d714f16a4612a5d33f462af7c2bc10ad.ppt

- Количество слайдов: 19

Daan Otter, Powergen Europe, 8 -10 june 2010 Source and emission measurements for power plants © ABB Group 16 March 2018 | Slide 1

Daan Otter, Powergen Europe, 8 -10 june 2010 Source and emission measurements for power plants © ABB Group 16 March 2018 | Slide 1

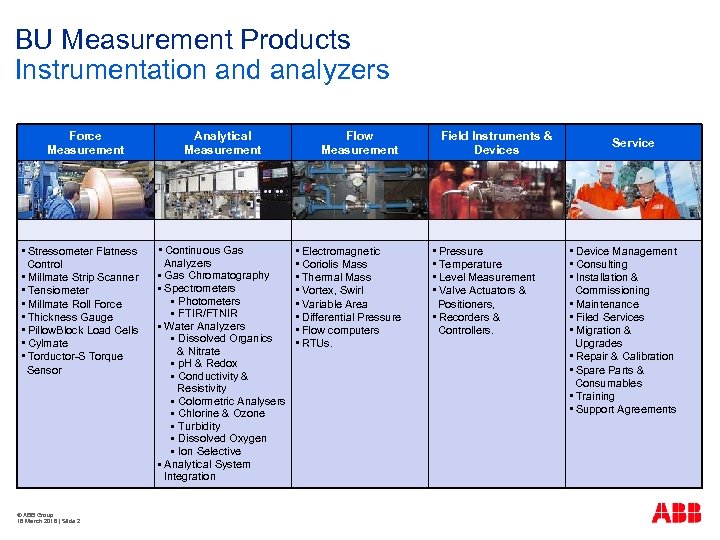

BU Measurement Products Instrumentation and analyzers Force Measurement • Stressometer Flatness Control • Millmate Strip Scanner • Tensiometer • Millmate Roll Force • Thickness Gauge • Pillow. Block Load Cells • Cylmate • Torductor-S Torque Sensor © ABB Group 16 March 2018 | Slide 2 Analytical Measurement • Continuous Gas Analyzers • Gas Chromatography • Spectrometers • Photometers • FTIR/FTNIR • Water Analyzers • Dissolved Organics & Nitrate • p. H & Redox • Conductivity & Resistivity • Colormetric Analysers • Chlorine & Ozone • Turbidity • Dissolved Oxygen • Ion Selective • Analytical System Integration Flow Measurement • Electromagnetic • Coriolis Mass • Thermal Mass • Vortex, Swirl • Variable Area • Differential Pressure • Flow computers • RTUs. Field Instruments & Devices • Pressure • Temperature • Level Measurement • Valve Actuators & Positioners, • Recorders & Controllers. Service • Device Management • Consulting • Installation & Commissioning • Maintenance • Filed Services • Migration & Upgrades • Repair & Calibration • Spare Parts & Consumables • Training • Support Agreements

BU Measurement Products Instrumentation and analyzers Force Measurement • Stressometer Flatness Control • Millmate Strip Scanner • Tensiometer • Millmate Roll Force • Thickness Gauge • Pillow. Block Load Cells • Cylmate • Torductor-S Torque Sensor © ABB Group 16 March 2018 | Slide 2 Analytical Measurement • Continuous Gas Analyzers • Gas Chromatography • Spectrometers • Photometers • FTIR/FTNIR • Water Analyzers • Dissolved Organics & Nitrate • p. H & Redox • Conductivity & Resistivity • Colormetric Analysers • Chlorine & Ozone • Turbidity • Dissolved Oxygen • Ion Selective • Analytical System Integration Flow Measurement • Electromagnetic • Coriolis Mass • Thermal Mass • Vortex, Swirl • Variable Area • Differential Pressure • Flow computers • RTUs. Field Instruments & Devices • Pressure • Temperature • Level Measurement • Valve Actuators & Positioners, • Recorders & Controllers. Service • Device Management • Consulting • Installation & Commissioning • Maintenance • Filed Services • Migration & Upgrades • Repair & Calibration • Spare Parts & Consumables • Training • Support Agreements

