682177a0623d902095f5efd5294c4bc7.ppt

- Количество слайдов: 95

Day 1 Lean Principles and practices The Ferryport Group, www. ferryport. org, contact@ferryport. org

Day 1 Lean Principles and practices The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers Please put your name on the blank piece of paper in front of you and place it on the desk for all to see. Who’s got the most interesting paper? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers Please put your name on the blank piece of paper in front of you and place it on the desk for all to see. Who’s got the most interesting paper? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers Please answer the following: Q. Where do you keep bleach/cleaning products? Q. Where do you keep your knives and forks? Q. Where do you keep spare bedding? Q. Where do you keep your beer? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers Please answer the following: Q. Where do you keep bleach/cleaning products? Q. Where do you keep your knives and forks? Q. Where do you keep spare bedding? Q. Where do you keep your beer? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers 1. Think of a number between 1 and 10. 2. Multiply the number by 9. 3. Add the digits of your result. 4. Subtract 5 from your new number. 5. Find the letter that corresponds to your number, if 1 = A, 2 = B, 3 = C, etc. 6. Think of a country that begins with your letter. 7. Write down the name of that country. 8. Think of an animal beginning with the second letter of your country. 9. Think of the colour of that animal. 10. Write down the animal and its colour. Did you get a Pink Elephant as well? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Introductions and Ice Breakers 1. Think of a number between 1 and 10. 2. Multiply the number by 9. 3. Add the digits of your result. 4. Subtract 5 from your new number. 5. Find the letter that corresponds to your number, if 1 = A, 2 = B, 3 = C, etc. 6. Think of a country that begins with your letter. 7. Write down the name of that country. 8. Think of an animal beginning with the second letter of your country. 9. Think of the colour of that animal. 10. Write down the animal and its colour. Did you get a Pink Elephant as well? The Ferryport Group, www. ferryport. org, contact@ferryport. org

A History of Lean Manufacturing

A History of Lean Manufacturing

Call it what you will Just another Modern Tool • • • Lean Manufacturing World Class Manufacturing Kaizen TPM Continuous Improvements Lean Thinking The Ferryport Group, www. ferryport. org, contact@ferryport. org

Call it what you will Just another Modern Tool • • • Lean Manufacturing World Class Manufacturing Kaizen TPM Continuous Improvements Lean Thinking The Ferryport Group, www. ferryport. org, contact@ferryport. org

A Brief History A number of sources • Eli Whitney – 1790 s – interchangeable parts • Henry Ford – 1910 s – production lines • Alfred Sloan – 1930 s (General Motors) – more strategic approach The Ferryport Group, www. ferryport. org, contact@ferryport. org

A Brief History A number of sources • Eli Whitney – 1790 s – interchangeable parts • Henry Ford – 1910 s – production lines • Alfred Sloan – 1930 s (General Motors) – more strategic approach The Ferryport Group, www. ferryport. org, contact@ferryport. org

Charles Sorensen Vice-President of Production for Ford "The only thing we can't make is something we can't think about. " A bomber an hour for the war effort rather than a bomber a day The Ferryport Group, www. ferryport. org, contact@ferryport. org

Charles Sorensen Vice-President of Production for Ford "The only thing we can't make is something we can't think about. " A bomber an hour for the war effort rather than a bomber a day The Ferryport Group, www. ferryport. org, contact@ferryport. org

Next Step Toyota's engineers looked to : Henry Ford Inventor of the assembly line Frederick W. Taylor Inventor of Modern Management Techniques and Industrial Engineering Dr. W. Edwards Deming Father of Modern Quality Management The Ferryport Group, www. ferryport. org, contact@ferryport. org

Next Step Toyota's engineers looked to : Henry Ford Inventor of the assembly line Frederick W. Taylor Inventor of Modern Management Techniques and Industrial Engineering Dr. W. Edwards Deming Father of Modern Quality Management The Ferryport Group, www. ferryport. org, contact@ferryport. org

Improvement – Toyota’s Kaizen Masters, Shingo and Ohno • Dr. Shigeo Shingo was asked “Who really discovered Lean, you or Taiichi Ohno? ” • He replied “I did, for I was Ohno’s teacher. ” however: • Toyota group manager Chihiro Nakao stated – “Which came first, the chicken or the egg? ” The Ferryport Group, www. ferryport. org, contact@ferryport. org

Improvement – Toyota’s Kaizen Masters, Shingo and Ohno • Dr. Shigeo Shingo was asked “Who really discovered Lean, you or Taiichi Ohno? ” • He replied “I did, for I was Ohno’s teacher. ” however: • Toyota group manager Chihiro Nakao stated – “Which came first, the chicken or the egg? ” The Ferryport Group, www. ferryport. org, contact@ferryport. org

The 7 Wastes – the Toyota concept of where it’s going wrong • • Over production Poor quality Movement of men Movement of materials Un-necessary processing Waiting times Stock The Ferryport Group, www. ferryport. org, contact@ferryport. org

The 7 Wastes – the Toyota concept of where it’s going wrong • • Over production Poor quality Movement of men Movement of materials Un-necessary processing Waiting times Stock The Ferryport Group, www. ferryport. org, contact@ferryport. org

Techniques • • 5 S - Housekeeping Total Productive Maintenance SMED – quick changeovers Problem Solving – CEDAC, brainstorming Poka-Yoke - foolproofing FMEA – prevention and contingency planning Standard Work – SOPs, all doing the same Kanban – stock control systems The Ferryport Group, www. ferryport. org, contact@ferryport. org

Techniques • • 5 S - Housekeeping Total Productive Maintenance SMED – quick changeovers Problem Solving – CEDAC, brainstorming Poka-Yoke - foolproofing FMEA – prevention and contingency planning Standard Work – SOPs, all doing the same Kanban – stock control systems The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lean Thinking FMEA and Contingency Planning HACCP Risk Analysis What can go wrong and how do we stop it? If we can’t stop it, how do we contain it? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lean Thinking FMEA and Contingency Planning HACCP Risk Analysis What can go wrong and how do we stop it? If we can’t stop it, how do we contain it? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Food Industry • What can go wrong? – Hair getting into the product • How do we stop it? – Use hair nets, training, supervision • If we can’t stop it, how do we contain it? – Stores quarantine, Product recall The Ferryport Group, www. ferryport. org, contact@ferryport. org

Food Industry • What can go wrong? – Hair getting into the product • How do we stop it? – Use hair nets, training, supervision • If we can’t stop it, how do we contain it? – Stores quarantine, Product recall The Ferryport Group, www. ferryport. org, contact@ferryport. org

Automotive • What can go wrong? – Carburettor blocking up • How do we stop it? – Filter systems through the petrochemical stages, in the petrol pumps and in the fuel pipes on the car • If we can’t stop it, how do we contain it? – Easy to work on engines, spare parts on stock/24 hour delivery, RAC/AA The Ferryport Group, www. ferryport. org, contact@ferryport. org

Automotive • What can go wrong? – Carburettor blocking up • How do we stop it? – Filter systems through the petrochemical stages, in the petrol pumps and in the fuel pipes on the car • If we can’t stop it, how do we contain it? – Easy to work on engines, spare parts on stock/24 hour delivery, RAC/AA The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lean Manufacturing is Suitable for Everyone • Not ‘too sexy’ for your any company • Not confined to Manufacturing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lean Manufacturing is Suitable for Everyone • Not ‘too sexy’ for your any company • Not confined to Manufacturing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Questions? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Questions? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Challenges What are the current challenges that British manufacturing faces? Global village Legislation – EU, environmental, H&S Market forces Other companies BOGOF – Buy One, Get One Free (Supermarkets force this on suppliers) The Ferryport Group, www. ferryport. org, contact@ferryport. org

