6379bbf6fbac8ffa6822e9fe73ebdfed.ppt

- Количество слайдов: 56

Darkroom and Film Processing Rad Tech A – Week 9 Spring 2009

Darkroom and Film Processing Rad Tech A – Week 9 Spring 2009

Darkrooms – Still Necessary? • Darkrooms are necessary for manually fed processors and daylight processors. -Loading automatic film processor magazines. • Necessary for conducting certain quality control tests (daily sensitometric strip).

Darkrooms – Still Necessary? • Darkrooms are necessary for manually fed processors and daylight processors. -Loading automatic film processor magazines. • Necessary for conducting certain quality control tests (daily sensitometric strip).

Darkroom

Darkroom

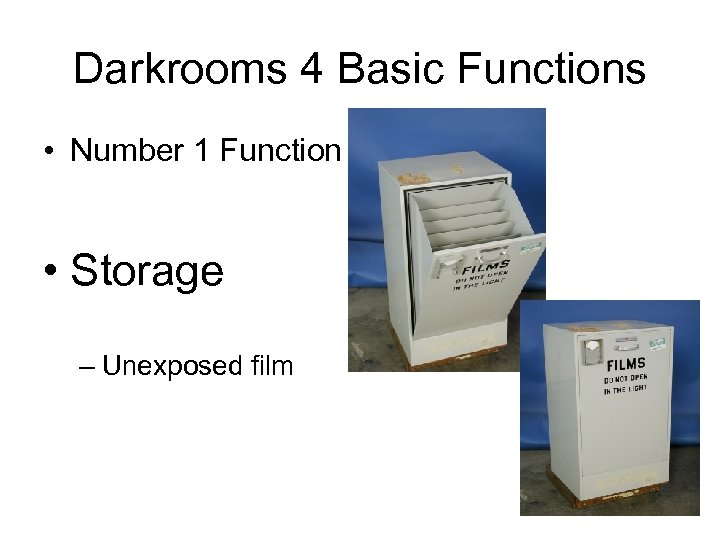

Darkrooms 4 Basic Functions • Number 1 Function • Storage – Unexposed film

Darkrooms 4 Basic Functions • Number 1 Function • Storage – Unexposed film

DARKROOM FUNCTION # 2 Purpose of Film Processing • Change silver halide crystals from film emulsion (after exposure to x-ray or light photons) to black metallic silver. • Latent image (invisible until processed) is developed into a Manifest image. • Improper or careless processing can cause poor diagnostic quality.

DARKROOM FUNCTION # 2 Purpose of Film Processing • Change silver halide crystals from film emulsion (after exposure to x-ray or light photons) to black metallic silver. • Latent image (invisible until processed) is developed into a Manifest image. • Improper or careless processing can cause poor diagnostic quality.

Manual Feed Processor

Manual Feed Processor

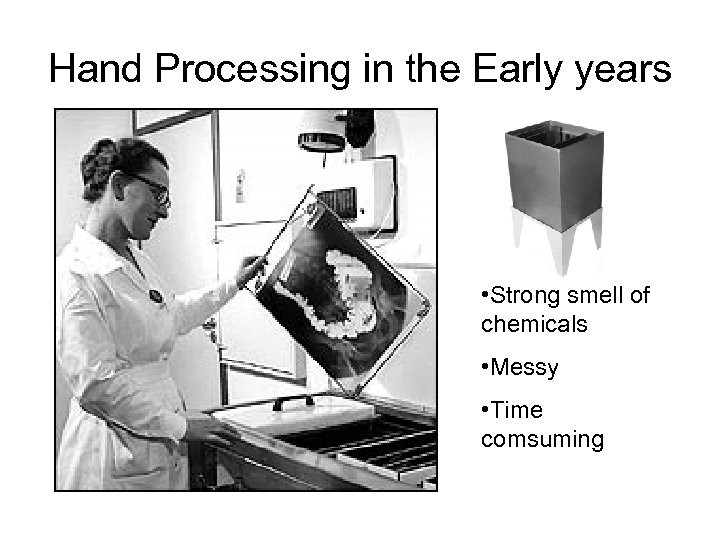

Hand Processing in the Early years • Strong smell of chemicals • Messy • Time comsuming

Hand Processing in the Early years • Strong smell of chemicals • Messy • Time comsuming