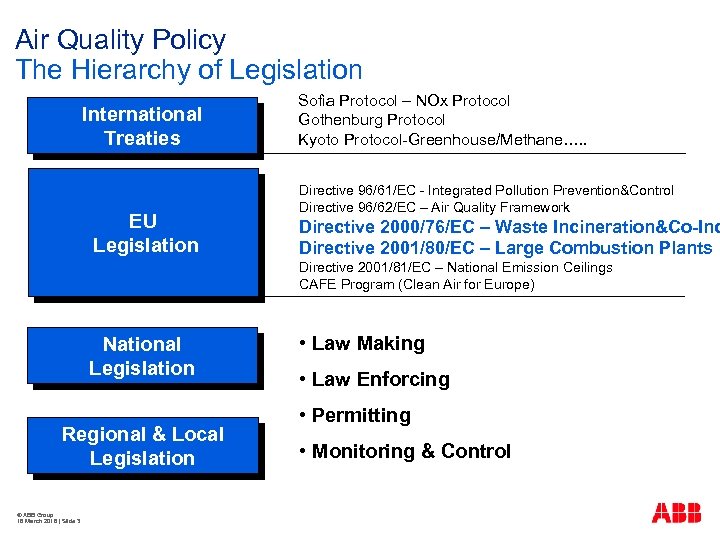

Air Quality Policy The Hierarchy of Legislation International Treaties EU Legislation Sofia Protocol – NOx Protocol Gothenburg Protocol Kyoto Protocol-Greenhouse/Methane…. . Directive 96/61/EC - Integrated Pollution Prevention&Control Directive 96/62/EC – Air Quality Framework Directive 2000/76/EC – Waste Incineration&Co-Inc Directive 2001/80/EC – Large Combustion Plants Directive 2001/81/EC – National Emission Ceilings CAFE Program (Clean Air for Europe) National Legislation Regional & Local Legislation © ABB Group 16 March 2018 | Slide 3 • Law Making • Law Enforcing • Permitting • Monitoring & Control

Air Quality Policy The Hierarchy of Legislation International Treaties EU Legislation Sofia Protocol – NOx Protocol Gothenburg Protocol Kyoto Protocol-Greenhouse/Methane…. . Directive 96/61/EC - Integrated Pollution Prevention&Control Directive 96/62/EC – Air Quality Framework Directive 2000/76/EC – Waste Incineration&Co-Inc Directive 2001/80/EC – Large Combustion Plants Directive 2001/81/EC – National Emission Ceilings CAFE Program (Clean Air for Europe) National Legislation Regional & Local Legislation © ABB Group 16 March 2018 | Slide 3 • Law Making • Law Enforcing • Permitting • Monitoring & Control

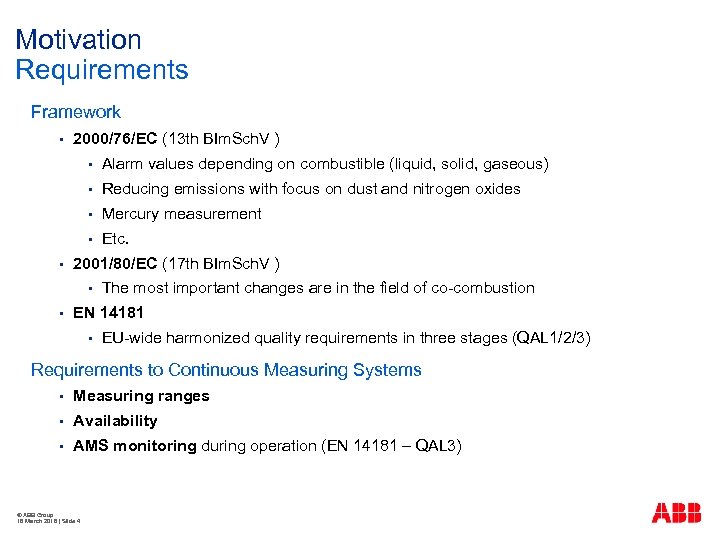

Motivation Requirements Framework § 2000/76/EC (13 th BIm. Sch. V ) § § Reducing emissions with focus on dust and nitrogen oxides § Mercury measurement § § Alarm values depending on combustible (liquid, solid, gaseous) Etc. 2001/80/EC (17 th BIm. Sch. V ) § § The most important changes are in the field of co-combustion EN 14181 § EU-wide harmonized quality requirements in three stages (QAL 1/2/3) Requirements to Continuous Measuring Systems § Measuring ranges § Availability § AMS monitoring during operation (EN 14181 – QAL 3) © ABB Group 16 March 2018 | Slide 4

Motivation Requirements Framework § 2000/76/EC (13 th BIm. Sch. V ) § § Reducing emissions with focus on dust and nitrogen oxides § Mercury measurement § § Alarm values depending on combustible (liquid, solid, gaseous) Etc. 2001/80/EC (17 th BIm. Sch. V ) § § The most important changes are in the field of co-combustion EN 14181 § EU-wide harmonized quality requirements in three stages (QAL 1/2/3) Requirements to Continuous Measuring Systems § Measuring ranges § Availability § AMS monitoring during operation (EN 14181 – QAL 3) © ABB Group 16 March 2018 | Slide 4