Challenges What are the current challenges that British manufacturing faces? Global village Legislation – EU, environmental, H&S Market forces Other companies BOGOF – Buy One, Get One Free (Supermarkets force this on suppliers) The Ferryport Group, www. ferryport. org, contact@ferryport. org

Challenges How do we know we are improving? How do we know that we need to improve? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Challenges How do we know we are improving? How do we know that we need to improve? The Ferryport Group, www. ferryport. org, contact@ferryport. org

KPIs • Give me a few examples of what you are currently using • Why do you use these KPIs in particular? • What initiated these KPIs? – Company specific quality, cost and delivery • What else can initiate KPIs? – Customer complaints, short term monitoring The Ferryport Group, www. ferryport. org, contact@ferryport. org

KPIs • Give me a few examples of what you are currently using • Why do you use these KPIs in particular? • What initiated these KPIs? – Company specific quality, cost and delivery • What else can initiate KPIs? – Customer complaints, short term monitoring The Ferryport Group, www. ferryport. org, contact@ferryport. org

Questions? Coffee The Ferryport Group, www. ferryport. org, contact@ferryport. org

Questions? Coffee The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping

Value Stream Mapping

Value Stream Mapping What parts of the process actually add value? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping What parts of the process actually add value? The Ferryport Group, www. ferryport. org, contact@ferryport. org

What do we mean by Value Stream Mapping? • Exercise 1 • Describe in as much detail as possible the steps required to make a cup of tea • Split into teams The Ferryport Group, www. ferryport. org, contact@ferryport. org

What do we mean by Value Stream Mapping? • Exercise 1 • Describe in as much detail as possible the steps required to make a cup of tea • Split into teams The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 1 – Cup of Tea • Review the Standard Operating Procedures (SOPs) or recipes as they are sometimes known. • Detail them in a clearer step-by-step process Detail the individual steps only for now Tracking Sheets Recipes Red and Green Markers The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 1 – Cup of Tea • Review the Standard Operating Procedures (SOPs) or recipes as they are sometimes known. • Detail them in a clearer step-by-step process Detail the individual steps only for now Tracking Sheets Recipes Red and Green Markers The Ferryport Group, www. ferryport. org, contact@ferryport. org

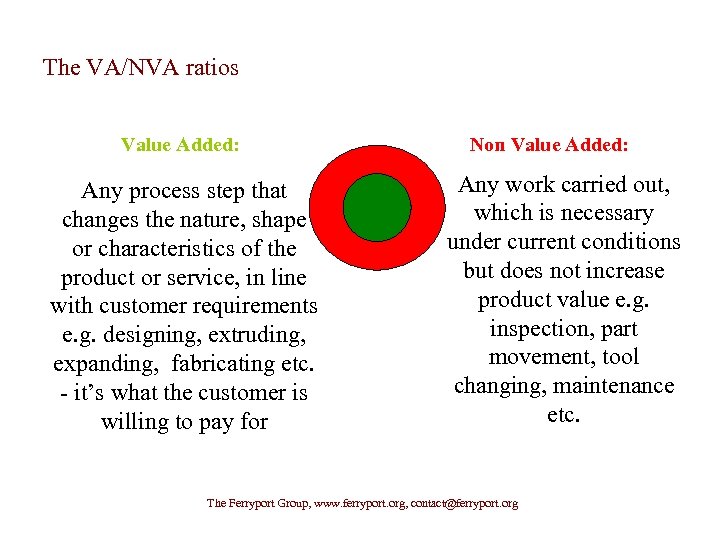

The VA/NVA ratios Value Added: Any process step that changes the nature, shape or characteristics of the product or service, in line with customer requirements e. g. designing, extruding, expanding, fabricating etc. - it’s what the customer is willing to pay for Non Value Added: Any work carried out, which is necessary under current conditions but does not increase product value e. g. inspection, part movement, tool changing, maintenance etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

The VA/NVA ratios Value Added: Any process step that changes the nature, shape or characteristics of the product or service, in line with customer requirements e. g. designing, extruding, expanding, fabricating etc. - it’s what the customer is willing to pay for Non Value Added: Any work carried out, which is necessary under current conditions but does not increase product value e. g. inspection, part movement, tool changing, maintenance etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

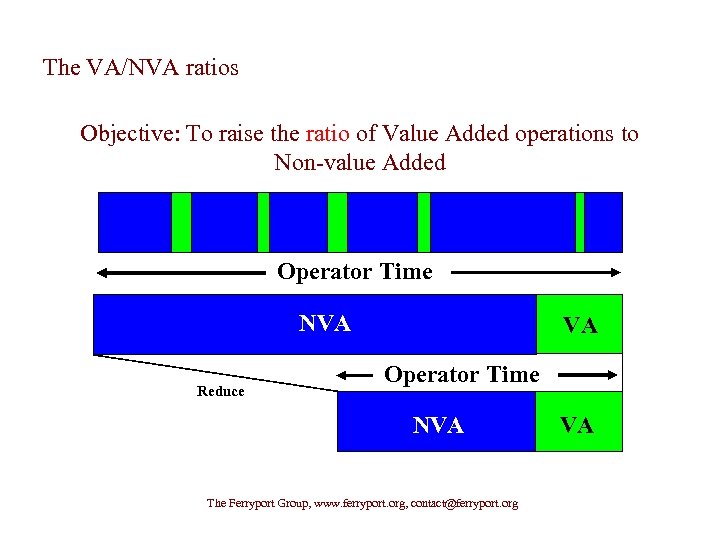

The VA/NVA ratios Objective: To raise the ratio of Value Added operations to Non-value Added Operator Time NVA Reduce VA Operator Time NVA The Ferryport Group, www. ferryport. org, contact@ferryport. org VA

The VA/NVA ratios Objective: To raise the ratio of Value Added operations to Non-value Added Operator Time NVA Reduce VA Operator Time NVA The Ferryport Group, www. ferryport. org, contact@ferryport. org VA

The Seven Wastes 1. 2. 3. 4. 5. 6. 7. Poor Quality Panic Production Time Movement 1 - Parts Movement 2 - People Stock Processing The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 1. 2. 3. 4. 5. 6. 7. Poor Quality Panic Production Time Movement 1 - Parts Movement 2 - People Stock Processing The Ferryport Group, www. ferryport. org, contact@ferryport. org