1956 – first roller transport 6 minute processing time

1956 – first roller transport 6 minute processing time

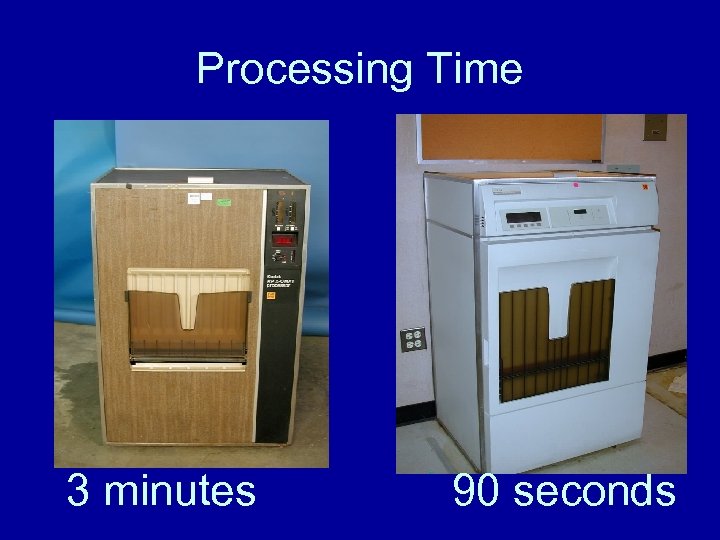

Processing Time 3 minutes 90 seconds

Processing Time 3 minutes 90 seconds

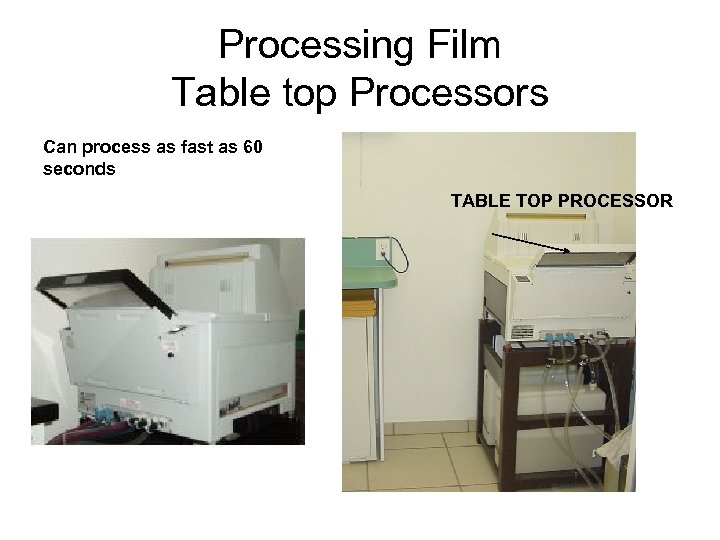

Processing Film Table top Processors Can process as fast as 60 seconds TABLE TOP PROCESSOR

Processing Film Table top Processors Can process as fast as 60 seconds TABLE TOP PROCESSOR

PROCSSING CHEMICALS n n Solutions are PRE- MIXED Outside Company usually provides servicel Weekly or monthly Solutions should be replenished as necessary & changed regularly Solutions must be monitored (Daily QC strip).

PROCSSING CHEMICALS n n Solutions are PRE- MIXED Outside Company usually provides servicel Weekly or monthly Solutions should be replenished as necessary & changed regularly Solutions must be monitored (Daily QC strip).

Replenishment tanks

Replenishment tanks

TABLE TOP FILM DUPLICATOR to MAKE COPIES OF FILMS

TABLE TOP FILM DUPLICATOR to MAKE COPIES OF FILMS

WILL THIS WORK ? ?

WILL THIS WORK ? ?

