4e7edcd72f9505accbf805affb8d8fe8.ppt

- Количество слайдов: 24

Current Regulations for Offshore Safety Cory WJ Sutherland February 10 th, 2011 www. intertek. com

Current Regulations for Offshore Safety Cory WJ Sutherland February 10 th, 2011 www. intertek. com

Nuclear and Aerospace Industries Heavily regulated due to consequences of failure • 3 Mile Island • Chernobyl • Challenger Disaster • Airline Crashes Much of what we can learn about risk, maintenance, inspection and the safe operation of equipment comes from these industries. Creation of Institute of Nuclear Power Operations (INPO) www. intertek. com

Nuclear and Aerospace Industries Heavily regulated due to consequences of failure • 3 Mile Island • Chernobyl • Challenger Disaster • Airline Crashes Much of what we can learn about risk, maintenance, inspection and the safe operation of equipment comes from these industries. Creation of Institute of Nuclear Power Operations (INPO) www. intertek. com

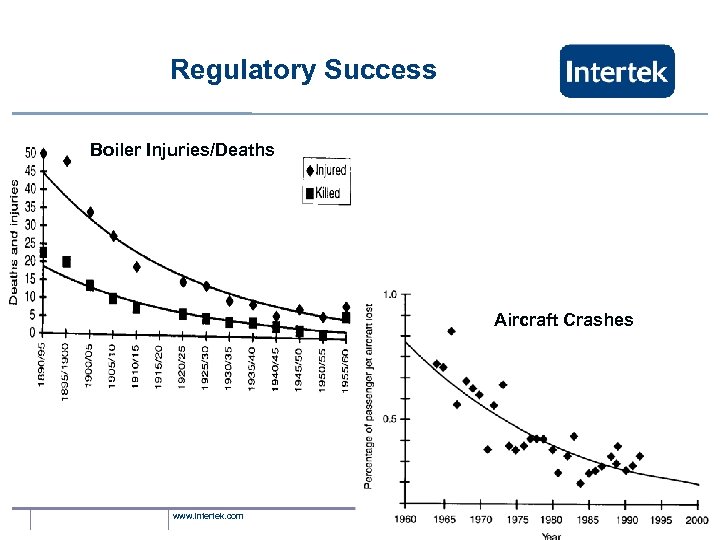

Regulatory Success Boiler Injuries/Deaths Aircraft Crashes www. intertek. com

Regulatory Success Boiler Injuries/Deaths Aircraft Crashes www. intertek. com

1984 UCC Facility - Bhopal, India Introduction of water into large tank containing methyl isocyanate Exothermic reaction - vapors vented to atmosphere Scrubbers and flares not working Tons of MIC escaped 20, 000 people sickened 2, 000 dying within weeks Many more died later Resulted in the Chemical Industry’s Responsible Care Program www. intertek. com

1984 UCC Facility - Bhopal, India Introduction of water into large tank containing methyl isocyanate Exothermic reaction - vapors vented to atmosphere Scrubbers and flares not working Tons of MIC escaped 20, 000 people sickened 2, 000 dying within weeks Many more died later Resulted in the Chemical Industry’s Responsible Care Program www. intertek. com

