536809b397e7543bbc582931455f3a88.ppt

- Количество слайдов: 14

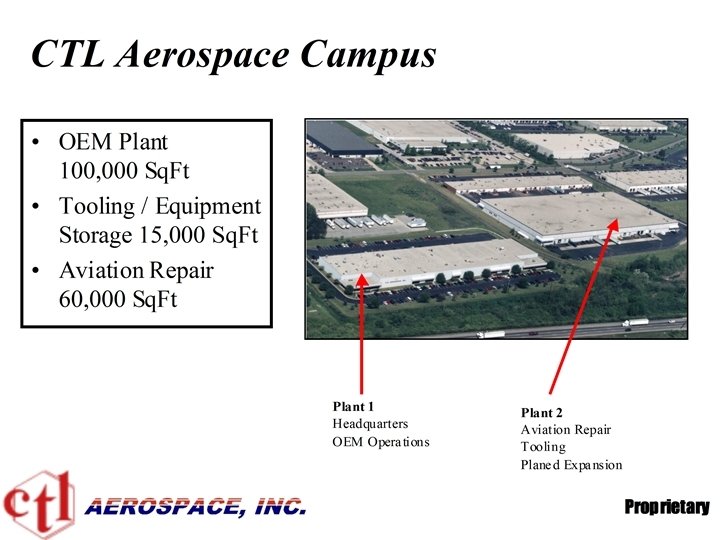

CTL Aerospace, Inc. Capabilities Presentation CTL Aerospace, Inc. 5616 Spellmire Drive, Cincinnati, OH 45246 ISO 9001 -2008 AND AS 9100 C Registered Contact: John Irwin – VP Sales/Marketing NADCAP Certified Email: info@ctlaerospace. com Office: 513 -874 -7900 Fax: 513 -874 -2499 www. ctlaerospace. com kkkk Proprietary

Proprietary

Approved Composite Supplier for: • • • GE Aircraft Engines Lockheed Martin Northrop Grumman Pratt & Whitney Hamilton Sundstrand Sikorsky Aircraft Vought Aircraft Rolls-Royce General Dynamics Proprietary

Processing & Material Capabilities • Resin Transfer Molding • Isostatic Laminates – Autoclave – Oven • Compression Molding • Filament Winding • Bondments Materials- Resin • • • Ceramic Matrix Composites (2000 ºF) Avimid N ( 700ºF) AFR-PE ( 700ºF) PMR-15 ( 600ºF) Bismaleimide -BMI Phenolic Epoxy Cyanate Ester Polyester Materials- Reinforcement • • • Glass Carbon / Graphite Aramids (Kevlar) Quartz Nextel Fiber (Aluminized Fiber) Proprietary

Equipment Summary List: • • Composite Processing Equipment 9 Autoclaves 22 Presses 13 Ovens 3 RTM (Resin Transfer Molding) Systems 21 CNC Machine Centers 5 Non-Conventional Machine Centers Proprietary

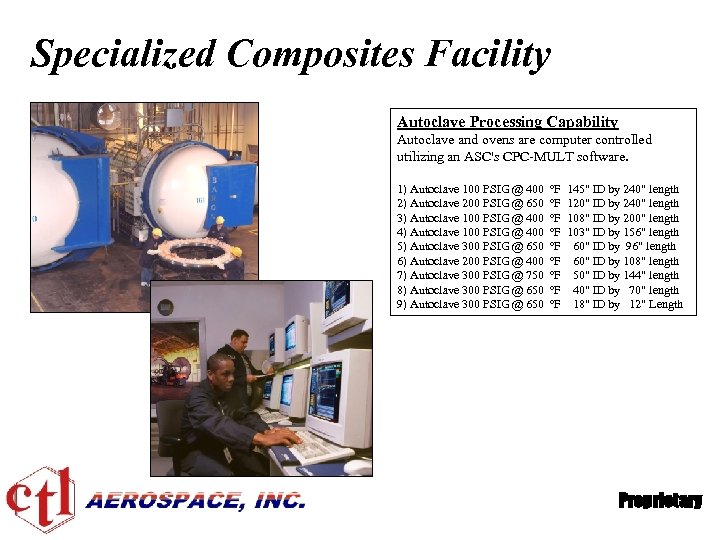

Specialized Composites Facility Autoclave Processing Capability Autoclave and ovens are computer controlled utilizing an ASC's CPC-MULT software. 1) Autoclave 100 PSIG @ 400 2) Autoclave 200 PSIG @ 650 3) Autoclave 100 PSIG @ 400 4) Autoclave 100 PSIG @ 400 5) Autoclave 300 PSIG @ 650 6) Autoclave 200 PSIG @ 400 7) Autoclave 300 PSIG @ 750 8) Autoclave 300 PSIG @ 650 9) Autoclave 300 PSIG @ 650 ºF ºF ºF 145" ID by 240" length 120" ID by 240" length 108" ID by 200" length 103" ID by 156" length 60" ID by 96" length 60" ID by 108" length 50" ID by 144" length 40" ID by 70" length 18" ID by 12" Length Proprietary