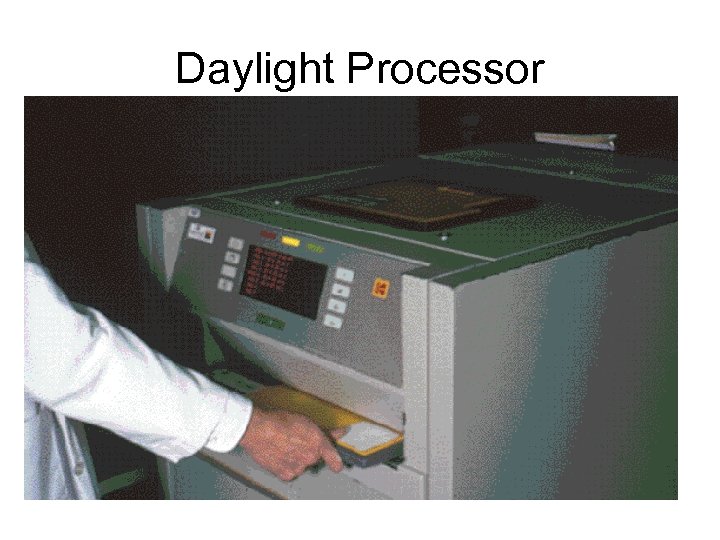

Daylight Processor

Daylight Processor

Function # 3: Handling of Film

Function # 3: Handling of Film

UNLOAD EXPOSED FILM

UNLOAD EXPOSED FILM

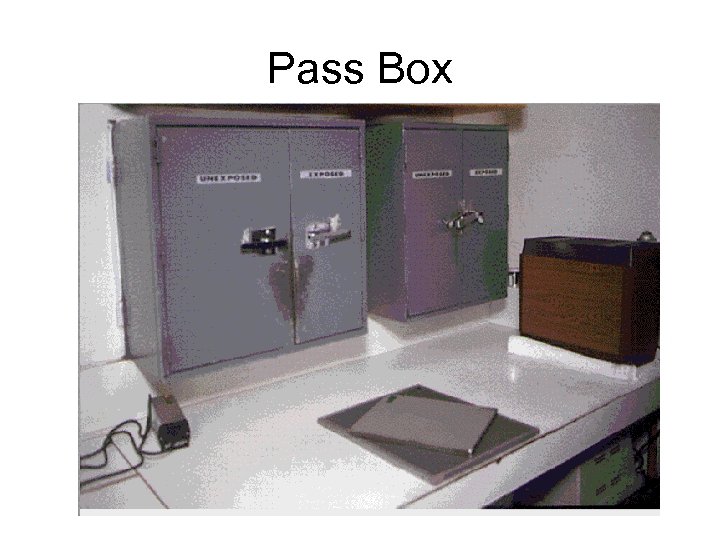

Pass Box

Pass Box

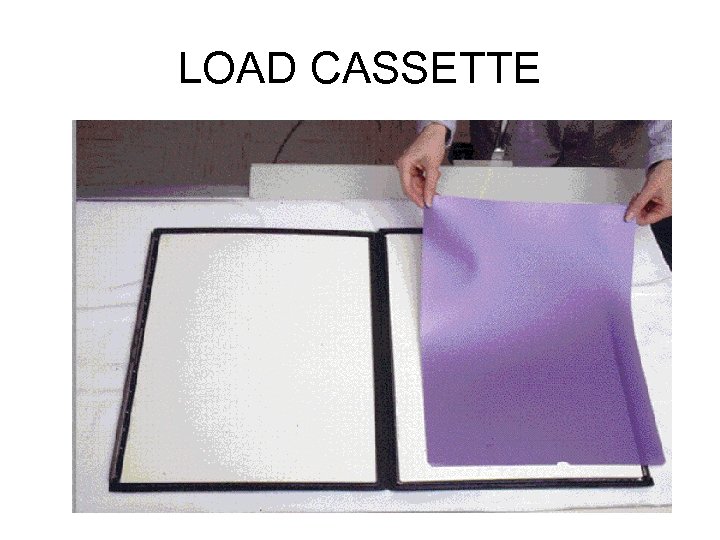

LOAD CASSETTE

LOAD CASSETTE

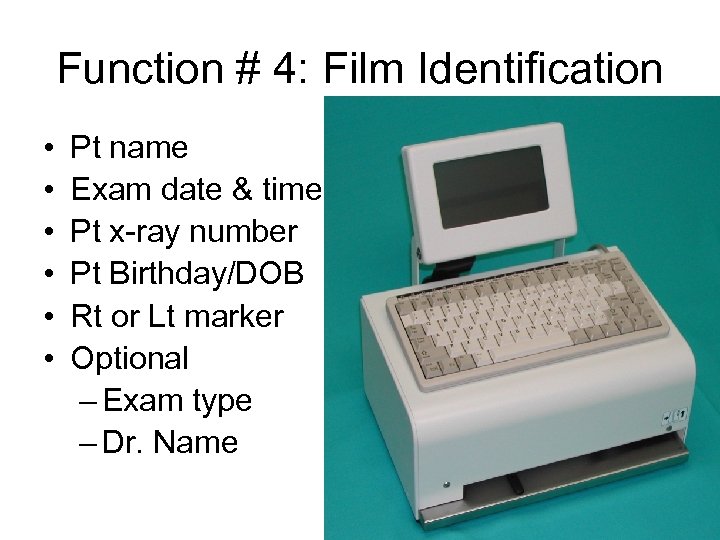

Function # 4: Film Identification • • • Pt name Exam date & time Pt x-ray number Pt Birthday/DOB Rt or Lt marker Optional – Exam type – Dr. Name

Function # 4: Film Identification • • • Pt name Exam date & time Pt x-ray number Pt Birthday/DOB Rt or Lt marker Optional – Exam type – Dr. Name

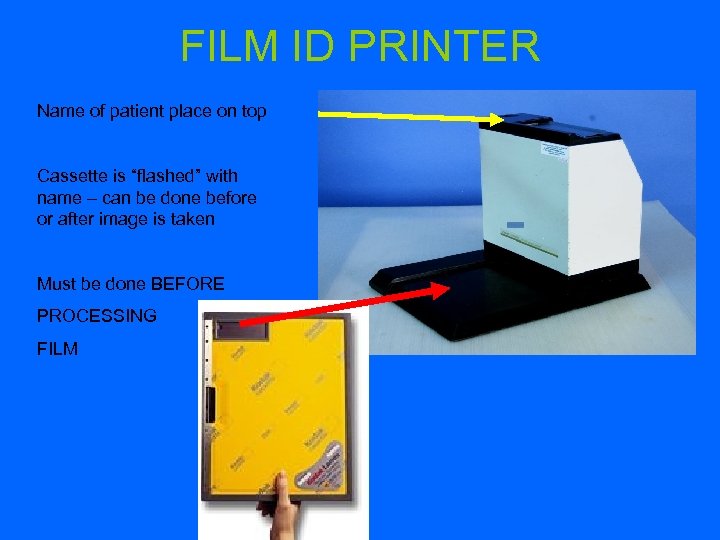

FILM ID PRINTER Name of patient place on top Cassette is “flashed” with name – can be done before or after image is taken Must be done BEFORE PROCESSING FILM