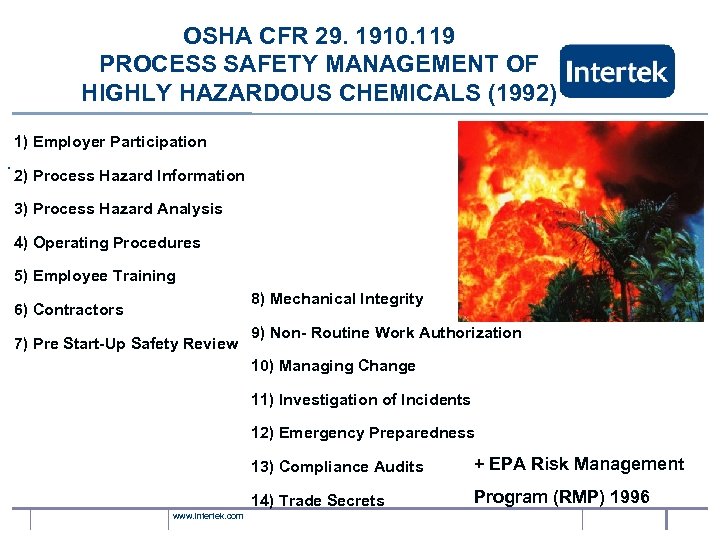

OSHA CFR 29. 1910. 119 PROCESS SAFETY MANAGEMENT OF HIGHLY HAZARDOUS CHEMICALS (1992) 1) Employer Participation. 2) Process Hazard Information 3) Process Hazard Analysis 4) Operating Procedures 5) Employee Training 8) Mechanical Integrity 6) Contractors 7) Pre Start-Up Safety Review 9) Non- Routine Work Authorization 10) Managing Change 11) Investigation of Incidents 12) Emergency Preparedness 13) Compliance Audits 14) Trade Secrets www. intertek. com + EPA Risk Management Program (RMP) 1996

OSHA CFR 29. 1910. 119 PROCESS SAFETY MANAGEMENT OF HIGHLY HAZARDOUS CHEMICALS (1992) 1) Employer Participation. 2) Process Hazard Information 3) Process Hazard Analysis 4) Operating Procedures 5) Employee Training 8) Mechanical Integrity 6) Contractors 7) Pre Start-Up Safety Review 9) Non- Routine Work Authorization 10) Managing Change 11) Investigation of Incidents 12) Emergency Preparedness 13) Compliance Audits 14) Trade Secrets www. intertek. com + EPA Risk Management Program (RMP) 1996

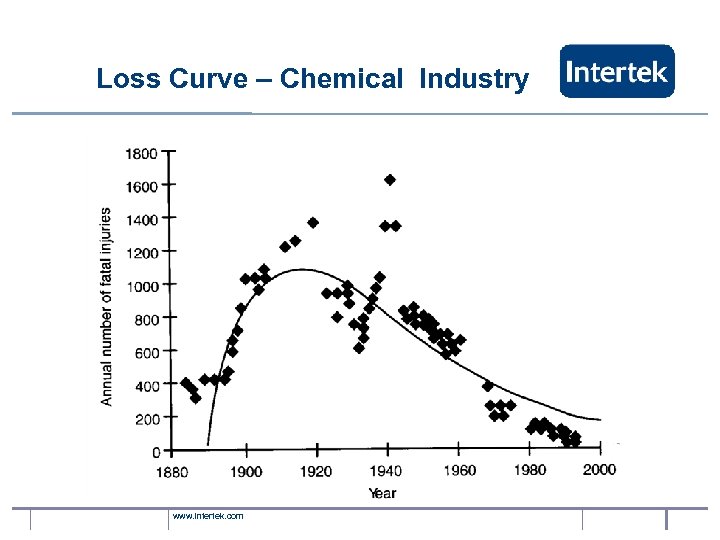

Loss Curve – Chemical Industry www. intertek. com

Loss Curve – Chemical Industry www. intertek. com

BP Texas City BP Isomerization Unit www. intertek. com

BP Texas City BP Isomerization Unit www. intertek. com

Intertek Asset Integrity Management Process & Operations Monitoring Information Technology Business & Finance Training Regulations Asset Integrity Management Inspection Materials Maintenance HSE Management www. intertek. com QA Design

Intertek Asset Integrity Management Process & Operations Monitoring Information Technology Business & Finance Training Regulations Asset Integrity Management Inspection Materials Maintenance HSE Management www. intertek. com QA Design

A. I. M. Evolution Best Practice Facilities “A comprehensive, fully integrated, strategy, process and culture directed at gaining greater lifetime effectiveness, value, availability, profitability and return from production and manufacturing assets”. Risk / Reliability Assessment, Control and Management are Essential to Successful Asset Management. www. intertek. com

