8c6c263892b6e9b11125803c658e4da1.ppt

- Количество слайдов: 20

Custom Orthotic Insole Using DDM Alhassane Dienta Thomas Koser Chiagoziem Uzor 3/15/2018 Q/A 1

Custom Orthotic Insole Using DDM Alhassane Dienta Thomas Koser Chiagoziem Uzor 3/15/2018 Q/A 1

Table of Contents DDM Overview SME Competition Idea Generation/Insole Background Why DDM ? Design Process Prototype Testing Cost Analysis Conclusion Acknowledgements 3/15/2018 Q/A 2

Table of Contents DDM Overview SME Competition Idea Generation/Insole Background Why DDM ? Design Process Prototype Testing Cost Analysis Conclusion Acknowledgements 3/15/2018 Q/A 2

DDM Overview DDM (Direct Digital Manufacturing) - Also know as “ 3 D printing” or “additive manufacturing , ” “rapid manufacturing” - Process of making 3 dimensional objects from digital file - Large variety of Materials - DDM as a game changer “the market is starting to take off, growing at a clip of up to 35 percent annually” – Armed Forces Journal 2011 3/15/2018 Q/A 3

DDM Overview DDM (Direct Digital Manufacturing) - Also know as “ 3 D printing” or “additive manufacturing , ” “rapid manufacturing” - Process of making 3 dimensional objects from digital file - Large variety of Materials - DDM as a game changer “the market is starting to take off, growing at a clip of up to 35 percent annually” – Armed Forces Journal 2011 3/15/2018 Q/A 3

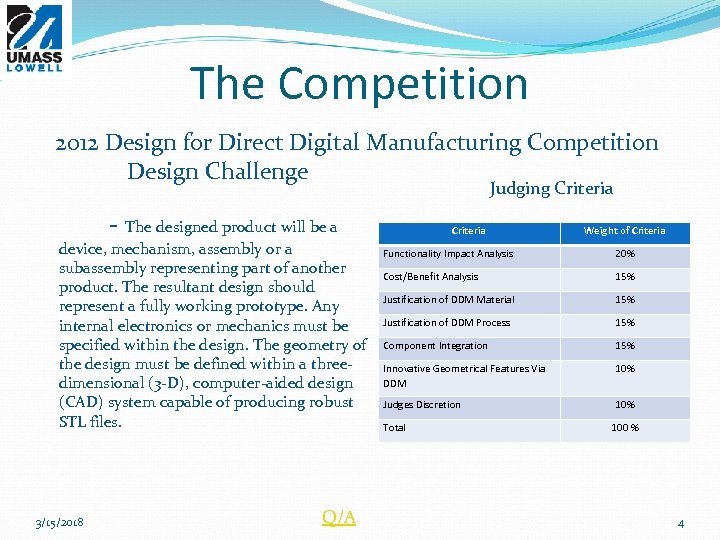

The Competition 2012 Design for Direct Digital Manufacturing Competition Design Challenge Judging Criteria - The designed product will be a device, mechanism, assembly or a subassembly representing part of another product. The resultant design should represent a fully working prototype. Any internal electronics or mechanics must be specified within the design. The geometry of the design must be defined within a threedimensional (3 -D), computer-aided design (CAD) system capable of producing robust STL files. 3/15/2018 Q/A Criteria Weight of Criteria Functionality Impact Analysis 20% Cost/Benefit Analysis 15% Justification of DDM Material 15% Justification of DDM Process 15% Component Integration 15% Innovative Geometrical Features Via DDM 10% Judges Discretion 10% Total 100 % 4

The Competition 2012 Design for Direct Digital Manufacturing Competition Design Challenge Judging Criteria - The designed product will be a device, mechanism, assembly or a subassembly representing part of another product. The resultant design should represent a fully working prototype. Any internal electronics or mechanics must be specified within the design. The geometry of the design must be defined within a threedimensional (3 -D), computer-aided design (CAD) system capable of producing robust STL files. 3/15/2018 Q/A Criteria Weight of Criteria Functionality Impact Analysis 20% Cost/Benefit Analysis 15% Justification of DDM Material 15% Justification of DDM Process 15% Component Integration 15% Innovative Geometrical Features Via DDM 10% Judges Discretion 10% Total 100 % 4

