, field winding current is 1. 20 A. Find the speed and torque.

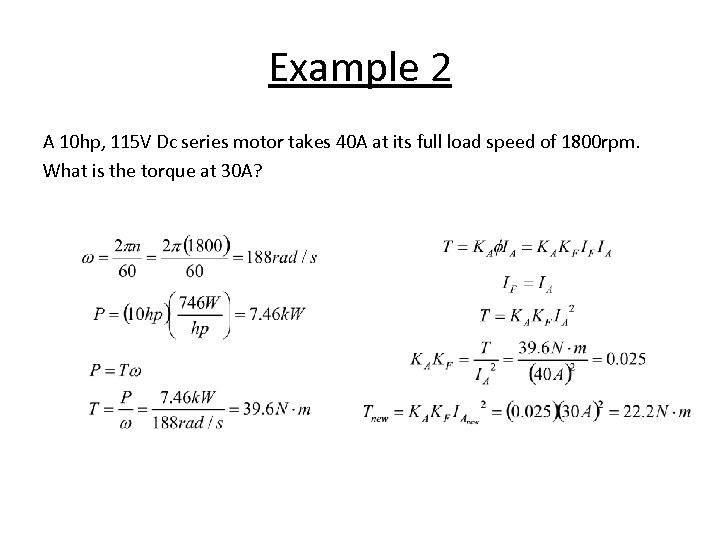

Example 2 A 10 hp, 115 V Dc series motor takes 40 A at its full load speed of 1800 rpm. What is the torque at 30 A?

Example 2 A 10 hp, 115 V Dc series motor takes 40 A at its full load speed of 1800 rpm. What is the torque at 30 A?

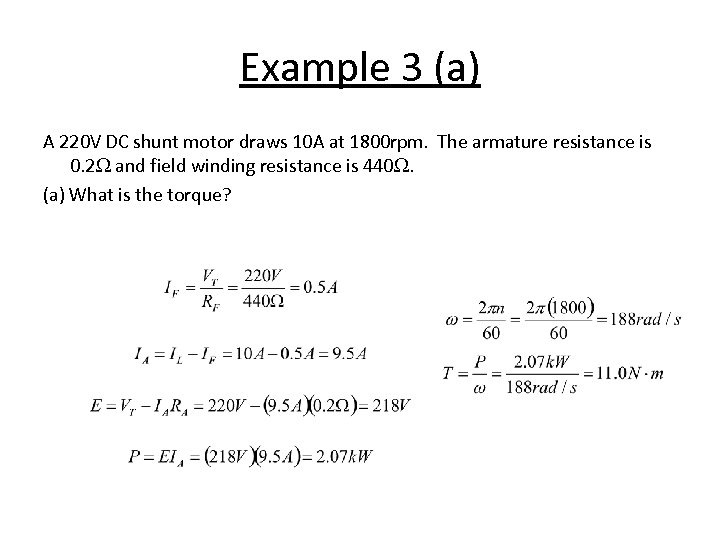

Example 3 (a) A 220 V DC shunt motor draws 10 A at 1800 rpm. The armature resistance is 0. 2 and field winding resistance is 440. (a) What is the torque?

Example 3 (a) A 220 V DC shunt motor draws 10 A at 1800 rpm. The armature resistance is 0. 2 and field winding resistance is 440. (a) What is the torque?

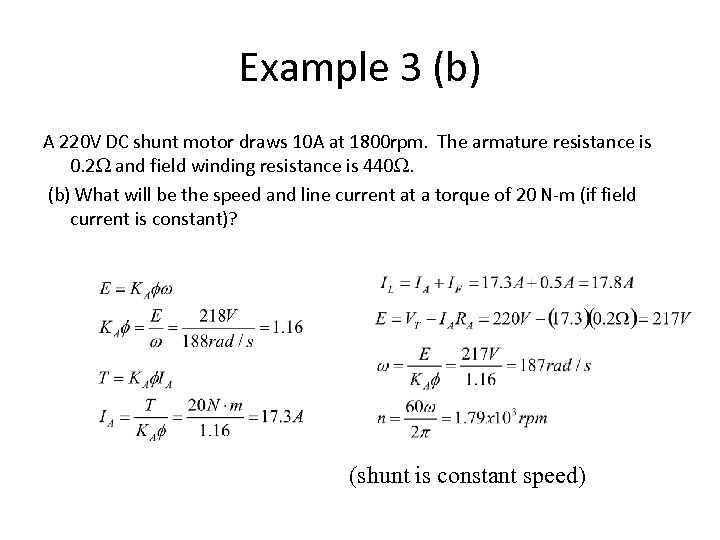

Example 3 (b) A 220 V DC shunt motor draws 10 A at 1800 rpm. The armature resistance is 0. 2 and field winding resistance is 440. (b) What will be the speed and line current at a torque of 20 N-m (if field current is constant)? (shunt is constant speed)