A. I. M. Evolution Best Practice Facilities “A comprehensive, fully integrated, strategy, process and culture directed at gaining greater lifetime effectiveness, value, availability, profitability and return from production and manufacturing assets”. Risk / Reliability Assessment, Control and Management are Essential to Successful Asset Management. www. intertek. com

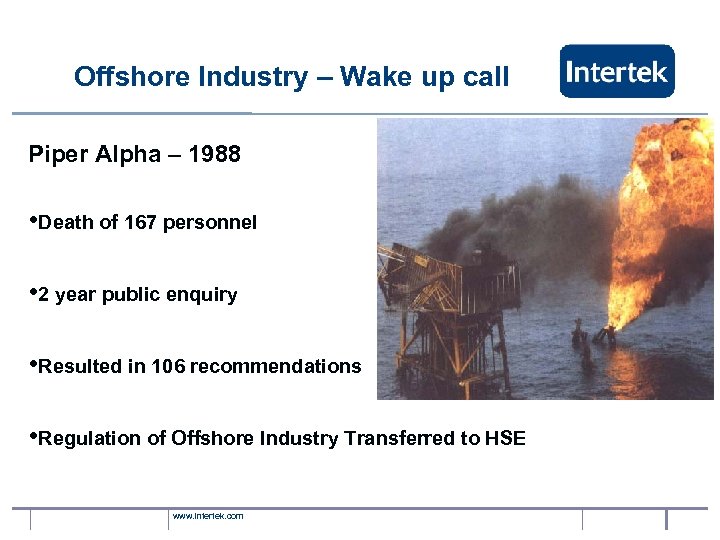

Offshore Industry – Wake up call Piper Alpha – 1988 • Death of 167 personnel • 2 year public enquiry • Resulted in 106 recommendations • Regulation of Offshore Industry Transferred to HSE www. intertek. com

Offshore Industry – Wake up call Piper Alpha – 1988 • Death of 167 personnel • 2 year public enquiry • Resulted in 106 recommendations • Regulation of Offshore Industry Transferred to HSE www. intertek. com

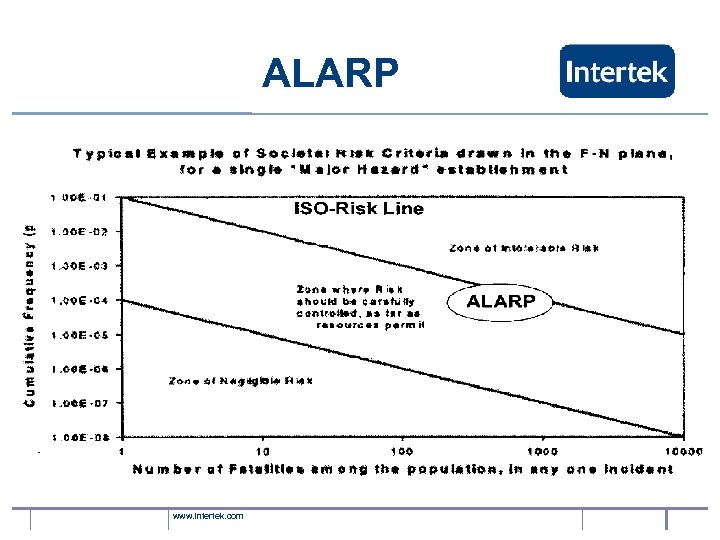

Offshore Installations Safety Case Regulations (OSCR) • By 1995 every offshore installation possessed a safety case that had been accepted and approved by the HSE • Each safety case demonstrated that the company had a safety management system in place and had identified risks and reduced them to acceptably low levels (ALARP) • Early lessons in applying safety case included: Excessive complexity Reliance on quantitative risk assessments Lack of workforce involvement • In 2005 OSCR was revised in order to enhance the safety cases value to the operator. Opinion is that the safety case and using a risk based approach is successful and now is used in UK, Norway and Canada www. intertek. com