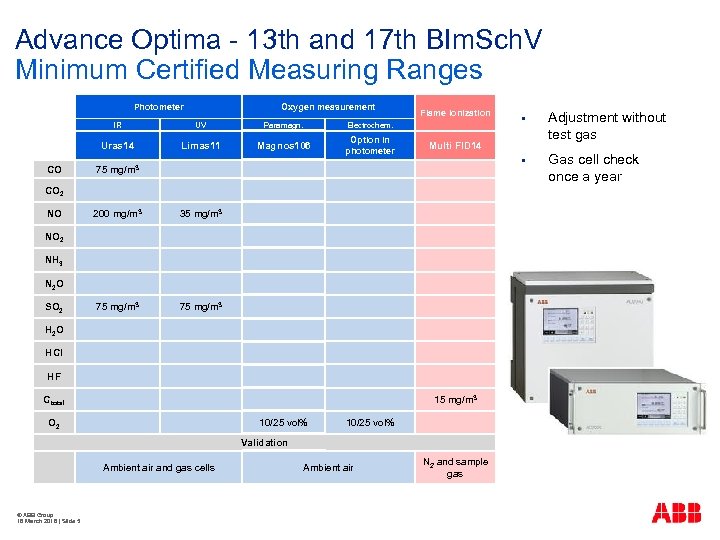

Advance Optima - 13 th and 17 th BIm. Sch. V Minimum Certified Measuring Ranges Photometer Oxygen measurement IR Paramagn. Limas 11 Magnos 106 Option in photometer Flame ionization 75 mg/m 3 200 mg/m 3 35 mg/m 3 75 mg/m 3 NO 2 NH 3 N 2 O SO 2 H 2 O HCl HF Ctotal 15 mg/m 3 O 2 10/25 vol% Validation Ambient air and gas cells © ABB Group 16 March 2018 | Slide 5 Ambient air Adjustment without test gas Gas cell check once a year Multi FID 14 CO 2 NO § § Electrochem. Uras 14 CO UV N 2 and sample gas

Advance Optima - 13 th and 17 th BIm. Sch. V Minimum Certified Measuring Ranges Photometer Oxygen measurement IR Paramagn. Limas 11 Magnos 106 Option in photometer Flame ionization 75 mg/m 3 200 mg/m 3 35 mg/m 3 75 mg/m 3 NO 2 NH 3 N 2 O SO 2 H 2 O HCl HF Ctotal 15 mg/m 3 O 2 10/25 vol% Validation Ambient air and gas cells © ABB Group 16 March 2018 | Slide 5 Ambient air Adjustment without test gas Gas cell check once a year Multi FID 14 CO 2 NO § § Electrochem. Uras 14 CO UV N 2 and sample gas

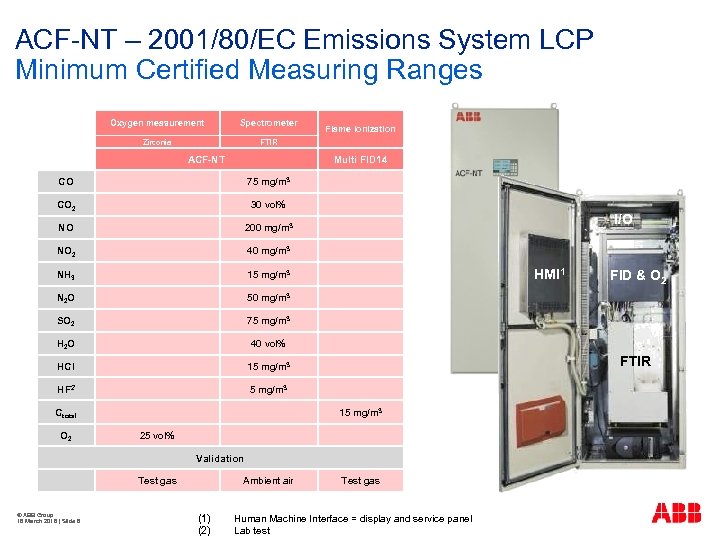

ACF-NT – 2001/80/EC Emissions System LCP Minimum Certified Measuring Ranges Oxygen measurement Spectrometer Zirconia FTIR ACF-NT Flame ionization Multi FID 14 CO 75 mg/m 3 CO 2 30 vol% NO 200 mg/m 3 NO 2 40 mg/m 3 NH 3 15 mg/m 3 N 2 O 50 mg/m 3 SO 2 75 mg/m 3 H 2 O 40 vol% HCl 15 mg/m 3 HF 2 5 mg/m 3 Ctotal O 2 I/O HMI 1 FTIR 15 mg/m 3 25 vol% Validation Test gas © ABB Group 16 March 2018 | Slide 6 Ambient air (1) (2) FID & O 2 Test gas Human Machine Interface = display and service panel Lab test

ACF-NT – 2001/80/EC Emissions System LCP Minimum Certified Measuring Ranges Oxygen measurement Spectrometer Zirconia FTIR ACF-NT Flame ionization Multi FID 14 CO 75 mg/m 3 CO 2 30 vol% NO 200 mg/m 3 NO 2 40 mg/m 3 NH 3 15 mg/m 3 N 2 O 50 mg/m 3 SO 2 75 mg/m 3 H 2 O 40 vol% HCl 15 mg/m 3 HF 2 5 mg/m 3 Ctotal O 2 I/O HMI 1 FTIR 15 mg/m 3 25 vol% Validation Test gas © ABB Group 16 March 2018 | Slide 6 Ambient air (1) (2) FID & O 2 Test gas Human Machine Interface = display and service panel Lab test