Idea Generation Brainstorming Customized Orthotic Insole background - Orthotic insoles are a very popular and effective way of correcting and adjusting to foot problems like over-pronation and supination which ultimately lead to plantar fasciitis, heel pain, ankle instability, heel spurs, knee pain, and lower back pain. - Millions of Customers - Our design is a custom ¾ length rigid orthotic insole to help restore regular foot bio mechanics. The ¾ length covers from the heel to the end of the metatarsals - The rigidity of the orthotic is due to its function: support and alignment. Market Research - Custom Orthotics cost between $400 -$600 3/15/2018 Q/A 5

Idea Generation Brainstorming Customized Orthotic Insole background - Orthotic insoles are a very popular and effective way of correcting and adjusting to foot problems like over-pronation and supination which ultimately lead to plantar fasciitis, heel pain, ankle instability, heel spurs, knee pain, and lower back pain. - Millions of Customers - Our design is a custom ¾ length rigid orthotic insole to help restore regular foot bio mechanics. The ¾ length covers from the heel to the end of the metatarsals - The rigidity of the orthotic is due to its function: support and alignment. Market Research - Custom Orthotics cost between $400 -$600 3/15/2018 Q/A 5

Why DDM ? Totally Customized to patients foot - The orthotic is customized to patients requirements due to the production procedure Cost Effective for producer - Use of less raw materials and lesser amount of man power saves a lot of production cost Unlimited Complexity - Easily matches the contours of the feet and shoes Eliminate lag time between design and production. - 24 hour turn around time from doctor visit to collection of fully customized orthotic insole Enable More Flexibility - Alterations in the design can easily be made directly using the CAD package 3/15/2018 Q/A 6

Why DDM ? Totally Customized to patients foot - The orthotic is customized to patients requirements due to the production procedure Cost Effective for producer - Use of less raw materials and lesser amount of man power saves a lot of production cost Unlimited Complexity - Easily matches the contours of the feet and shoes Eliminate lag time between design and production. - 24 hour turn around time from doctor visit to collection of fully customized orthotic insole Enable More Flexibility - Alterations in the design can easily be made directly using the CAD package 3/15/2018 Q/A 6

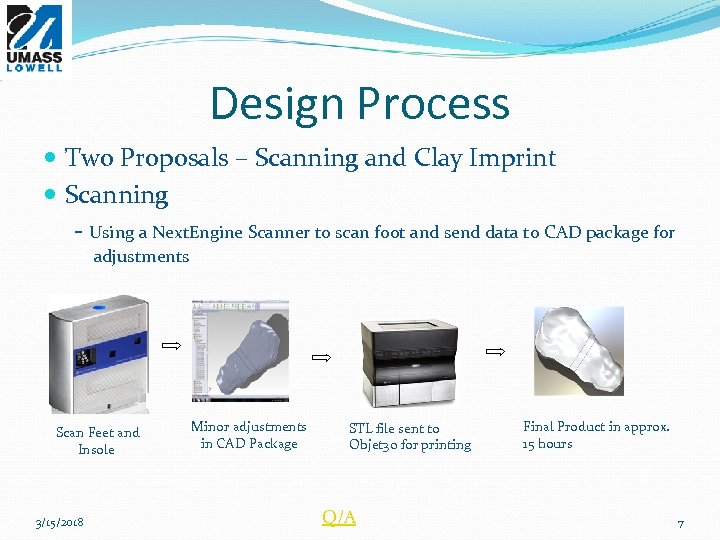

Design Process Two Proposals – Scanning and Clay Imprint Scanning - Using a Next. Engine Scanner to scan foot and send data to CAD package for adjustments Scan Feet and Insole 3/15/2018 Minor adjustments in CAD Package STL file sent to Objet 30 for printing Q/A Final Product in approx. 15 hours 7