Offshore Installations Safety Case Regulations (OSCR) • By 1995 every offshore installation possessed a safety case that had been accepted and approved by the HSE • Each safety case demonstrated that the company had a safety management system in place and had identified risks and reduced them to acceptably low levels (ALARP) • Early lessons in applying safety case included: Excessive complexity Reliance on quantitative risk assessments Lack of workforce involvement • In 2005 OSCR was revised in order to enhance the safety cases value to the operator. Opinion is that the safety case and using a risk based approach is successful and now is used in UK, Norway and Canada www. intertek. com

Risk Management of Offshore Events High L I k High Likelihood Negligible Consequence High Consequence e l I h o o Low Likelihood Low Consequence d High Consequence Low Negligible Consequence www. intertek. com Very Serious

Risk Management of Offshore Events High L I k High Likelihood Negligible Consequence High Consequence e l I h o o Low Likelihood Low Consequence d High Consequence Low Negligible Consequence www. intertek. com Very Serious

ALARP www. intertek. com

ALARP www. intertek. com

US Offshore Industry 1978 MMS formed - Regulatory Oversight of Offshore Drilling and Collecting Revenue 1991 Published Notice requesting comments on strategies to promote safety and environmental protection, specifically a requirement that outer continental shelf operators develop and maintain and implement a “Safety and Environmental Management Program”(SEMP) API asked MMS to postpone action so it could develop an offshore safety standard 1993 API published a Recommended Practice guidance document (API 75) 1996 MMS conceded that the best it could do was to encourage voluntary compliance with SEMP At the time of the BP blowout, about 20 years later, MMS still had not published a rule mandating all operators to have plans to manage safety and environmental risks www. intertek. com

US Offshore Industry 1978 MMS formed - Regulatory Oversight of Offshore Drilling and Collecting Revenue 1991 Published Notice requesting comments on strategies to promote safety and environmental protection, specifically a requirement that outer continental shelf operators develop and maintain and implement a “Safety and Environmental Management Program”(SEMP) API asked MMS to postpone action so it could develop an offshore safety standard 1993 API published a Recommended Practice guidance document (API 75) 1996 MMS conceded that the best it could do was to encourage voluntary compliance with SEMP At the time of the BP blowout, about 20 years later, MMS still had not published a rule mandating all operators to have plans to manage safety and environmental risks www. intertek. com

API RP 75 • Objective of this Recommended Practice (RP) is to form the basis for a Safety and Environmental Management Program (SEMP) • Original document (1993) did not cover standard safety management or drill rigs (current edition is from circa 2004) • Recommended Practice, use of “should” or “may” (i. e. “not compulsory”) • Has been utilized by MMS to evaluate companies • Discusses all phases of life cycle: • Design, Construction, Start up • Operation, Inspection Maintenance • Linked to other API RP’s www. intertek. com

API RP 75 • Objective of this Recommended Practice (RP) is to form the basis for a Safety and Environmental Management Program (SEMP) • Original document (1993) did not cover standard safety management or drill rigs (current edition is from circa 2004) • Recommended Practice, use of “should” or “may” (i. e. “not compulsory”) • Has been utilized by MMS to evaluate companies • Discusses all phases of life cycle: • Design, Construction, Start up • Operation, Inspection Maintenance • Linked to other API RP’s www. intertek. com

BP Horizon – Go. M April 20, 2010 Deepwater Horizon Blow-Out/Loss-of-Control/Ignition The incident resulted in 11 deaths on the platform and injured 17 others On July 15, the leak was stopped by capping the gushing wellhead, after it had released about [est. ] 4. 9 million barrels (780× 10^3 m 3), or 205. 8 million gallons of crude oil. www. intertek. com