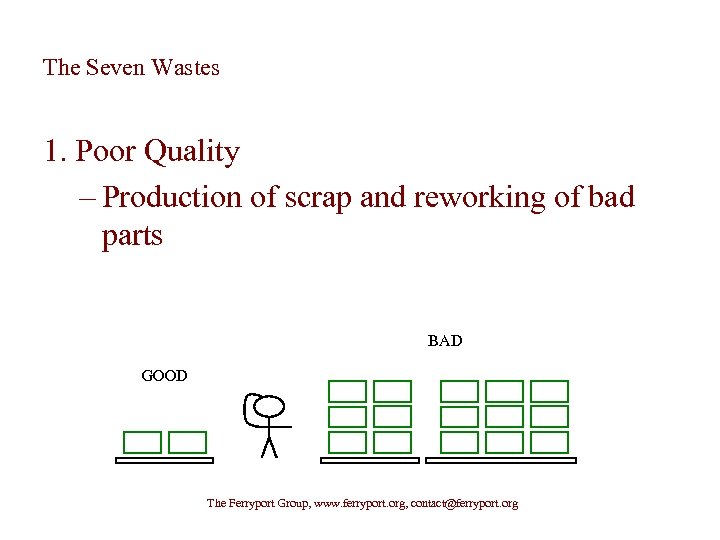

The Seven Wastes 1. Poor Quality – Production of scrap and reworking of bad parts BAD GOOD The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 1. Poor Quality – Production of scrap and reworking of bad parts BAD GOOD The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating bad quality: • Improved customer satisfaction. • Lower costs of correction and materials used • Improved efficiency and ability to meet workload requirements • Less stress and distraction The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating bad quality: • Improved customer satisfaction. • Lower costs of correction and materials used • Improved efficiency and ability to meet workload requirements • Less stress and distraction The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 2. Over production Over running an unstable process – Manufacturing ahead of schedule • • Worst waste of all Produces excess inventory throughout system All other wastes are produced as a result Hides manufacturing problems The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 2. Over production Over running an unstable process – Manufacturing ahead of schedule • • Worst waste of all Produces excess inventory throughout system All other wastes are produced as a result Hides manufacturing problems The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of not overproducing: • Releases time to meet current requirement. • Eliminates double-handling, filing etc. • Reduced risk to changes in plans etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of not overproducing: • Releases time to meet current requirement. • Eliminates double-handling, filing etc. • Reduced risk to changes in plans etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 3. Time Waiting for things to happen – Machinery availability – Stock to arrive – people The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 3. Time Waiting for things to happen – Machinery availability – Stock to arrive – people The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating idle time: • Better utilisation of staff time. • Better utilisation of equipment. • Less boredom or frustration The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating idle time: • Better utilisation of staff time. • Better utilisation of equipment. • Less boredom or frustration The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 4. Movement 1 – Parts – Unnecessary movement or handling – Moving with no load – Moving batches around The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 4. Movement 1 – Parts – Unnecessary movement or handling – Moving with no load – Moving batches around The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of reducing transportation: • Reduced cost of handling systems. • Less activity and disruption. • Reduced risk of handling damage, lost documents etc • Can lead to single piece flow The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of reducing transportation: • Reduced cost of handling systems. • Less activity and disruption. • Reduced risk of handling damage, lost documents etc • Can lead to single piece flow The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 5. Movement 2 – People • Operator Motion – Unnecessary or excessive – walking, bending, stretching, twisting and reaching – Moving from one machine to another The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 5. Movement 2 – People • Operator Motion – Unnecessary or excessive – walking, bending, stretching, twisting and reaching – Moving from one machine to another The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating operator motion waste: • Better working environment – less employee fatigue. • Less work related injuries and absence. • More productive work environment – happier staff The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating operator motion waste: • Better working environment – less employee fatigue. • Less work related injuries and absence. • More productive work environment – happier staff The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 6. Stock – Raw Material – WIP – Stock The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 6. Stock – Raw Material – WIP – Stock The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of reducing Stock: • • Less money tied up. Less floor space and storage equipment needed. Less handling and transportation. Quicker discovery of quality problems and response to change in requirements. • Reduced risk of obsolete stock and stock loss. The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of reducing Stock: • • Less money tied up. Less floor space and storage equipment needed. Less handling and transportation. Quicker discovery of quality problems and response to change in requirements. • Reduced risk of obsolete stock and stock loss. The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 7. Processing – Set-up times or breakdown – Too much in the process – not doing what the customer wants The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes 7. Processing – Set-up times or breakdown – Too much in the process – not doing what the customer wants The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating process waste: • Eliminate cost of unnecessary processes • Improved flow of work through the factory • Increased availability of resources The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Benefits of eliminating process waste: • Eliminate cost of unnecessary processes • Improved flow of work through the factory • Increased availability of resources The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Identify - Observe and map the process - Share observations with the team Categorise - value adding and non-value adding activities - Prioritise wastes, which ones do we solve first? Eliminate - Countermeasure The Ferryport Group, www. ferryport. org, contact@ferryport. org

The Seven Wastes Identify - Observe and map the process - Share observations with the team Categorise - value adding and non-value adding activities - Prioritise wastes, which ones do we solve first? Eliminate - Countermeasure The Ferryport Group, www. ferryport. org, contact@ferryport. org

Decide on Value Adding and Non-Value Adding Value adding is described as: “ ” Non-value adding is everything else The Ferryport Group, www. ferryport. org, contact@ferryport. org

Decide on Value Adding and Non-Value Adding Value adding is described as: “ ” Non-value adding is everything else The Ferryport Group, www. ferryport. org, contact@ferryport. org

VA and NVA I prefer to think of it as: ‘something that the customer would be willing to pay for’ The Ferryport Group, www. ferryport. org, contact@ferryport. org

VA and NVA I prefer to think of it as: ‘something that the customer would be willing to pay for’ The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping • Exercise 2 • Decide which of the steps you have detailed are actually adding value to the tea making process • What percentage do you think this will be? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping • Exercise 2 • Decide which of the steps you have detailed are actually adding value to the tea making process • What percentage do you think this will be? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping Typically this will come in at around 5% The Ferryport Group, www. ferryport. org, contact@ferryport. org

Value Stream Mapping Typically this will come in at around 5% The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lunch The Ferryport Group, www. ferryport. org, contact@ferryport. org

Lunch The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 2 – Timing the Process • Split the process up into distinct process groups and time each one • Go into as much detail as possible • Prepare this information in order to run the process as a production line The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 2 – Timing the Process • Split the process up into distinct process groups and time each one • Go into as much detail as possible • Prepare this information in order to run the process as a production line The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time Lead time analysis is simply calculating how far in advance certain items have to be ordered or certain processes have to start We’ve all asked the question ‘what’s the lead time on that? ’ The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time Lead time analysis is simply calculating how far in advance certain items have to be ordered or certain processes have to start We’ve all asked the question ‘what’s the lead time on that? ’ The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • When you make a cup of tea, what is the first major step that you do? Check the water level in the kettle and switch the kettle on • Why? Because whilst you are waiting for the kettle to boil, other work can be completed The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • When you make a cup of tea, what is the first major step that you do? Check the water level in the kettle and switch the kettle on • Why? Because whilst you are waiting for the kettle to boil, other work can be completed The Ferryport Group, www. ferryport. org, contact@ferryport. org