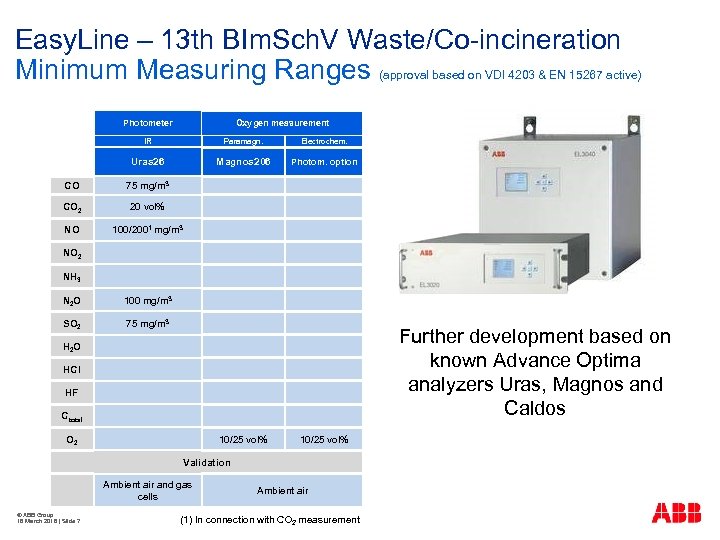

Easy. Line – 13 th BIm. Sch. V Waste/Co-incineration Minimum Measuring Ranges (approval based on VDI 4203 & EN 15267 active) Photometer Oxygen measurement IR Paramagn. Electrochem. Uras 26 Magnos 206 Photom. option CO 75 mg/m 3 CO 2 20 vol% NO 100/2001 mg/m 3 NO 2 NH 3 N 2 O 100 mg/m 3 SO 2 75 mg/m 3 Further development based on known Advance Optima analyzers Uras, Magnos and Caldos H 2 O HCl HF Ctotal O 2 10/25 vol% Validation Ambient air and gas cells © ABB Group 16 March 2018 | Slide 7 Ambient air (1) In connection with CO 2 measurement

Easy. Line – 13 th BIm. Sch. V Waste/Co-incineration Minimum Measuring Ranges (approval based on VDI 4203 & EN 15267 active) Photometer Oxygen measurement IR Paramagn. Electrochem. Uras 26 Magnos 206 Photom. option CO 75 mg/m 3 CO 2 20 vol% NO 100/2001 mg/m 3 NO 2 NH 3 N 2 O 100 mg/m 3 SO 2 75 mg/m 3 Further development based on known Advance Optima analyzers Uras, Magnos and Caldos H 2 O HCl HF Ctotal O 2 10/25 vol% Validation Ambient air and gas cells © ABB Group 16 March 2018 | Slide 7 Ambient air (1) In connection with CO 2 measurement

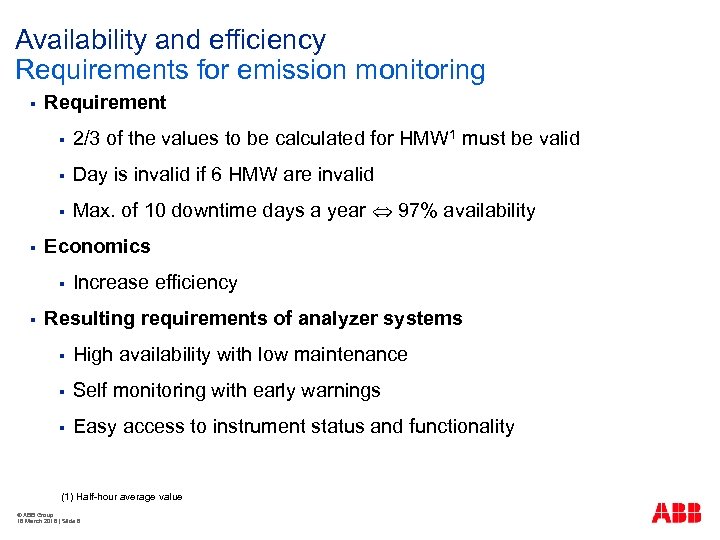

Availability and efficiency Requirements for emission monitoring § Requirement § § Day is invalid if 6 HMW are invalid § § 2/3 of the values to be calculated for HMW 1 must be valid Max. of 10 downtime days a year 97% availability Economics § § Increase efficiency Resulting requirements of analyzer systems § High availability with low maintenance § Self monitoring with early warnings § Easy access to instrument status and functionality (1) Half-hour average value © ABB Group 16 March 2018 | Slide 8

Availability and efficiency Requirements for emission monitoring § Requirement § § Day is invalid if 6 HMW are invalid § § 2/3 of the values to be calculated for HMW 1 must be valid Max. of 10 downtime days a year 97% availability Economics § § Increase efficiency Resulting requirements of analyzer systems § High availability with low maintenance § Self monitoring with early warnings § Easy access to instrument status and functionality (1) Half-hour average value © ABB Group 16 March 2018 | Slide 8