Example 3 (b) A 220 V DC shunt motor draws 10 A at 1800 rpm. The armature resistance is 0. 2 and field winding resistance is 440. (b) What will be the speed and line current at a torque of 20 N-m (if field current is constant)? (shunt is constant speed)

ac Machine ý Alternating current (ac) is the primary source of electrical energy. ý It is less expensive to produce and transmit than direct current. ý For this reason, and because ac voltage is induced into the armature of all generators, ac machines are generally more practical. ý May function as a generator (mechanical to electrical) or a motor (electrical to mechanical)

ac Machine ý Alternating current (ac) is the primary source of electrical energy. ý It is less expensive to produce and transmit than direct current. ý For this reason, and because ac voltage is induced into the armature of all generators, ac machines are generally more practical. ý May function as a generator (mechanical to electrical) or a motor (electrical to mechanical)

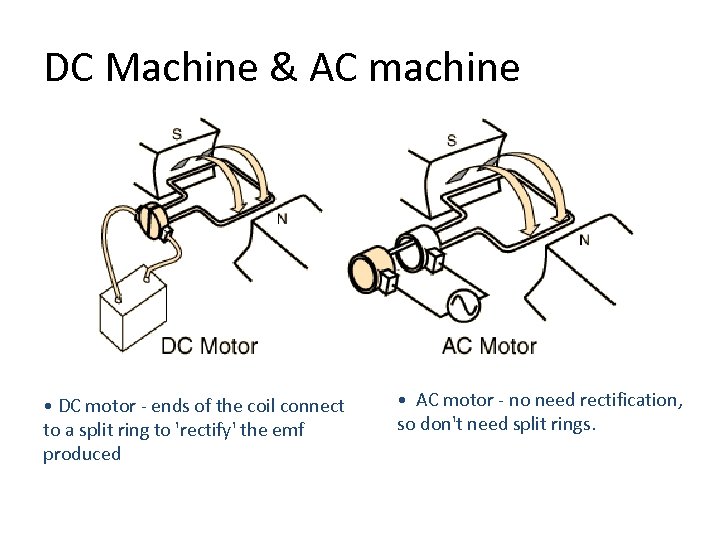

DC Machine & AC machine • DC motor - ends of the coil connect to a split ring to 'rectify' the emf produced • AC motor - no need rectification, so don't need split rings.

DC Machine & AC machine • DC motor - ends of the coil connect to a split ring to 'rectify' the emf produced • AC motor - no need rectification, so don't need split rings.

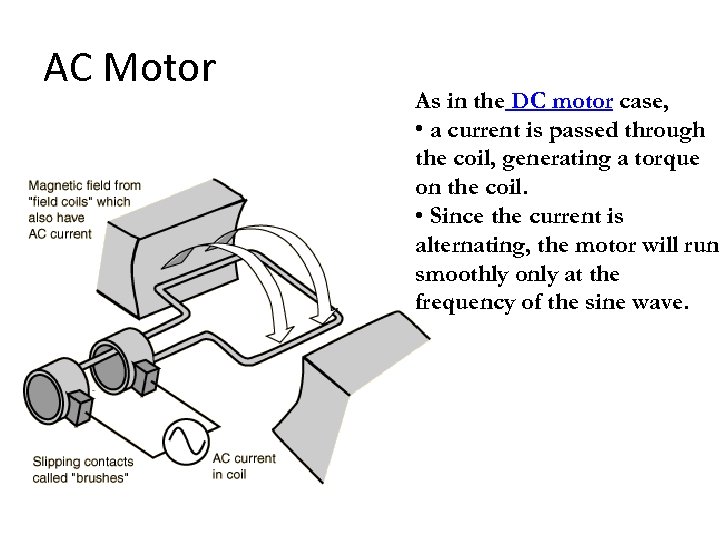

AC Motor As in the DC motor case, • a current is passed through the coil, generating a torque on the coil. • Since the current is alternating, the motor will run smoothly only at the frequency of the sine wave.

AC Motor As in the DC motor case, • a current is passed through the coil, generating a torque on the coil. • Since the current is alternating, the motor will run smoothly only at the frequency of the sine wave.

