4237730f7c80c12d76abe4769eb5d043.ppt

- Количество слайдов: 31

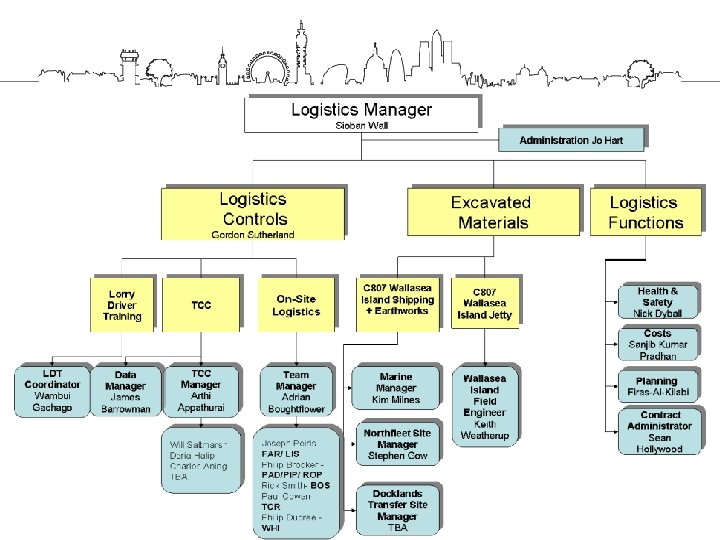

Crossrail Central - Logistics Gordon Sutherland Adrian Boughtflower

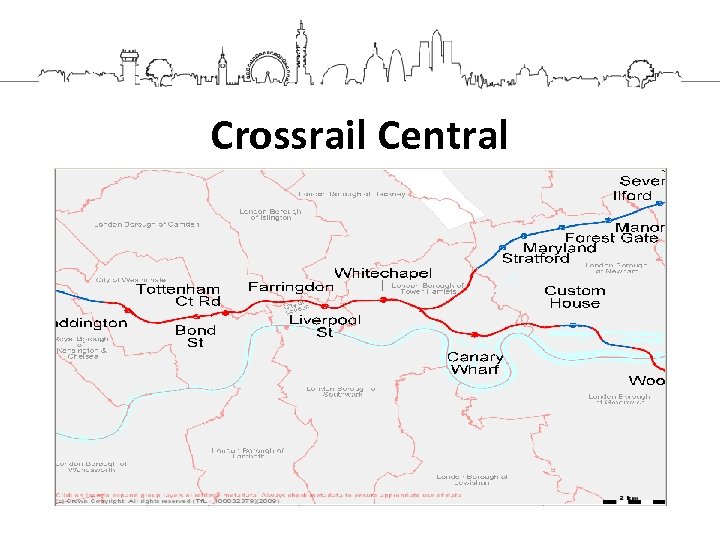

Crossrail Central

Traffic co-ordination & Logistics • Background • Sustainable transport • Lorry routes • Traffic Co-ordination Centre • Lorry Holding Areas • Lorry driver training • Freight Operators Recognition Scheme • Construction