FILM ID PRINTER Name of patient place on top Cassette is “flashed” with name – can be done before or after image is taken Must be done BEFORE PROCESSING FILM

AUTOMATIC PROCESSING • TRANSPORTATION SYSTEM • DEVELOPER • FIXER • WASHER • DRYER • REPLENISHMENT SYSTEM

AUTOMATIC PROCESSING • TRANSPORTATION SYSTEM • DEVELOPER • FIXER • WASHER • DRYER • REPLENISHMENT SYSTEM

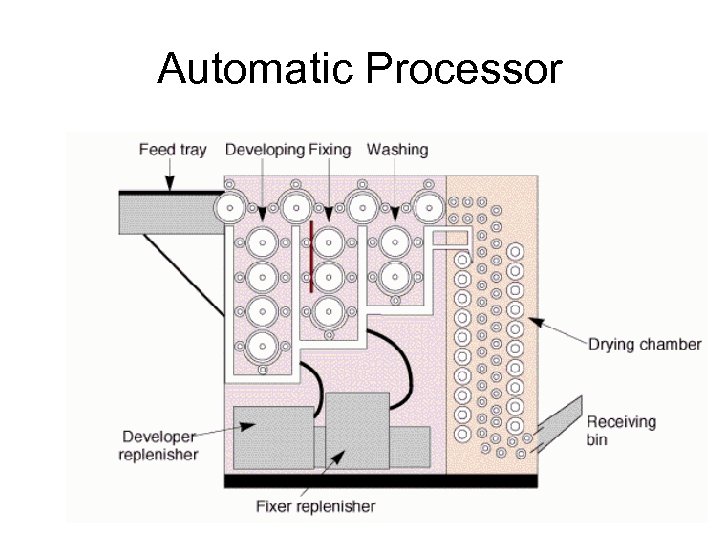

Automatic Processor

Automatic Processor

Processor Chemistry Overview • Developer – converts latent image into manifest image • Fixer – clear the film of unexposed, undeveloped silver bromide crystals, promotes archival quality • Wash – rid the film of residual chemicals

Processor Chemistry Overview • Developer – converts latent image into manifest image • Fixer – clear the film of unexposed, undeveloped silver bromide crystals, promotes archival quality • Wash – rid the film of residual chemicals

Developer Solution (6 Ingredients) 1. Reducing Agent: reduce exposed silver halide to black metallic silver -Hydroquinone (Blacks) -Phenidone (Grays) 2. Activator: softens gelatin, maintains alkaline p. H (increase p. H) -Sodium Carbonate

Developer Solution (6 Ingredients) 1. Reducing Agent: reduce exposed silver halide to black metallic silver -Hydroquinone (Blacks) -Phenidone (Grays) 2. Activator: softens gelatin, maintains alkaline p. H (increase p. H) -Sodium Carbonate

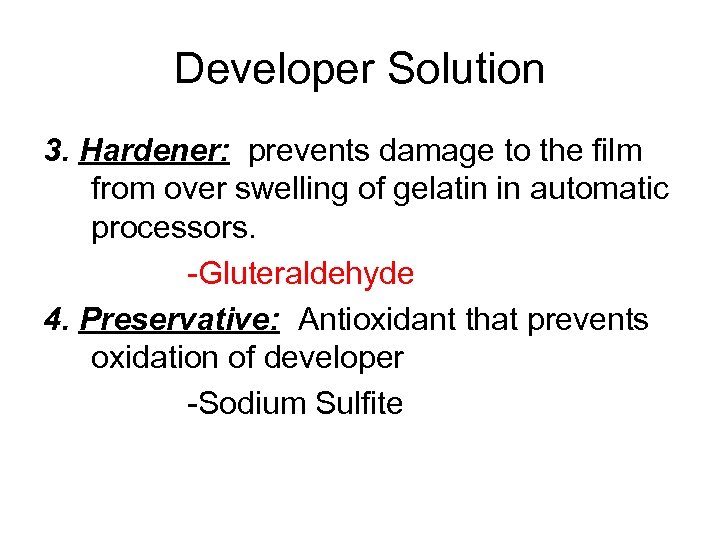

Developer Solution 3. Hardener: prevents damage to the film from over swelling of gelatin in automatic processors. -Gluteraldehyde 4. Preservative: Antioxidant that prevents oxidation of developer -Sodium Sulfite

Developer Solution 3. Hardener: prevents damage to the film from over swelling of gelatin in automatic processors. -Gluteraldehyde 4. Preservative: Antioxidant that prevents oxidation of developer -Sodium Sulfite