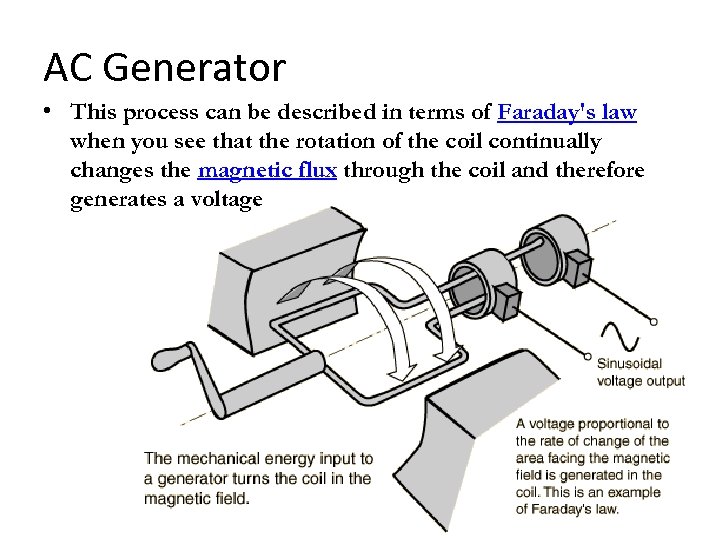

AC Generator • This process can be described in terms of Faraday's law when you see that the rotation of the coil continually changes the magnetic flux through the coil and therefore generates a voltage

AC Generator • This process can be described in terms of Faraday's law when you see that the rotation of the coil continually changes the magnetic flux through the coil and therefore generates a voltage

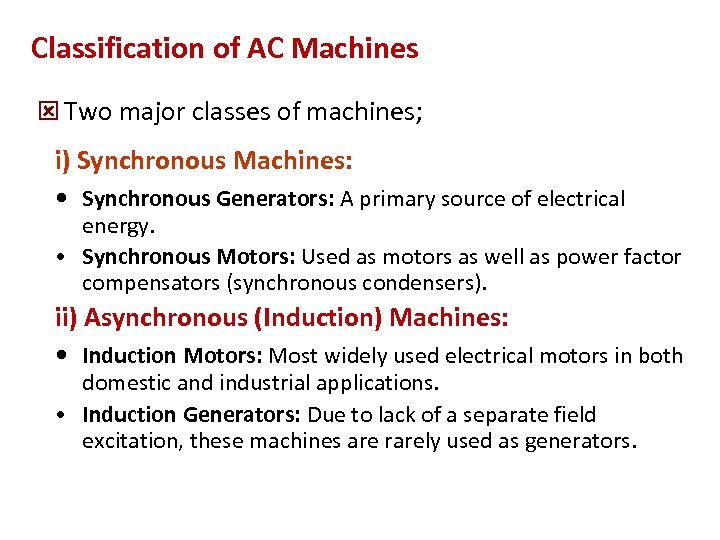

Classification of AC Machines ý Two major classes of machines; i) Synchronous Machines: • Synchronous Generators: A primary source of electrical energy. • Synchronous Motors: Used as motors as well as power factor compensators (synchronous condensers). ii) Asynchronous (Induction) Machines: • Induction Motors: Most widely used electrical motors in both domestic and industrial applications. • Induction Generators: Due to lack of a separate field excitation, these machines are rarely used as generators.

Classification of AC Machines ý Two major classes of machines; i) Synchronous Machines: • Synchronous Generators: A primary source of electrical energy. • Synchronous Motors: Used as motors as well as power factor compensators (synchronous condensers). ii) Asynchronous (Induction) Machines: • Induction Motors: Most widely used electrical motors in both domestic and industrial applications. • Induction Generators: Due to lack of a separate field excitation, these machines are rarely used as generators.

Synchronous Machine

Synchronous Machine

Synchronous Machine ý Origin of name: syn = equal, chronos = time ý Synchronous machines are called ‘synchronous’ because their mechanical shaft speed is directly related to the power system’s line frequency. ý the rotating air gap field and the rotor rotate at the same speed, called the synchronous speed. ý Synchronous machines are ac machine that have a field circuit supplied by an external dc source. – DC field winding on the rotor, – AC armature winding on the stator

Synchronous Machine ý Origin of name: syn = equal, chronos = time ý Synchronous machines are called ‘synchronous’ because their mechanical shaft speed is directly related to the power system’s line frequency. ý the rotating air gap field and the rotor rotate at the same speed, called the synchronous speed. ý Synchronous machines are ac machine that have a field circuit supplied by an external dc source. – DC field winding on the rotor, – AC armature winding on the stator

Synchronous Machine ý Synchronous machines are used primarily as generators of electrical power, called synchronous generators or alternators. ý They are usually large machines generating electrical power at hydro, nuclear, or thermal power stations. ý Synchronous motors are built in large units compare to induction motors (Induction motors are cheaper for smaller ratings) and used for constant speed industrial drives ý Application as a motor: pumps in generating stations, electric clocks, timers, and so forth where constant speed is desired.