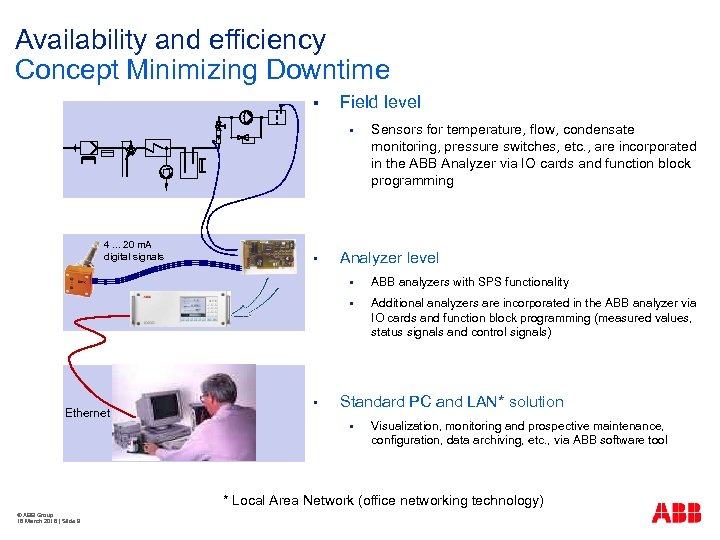

Availability and efficiency Concept Minimizing Downtime § Field level § 4. . . 20 m. A digital signals § Sensors for temperature, flow, condensate monitoring, pressure switches, etc. , are incorporated in the ABB Analyzer via IO cards and function block programming Analyzer level § § Ethernet § ABB analyzers with SPS functionality Additional analyzers are incorporated in the ABB analyzer via IO cards and function block programming (measured values, status signals and control signals) Standard PC and LAN* solution § Visualization, monitoring and prospective maintenance, configuration, data archiving, etc. , via ABB software tool * Local Area Network (office networking technology) © ABB Group 16 March 2018 | Slide 9

Availability and efficiency Concept Minimizing Downtime § Field level § 4. . . 20 m. A digital signals § Sensors for temperature, flow, condensate monitoring, pressure switches, etc. , are incorporated in the ABB Analyzer via IO cards and function block programming Analyzer level § § Ethernet § ABB analyzers with SPS functionality Additional analyzers are incorporated in the ABB analyzer via IO cards and function block programming (measured values, status signals and control signals) Standard PC and LAN* solution § Visualization, monitoring and prospective maintenance, configuration, data archiving, etc. , via ABB software tool * Local Area Network (office networking technology) © ABB Group 16 March 2018 | Slide 9

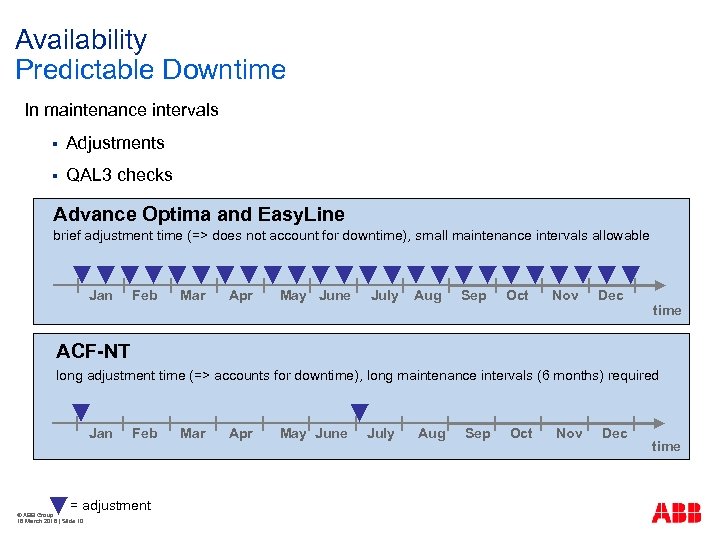

Availability Predictable Downtime In maintenance intervals § Adjustments § QAL 3 checks Advance Optima and Easy. Line brief adjustment time (=> does not account for downtime), small maintenance intervals allowable Jan Feb Mar Apr May June July Aug Sep Oct Nov Dec time ACF-NT long adjustment time (=> accounts for downtime), long maintenance intervals (6 months) required Jan Feb Mar Apr May June July Aug Sep Oct Nov Dec = adjustment © ABB Group 16 March 2018 | Slide 10 time

Availability Predictable Downtime In maintenance intervals § Adjustments § QAL 3 checks Advance Optima and Easy. Line brief adjustment time (=> does not account for downtime), small maintenance intervals allowable Jan Feb Mar Apr May June July Aug Sep Oct Nov Dec time ACF-NT long adjustment time (=> accounts for downtime), long maintenance intervals (6 months) required Jan Feb Mar Apr May June July Aug Sep Oct Nov Dec = adjustment © ABB Group 16 March 2018 | Slide 10 time