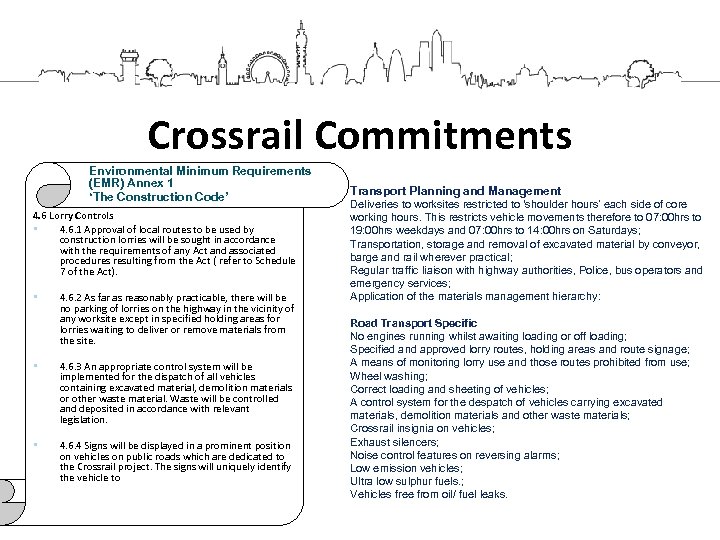

Crossrail Commitments Environmental Minimum Requirements (EMR) Annex 1 ‘The Construction Code’ 4. 6 Lorry Controls • 4. 6. 1 Approval of local routes to be used by construction lorries will be sought in accordance with the requirements of any Act and associated procedures resulting from the Act ( refer to Schedule 7 of the Act). • 4. 6. 2 As far as reasonably practicable, there will be no parking of lorries on the highway in the vicinity of any worksite except in specified holding areas for lorries waiting to deliver or remove materials from the site. • 4. 6. 3 An appropriate control system will be implemented for the dispatch of all vehicles containing excavated material, demolition materials or other waste material. Waste will be controlled and deposited in accordance with relevant legislation. • 4. 6. 4 Signs will be displayed in a prominent position on vehicles on public roads which are dedicated to the Crossrail project. The signs will uniquely identify the vehicle to Transport Planning and Management Deliveries to worksites restricted to ‘shoulder hours’ each side of core working hours. This restricts vehicle movements therefore to 07: 00 hrs to 19: 00 hrs weekdays and 07: 00 hrs to 14: 00 hrs on Saturdays; Transportation, storage and removal of excavated material by conveyor, barge and rail wherever practical; Regular traffic liaison with highway authorities, Police, bus operators and emergency services; Application of the materials management hierarchy: Road Transport Specific No engines running whilst awaiting loading or off loading; Specified and approved lorry routes, holding areas and route signage; A means of monitoring lorry use and those routes prohibited from use; Wheel washing; Correct loading and sheeting of vehicles; A control system for the despatch of vehicles carrying excavated materials, demolition materials and other waste materials; Crossrail insignia on vehicles; Exhaust silencers; Noise control features on reversing alarms; Low emission vehicles; Ultra low sulphur fuels. ; Vehicles free from oil/ fuel leaks.

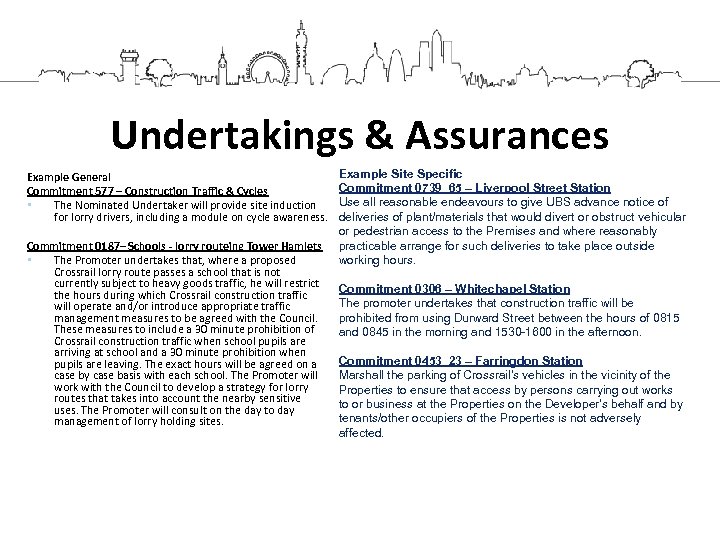

Undertakings & Assurances Example General Commitment 577 – Construction Traffic & Cycles • The Nominated Undertaker will provide site induction for lorry drivers, including a module on cycle awareness. Commitment 0187– Schools - lorry routeing Tower Hamlets • The Promoter undertakes that, where a proposed Crossrail lorry route passes a school that is not currently subject to heavy goods traffic, he will restrict the hours during which Crossrail construction traffic will operate and/or introduce appropriate traffic management measures to be agreed with the Council. These measures to include a 30 minute prohibition of Crossrail construction traffic when school pupils are arriving at school and a 30 minute prohibition when pupils are leaving. The exact hours will be agreed on a case by case basis with each school. The Promoter will work with the Council to develop a strategy for lorry routes that takes into account the nearby sensitive uses. The Promoter will consult on the day to day management of lorry holding sites. Example Site Specific Commitment 0739_65 – Liverpool Street Station Use all reasonable endeavours to give UBS advance notice of deliveries of plant/materials that would divert or obstruct vehicular or pedestrian access to the Premises and where reasonably practicable arrange for such deliveries to take place outside working hours. Commitment 0306 – Whitechapel Station The promoter undertakes that construction traffic will be prohibited from using Durward Street between the hours of 0815 and 0845 in the morning and 1530 -1600 in the afternoon. Commitment 0453_23 – Farringdon Station Marshall the parking of Crossrail's vehicles in the vicinity of the Properties to ensure that access by persons carrying out works to or business at the Properties on the Developer's behalf and by tenants/other occupiers of the Properties is not adversely affected.