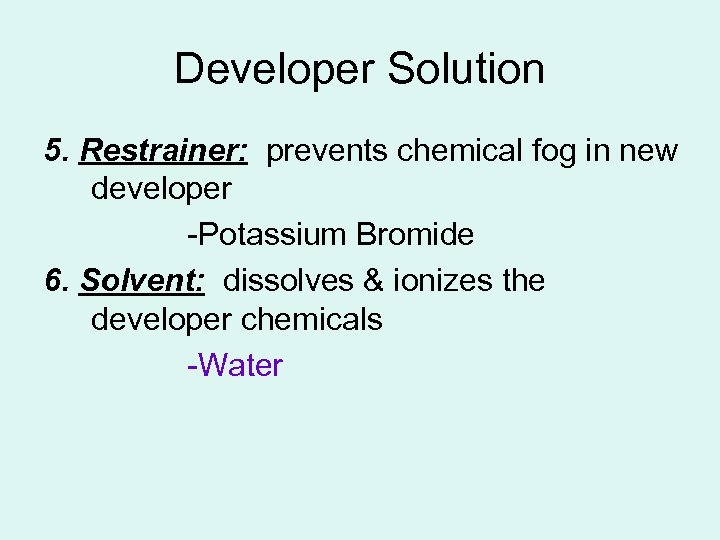

Developer Solution 5. Restrainer: prevents chemical fog in new developer -Potassium Bromide 6. Solvent: dissolves & ionizes the developer chemicals -Water

Developer Solution 5. Restrainer: prevents chemical fog in new developer -Potassium Bromide 6. Solvent: dissolves & ionizes the developer chemicals -Water

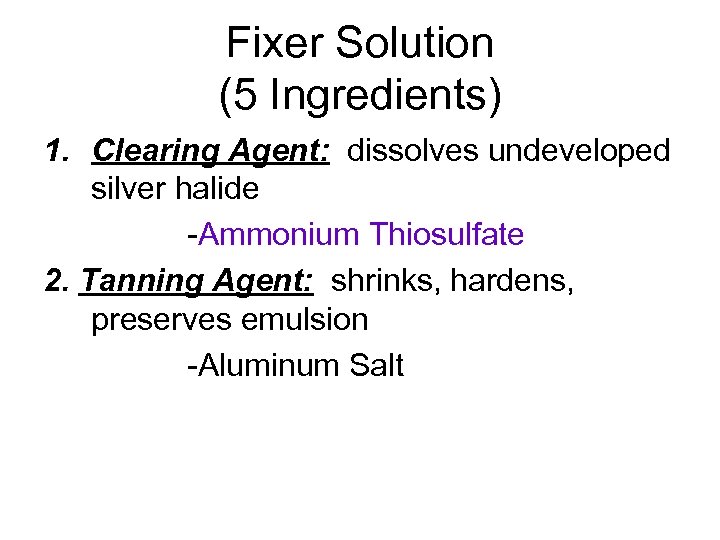

Fixer Solution (5 Ingredients) 1. Clearing Agent: dissolves undeveloped silver halide -Ammonium Thiosulfate 2. Tanning Agent: shrinks, hardens, preserves emulsion -Aluminum Salt

Fixer Solution (5 Ingredients) 1. Clearing Agent: dissolves undeveloped silver halide -Ammonium Thiosulfate 2. Tanning Agent: shrinks, hardens, preserves emulsion -Aluminum Salt

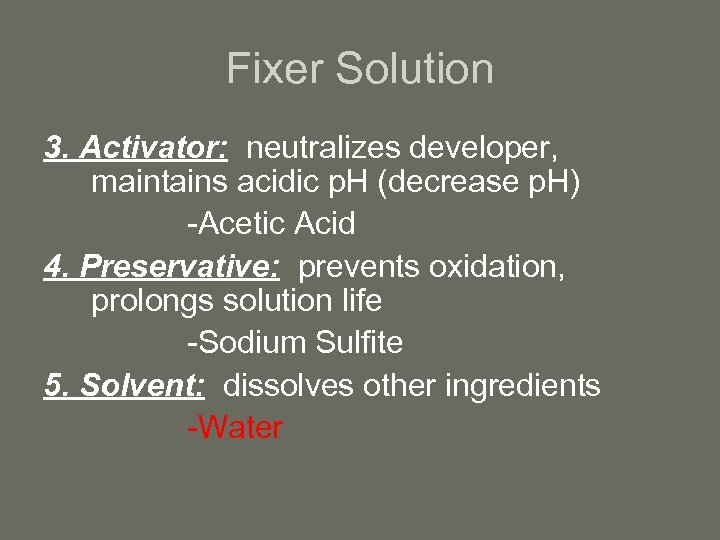

Fixer Solution 3. Activator: neutralizes developer, maintains acidic p. H (decrease p. H) -Acetic Acid 4. Preservative: prevents oxidation, prolongs solution life -Sodium Sulfite 5. Solvent: dissolves other ingredients -Water

Fixer Solution 3. Activator: neutralizes developer, maintains acidic p. H (decrease p. H) -Acetic Acid 4. Preservative: prevents oxidation, prolongs solution life -Sodium Sulfite 5. Solvent: dissolves other ingredients -Water

Wash • Rid the film of residual chemicals • Residual chemicals on the film will discolor radiograph over time. • Cold water processors are less efficient in removing chemicals – Warm water processors much better. • Agitation during wash process is essential

Wash • Rid the film of residual chemicals • Residual chemicals on the film will discolor radiograph over time. • Cold water processors are less efficient in removing chemicals – Warm water processors much better. • Agitation during wash process is essential