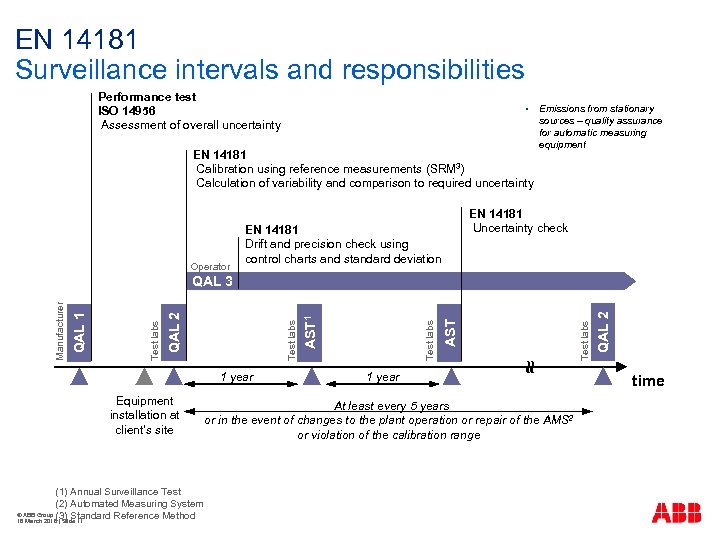

EN 14181 Surveillance intervals and responsibilities Performance test ISO 14956 Assessment of overall uncertainty § EN 14181 Calibration using reference measurements (SRM 3) Calculation of variability and comparison to required uncertainty Operator Emissions from stationary sources – quality assurance for automatic measuring equipment EN 14181 Uncertainty check EN 14181 Drift and precision check using control charts and standard deviation Equipment installation at client’s site (1) Annual Surveillance Test (2) Automated Measuring System © ABB Group (3) Standard Reference Method 16 March 2018 | Slide 11 At least every 5 years or in the event of changes to the plant operation or repair of the AMS 2 or violation of the calibration range QAL 2 Test labs AST Test labs 1 year ~ 1 year AST 1 Test labs QAL 2 Test labs QAL 1 Manufacturer QAL 3 time

EN 14181 Surveillance intervals and responsibilities Performance test ISO 14956 Assessment of overall uncertainty § EN 14181 Calibration using reference measurements (SRM 3) Calculation of variability and comparison to required uncertainty Operator Emissions from stationary sources – quality assurance for automatic measuring equipment EN 14181 Uncertainty check EN 14181 Drift and precision check using control charts and standard deviation Equipment installation at client’s site (1) Annual Surveillance Test (2) Automated Measuring System © ABB Group (3) Standard Reference Method 16 March 2018 | Slide 11 At least every 5 years or in the event of changes to the plant operation or repair of the AMS 2 or violation of the calibration range QAL 2 Test labs AST Test labs 1 year ~ 1 year AST 1 Test labs QAL 2 Test labs QAL 1 Manufacturer QAL 3 time

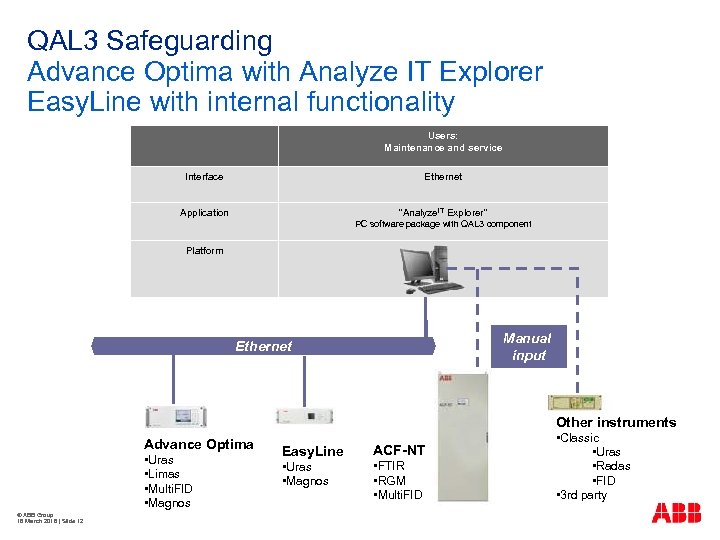

QAL 3 Safeguarding Advance Optima with Analyze IT Explorer Easy. Line with internal functionality Users: Maintenance and service Interface Ethernet Application “Analyze. IT Explorer” PC software package with QAL 3 component Platform Manual input Ethernet Other instruments Advance Optima • Uras • Limas • Multi. FID • Magnos © ABB Group 16 March 2018 | Slide 12 Easy. Line ACF-NT • Uras • Magnos • FTIR • RGM • Multi. FID • Classic • Uras • Radas • FID • 3 rd party

QAL 3 Safeguarding Advance Optima with Analyze IT Explorer Easy. Line with internal functionality Users: Maintenance and service Interface Ethernet Application “Analyze. IT Explorer” PC software package with QAL 3 component Platform Manual input Ethernet Other instruments Advance Optima • Uras • Limas • Multi. FID • Magnos © ABB Group 16 March 2018 | Slide 12 Easy. Line ACF-NT • Uras • Magnos • FTIR • RGM • Multi. FID • Classic • Uras • Radas • FID • 3 rd party

