c7a79bdffd443011acad7f3796d1e9c3.ppt

- Количество слайдов: 18

Cyrel® Digi. Corr Higher Quality Graphics for Corrugated Board

Cyrel® Digi. Corr Higher Quality Graphics for Corrugated Board

2 Background • Around the year 2000 flexo plate making moved Digital • Driver for this was higher print quality achievable first of all in the Market Segments ‘Flexible Packaging’ and ‘Tag&Label’ • Very quickly it became apparent that apart from the quality improvement there were also work flow advantages by going digital • Today, around 75% of all flexo plates used in the printing industry are digital plates

2 Background • Around the year 2000 flexo plate making moved Digital • Driver for this was higher print quality achievable first of all in the Market Segments ‘Flexible Packaging’ and ‘Tag&Label’ • Very quickly it became apparent that apart from the quality improvement there were also work flow advantages by going digital • Today, around 75% of all flexo plates used in the printing industry are digital plates

3 Background • Move from analog to digital in the Corrugated Industry has always lagged behind the other Market Segments mentioned – here the share of digital is only around 50% • This has been due to the fact that for a large portion of the Corrugated work there was no apparent quality advantage in going digital – in some cases even adverse effects became visible, which was more apparent fluting as compared to analog plate printing • Now the challenge is to reduce this fluting effect in order for the Corrugated Industry to be able to catch up with the developments in digital plate making • The Du. Pont Cyrel® answer to this challenge is Digi. Corr

3 Background • Move from analog to digital in the Corrugated Industry has always lagged behind the other Market Segments mentioned – here the share of digital is only around 50% • This has been due to the fact that for a large portion of the Corrugated work there was no apparent quality advantage in going digital – in some cases even adverse effects became visible, which was more apparent fluting as compared to analog plate printing • Now the challenge is to reduce this fluting effect in order for the Corrugated Industry to be able to catch up with the developments in digital plate making • The Du. Pont Cyrel® answer to this challenge is Digi. Corr

4 The Digi. Corr Solution What is Digi. Corr? • A workflow innovation to produce a Digital Cyrel® plate that is optimized for the needs of the corrugated printer. What Does Digi. Corr Do? • The Du. Pont Digi. Corr modified workflow produces a hybrid dot profile for corrugated printing resulting in: • Reduced fluting (washboarding) • Improved solid ink density • Superior highlights & vignettes • Improved run length

4 The Digi. Corr Solution What is Digi. Corr? • A workflow innovation to produce a Digital Cyrel® plate that is optimized for the needs of the corrugated printer. What Does Digi. Corr Do? • The Du. Pont Digi. Corr modified workflow produces a hybrid dot profile for corrugated printing resulting in: • Reduced fluting (washboarding) • Improved solid ink density • Superior highlights & vignettes • Improved run length