Design Process Two Proposals – Scanning and Clay Imprint Scanning - Using a Next. Engine Scanner to scan foot and send data to CAD package for adjustments Scan Feet and Insole 3/15/2018 Minor adjustments in CAD Package STL file sent to Objet 30 for printing Q/A Final Product in approx. 15 hours 7

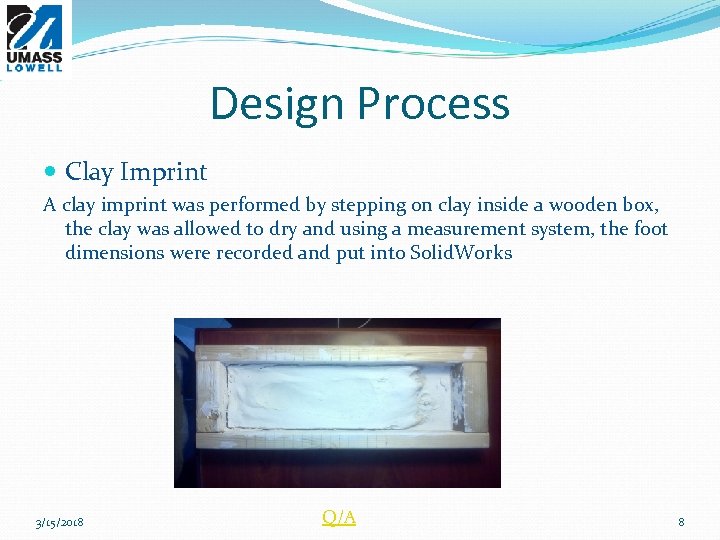

Design Process Clay Imprint A clay imprint was performed by stepping on clay inside a wooden box, the clay was allowed to dry and using a measurement system, the foot dimensions were recorded and put into Solid. Works 3/15/2018 Q/A 8

Design Process Clay Imprint A clay imprint was performed by stepping on clay inside a wooden box, the clay was allowed to dry and using a measurement system, the foot dimensions were recorded and put into Solid. Works 3/15/2018 Q/A 8

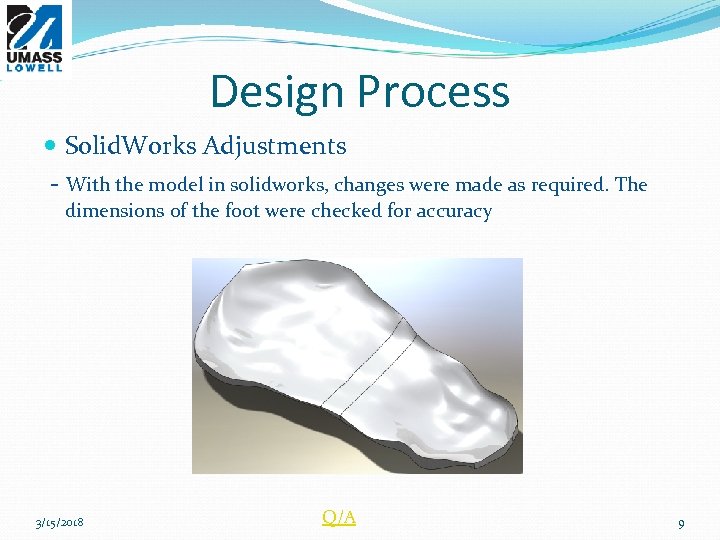

Design Process Solid. Works Adjustments - With the model in solidworks, changes were made as required. The dimensions of the foot were checked for accuracy 3/15/2018 Q/A 9

Design Process Solid. Works Adjustments - With the model in solidworks, changes were made as required. The dimensions of the foot were checked for accuracy 3/15/2018 Q/A 9

Printing Design Process - The model is to be printed on an objet 30 desktop printer. - Printer chose due to type of material required. The material used is Durus. White 430 Cure. It is a polyproylene-like material that possesses the properties required functional orthotic insoles 3/15/2018 Q/A 10

Printing Design Process - The model is to be printed on an objet 30 desktop printer. - Printer chose due to type of material required. The material used is Durus. White 430 Cure. It is a polyproylene-like material that possesses the properties required functional orthotic insoles 3/15/2018 Q/A 10