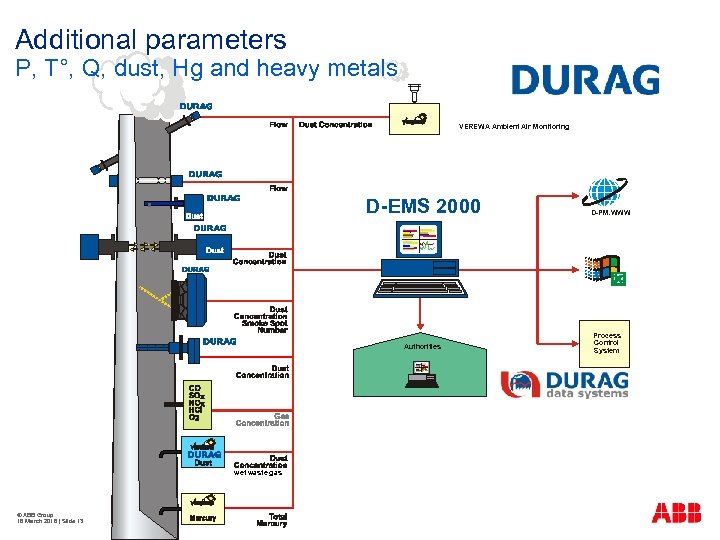

Additional parameters P, T°, Q, dust, Hg and heavy metals VEREWA Ambient Air Monitoring D-EMS 2000 Authorities wet waste gas © ABB Group 16 March 2018 | Slide 13 D-PM. WWW Process Control System

Additional parameters P, T°, Q, dust, Hg and heavy metals VEREWA Ambient Air Monitoring D-EMS 2000 Authorities wet waste gas © ABB Group 16 March 2018 | Slide 13 D-PM. WWW Process Control System

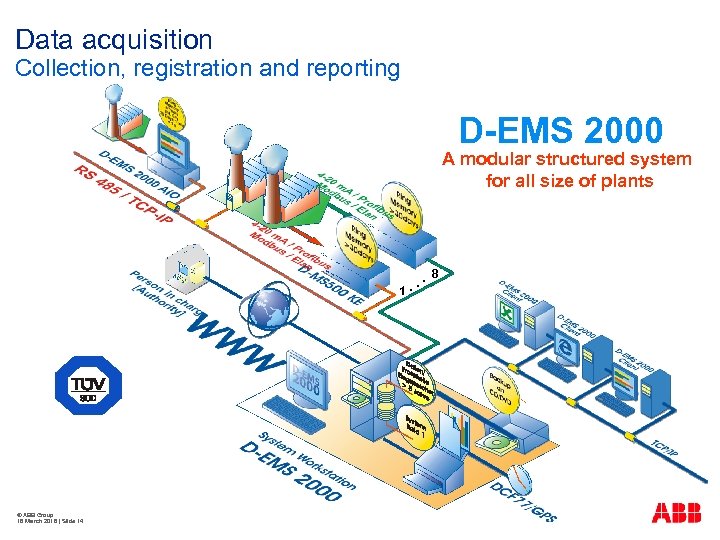

Data acquisition Collection, registration and reporting D-EMS 2000 A modular structured system for all size of plants 8 . . . 1 © ABB Group 16 March 2018 | Slide 14

Data acquisition Collection, registration and reporting D-EMS 2000 A modular structured system for all size of plants 8 . . . 1 © ABB Group 16 March 2018 | Slide 14

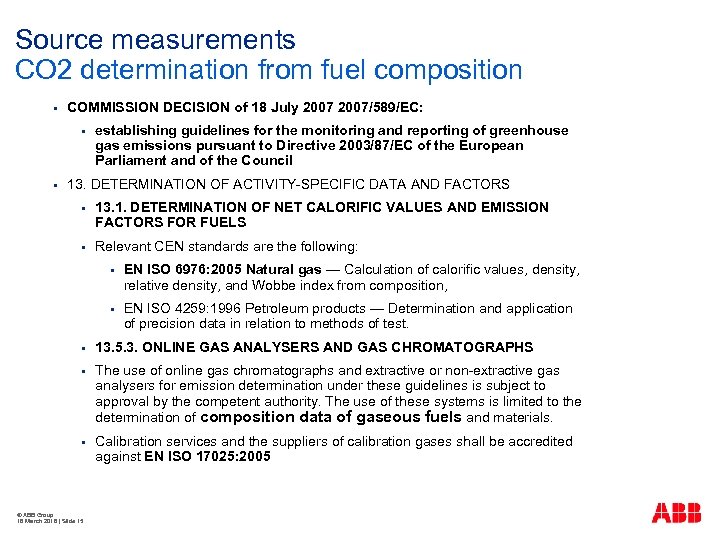

Source measurements CO 2 determination from fuel composition § COMMISSION DECISION of 18 July 2007/589/EC: § § establishing guidelines for the monitoring and reporting of greenhouse gas emissions pursuant to Directive 2003/87/EC of the European Parliament and of the Council 13. DETERMINATION OF ACTIVITY-SPECIFIC DATA AND FACTORS § 13. 1. DETERMINATION OF NET CALORIFIC VALUES AND EMISSION FACTORS FOR FUELS § Relevant CEN standards are the following: § EN ISO 6976: 2005 Natural gas — Calculation of calorific values, density, relative density, and Wobbe index from composition, § EN ISO 4259: 1996 Petroleum products — Determination and application of precision data in relation to methods of test. § 13. 5. 3. ONLINE GAS ANALYSERS AND GAS CHROMATOGRAPHS § The use of online gas chromatographs and extractive or non-extractive gas analysers for emission determination under these guidelines is subject to approval by the competent authority. The use of these systems is limited to the determination of composition data of gaseous fuels and materials. § Calibration services and the suppliers of calibration gases shall be accredited against EN ISO 17025: 2005 © ABB Group 16 March 2018 | Slide 15