Synchronous Machine ý Synchronous machines are used primarily as generators of electrical power, called synchronous generators or alternators. ý They are usually large machines generating electrical power at hydro, nuclear, or thermal power stations. ý Synchronous motors are built in large units compare to induction motors (Induction motors are cheaper for smaller ratings) and used for constant speed industrial drives ý Application as a motor: pumps in generating stations, electric clocks, timers, and so forth where constant speed is desired.

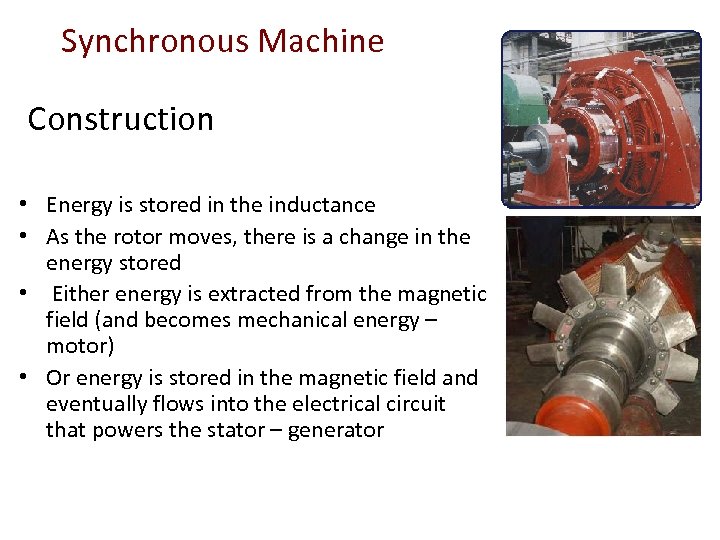

Synchronous Machine Construction • Energy is stored in the inductance • As the rotor moves, there is a change in the energy stored • Either energy is extracted from the magnetic field (and becomes mechanical energy – motor) • Or energy is stored in the magnetic field and eventually flows into the electrical circuit that powers the stator – generator

Synchronous Machine Construction • Energy is stored in the inductance • As the rotor moves, there is a change in the energy stored • Either energy is extracted from the magnetic field (and becomes mechanical energy – motor) • Or energy is stored in the magnetic field and eventually flows into the electrical circuit that powers the stator – generator

Synchronous Machine Construction • DC field windings are mounted on the (rotating) rotor - which is thus a rotating electromagnet • AC windings are mounted on the (stationary) stator resulting in three-phase AC stator voltages and currents ý The main part in the synchronous machines are i) Rotor ii) Stator

Synchronous Machine Construction • DC field windings are mounted on the (rotating) rotor - which is thus a rotating electromagnet • AC windings are mounted on the (stationary) stator resulting in three-phase AC stator voltages and currents ý The main part in the synchronous machines are i) Rotor ii) Stator

Synchronous Machine Rotor ý There are two types of rotors used in synchronous machines: i) cylindrical (or round) rotors ii) salient pole rotors ý Machines with cylindrical rotors are typically found in higher speed higher power applications such as turbogenerators. Using 2 or 4 poles, these machines rotate at 3600 or 1800 rpm (with 60 hz systems). ý Salient pole machines are typically found in large (many MW), low mechanical speed applications, including hydrogenerators, or smaller higher speed machines (up to 1 -2 MW). ý Salient pole rotors are less expensive than round rotors.

Synchronous Machine Rotor ý There are two types of rotors used in synchronous machines: i) cylindrical (or round) rotors ii) salient pole rotors ý Machines with cylindrical rotors are typically found in higher speed higher power applications such as turbogenerators. Using 2 or 4 poles, these machines rotate at 3600 or 1800 rpm (with 60 hz systems). ý Salient pole machines are typically found in large (many MW), low mechanical speed applications, including hydrogenerators, or smaller higher speed machines (up to 1 -2 MW). ý Salient pole rotors are less expensive than round rotors.