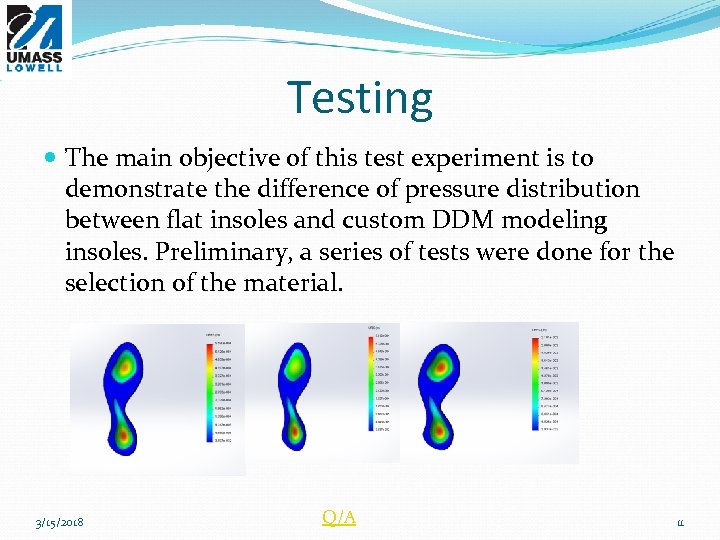

Testing The main objective of this test experiment is to demonstrate the difference of pressure distribution between flat insoles and custom DDM modeling insoles. Preliminary, a series of tests were done for the selection of the material. 3/15/2018 Q/A 11

Testing The main objective of this test experiment is to demonstrate the difference of pressure distribution between flat insoles and custom DDM modeling insoles. Preliminary, a series of tests were done for the selection of the material. 3/15/2018 Q/A 11