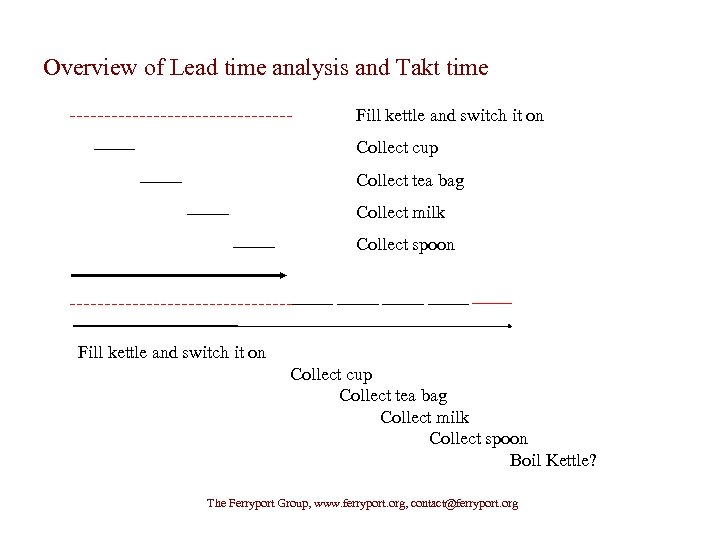

Overview of Lead time analysis and Takt time Fill kettle and switch it on Collect cup Collect tea bag Collect milk Collect spoon Boil Kettle? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time Fill kettle and switch it on Collect cup Collect tea bag Collect milk Collect spoon Boil Kettle? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • You can see from here that the process might take twice as long without this analysis. • You might have to stop production whilst you wait for materials to arrive The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • You can see from here that the process might take twice as long without this analysis. • You might have to stop production whilst you wait for materials to arrive The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • TAKT time • In effect, the amount of time that you have to fulfil your customer demands • Not to be confused with: • Lead time • Cycle time The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • TAKT time • In effect, the amount of time that you have to fulfil your customer demands • Not to be confused with: • Lead time • Cycle time The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • If your customer wants eight pallets per day and you work an eight hour day, you could state that the takt time is one hour per pallet. • Each pallet has sixty boxes, therefore you have a takt time of one minute per box. • Each box has 12 components, therefore takt time is 5 seconds per component. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • If your customer wants eight pallets per day and you work an eight hour day, you could state that the takt time is one hour per pallet. • Each pallet has sixty boxes, therefore you have a takt time of one minute per box. • Each box has 12 components, therefore takt time is 5 seconds per component. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • This then means that every five seconds you have to be able to produce one component. • ‘Easy’ you might say. • Breakdowns • Poor productivity – hangovers, cigarette breaks • Changeovers These all have to be considered. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • This then means that every five seconds you have to be able to produce one component. • ‘Easy’ you might say. • Breakdowns • Poor productivity – hangovers, cigarette breaks • Changeovers These all have to be considered. The Ferryport Group, www. ferryport. org, contact@ferryport. org

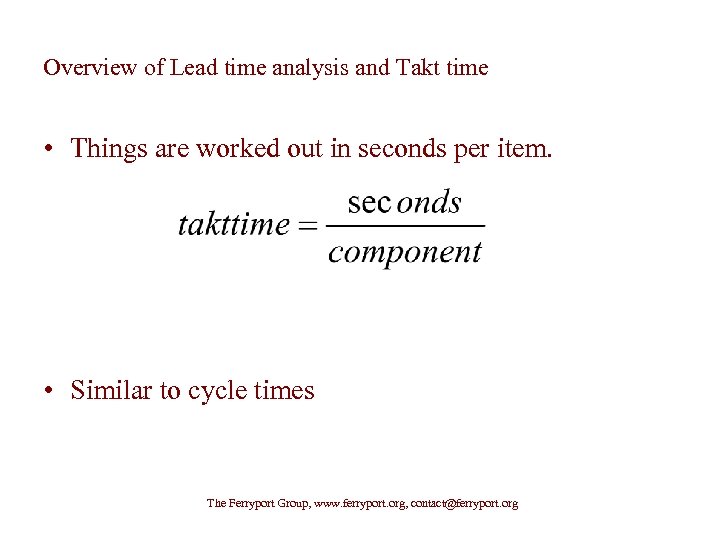

Overview of Lead time analysis and Takt time • Things are worked out in seconds per item. • Similar to cycle times The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • Things are worked out in seconds per item. • Similar to cycle times The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • We can then have a direct comparison If TT > CT then you cope with the demand. - you have capacity If TT = CT then production is breaking even. - good luck If TT < CT then you will have to catch up. - double shift, capital money, overtime etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • We can then have a direct comparison If TT > CT then you cope with the demand. - you have capacity If TT = CT then production is breaking even. - good luck If TT < CT then you will have to catch up. - double shift, capital money, overtime etc. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • That is why we looked at Value Stream Mapping earlier • Analyse and reduce waste • Increase capacity – Tell the sales team to get you more work – Pay people off And if you’ve already done all of this? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • That is why we looked at Value Stream Mapping earlier • Analyse and reduce waste • Increase capacity – Tell the sales team to get you more work – Pay people off And if you’ve already done all of this? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • From the earlier figures • Takt time equals one component every five seconds • What do you do if the customer is having a promotion of their product and suddenly wants 10 pallets per day? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • From the earlier figures • Takt time equals one component every five seconds • What do you do if the customer is having a promotion of their product and suddenly wants 10 pallets per day? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • If your customer wants ten pallets per day and you work an eight hour day, you could state that the takt time is 48 minutes per pallet. • Each pallet has sixty boxes, therefore you have a takt time of 48 seconds per box. • Each box has 12 components, therefore takt time is 4 seconds per component. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • If your customer wants ten pallets per day and you work an eight hour day, you could state that the takt time is 48 minutes per pallet. • Each pallet has sixty boxes, therefore you have a takt time of 48 seconds per box. • Each box has 12 components, therefore takt time is 4 seconds per component. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • Are you going to introduce 25% more machinery? • Work 25% more overtime? • Start working weekends at time and a half? One option : cellular manufacturing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Overview of Lead time analysis and Takt time • Are you going to introduce 25% more machinery? • Work 25% more overtime? • Start working weekends at time and a half? One option : cellular manufacturing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing “Describe in as much detail as possible the steps required to make a coconut mouse. ” With detailed information we can begin to look at sharing the work out The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing “Describe in as much detail as possible the steps required to make a coconut mouse. ” With detailed information we can begin to look at sharing the work out The Ferryport Group, www. ferryport. org, contact@ferryport. org

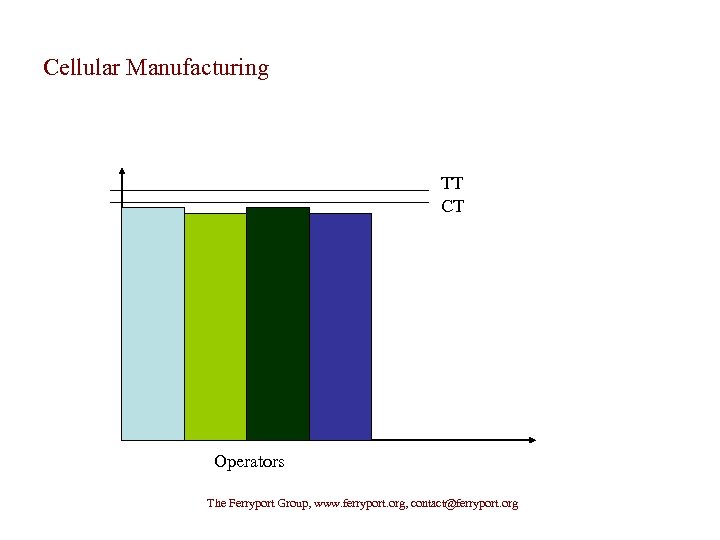

Cellular Manufacturing TT CT Operators The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing TT CT Operators The Ferryport Group, www. ferryport. org, contact@ferryport. org