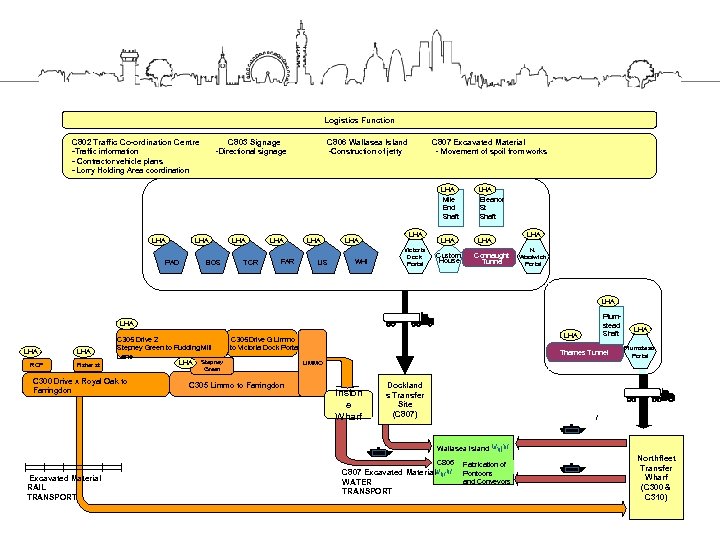

Logistics Function C 802 Traffic Co-ordination Centre -Traffic information - Contractor vehicle plans - Lorry Holding Area coordination C 803 Signage -Directional signage C 806 Wallasea Island -Construction of jetty C 807 Excavated Material - Movement of spoil from works LHA Mile End Shaft LHA PAD LHA BOS LHA TCR LHA FAR LHA LIS LHA WHI LHA Victoria Dock Portal LHA Eleanor St Shaft LHA Custom House Connaught Tunnel LHA N. Woolwich Portal LHA Plumstead Shaft LHA ROP LHA Fisher st LHA C 305 Drive G Limmo C 305 Drive Z to Victoria Dock Portal Stepney Green to Pudding Mill Lane LIMMO LHA Stepney C 300 Drive x Royal Oak to Farringdon Thames Tunnel LHA Plumstead Portal Green C 305 Limmo to Farringdon Inston e Wharf Dockland s Transfer Site (C 807) / Wallasea Island C 806 Excavated Material RAIL TRANSPORT C 807 Excavated Material WATER TRANSPORT Fabrication of Pontoons and Conveyors Northfleet Transfer Wharf (C 300 & C 310)

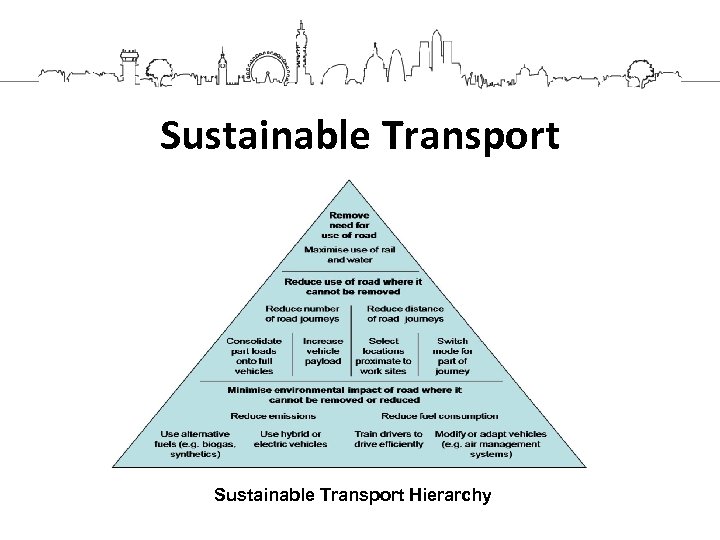

Sustainable Transport • Contractors must produce a Sustainable Transport Plan, prioritising the use of rail & water (where practicable) • Contractors must comply with Crossrail’s sustainability measures • Minimise part loads, maximise consolidation • Support the principles of the London Freight Plan