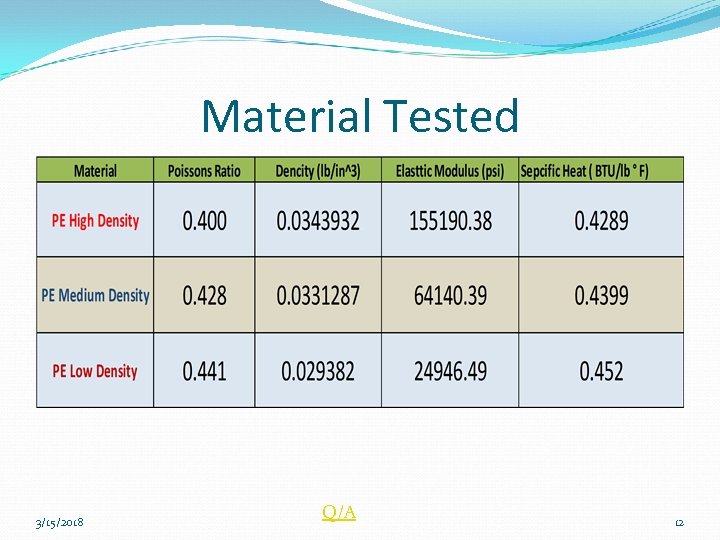

Material Tested 3/15/2018 Q/A 12

Material Tested 3/15/2018 Q/A 12

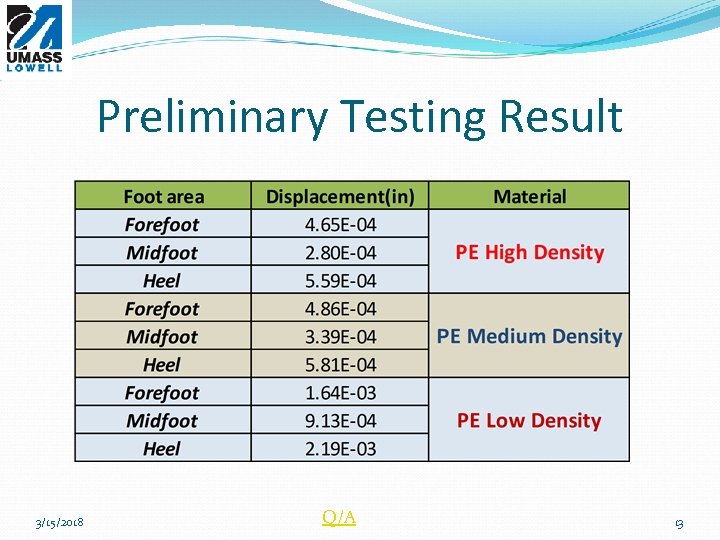

Preliminary Testing Result 3/15/2018 Q/A 13

Preliminary Testing Result 3/15/2018 Q/A 13

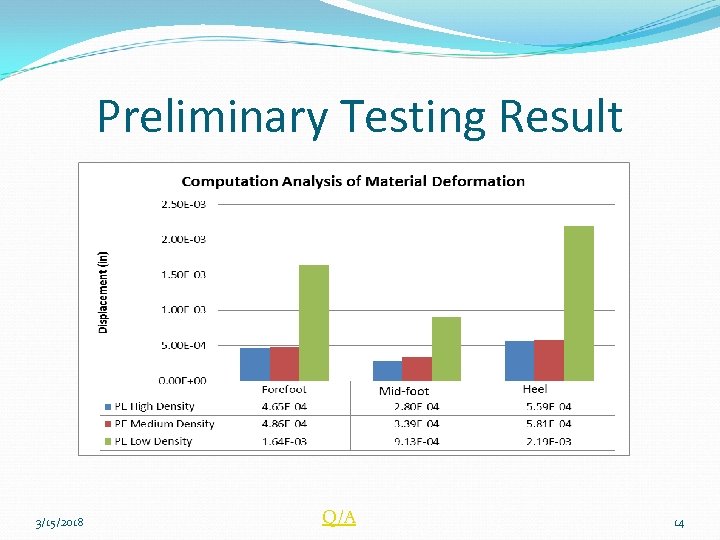

Preliminary Testing Result 3/15/2018 Q/A 14

Preliminary Testing Result 3/15/2018 Q/A 14

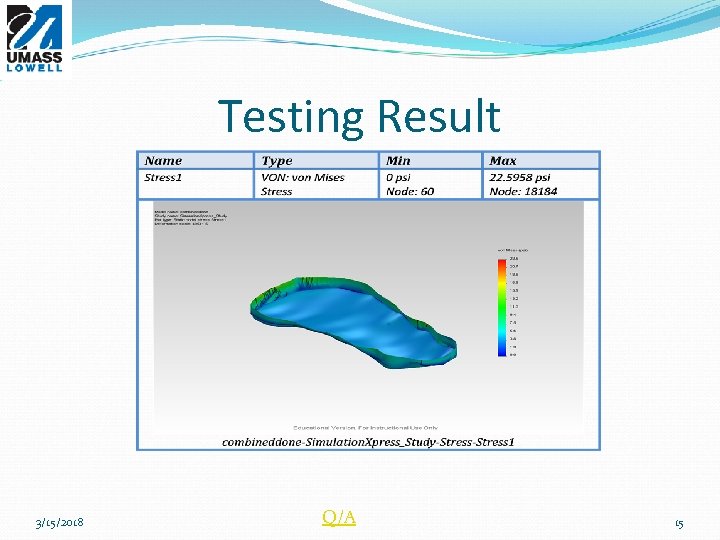

Testing Result 3/15/2018 Q/A 15

Testing Result 3/15/2018 Q/A 15

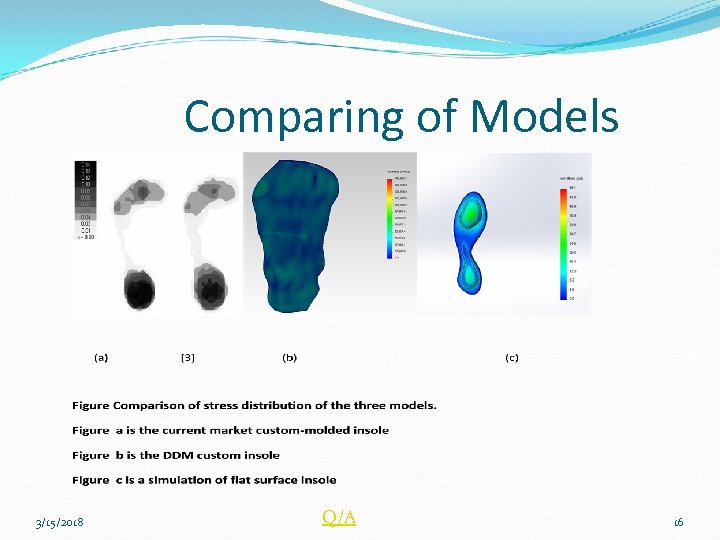

Comparing of Models 3/15/2018 Q/A 16

Comparing of Models 3/15/2018 Q/A 16

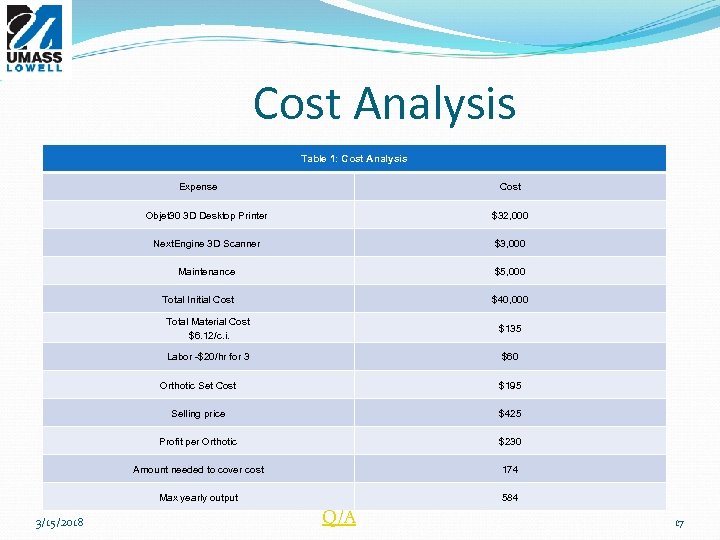

Cost Analysis Table 1: Cost Analysis Expense Cost Objet 30 3 D Desktop Printer $32, 000 Next. Engine 3 D Scanner $3, 000 Maintenance $5, 000 Total Initial Cost $40, 000 Total Material Cost $6. 12/c. i. $135 Labor -$20/hr for 3 $60 Orthotic Set Cost Selling price $425 Profit per Orthotic $230 Amount needed to cover cost 174 Max yearly output 3/15/2018 $195 584 Q/A 17

Cost Analysis Table 1: Cost Analysis Expense Cost Objet 30 3 D Desktop Printer $32, 000 Next. Engine 3 D Scanner $3, 000 Maintenance $5, 000 Total Initial Cost $40, 000 Total Material Cost $6. 12/c. i. $135 Labor -$20/hr for 3 $60 Orthotic Set Cost Selling price $425 Profit per Orthotic $230 Amount needed to cover cost 174 Max yearly output 3/15/2018 $195 584 Q/A 17

Conclusion The DDM process allows for a quick transition between design and production Foot scanning is a faster, more efficient way of measuring foot dimensions Design alterations can be made easily in the CAD package 3/15/2018 Q/A 18

Conclusion The DDM process allows for a quick transition between design and production Foot scanning is a faster, more efficient way of measuring foot dimensions Design alterations can be made easily in the CAD package 3/15/2018 Q/A 18

Acknowledgment Capstone Advisors Byungki Kim, Ph. D. 3/15/2018 Stephen Johnston, Ph. D. Q/A 19

Acknowledgment Capstone Advisors Byungki Kim, Ph. D. 3/15/2018 Stephen Johnston, Ph. D. Q/A 19

Any Questions? DDM Overview SME Competition Idea Generation/Insole Background Why DDM ? Design Process Preliminary Testing Result Cost Analysis Conclusion Acknowledgements 3/15/2018 20

Any Questions? DDM Overview SME Competition Idea Generation/Insole Background Why DDM ? Design Process Preliminary Testing Result Cost Analysis Conclusion Acknowledgements 3/15/2018 20