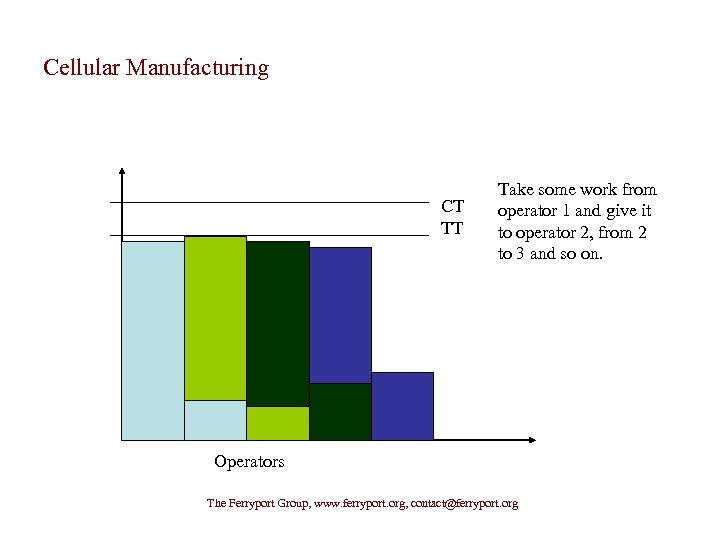

Cellular Manufacturing CT TT Take some work from operator 1 and give it to operator 2, from 2 to 3 and so on. Operators The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing CT TT Take some work from operator 1 and give it to operator 2, from 2 to 3 and so on. Operators The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing You can not alter the takt time, that is for your customer, but you may be able to alter the Cycle Times of the individual operators. Only if you have detailed information The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing You can not alter the takt time, that is for your customer, but you may be able to alter the Cycle Times of the individual operators. Only if you have detailed information The Ferryport Group, www. ferryport. org, contact@ferryport. org

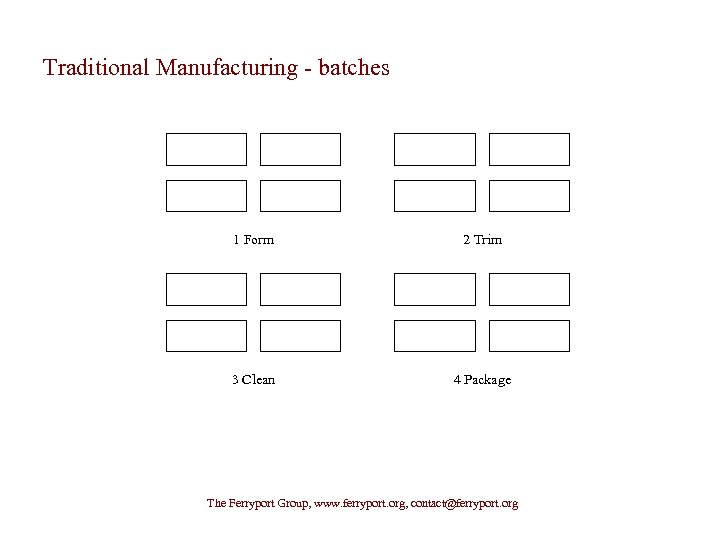

Traditional Manufacturing - batches 1 Form 2 Trim 3 Clean 4 Package The Ferryport Group, www. ferryport. org, contact@ferryport. org

Traditional Manufacturing - batches 1 Form 2 Trim 3 Clean 4 Package The Ferryport Group, www. ferryport. org, contact@ferryport. org

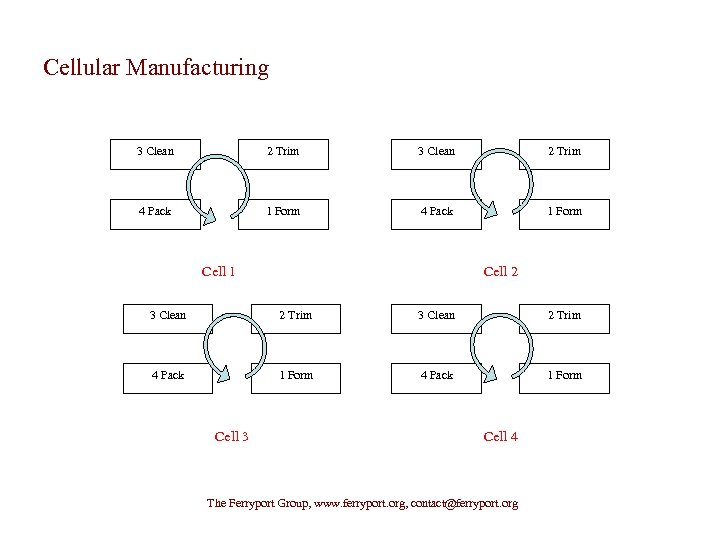

Cellular Manufacturing 3 Clean 2 Trim 4 Pack 1 Form Cell 1 Cell 2 3 Clean 2 Trim 4 Pack 1 Form Cell 3 Cell 4 The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing 3 Clean 2 Trim 4 Pack 1 Form Cell 1 Cell 2 3 Clean 2 Trim 4 Pack 1 Form Cell 3 Cell 4 The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing • One operator can run a number of machines • When takt time decreases it might be possible to bring in a second operator • This might even be for half the time The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing • One operator can run a number of machines • When takt time decreases it might be possible to bring in a second operator • This might even be for half the time The Ferryport Group, www. ferryport. org, contact@ferryport. org

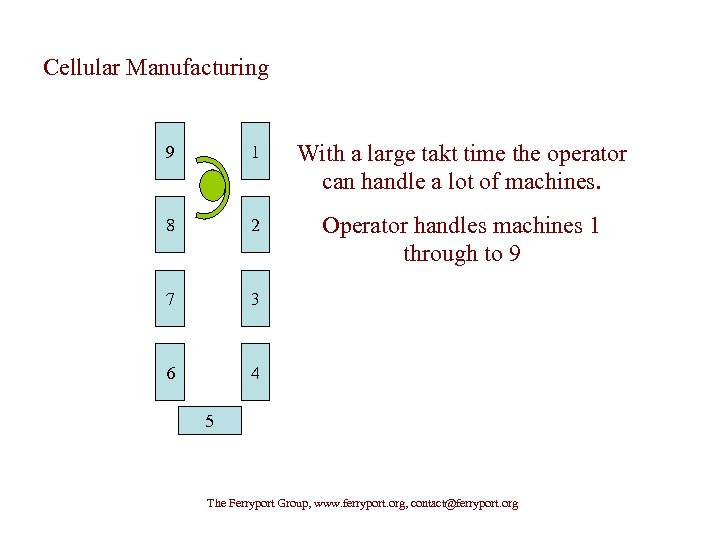

Cellular Manufacturing 9 1 With a large takt time the operator can handle a lot of machines. 8 2 Operator handles machines 1 through to 9 7 3 6 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing 9 1 With a large takt time the operator can handle a lot of machines. 8 2 Operator handles machines 1 through to 9 7 3 6 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