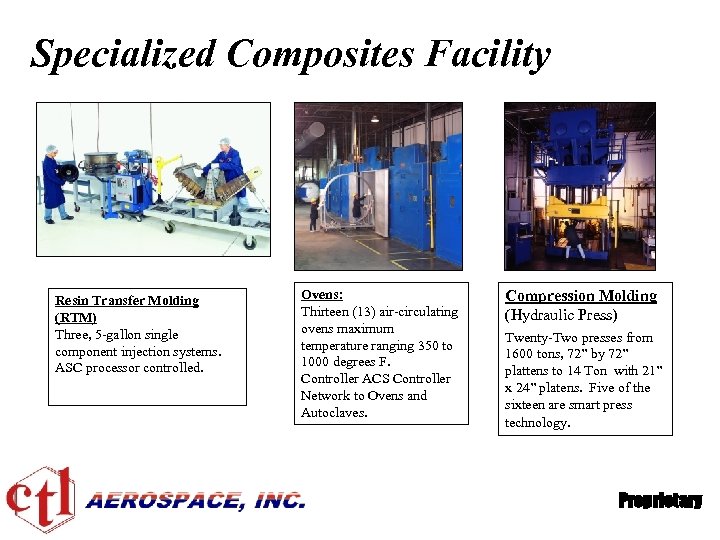

Specialized Composites Facility Resin Transfer Molding (RTM) Three, 5 -gallon single component injection systems. ASC processor controlled. Ovens: Thirteen (13) air-circulating ovens maximum temperature ranging 350 to 1000 degrees F. Controller ACS Controller Network to Ovens and Autoclaves. Compression Molding (Hydraulic Press) Twenty-Two presses from 1600 tons, 72” by 72” plattens to 14 Ton with 21” x 24” platens. Five of the sixteen are smart press technology. Proprietary

Specialized Composites Facility CNC Machining • Haas 5 Axis VMC • Thermwood 5 -Axis Router • Cell Con 4 Axis HMC • (2) Johnford 4 Axis VMCs (Troyke Rotary Table) • (2) Mazak 4 Axis VMC • Hurco 4 Axis VMC • Chevalier 3 axis VMC • (2) Fadel 3 Axis VMC • MAHO 600, True 4 Axis Milling Center • Acer 3 Axis Bridgeport Knee Mill • (2) Clausing / Colchester CNC Lathes • Haas CNC Lathe • Parish Mill - 12' * 12 ' , 4 Axis • (3) Renishaw MP 12 Probing Systems • Chevalier CNC Turning Center Proprietary

Specialized Composites Facility Non-Conventional Equipment • Thermwood 5 Axis Router • Thermwood Cartesian 5 Axis Water-jet • Flow System Water-jet Cleaning/Striping System • Plastic Media Striping Cabinet • Mc. Clean Anderson Filament Winding System Proprietary

Specialized Composites Facility Class 10, 000 Micro Clean-room to Fed Std 209 Platinum Faro. Arm CMM Cellularized Manufacturing Material Kit Cutting Proprietary

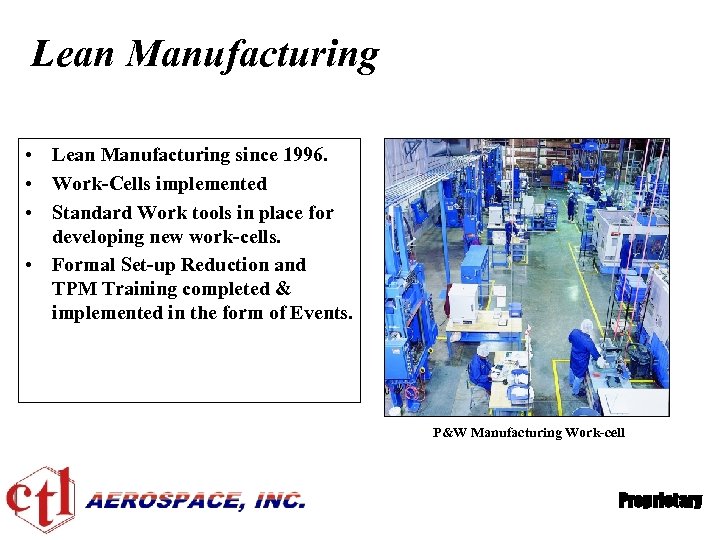

Lean Manufacturing • Lean Manufacturing since 1996. • Work-Cells implemented • Standard Work tools in place for developing new work-cells. • Formal Set-up Reduction and TPM Training completed & implemented in the form of Events. P&W Manufacturing Work-cell Proprietary

Continuous Improvement • Corrective Action Board • Quality Control Process Charts (QCPC) • Relentless Root Cause Analysis (RRCA) Six Sigma • Eight years experience using GE Supplied Six Sigma Tools A. C. E. Initiative (Achieving Competitive Excellence) • First UTC Supplier to achieve Silver Level Certification Proprietary

Quality Assurance • CMM Dimensional Verification • Configuration Management • Non Destructive Testing • Mechanical Testing • ISO 9001 -2000 Registered • AS-9100 B Registered Proprietary

Registrations and Certifications • ISO 9001: 2008 & AS 9100 C Registered • FAA Repair Station Certificate • EASA Certificate • NADCAP Certificate Proprietary

536809b397e7543bbc582931455f3a88.ppt