3d5073ebc2aa24aff18a643ff40cf385.ppt

- Количество слайдов: 21

Customer Profile Presented By: Bruce Armstrong, Software Leader Advanced Glass. Fiber Yarns, LLC

Advanced Glass. Fiber Yarns, LLC Presented By Bruce Armstrong • • • Software Leader of Advanced Glassfiber Yarns. Project leader for implementation of Oracle Financials and Oracle Process Manufacturing 20 years experience in manufacturing systems with Owens-Corning, Dupont and Advanced Glassfiber Yarns.

Advanced Glass. Fiber Yarns, LLC Background • Joint Venture Between Owens Corning and Groupe Porcher formed September, 1998 • Dependent on Owens Corning Legacy Systems • NO legacy systems compliant for Y 2 K

Advanced Glass. Fiber Yarns, LLC Business • Industrial, Construction & Electronics Markets • Producing Glass Fiber Yarns • Three Manufacturing Facilities: – Aiken, South Carolina – Huntingdon, Pennsylvania – South Hill, Virginia • Highly Automated • High Volume • International

Software profile: Financials • • • Financials 11. 0 purchased November, 1998. Financials live by April, 1999. Implemented AP, AR and GL integrated with OPM. GL and AP integrated with MP 2.

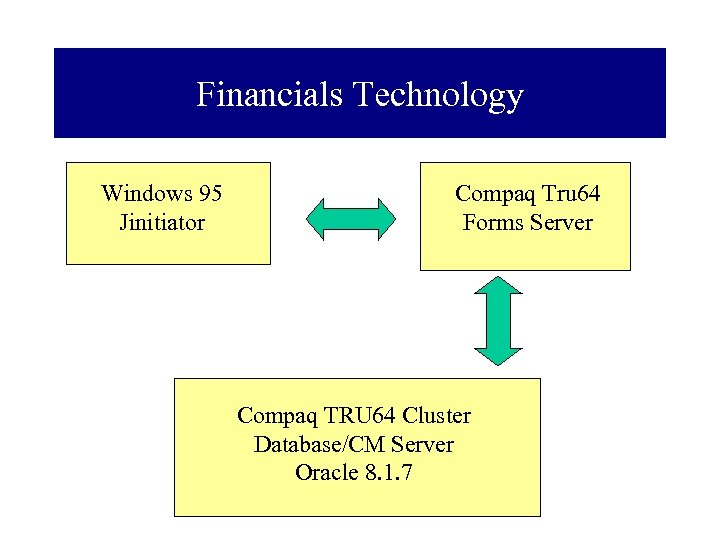

Financials Technology Windows 95 Jinitiator Compaq Tru 64 Forms Server Compaq TRU 64 Cluster Database/CM Server Oracle 8. 1. 7

Software profile: OPM • OPM 4. 10 purchased March, 1999 • Custom programming for production and shipping. • Implemented PM, INV, Cost, PO, OF • OPM live by September, 1999

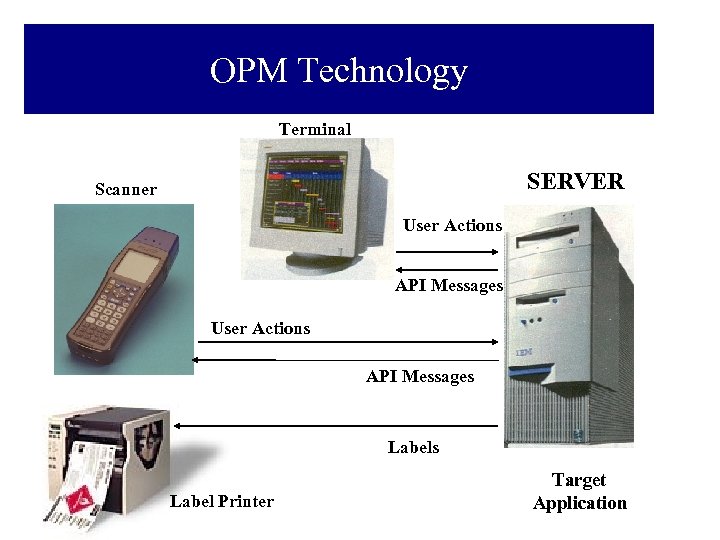

OPM Technology Terminal SERVER Scanner User Actions API Messages Labels Label Printer Target Application

Software profile: MP 2 • • Datastream’s MP 2 purchased April, 1999 Integrated with Financials using MOAI Implemented PO, MM MP 2 live by October, 1999.

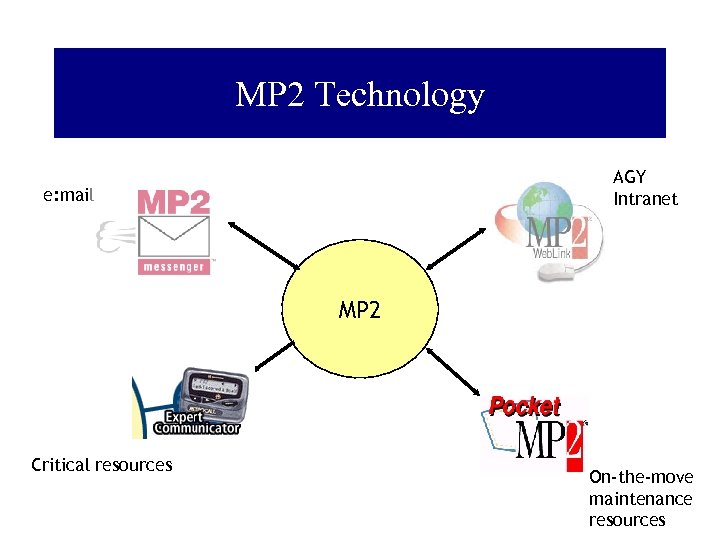

MP 2 Technology AGY Intranet e: mail MP 2 Critical resources On-the-move maintenance resources