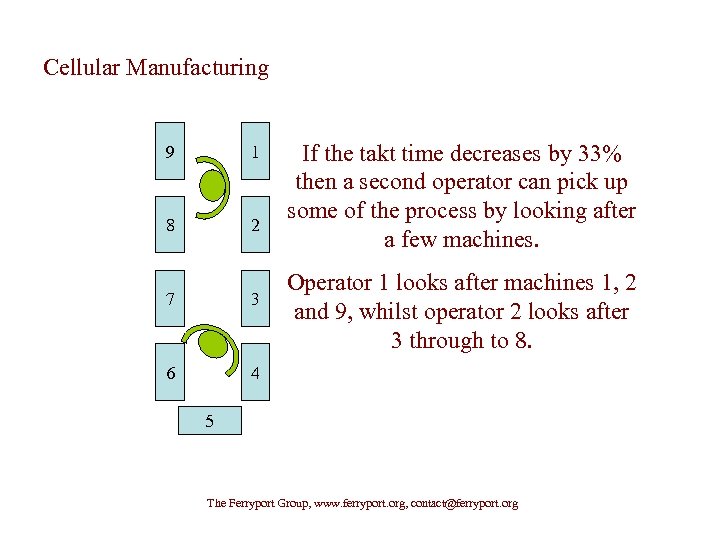

Cellular Manufacturing 9 1 8 2 7 3 6 If the takt time decreases by 33% then a second operator can pick up some of the process by looking after a few machines. Operator 1 looks after machines 1, 2 and 9, whilst operator 2 looks after 3 through to 8. 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing 9 1 8 2 7 3 6 If the takt time decreases by 33% then a second operator can pick up some of the process by looking after a few machines. Operator 1 looks after machines 1, 2 and 9, whilst operator 2 looks after 3 through to 8. 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

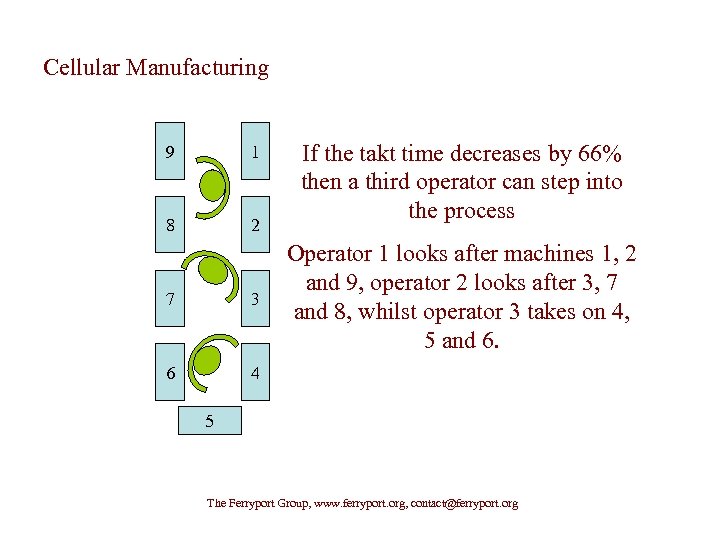

Cellular Manufacturing 9 1 8 2 7 3 6 If the takt time decreases by 66% then a third operator can step into the process Operator 1 looks after machines 1, 2 and 9, operator 2 looks after 3, 7 and 8, whilst operator 3 takes on 4, 5 and 6. 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing 9 1 8 2 7 3 6 If the takt time decreases by 66% then a third operator can step into the process Operator 1 looks after machines 1, 2 and 9, operator 2 looks after 3, 7 and 8, whilst operator 3 takes on 4, 5 and 6. 4 5 The Ferryport Group, www. ferryport. org, contact@ferryport. org

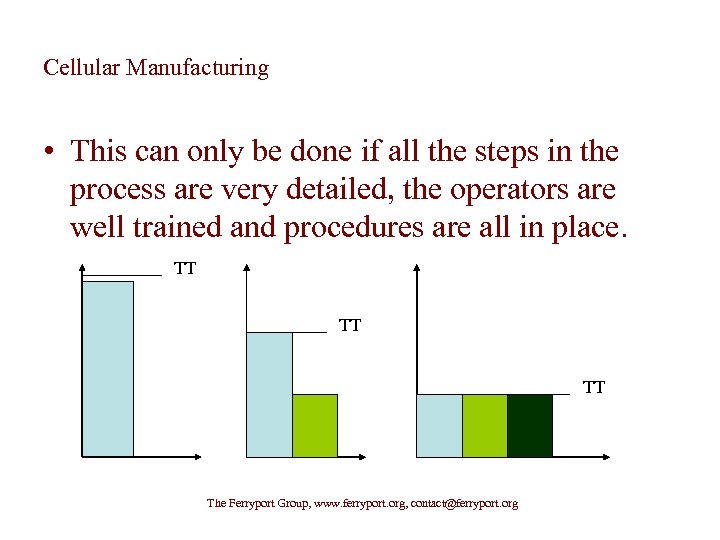

Cellular Manufacturing • This can only be done if all the steps in the process are very detailed, the operators are well trained and procedures are all in place. TT TT TT The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing • This can only be done if all the steps in the process are very detailed, the operators are well trained and procedures are all in place. TT TT TT The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing Less WIP - less money tied up, less storage costs, less administration required, less large scale defects. Greater Quality Control - would you rather have to scrap or rework 2 minutes worth of production or two months worth of production? Reduced Lead Times - the customer is the next person in the process – see below Less Physical Work – cellular manufacturing bring in the opportunity to automatically transfer components The Ferryport Group, www. ferryport. org, contact@ferryport. org

Cellular Manufacturing Less WIP - less money tied up, less storage costs, less administration required, less large scale defects. Greater Quality Control - would you rather have to scrap or rework 2 minutes worth of production or two months worth of production? Reduced Lead Times - the customer is the next person in the process – see below Less Physical Work – cellular manufacturing bring in the opportunity to automatically transfer components The Ferryport Group, www. ferryport. org, contact@ferryport. org

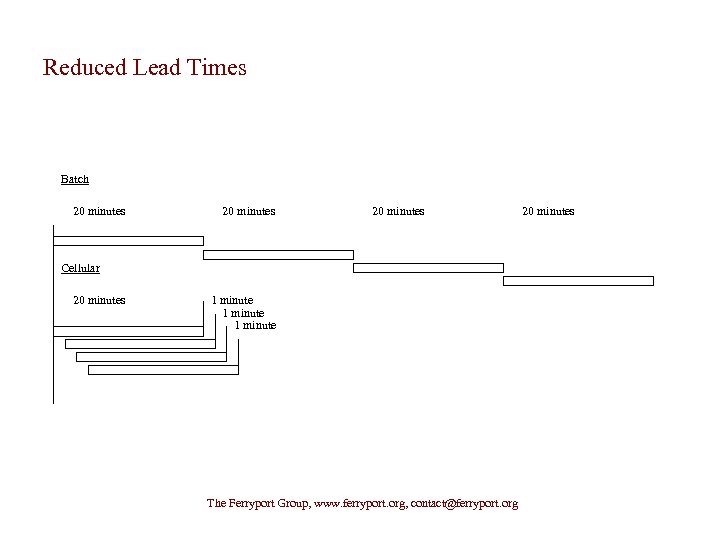

Reduced Lead Times Batch 20 minutes Cellular 20 minutes 1 minute The Ferryport Group, www. ferryport. org, contact@ferryport. org 20 minutes

Reduced Lead Times Batch 20 minutes Cellular 20 minutes 1 minute The Ferryport Group, www. ferryport. org, contact@ferryport. org 20 minutes