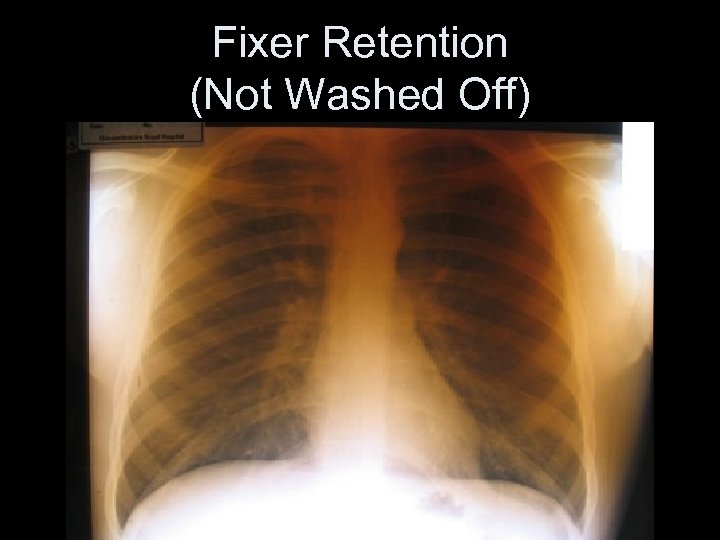

Fixer Retention (Not Washed Off)

Fixer Retention (Not Washed Off)

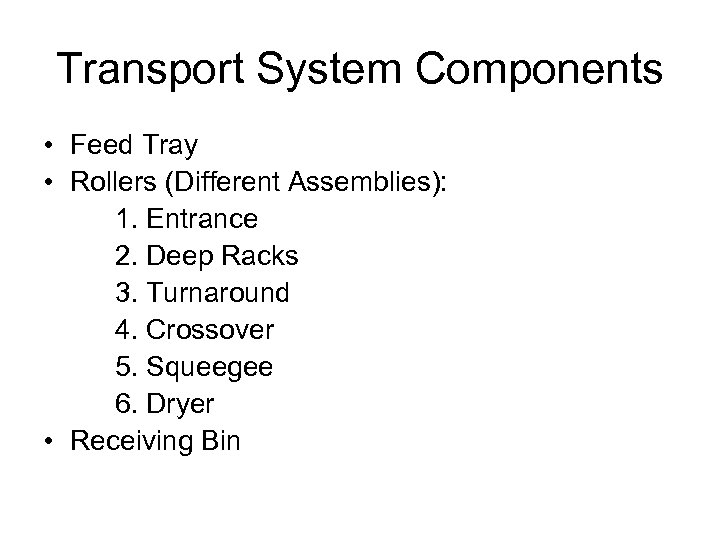

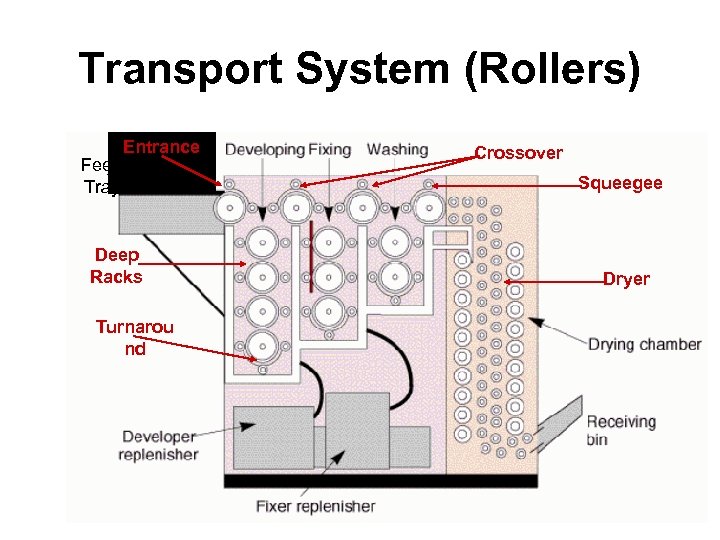

Transport System Components • Feed Tray • Rollers (Different Assemblies): 1. Entrance 2. Deep Racks 3. Turnaround 4. Crossover 5. Squeegee 6. Dryer • Receiving Bin

Transport System Components • Feed Tray • Rollers (Different Assemblies): 1. Entrance 2. Deep Racks 3. Turnaround 4. Crossover 5. Squeegee 6. Dryer • Receiving Bin

Transport System (Rollers) Feed Tray Entrance Deep Racks Turnarou nd Crossover Squeegee Dryer

Transport System (Rollers) Feed Tray Entrance Deep Racks Turnarou nd Crossover Squeegee Dryer