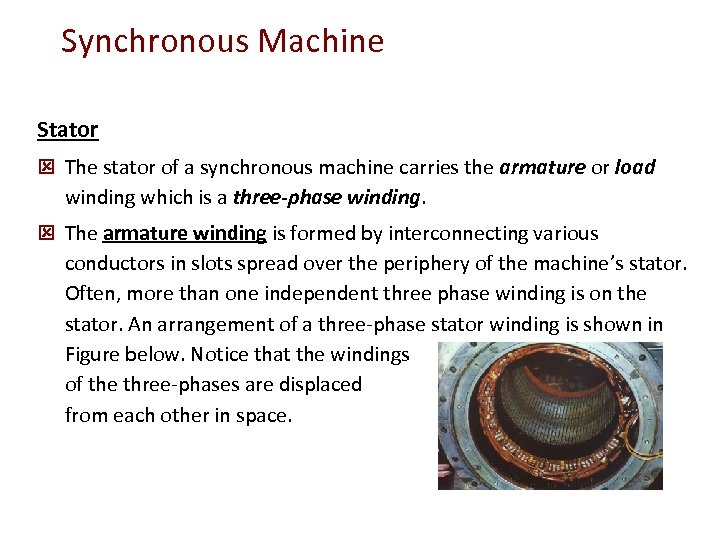

Synchronous Machine Stator ý The stator of a synchronous machine carries the armature or load winding which is a three-phase winding. ý The armature winding is formed by interconnecting various conductors in slots spread over the periphery of the machine’s stator. Often, more than one independent three phase winding is on the stator. An arrangement of a three-phase stator winding is shown in Figure below. Notice that the windings of the three-phases are displaced from each other in space.

Synchronous Machine Stator ý The stator of a synchronous machine carries the armature or load winding which is a three-phase winding. ý The armature winding is formed by interconnecting various conductors in slots spread over the periphery of the machine’s stator. Often, more than one independent three phase winding is on the stator. An arrangement of a three-phase stator winding is shown in Figure below. Notice that the windings of the three-phases are displaced from each other in space.