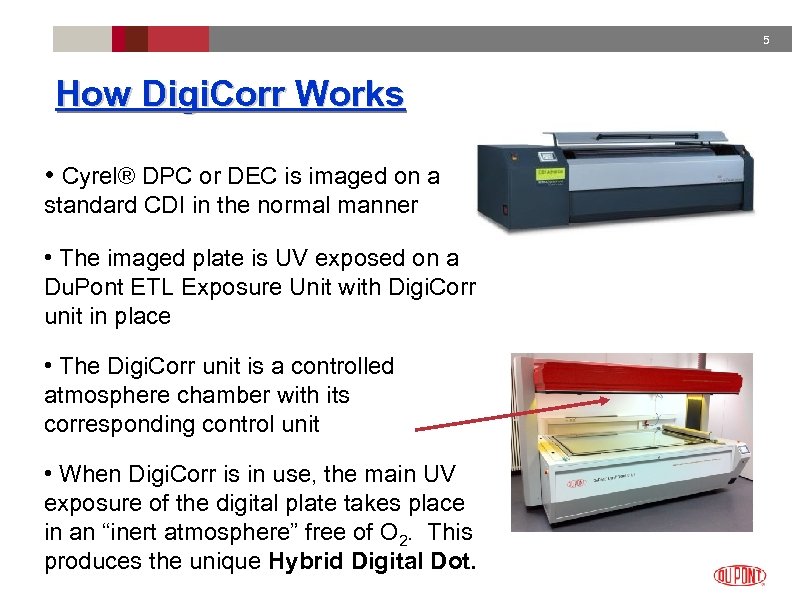

5 How Digi. Corr Works • Cyrel® DPC or DEC is imaged on a standard CDI in the normal manner • The imaged plate is UV exposed on a Du. Pont ETL Exposure Unit with Digi. Corr unit in place • The Digi. Corr unit is a controlled atmosphere chamber with its corresponding control unit • When Digi. Corr is in use, the main UV exposure of the digital plate takes place in an “inert atmosphere” free of O 2. This produces the unique Hybrid Digital Dot.

5 How Digi. Corr Works • Cyrel® DPC or DEC is imaged on a standard CDI in the normal manner • The imaged plate is UV exposed on a Du. Pont ETL Exposure Unit with Digi. Corr unit in place • The Digi. Corr unit is a controlled atmosphere chamber with its corresponding control unit • When Digi. Corr is in use, the main UV exposure of the digital plate takes place in an “inert atmosphere” free of O 2. This produces the unique Hybrid Digital Dot.

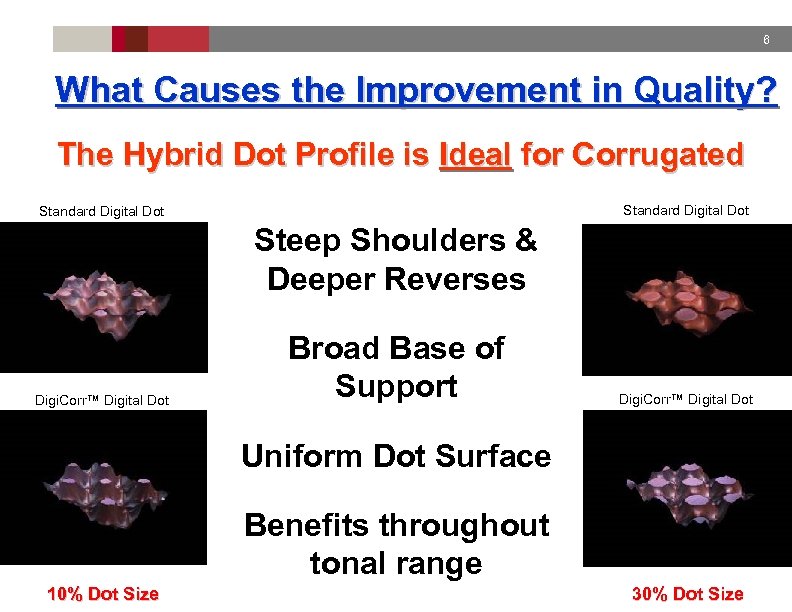

6 What Causes the Improvement in Quality? The Hybrid Dot Profile is Ideal for Corrugated Standard Digital Dot Steep Shoulders & Deeper Reverses Digi. Corr™ Digital Dot Broad Base of Support Digi. Corr™ Digital Dot Uniform Dot Surface Benefits throughout tonal range 10% Dot Size 30% Dot Size

6 What Causes the Improvement in Quality? The Hybrid Dot Profile is Ideal for Corrugated Standard Digital Dot Steep Shoulders & Deeper Reverses Digi. Corr™ Digital Dot Broad Base of Support Digi. Corr™ Digital Dot Uniform Dot Surface Benefits throughout tonal range 10% Dot Size 30% Dot Size