Questions? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Questions? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull and Visual Management • Kanban Systems address three of the 7 Wastes – Poor Quality – Panic Production – Stock levels The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull and Visual Management • Kanban Systems address three of the 7 Wastes – Poor Quality – Panic Production – Stock levels The Ferryport Group, www. ferryport. org, contact@ferryport. org

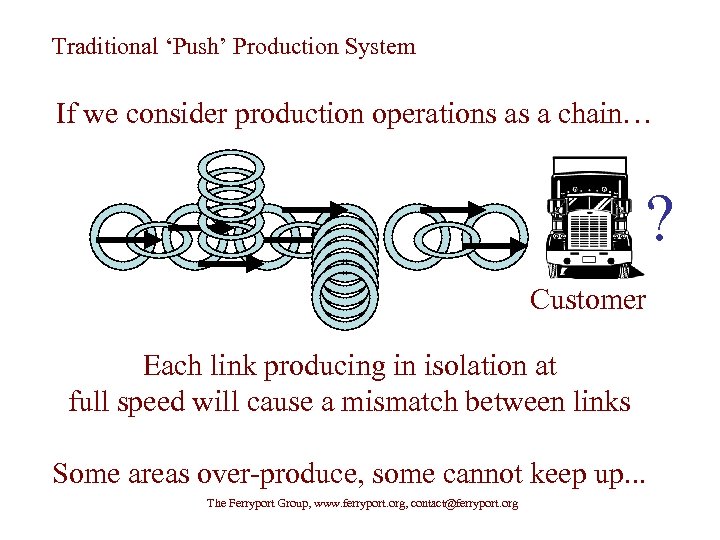

Traditional ‘Push’ Production System If we consider production operations as a chain… ? Customer Each link producing in isolation at full speed will cause a mismatch between links Some areas over-produce, some cannot keep up. . . The Ferryport Group, www. ferryport. org, contact@ferryport. org

Traditional ‘Push’ Production System If we consider production operations as a chain… ? Customer Each link producing in isolation at full speed will cause a mismatch between links Some areas over-produce, some cannot keep up. . . The Ferryport Group, www. ferryport. org, contact@ferryport. org

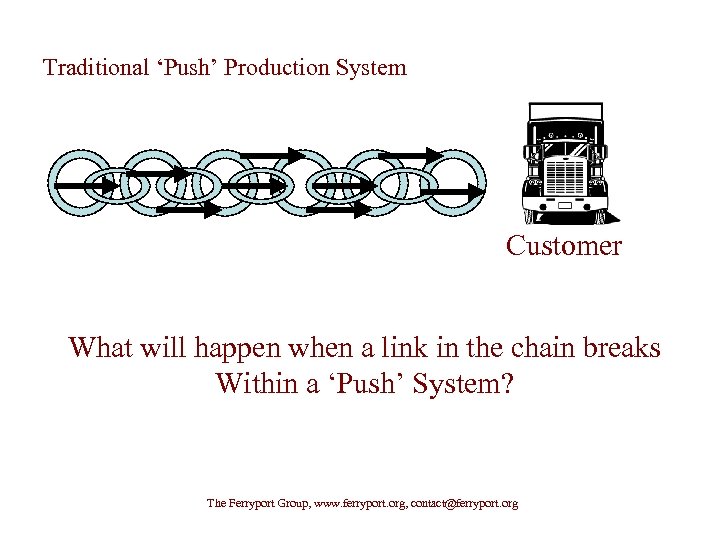

Traditional ‘Push’ Production System Customer What will happen when a link in the chain breaks Within a ‘Push’ System? The Ferryport Group, www. ferryport. org, contact@ferryport. org

Traditional ‘Push’ Production System Customer What will happen when a link in the chain breaks Within a ‘Push’ System? The Ferryport Group, www. ferryport. org, contact@ferryport. org

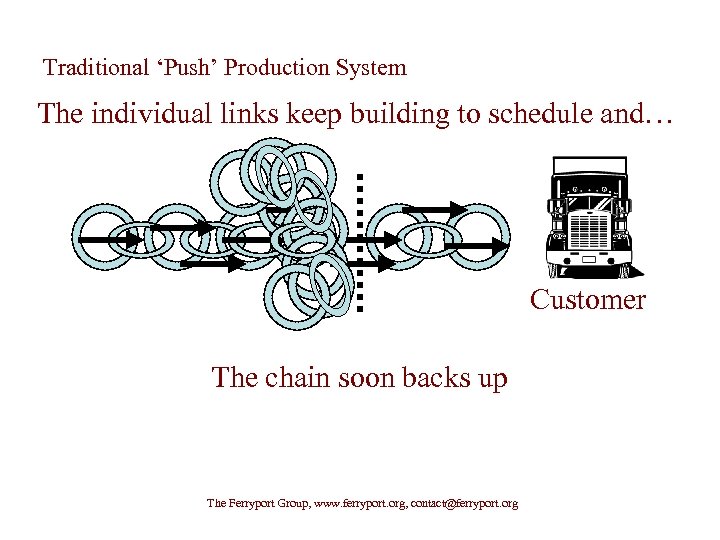

Traditional ‘Push’ Production System The individual links keep building to schedule and… Customer The chain soon backs up The Ferryport Group, www. ferryport. org, contact@ferryport. org

Traditional ‘Push’ Production System The individual links keep building to schedule and… Customer The chain soon backs up The Ferryport Group, www. ferryport. org, contact@ferryport. org

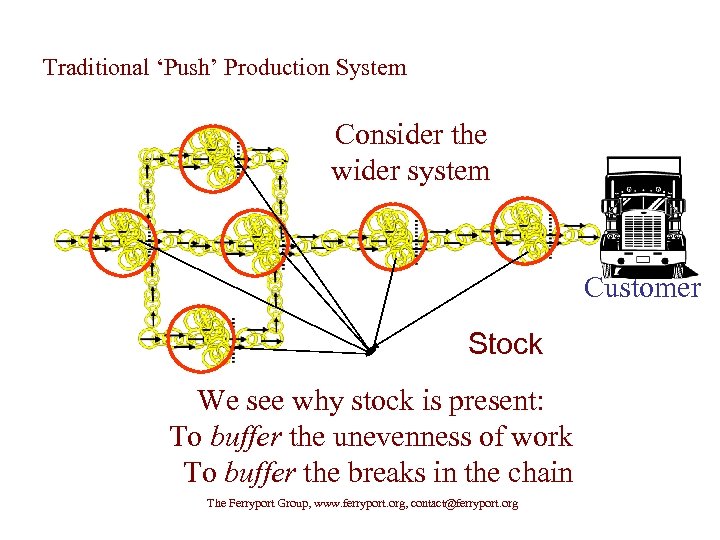

Traditional ‘Push’ Production System Consider the wider system Customer Stock We see why stock is present: To buffer the unevenness of work To buffer the breaks in the chain The Ferryport Group, www. ferryport. org, contact@ferryport. org

Traditional ‘Push’ Production System Consider the wider system Customer Stock We see why stock is present: To buffer the unevenness of work To buffer the breaks in the chain The Ferryport Group, www. ferryport. org, contact@ferryport. org