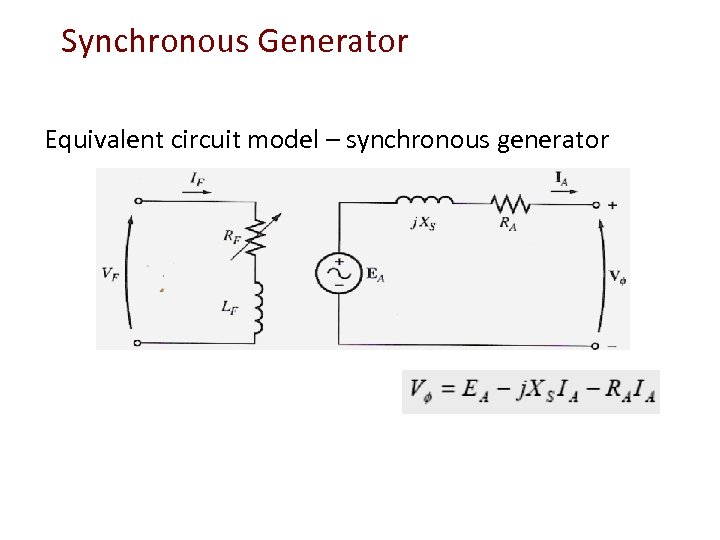

Synchronous Generator Equivalent circuit model – synchronous generator

Synchronous Generator Equivalent circuit model – synchronous generator

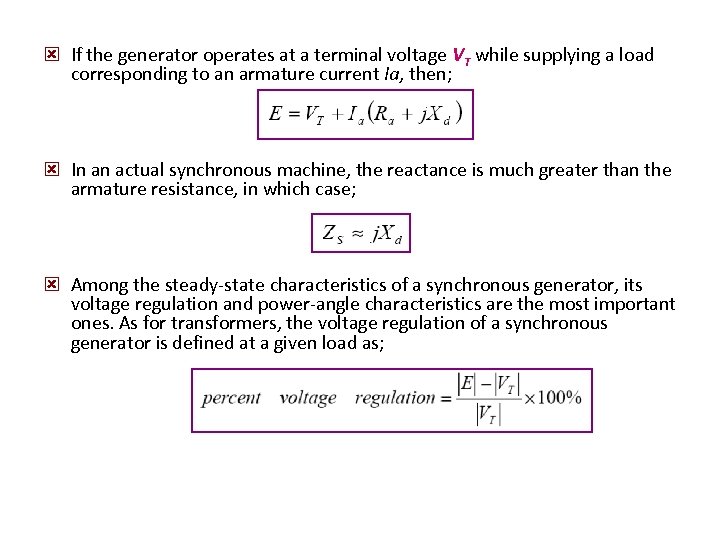

ý If the generator operates at a terminal voltage VT while supplying a load corresponding to an armature current Ia, then; ý In an actual synchronous machine, the reactance is much greater than the armature resistance, in which case; ý Among the steady-state characteristics of a synchronous generator, its voltage regulation and power-angle characteristics are the most important ones. As for transformers, the voltage regulation of a synchronous generator is defined at a given load as;

ý If the generator operates at a terminal voltage VT while supplying a load corresponding to an armature current Ia, then; ý In an actual synchronous machine, the reactance is much greater than the armature resistance, in which case; ý Among the steady-state characteristics of a synchronous generator, its voltage regulation and power-angle characteristics are the most important ones. As for transformers, the voltage regulation of a synchronous generator is defined at a given load as;

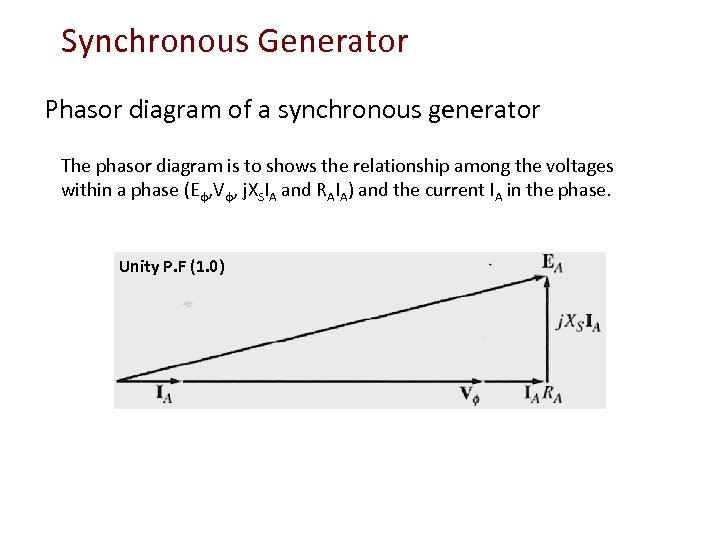

Synchronous Generator Phasor diagram of a synchronous generator The phasor diagram is to shows the relationship among the voltages within a phase (Eφ, Vφ, j. XSIA and RAIA) and the current IA in the phase. Unity P. F (1. 0)

Synchronous Generator Phasor diagram of a synchronous generator The phasor diagram is to shows the relationship among the voltages within a phase (Eφ, Vφ, j. XSIA and RAIA) and the current IA in the phase. Unity P. F (1. 0)

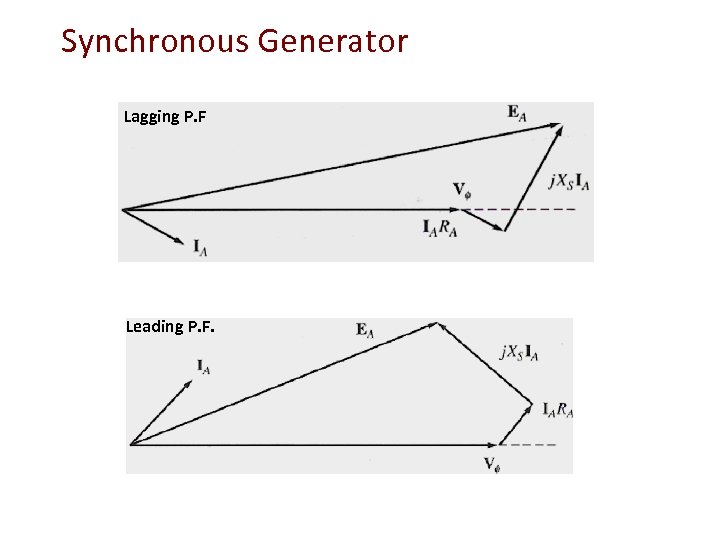

Synchronous Generator Lagging P. F Leading P. F.

Synchronous Generator Lagging P. F Leading P. F.