Sustainable Transport Hierarchy

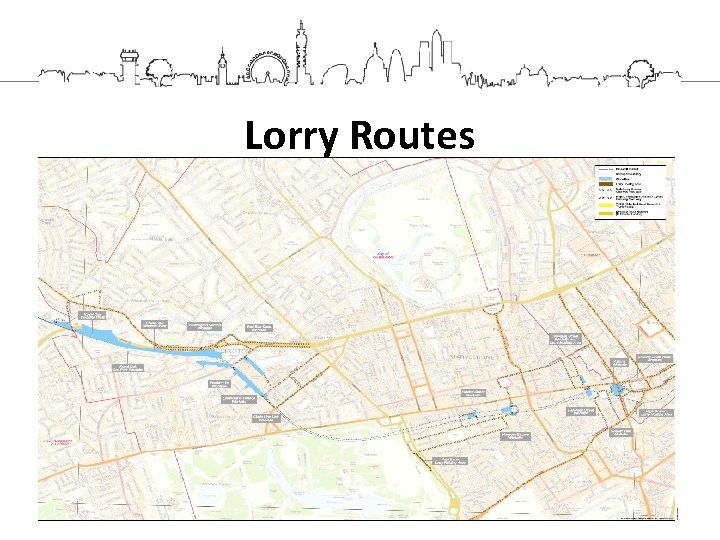

Lorry Routes

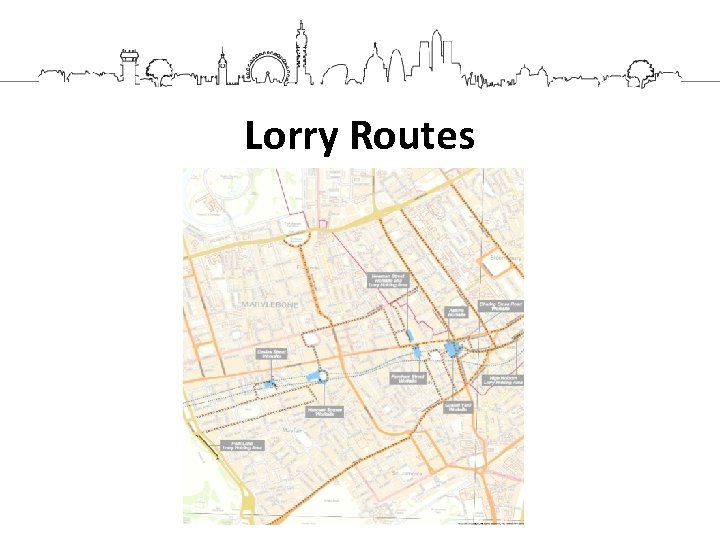

Lorry Routes

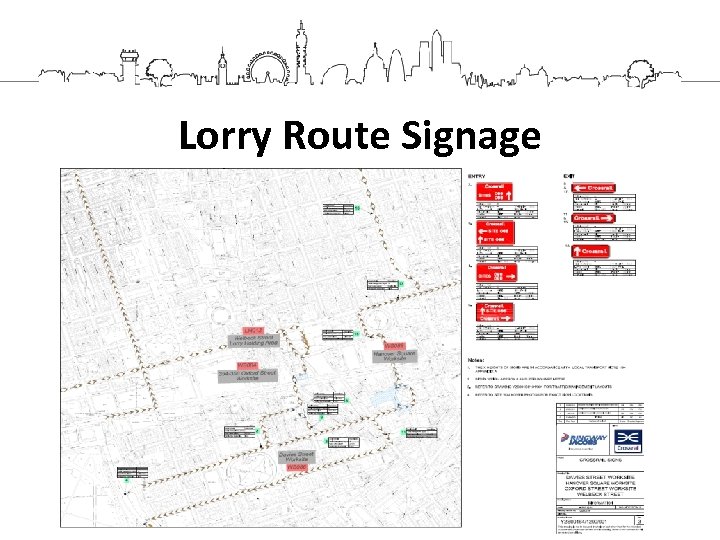

Lorry Route Signage

Vehicle Identification Contractor must ensure that all hauliers are given and display the agreed Crossrail identifying sign in the cabs of all their vehicles.