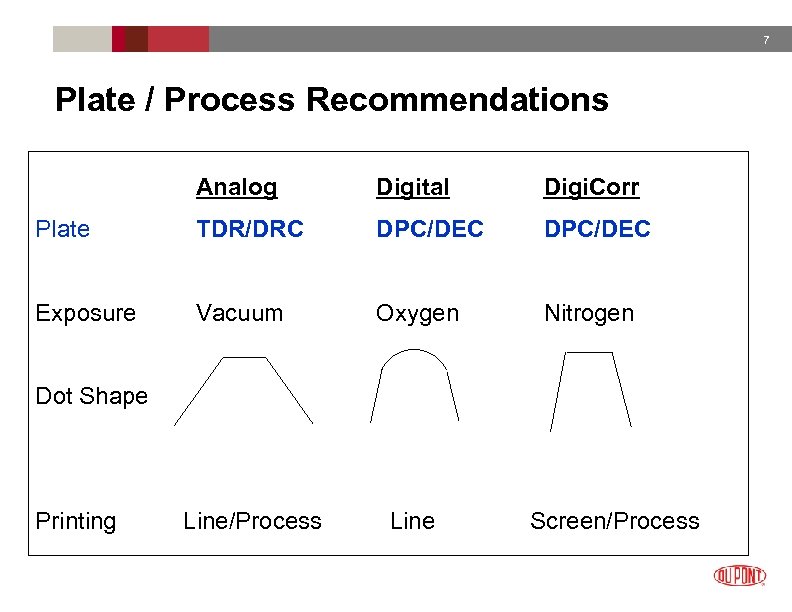

7 Plate / Process Recommendations Analog Digital Digi. Corr Plate TDR/DRC DPC/DEC Exposure Vacuum Oxygen Nitrogen Dot Shape Printing Line/Process Line Screen/Process

7 Plate / Process Recommendations Analog Digital Digi. Corr Plate TDR/DRC DPC/DEC Exposure Vacuum Oxygen Nitrogen Dot Shape Printing Line/Process Line Screen/Process