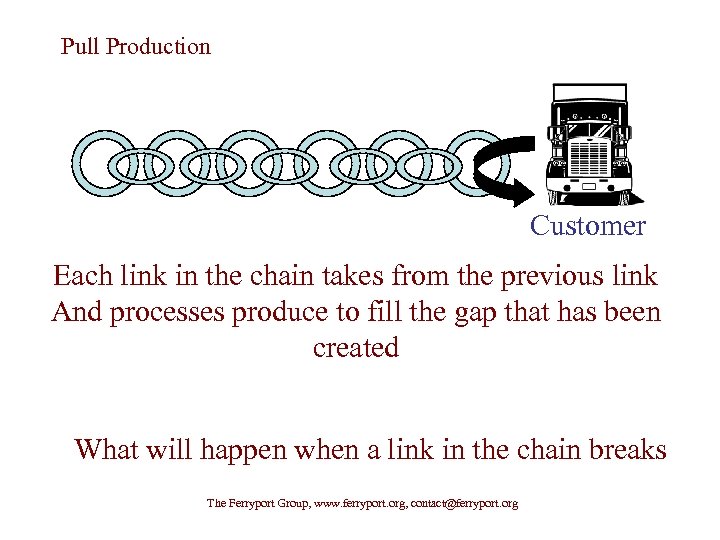

Pull Production Customer The customer takes a product from the end Each link in the chain takes from the previous link Of the fill the And processes produce to chain gap that has been created What will happen when a link in the chain breaks The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull Production Customer The customer takes a product from the end Each link in the chain takes from the previous link Of the fill the And processes produce to chain gap that has been created What will happen when a link in the chain breaks The Ferryport Group, www. ferryport. org, contact@ferryport. org

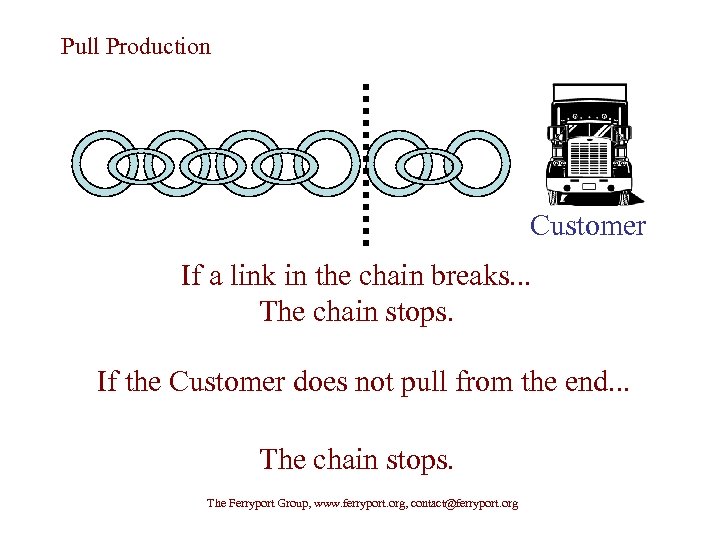

Pull Production Customer If a link in the chain breaks. . . The chain stops. If the Customer does not pull from the end. . . The chain stops. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull Production Customer If a link in the chain breaks. . . The chain stops. If the Customer does not pull from the end. . . The chain stops. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull and Visual Management This is traditionally done with the use of coloured cards but can be a number of things: – Colour coding on walls – Automatic lighting system on roller slides – Amount check sheet The Ferryport Group, www. ferryport. org, contact@ferryport. org

Pull and Visual Management This is traditionally done with the use of coloured cards but can be a number of things: – Colour coding on walls – Automatic lighting system on roller slides – Amount check sheet The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 4 - ‘Cup of Tea Manufacturing’ Run the process once more, using: • Visual pull systems • Cellular manufacturing • Takt time awareness The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 4 - ‘Cup of Tea Manufacturing’ Run the process once more, using: • Visual pull systems • Cellular manufacturing • Takt time awareness The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • Did anything go wrong with that? • What can we do to stop it from happening? – Training – SOPs – Visual Management – specifications etc. – Materials available The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • Did anything go wrong with that? • What can we do to stop it from happening? – Training – SOPs – Visual Management – specifications etc. – Materials available The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • This is also called: Poka-Yoke What other error proofing can you think of? • Electrical plugs • An envelope with a clear viewing window for the address to be seen • A sink with a hole at the top prevents the sink from overflowing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • This is also called: Poka-Yoke What other error proofing can you think of? • Electrical plugs • An envelope with a clear viewing window for the address to be seen • A sink with a hole at the top prevents the sink from overflowing The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • • Less scrap and rework Greater quality control Safety issues can be addressed Machinery can be protected The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing • • Less scrap and rework Greater quality control Safety issues can be addressed Machinery can be protected The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing A good Poka Yoke device does not need to be expensive and complex. In many cases they are: • Simple • Cheap • Part of the process • Close to where the mistakes occur • Provide good feedback so the mistake can be corrected. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Error Proofing A good Poka Yoke device does not need to be expensive and complex. In many cases they are: • Simple • Cheap • Part of the process • Close to where the mistakes occur • Provide good feedback so the mistake can be corrected. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 5 - ‘Cup of Tea Manufacturing’ What are some of the error proofing techniques that can be put in place for your tea production line? 1. 2. 3. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Exercise 5 - ‘Cup of Tea Manufacturing’ What are some of the error proofing techniques that can be put in place for your tea production line? 1. 2. 3. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Higher level Error Proofing TPM Total Productive Maintenance: “Trying to solve the problem before the problem actually occurs. ” Everyday examples: Oil checks on cars, pressure gauges on tyres, colour changing filters on extractor fans, hot spoons and kettles change colour The Ferryport Group, www. ferryport. org, contact@ferryport. org

Higher level Error Proofing TPM Total Productive Maintenance: “Trying to solve the problem before the problem actually occurs. ” Everyday examples: Oil checks on cars, pressure gauges on tyres, colour changing filters on extractor fans, hot spoons and kettles change colour The Ferryport Group, www. ferryport. org, contact@ferryport. org

Higher level Error Proofing What TPM would you need to have in place on your production line? Look at the equipment mainly: Kettle Spoons Cups Pot The Ferryport Group, www. ferryport. org, contact@ferryport. org

Higher level Error Proofing What TPM would you need to have in place on your production line? Look at the equipment mainly: Kettle Spoons Cups Pot The Ferryport Group, www. ferryport. org, contact@ferryport. org

Single Minute Exchange of Dies SMED LINK to separate presentation The Ferryport Group, www. ferryport. org, contact@ferryport. org

Single Minute Exchange of Dies SMED LINK to separate presentation The Ferryport Group, www. ferryport. org, contact@ferryport. org

Finally What answers did you put? Q. Where do you keep bleach/cleaning products? Under the kitchen sink or next to the toilet Q. Where do you keep your knives and forks? In a top drawer in the kitchen, or on a small stand on the worktop. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Finally What answers did you put? Q. Where do you keep bleach/cleaning products? Under the kitchen sink or next to the toilet Q. Where do you keep your knives and forks? In a top drawer in the kitchen, or on a small stand on the worktop. The Ferryport Group, www. ferryport. org, contact@ferryport. org

Finally Q. Where do you keep spare bedding? In the same cupboard as the hot water tank Q. Where do you keep your beer? In the fridge or in the garage The Ferryport Group, www. ferryport. org, contact@ferryport. org

Finally Q. Where do you keep spare bedding? In the same cupboard as the hot water tank Q. Where do you keep your beer? In the fridge or in the garage The Ferryport Group, www. ferryport. org, contact@ferryport. org