• Traffic Co-ordination Centre (TCC) central London To co-ordinate Crossrail traffic across contracts • To manage deliveries via the Vehicle Movement Booking System (VMBS) • Communication with external parties such as Police, Tf. L, local authorities etc, to obtain information on factors which could affect vehicle movements

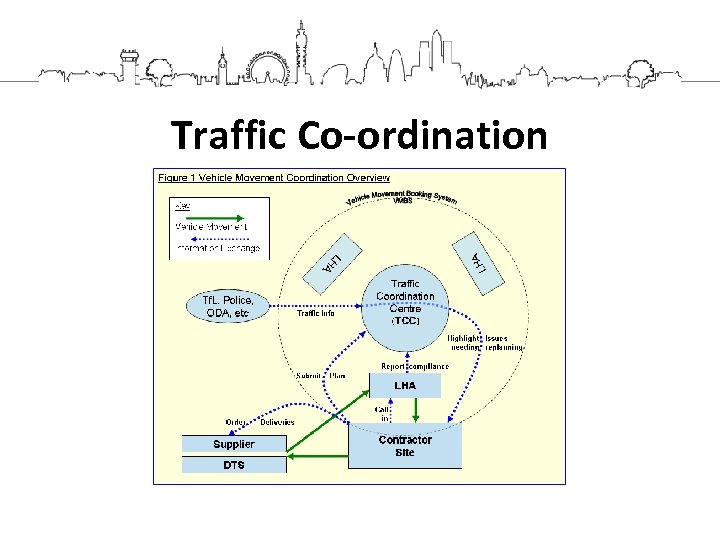

Traffic Co-ordination

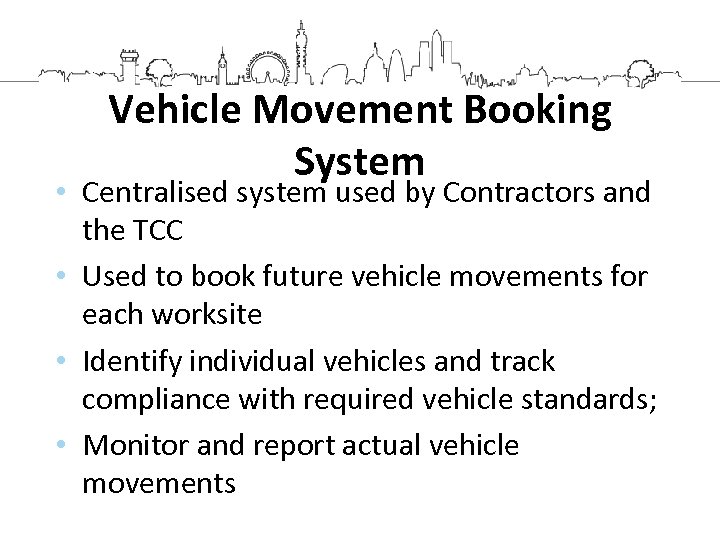

Vehicle Movement Booking System • Centralised system used by Contractors and the TCC • Used to book future vehicle movements for each worksite • Identify individual vehicles and track compliance with required vehicle standards; • Monitor and report actual vehicle movements