Source measurements CO 2 determination from fuel composition § COMMISSION DECISION of 18 July 2007/589/EC: § § establishing guidelines for the monitoring and reporting of greenhouse gas emissions pursuant to Directive 2003/87/EC of the European Parliament and of the Council 13. DETERMINATION OF ACTIVITY-SPECIFIC DATA AND FACTORS § 13. 1. DETERMINATION OF NET CALORIFIC VALUES AND EMISSION FACTORS FOR FUELS § Relevant CEN standards are the following: § EN ISO 6976: 2005 Natural gas — Calculation of calorific values, density, relative density, and Wobbe index from composition, § EN ISO 4259: 1996 Petroleum products — Determination and application of precision data in relation to methods of test. § 13. 5. 3. ONLINE GAS ANALYSERS AND GAS CHROMATOGRAPHS § The use of online gas chromatographs and extractive or non-extractive gas analysers for emission determination under these guidelines is subject to approval by the competent authority. The use of these systems is limited to the determination of composition data of gaseous fuels and materials. § Calibration services and the suppliers of calibration gases shall be accredited against EN ISO 17025: 2005 © ABB Group 16 March 2018 | Slide 15

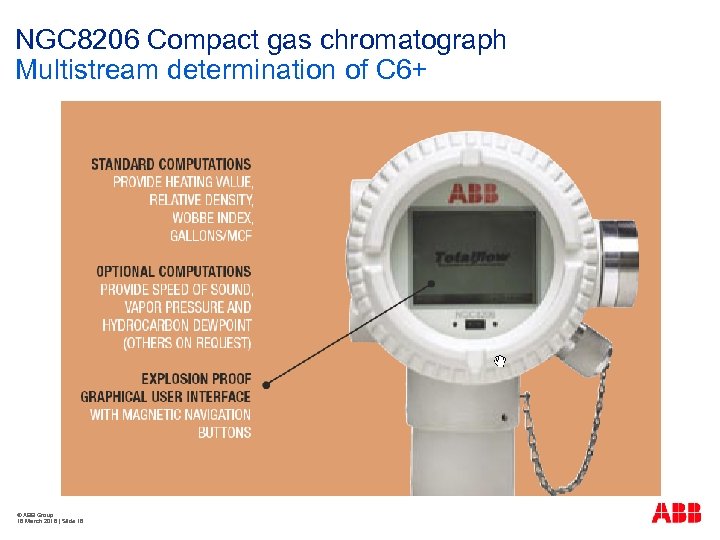

NGC 8206 Compact gas chromatograph Multistream determination of C 6+ © ABB Group 16 March 2018 | Slide 16

NGC 8206 Compact gas chromatograph Multistream determination of C 6+ © ABB Group 16 March 2018 | Slide 16

International standards Compliance to highest level § ISO/IEC 17025: 2005 -- General requirements for the competence of testing and calibration laboratories lab accreditation § ISO 10723: 1995 Natural gas -- Performance evaluation for online analytical systems report available from such lab § ISO 6976: 2005 Natural gas -- Calculation of calorific values, density, relative density, and Wobbe index from composition § OIML R-140 --Measuring systems for Gaseous Fuel § R-140 includes requirements for online GC’s § Certified by LNE © ABB Group 16 March 2018 | Slide 17

International standards Compliance to highest level § ISO/IEC 17025: 2005 -- General requirements for the competence of testing and calibration laboratories lab accreditation § ISO 10723: 1995 Natural gas -- Performance evaluation for online analytical systems report available from such lab § ISO 6976: 2005 Natural gas -- Calculation of calorific values, density, relative density, and Wobbe index from composition § OIML R-140 --Measuring systems for Gaseous Fuel § R-140 includes requirements for online GC’s § Certified by LNE © ABB Group 16 March 2018 | Slide 17

Summary Availability and precision optimised § Approved and compliant equipment § Dedicated calibration concepts § Use of intelligent AMS § Optimum systemdesign with a. o. integrated peripheral diagnostics § Intelligent Software for § § § © ABB Group 16 March 2018 | Slide 18 Remote diagnositcs Remote connection Tailor made maintenance contracts So you can do you work in peace ; -)

Summary Availability and precision optimised § Approved and compliant equipment § Dedicated calibration concepts § Use of intelligent AMS § Optimum systemdesign with a. o. integrated peripheral diagnostics § Intelligent Software for § § § © ABB Group 16 March 2018 | Slide 18 Remote diagnositcs Remote connection Tailor made maintenance contracts So you can do you work in peace ; -)

© ABB Group 16 March 2018 | Slide 19

© ABB Group 16 March 2018 | Slide 19