Software profile: Camstar • • Camstar purchased February 2001 Integrated with PLC’s and OPM PM Custom ASP and Visual Basic Implemented July, 2002

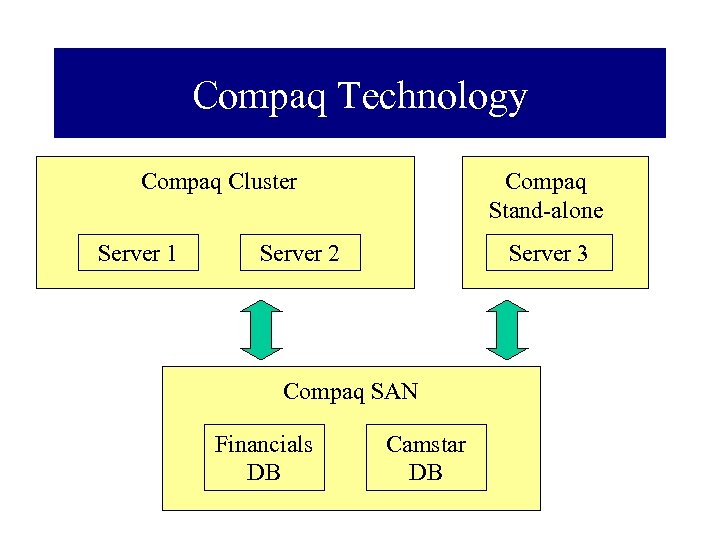

Compaq Technology Compaq Cluster Server 1 Compaq Stand-alone Server 2 Server 3 Compaq SAN Financials DB Camstar DB

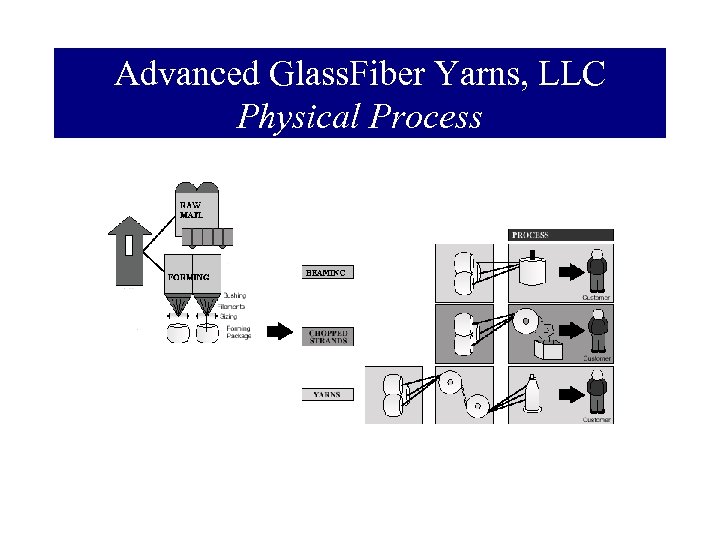

Advanced Glass. Fiber Yarns, LLC Physical Process

OPM Production Pallet Label Functional Steps • Create Batches of WIP and Finished Goods • Build Pallet with Bobbins of Glass Yarn • Create Production Label for Completed Pallet • Pallet Moved to Warehouse Door 12345 61321 65875 21435 43518 73211

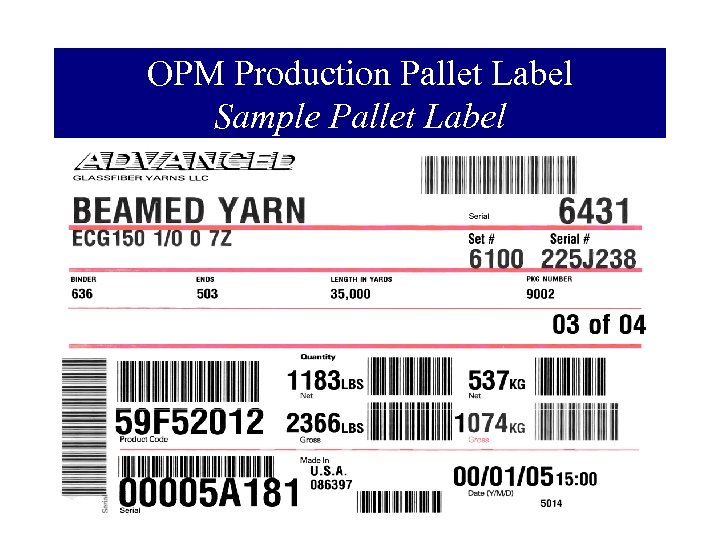

OPM Production Pallet Label Sample Pallet Label

Warehouse Finished Goods Receipt Process Functional Steps • Warehouse Scans Pallet Lot Number • Scans Row Location • Place Pallet into Warehouse Row

Shipping & Shipping Exception Process Functional Steps • • • Warehouse Retrieves Pallet for Shipment Pallet Placed in Shipping Staging Area Pallets are Scanned to Build Shipment Exception Report Printed Shipment is Released

Key Concerns • • • Conduct business as a new company. Become Y 2 K compliant. Improve productivity of new systems. Implement new technology. Install new applications.

Future Plans • • • Oracle Fixed Assets Oracle 11 i Purchasing system consolidation Oracle Projects Order Management Warehouse Management

Questions & Answers

Contact Me Advanced Glass. Fiber Yarns, LLC Bruce Armstrong bruce. armstrong@agy. com (803) 643 -1215

3d5073ebc2aa24aff18a643ff40cf385.ppt