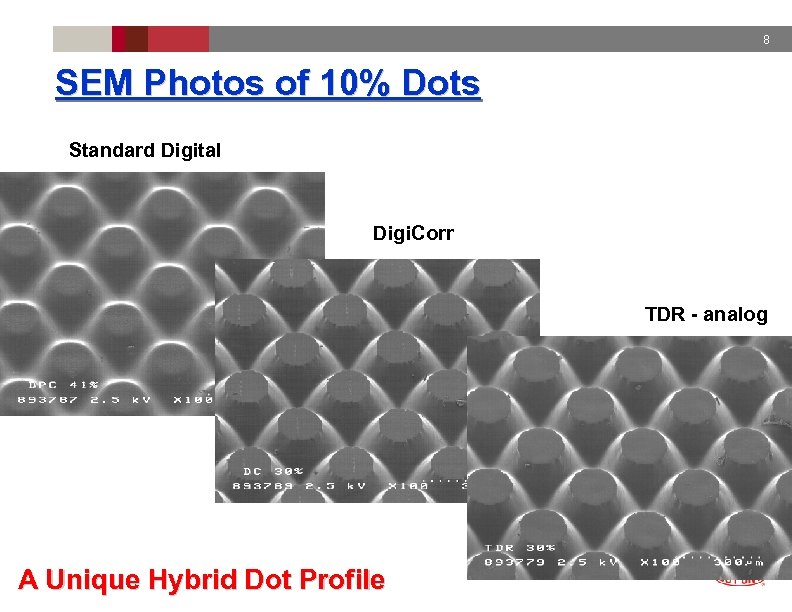

8 SEM Photos of 10% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

8 SEM Photos of 10% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

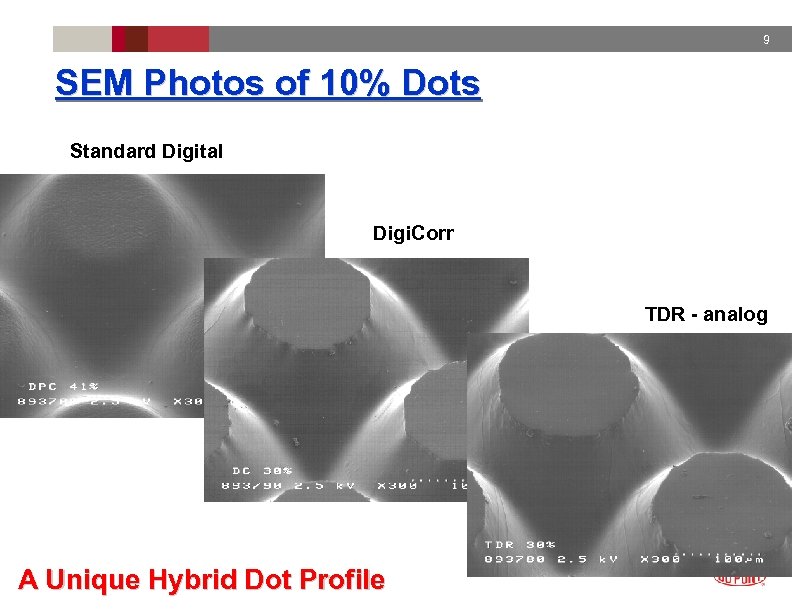

9 SEM Photos of 10% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

9 SEM Photos of 10% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

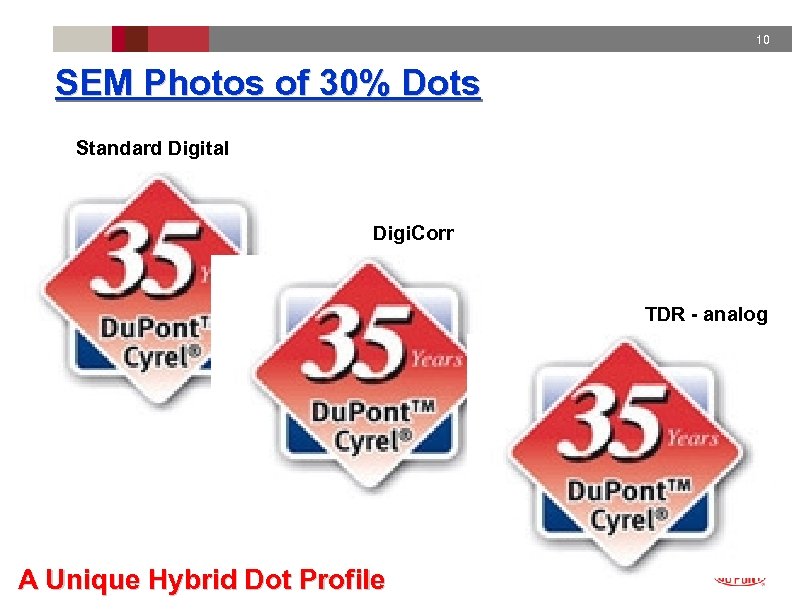

10 SEM Photos of 30% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

10 SEM Photos of 30% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

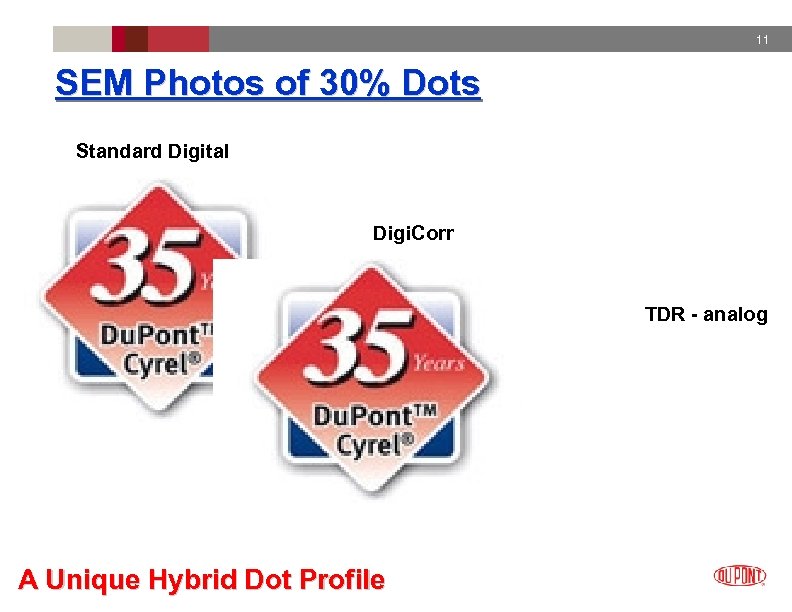

11 SEM Photos of 30% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

11 SEM Photos of 30% Dots Standard Digital Digi. Corr TDR - analog A Unique Hybrid Dot Profile

12 Standard Digital – 34 l/cm

12 Standard Digital – 34 l/cm

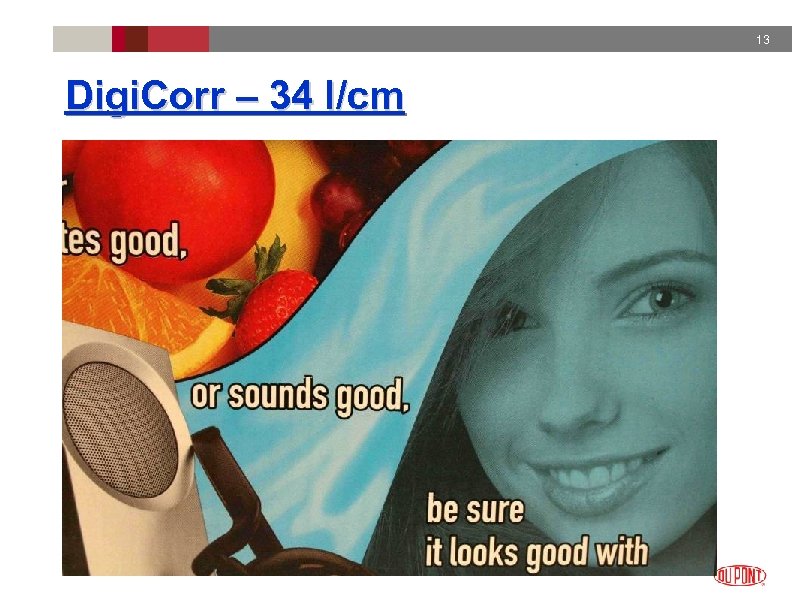

13 Digi. Corr – 34 l/cm

13 Digi. Corr – 34 l/cm

14 Digi. Corr Benefits • Simple to use process • Switchable, only use when altered dot profile preferred • No additional plate material needed • Superior corrugated print quality Du. Pont Digi. Corr will provide the Corrugated Tradeshops and Converters with a competitive quality advantage

14 Digi. Corr Benefits • Simple to use process • Switchable, only use when altered dot profile preferred • No additional plate material needed • Superior corrugated print quality Du. Pont Digi. Corr will provide the Corrugated Tradeshops and Converters with a competitive quality advantage

15 Digi. Corr Benefits • Some printers still think that very thick printing plates are necessary in order to successfully print on corrugated board in order to allow for it to adapt to the wavy surface • With Digi. Corr this for sure is not necessary anymore When doing your next investment into new printing presses, consider to not go thicker than 155 mil / 3. 94 mm for your printing plates! • Combine Digi. Corr and Thin Cyrel® Plates and you will enjoy • Better Print Quality • Ease of Handling • Environmental Sustainability

15 Digi. Corr Benefits • Some printers still think that very thick printing plates are necessary in order to successfully print on corrugated board in order to allow for it to adapt to the wavy surface • With Digi. Corr this for sure is not necessary anymore When doing your next investment into new printing presses, consider to not go thicker than 155 mil / 3. 94 mm for your printing plates! • Combine Digi. Corr and Thin Cyrel® Plates and you will enjoy • Better Print Quality • Ease of Handling • Environmental Sustainability

16 Digi. Corr Installations

16 Digi. Corr Installations

17 Summary • Du. Pont continues to lead the effort in driving digital solutions into the corrugated industry. • We have the knowledge and expertise of how to apply these solutions to fit your specific business processes • Work with Du. Pont to analyze your current workflows and costs to determine the best solutions to meet your productivity and profit goals. • Plan a visit to our Customer Technology Center to see first-hand these latest technologies in action.

17 Summary • Du. Pont continues to lead the effort in driving digital solutions into the corrugated industry. • We have the knowledge and expertise of how to apply these solutions to fit your specific business processes • Work with Du. Pont to analyze your current workflows and costs to determine the best solutions to meet your productivity and profit goals. • Plan a visit to our Customer Technology Center to see first-hand these latest technologies in action.

18 Thank You

18 Thank You