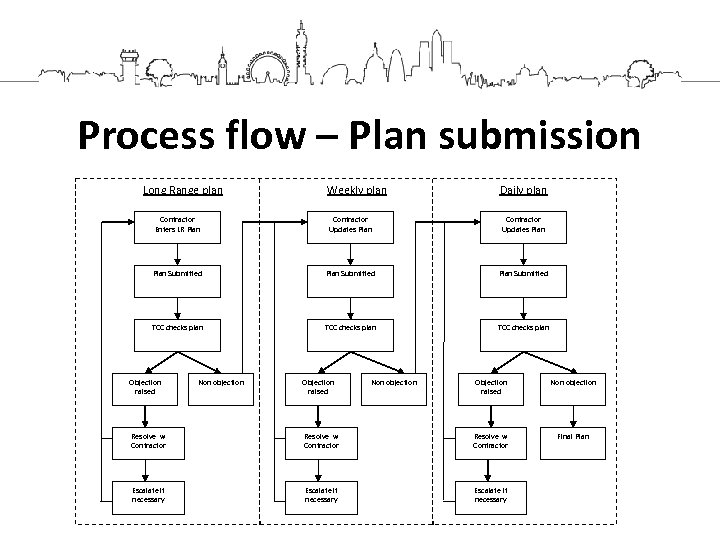

Process flow – Plan submission Long Range plan Weekly plan Daily plan Contractor Enters LR Plan Contractor Updates Plan Submitted TCC checks plan Objection raised Non objection Final Plan Resolve w Contractor Escalate if necessary

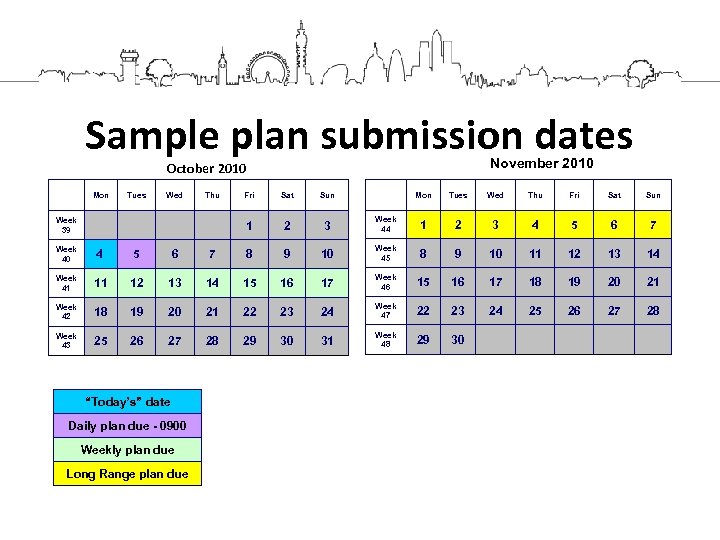

Sample plan submission dates November 2010 October 2010 Mon Tues Wed Thu Sat 2 3 Mon Tues Wed Thu Fri Sat Sun Week 44 1 2 3 4 5 6 7 Sun 1 Week 39 Fri Week 40 4 5 6 7 8 9 10 Week 45 8 9 10 11 12 13 14 Week 41 11 12 13 14 15 16 17 Week 46 15 16 17 18 19 20 21 Week 42 18 19 20 21 22 23 24 Week 47 22 23 24 25 26 27 28 Week 43 25 26 27 28 29 30 31 Week 48 29 30 “Today’s” date Daily plan due - 0900 Weekly plan due Long Range plan due

Lorry Holding Areas • Regulates flow of traffic to site • Vehicle safety checking point • Reduces the risk of congestion • Prevents vehicles circulating locally