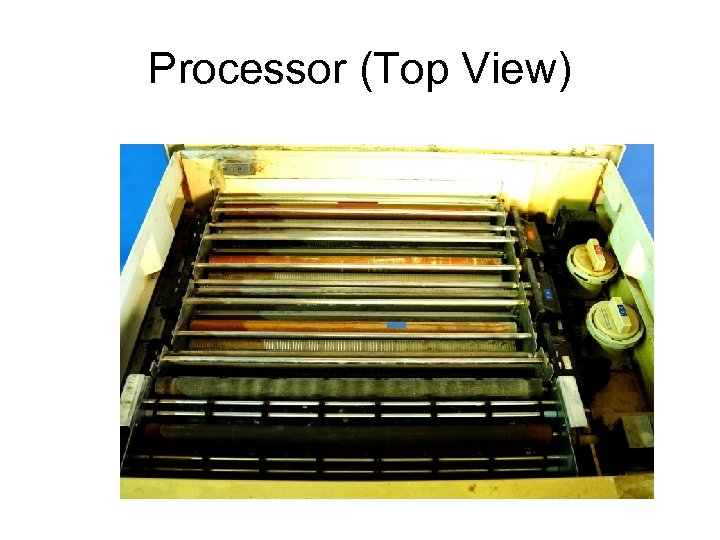

Processor (Top View)

Processor (Top View)

Replenishment System • Main function: Keep solution tanks full and assure proper solution concentration. • As film is introduced into processor, sensor initiates solution replenishment • Right & wrong way to feed in film -Feed in along short edge

Replenishment System • Main function: Keep solution tanks full and assure proper solution concentration. • As film is introduced into processor, sensor initiates solution replenishment • Right & wrong way to feed in film -Feed in along short edge

Transport System in Automatic Processors • Conveys the film through different solutions (sections) by a series of rollers driven by gears, chains & sprockets. • Done at a prescribed speed – determines length of time the film is in each solution

Transport System in Automatic Processors • Conveys the film through different solutions (sections) by a series of rollers driven by gears, chains & sprockets. • Done at a prescribed speed – determines length of time the film is in each solution

Temperature Regulation • Main function: To control the temperature of each section of the processor. • Developer – most important solution to regulate • Usually between 92 degrees and 95 degrees • Thermostatically controlled

Temperature Regulation • Main function: To control the temperature of each section of the processor. • Developer – most important solution to regulate • Usually between 92 degrees and 95 degrees • Thermostatically controlled

Recirculation System • Provides agitation necessary for uniform solution concentration

Recirculation System • Provides agitation necessary for uniform solution concentration

Wash & Dryer Systems • Wash: Provide thorough removal of chemical solutions from the film. -Archival film quality • Dryer: Removes water from film by blowing warm, dry air -Between 120 degrees & 130 degrees F.

Wash & Dryer Systems • Wash: Provide thorough removal of chemical solutions from the film. -Archival film quality • Dryer: Removes water from film by blowing warm, dry air -Between 120 degrees & 130 degrees F.

Silver Recovery • About ½ of the film’s silver remains in the emulsion after exposure & processing. • Other ½ (unexposed silver) is removed from the film during fixing process. • Silver is toxic to public water supply – must have proper disposal. Silver can be harvested from the fixer tank and recycled.

Silver Recovery • About ½ of the film’s silver remains in the emulsion after exposure & processing. • Other ½ (unexposed silver) is removed from the film during fixing process. • Silver is toxic to public water supply – must have proper disposal. Silver can be harvested from the fixer tank and recycled.

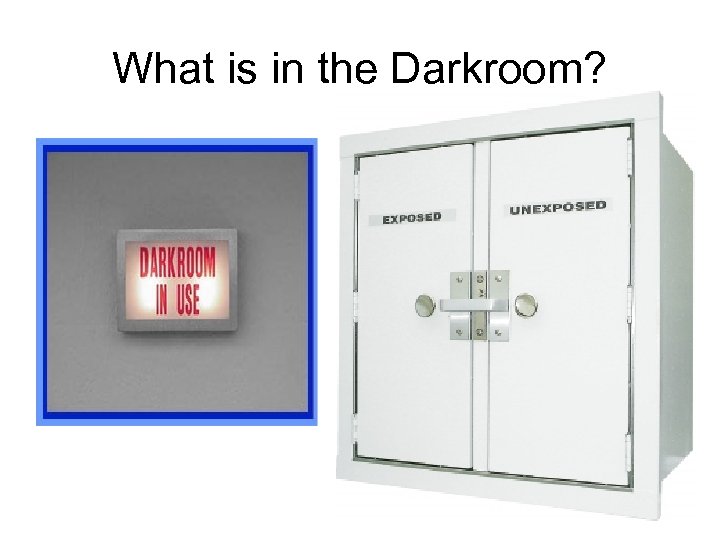

What is in the Darkroom?

What is in the Darkroom?