BP Horizon – Go. M April 20, 2010 Deepwater Horizon Blow-Out/Loss-of-Control/Ignition The incident resulted in 11 deaths on the platform and injured 17 others On July 15, the leak was stopped by capping the gushing wellhead, after it had released about [est. ] 4. 9 million barrels (780× 10^3 m 3), or 205. 8 million gallons of crude oil. www. intertek. com

Government Response On 15 June, the President articulated a three-part response plan to the Gulf oil spill: • Environmental cleanup • Development of a recovery and restoration plan • Steps to ensure that disaster like this does not happen again (National Commission) On May 27, after a 30 -day interagency examination of deepwater drilling operations, Secretary Ken Salazar directed MMS to issue a six-month moratorium on all drilling at a water depth of more than 500 feet in the Go. M and the Pacific Ocean. The Department lifted the moratorium on October 12, seven weeks ahead of its scheduled November 30 expiration. On September 30, a few weeks before lifting the moratorium, the Department promulgated new regulations on topics such as well casing and cementing, blowout preventers, safety certification, emergency response, and worker training. www. intertek. com

Government Response On 15 June, the President articulated a three-part response plan to the Gulf oil spill: • Environmental cleanup • Development of a recovery and restoration plan • Steps to ensure that disaster like this does not happen again (National Commission) On May 27, after a 30 -day interagency examination of deepwater drilling operations, Secretary Ken Salazar directed MMS to issue a six-month moratorium on all drilling at a water depth of more than 500 feet in the Go. M and the Pacific Ocean. The Department lifted the moratorium on October 12, seven weeks ahead of its scheduled November 30 expiration. On September 30, a few weeks before lifting the moratorium, the Department promulgated new regulations on topics such as well casing and cementing, blowout preventers, safety certification, emergency response, and worker training. www. intertek. com

Minerals Management Service Not long after the tragedy, its repercussions shifted to the Minerals Management Service (MMS), the Federal Agency responsible for overseeing the well’s drilling and operation. Nineteen days after the rig sank, Secretary of the Interior Ken Salazar announced his intention to strip MMS’s safety and environmental enforcement responsibilities away from its leasing, revenue collection, and permitting functions, and to place the former within a “separate and independent” entity. A week later, he announced MMS would be reorganized into three separate entities with distinct missions: • Bureau of Ocean Energy Management; • Bureau of Safety and Environmental Enforcement; • Office of Natural Resources Revenue. By June 19, Ken Salazar had discarded the “MMS” name altogether. www. intertek. com

Minerals Management Service Not long after the tragedy, its repercussions shifted to the Minerals Management Service (MMS), the Federal Agency responsible for overseeing the well’s drilling and operation. Nineteen days after the rig sank, Secretary of the Interior Ken Salazar announced his intention to strip MMS’s safety and environmental enforcement responsibilities away from its leasing, revenue collection, and permitting functions, and to place the former within a “separate and independent” entity. A week later, he announced MMS would be reorganized into three separate entities with distinct missions: • Bureau of Ocean Energy Management; • Bureau of Safety and Environmental Enforcement; • Office of Natural Resources Revenue. By June 19, Ken Salazar had discarded the “MMS” name altogether. www. intertek. com

June 2009 – MMS 30 CFR Part 250 MMS Proposes that Operators develop and implement a Safety and Environmental Management System (SEMS) to address oil and gas operations in the Outer Continental Shelf. The MMS analyzed accidental panel reports, incident reports and non compliance and determined that the root cause of most safety and environmental accidents is caused by four elements. The SEMP program would therefore consist of four elements: • Hazards Analysis • Management of Change • Operating Procedures • Mechanical Integrity www. intertek. com

June 2009 – MMS 30 CFR Part 250 MMS Proposes that Operators develop and implement a Safety and Environmental Management System (SEMS) to address oil and gas operations in the Outer Continental Shelf. The MMS analyzed accidental panel reports, incident reports and non compliance and determined that the root cause of most safety and environmental accidents is caused by four elements. The SEMP program would therefore consist of four elements: • Hazards Analysis • Management of Change • Operating Procedures • Mechanical Integrity www. intertek. com