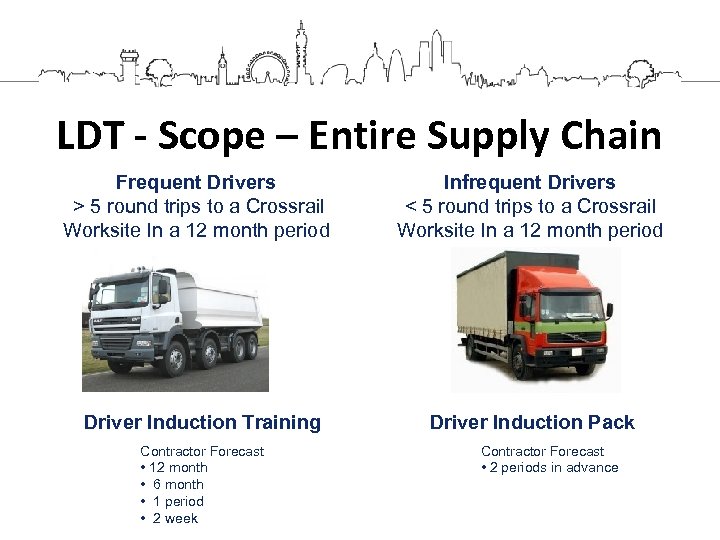

Lorry Driver Training (LDT) • A programme designed to train frequent drivers engaged on the project • 1 day course, focussing on sharing the road with vulnerable users (e. g. cyclists); and fuel efficiency (reducing emissions) • To date approximately 700 drivers have been trained • Help lorry drivers understand how they can contribute to reducing the threat of terrorism in London • Enable Crossrail to demonstrate best practice in construction road safety

LDT - Scope – Entire Supply Chain Frequent Drivers > 5 round trips to a Crossrail Worksite In a 12 month period Infrequent Drivers < 5 round trips to a Crossrail Worksite In a 12 month period Driver Induction Training Driver Induction Pack Contractor Forecast • 12 month • 6 month • 1 period • 2 week Contractor Forecast • 2 periods in advance

LDT - Course Benefits • Drivers complete a unique ‘Crossrail Centric’ driver training course to become a safer driver. • The course accumulates ‘Driver CPC’ periodic training of 7 hours. • Employers save on costs associated with 7 hours D CPC • Drivers gain a greater understanding of the safety issues related to sharing London’s roads with vulnerable road users. • Drivers gain an understanding of how they can ‘Contribute to reducing the Threat of Terrorism’. • Drivers gain a ‘Crossrail Induction Trained Driver’ certificate and ID Tag. • Provides CRL with a clear audit trail and the ability to demonstrate • that the requirements behind Undertaking 577 are being met.

Freight Operators Recognition Scheme (FORS) • Recognises & rewards excellence • Raises standards • Promotes sustainability

FORS • Contractors must ensure that they and any suppliers of any tier are registered with Tf. L’s FORS • Attain bronze standard as a minimum within 3 months of contract award • If not FORS registered, a suitable equivalent standard of achievement must be demonstrated

Vehicle safety equipment • Minimum set of safety equipment to be fitted to all vehicles • Vehicles > 3. 5 tonnes have additional safety requirements • Vehicle and Driver Safety Management Plan • Refer to Works Information Volume 2 B Part 26 Section 26. 14

Contractor Responsibilities Appoint a Logistics Manager with relevant competencies All Logistics activities within the site All Logistics activities to deliver the works All movement of plant, equipment, materials & people to and from site • The removal and treatment of all waste & excavated material • Coordination of all logistics activities with others • Develop, plan and implement logistics solutions to deliver the works • •

Contractor’s Logistics Plan • The Contractor shall; – ensure the plan is appropriate to all logistics activities included in the works. – train all employees, including subcontractors and suppliers of any tier, with direct or indirect responsibilities under the plan, on the contents of the plan that apply to its work. • The Contractor shall review and update the plan to ensure it remains suitable, adequate and effective as the works progress, ensure that it reflects the current status of the works and: – following any material change to the status of the works or Working Areas that has an impact on logistics requirements; – as instructed by the Project Manager; and – at least every 6 months. • The revised plan shall be submitted to the Project Manager for acceptance.

Contractor Plans • Excavated materials – – Duty of care Load tracking & compliance management Waste & recycling Forecast of daily volumes • Sustainable transport – Rail & water – Hierarchy • Modularisation & Off-Site Manufacture & Assembly – Improve site working areas

Contractor Plans • Consolidation – Minimise vehicle movements • Lorry Driver Induction Training – Training plan • Freight Operators – Selection criteria – Freight Operators Recognition Scheme

Contractor Plans • Control & Coordination of Vehicle Movements – – – TCC / VMBS / LHA Vehicle movement plan Contingency plan Training plan London Lorry Ban permits Site Traffic Control • Vehicle Security – All equipment, plant and materials • Vehicle Safety Equipment Standards – Vehicle & driver safety management plan – Safety equipment

Delivering a world-class affordable railway safely through effective partnerships

4237730f7c80c12d76abe4769eb5d043.ppt