Darkroom Contents Loading Bench Film Bin Film I. D. Printer Safelights Pass Box Light-tight Room Ample ventilation Warning Light outside room Lockable Door Wall Shielding if adjacent to x-ray room Walls painted with light color to reflect safelight

Darkroom Contents Loading Bench Film Bin Film I. D. Printer Safelights Pass Box Light-tight Room Ample ventilation Warning Light outside room Lockable Door Wall Shielding if adjacent to x-ray room Walls painted with light color to reflect safelight

Darkroom Equipment

Darkroom Equipment

SAFELIGHTS

SAFELIGHTS

Safe Light • 15 Watts • Red filter • Must be 3 -6 feet from counter top or feed tray of processor • Used to be amber or orange filter

Safe Light • 15 Watts • Red filter • Must be 3 -6 feet from counter top or feed tray of processor • Used to be amber or orange filter

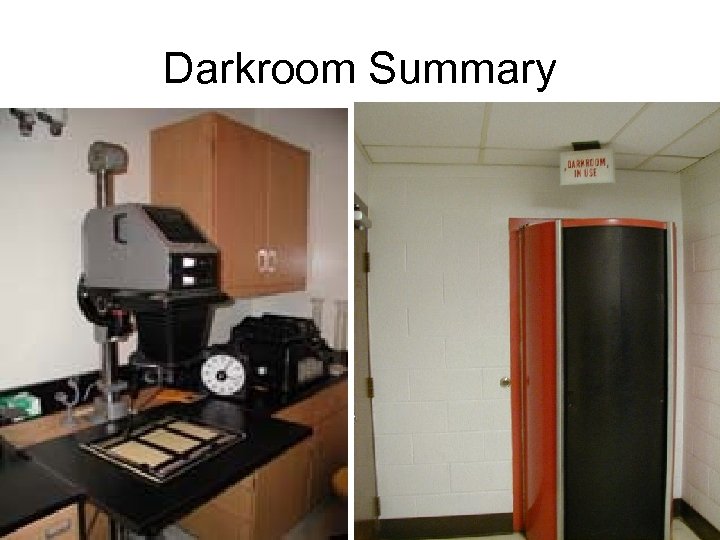

Darkroom Summary

Darkroom Summary

Summary & Questions

Summary & Questions

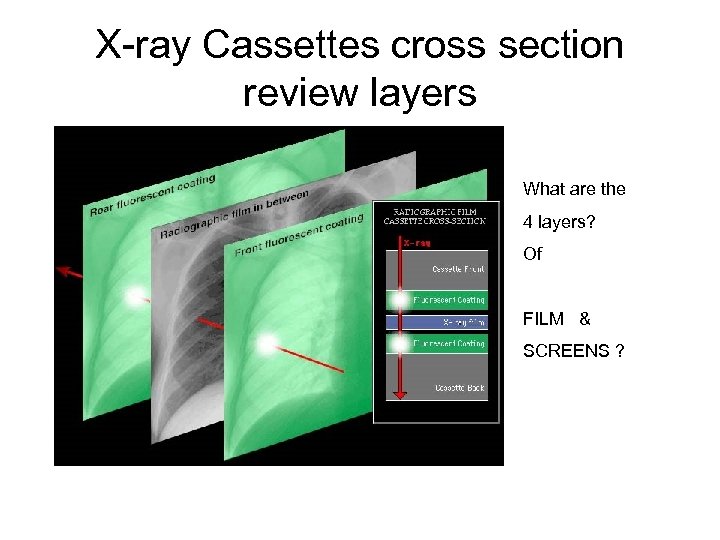

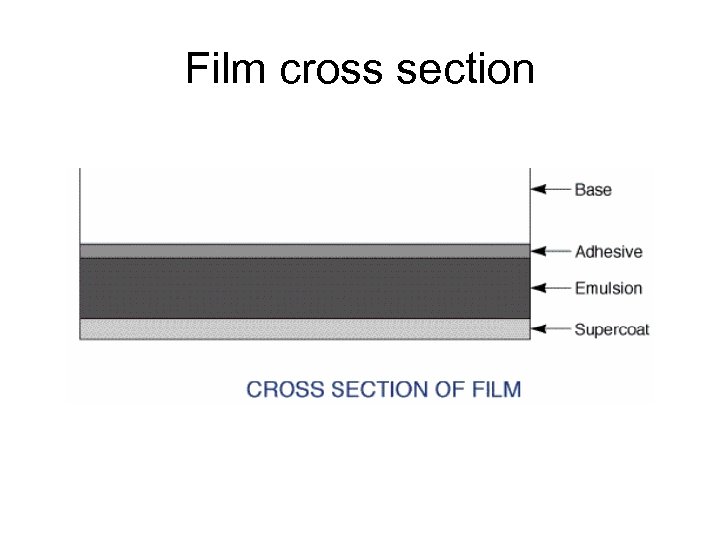

X-ray Cassettes cross section review layers What are the 4 layers? Of FILM & SCREENS ?

X-ray Cassettes cross section review layers What are the 4 layers? Of FILM & SCREENS ?

Film cross section

Film cross section

RTA LAB 2 Next Week : PROCESSING & SCREEN EXPOSURE • IONIZING LAB INTENSIFYING SCREEN • DARKROOM PROCESSING & CHEMISTRY • COMPLETE IN CLASS WORKSHEET

RTA LAB 2 Next Week : PROCESSING & SCREEN EXPOSURE • IONIZING LAB INTENSIFYING SCREEN • DARKROOM PROCESSING & CHEMISTRY • COMPLETE IN CLASS WORKSHEET