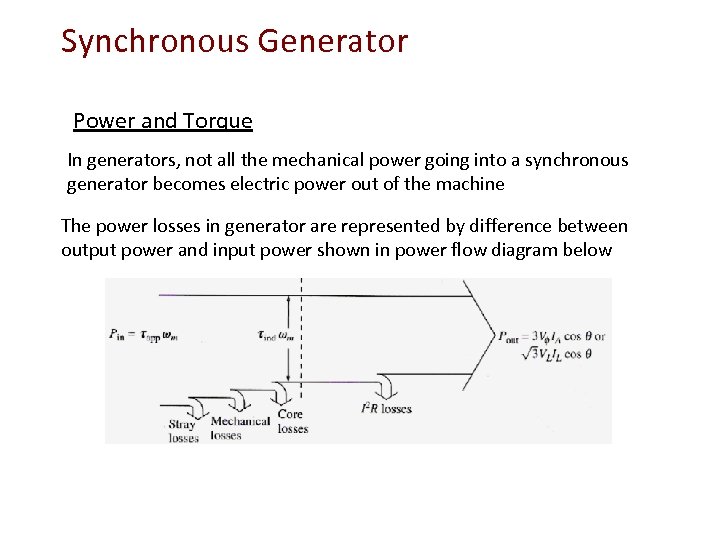

Synchronous Generator Power and Torque In generators, not all the mechanical power going into a synchronous generator becomes electric power out of the machine The power losses in generator are represented by difference between output power and input power shown in power flow diagram below

Synchronous Generator Power and Torque In generators, not all the mechanical power going into a synchronous generator becomes electric power out of the machine The power losses in generator are represented by difference between output power and input power shown in power flow diagram below

Synchronous Generator Losses Rotor - resistance; iron parts moving in a magnetic field causing currents to be generated in the rotor body - resistance of connections to the rotor (slip rings) Stator - resistance; magnetic losses (e. g. , hysteresis) Mechanical - friction at bearings, friction at slip rings Stray load losses - due to non-uniform current distribution

Synchronous Generator Losses Rotor - resistance; iron parts moving in a magnetic field causing currents to be generated in the rotor body - resistance of connections to the rotor (slip rings) Stator - resistance; magnetic losses (e. g. , hysteresis) Mechanical - friction at bearings, friction at slip rings Stray load losses - due to non-uniform current distribution

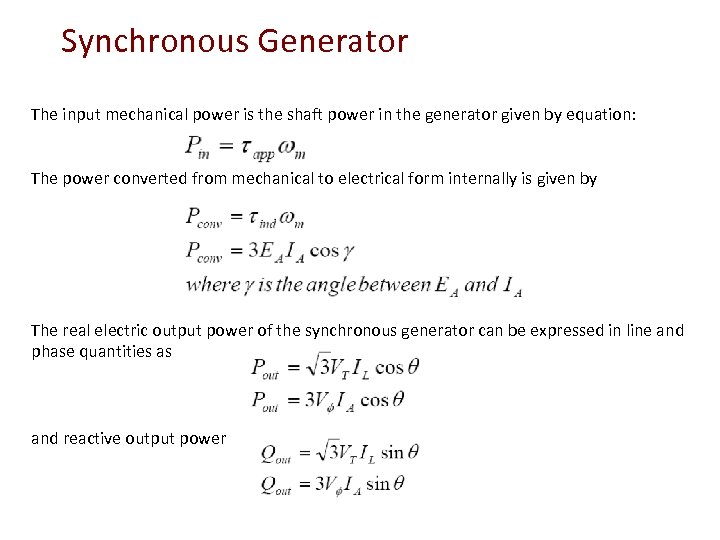

Synchronous Generator The input mechanical power is the shaft power in the generator given by equation: The power converted from mechanical to electrical form internally is given by The real electric output power of the synchronous generator can be expressed in line and phase quantities as and reactive output power

Synchronous Generator The input mechanical power is the shaft power in the generator given by equation: The power converted from mechanical to electrical form internally is given by The real electric output power of the synchronous generator can be expressed in line and phase quantities as and reactive output power