30 CFR Part 250 In addition to the Industry complying with the 4 elements and electing to model their SEMS Program after a comprehensive SEMS program like API RP 75, lessees and operators are also encouraged to consider implementing ISO 9001 and ISO 14001 The proposed rule will also require operators to have their SEMS program audited at least twice every 3 years by a qualified, independent 3 rd party www. intertek. com

30 CFR Part 250 In addition to the Industry complying with the 4 elements and electing to model their SEMS Program after a comprehensive SEMS program like API RP 75, lessees and operators are also encouraged to consider implementing ISO 9001 and ISO 14001 The proposed rule will also require operators to have their SEMS program audited at least twice every 3 years by a qualified, independent 3 rd party www. intertek. com

National Commission Report Lessons Learned – Industry, Government, Energy Policy • Changing business as usual The record shows that without effective government oversight, the offshore oil and gas industry will not adequately reduce the risk of accidents, nor prepare effectively to respond in emergencies • Absence of Adequate Safety Culture in the Offshore U. S. Oil and Gas Industry • API , (Expert or Advocate)? • Learning from Accidents • INPO for Oil • Self-Policing Safety Organization for the Oil and Gas Industry • Challenge of Change www. intertek. com

National Commission Report Lessons Learned – Industry, Government, Energy Policy • Changing business as usual The record shows that without effective government oversight, the offshore oil and gas industry will not adequately reduce the risk of accidents, nor prepare effectively to respond in emergencies • Absence of Adequate Safety Culture in the Offshore U. S. Oil and Gas Industry • API , (Expert or Advocate)? • Learning from Accidents • INPO for Oil • Self-Policing Safety Organization for the Oil and Gas Industry • Challenge of Change www. intertek. com

Some of the Overlapping Authorities, Regulations and Players • MMS • API • US Coast Guard • EPA • DOT • NOAA • Army Corps of Engineers www. intertek. com

Some of the Overlapping Authorities, Regulations and Players • MMS • API • US Coast Guard • EPA • DOT • NOAA • Army Corps of Engineers www. intertek. com

![Future – “What Could Be” Initially, a delay [for Revised Regulations & Enforcement] is Future – “What Could Be” Initially, a delay [for Revised Regulations & Enforcement] is](https://present5.com/presentation/4e7edcd72f9505accbf805affb8d8fe8/image-23.jpg) Future – “What Could Be” Initially, a delay [for Revised Regulations & Enforcement] is likely due to reorganization of MMS May include Mandated [Compulsory] Inclusion of all 12 elements (such as OSHA 1910. 119 PSM) May include Safety Case Approach (i. e. OSCR Framework) Inevitably the Industry will become more Prescriptive with Verification of Compliance by 3 rd party audits Needs understanding and expertise in all AIM elements, including Software Tools, Human Factors [experience], and education in Behavioral Safety. www. intertek. com

Future – “What Could Be” Initially, a delay [for Revised Regulations & Enforcement] is likely due to reorganization of MMS May include Mandated [Compulsory] Inclusion of all 12 elements (such as OSHA 1910. 119 PSM) May include Safety Case Approach (i. e. OSCR Framework) Inevitably the Industry will become more Prescriptive with Verification of Compliance by 3 rd party audits Needs understanding and expertise in all AIM elements, including Software Tools, Human Factors [experience], and education in Behavioral Safety. www. intertek. com

For More Information Please Visit Our Website www. intertek. com THE DIFFERENCE BETWEEN THE AVERAGE PERFORMER AND THE PACESETTER IS: THE PACESETTER IMPLEMENTS. www. intertek. com

For More Information Please Visit Our Website www. intertek. com THE DIFFERENCE BETWEEN THE AVERAGE PERFORMER AND THE PACESETTER IS: THE PACESETTER IMPLEMENTS. www. intertek. com