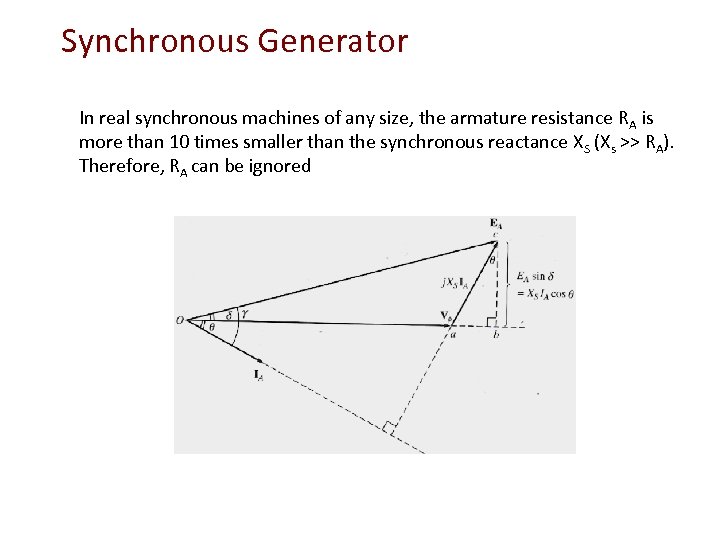

Synchronous Generator In real synchronous machines of any size, the armature resistance RA is more than 10 times smaller than the synchronous reactance XS (Xs >> RA). Therefore, RA can be ignored

Synchronous Generator In real synchronous machines of any size, the armature resistance RA is more than 10 times smaller than the synchronous reactance XS (Xs >> RA). Therefore, RA can be ignored

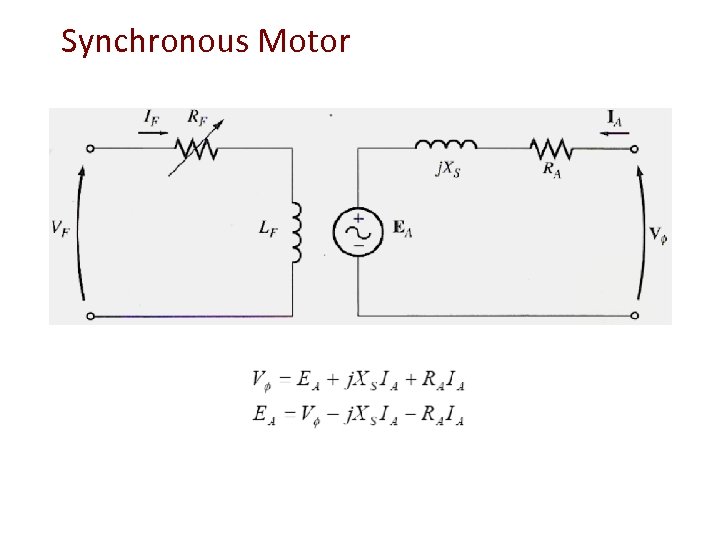

Synchronous Motor

Synchronous Motor

Example : Synchronous Generator. A three-phase, wye-connected 2500 k. VA and 6. 6 k. V generator operates at full-load. The per-phase armature resistance Ra and the synchronous reactance, Xd, are (0. 07+j 10. 4). Calculate the percent voltage regulation at (a) 0. 8 power-factor lagging, and (b) 0. 8 power-factor leading. ý

Example : Synchronous Generator. A three-phase, wye-connected 2500 k. VA and 6. 6 k. V generator operates at full-load. The per-phase armature resistance Ra and the synchronous reactance, Xd, are (0. 07+j 10. 4). Calculate the percent voltage regulation at (a) 0. 8 power-factor lagging, and (b) 0. 8 power-factor leading. ý

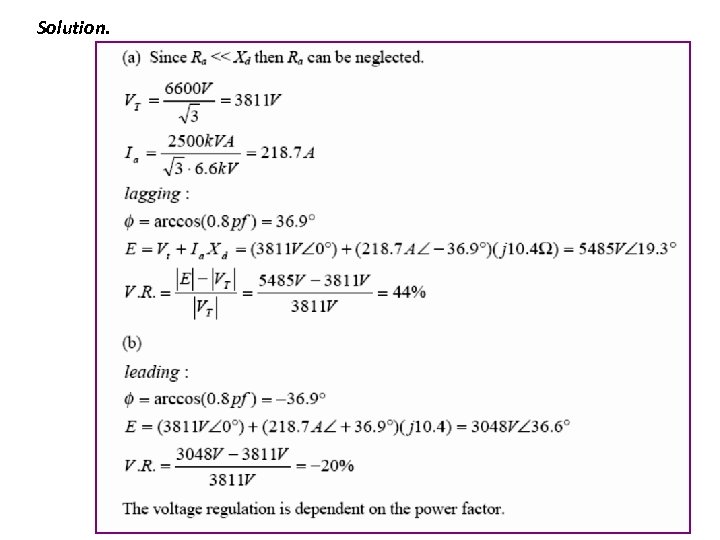

Solution.

Solution.