bccb595c5fa8152e8c8f48121ba95c22.ppt

- Количество слайдов: 20

Cristopia (CIAT) energy savings systems in air conditioning

Cristopia (CIAT) energy savings systems in air conditioning

CRISTOPIA Energy Systems l l Developed an original energy storage system in 1982 Became a subsidary of CIAT in January 1988 ñ LOCATION l l l Head office & factory in Vence (French Riviera) French Commercial Office located near Paris Asian Office in Kuala Lumpur (Malaysia) ñ WORLD-WIDE REPRESENTATION l Distributors of CRISTOPIA technology in more than 25 countries ñ LICENCE AGREEMENTS l l in Japan : Mitsubishi Corporation in South Korea : D. I. Corporation in India : Cristopia Energy Systems India Private Ltd. (Joint Venture) in China : Hangzhou CIAT Refrigeration Equipments Co. Ltd More than 500 references in 25 countries 2. 5 millions of k. Wh daily shifted 150 MWe saved

CRISTOPIA Energy Systems l l Developed an original energy storage system in 1982 Became a subsidary of CIAT in January 1988 ñ LOCATION l l l Head office & factory in Vence (French Riviera) French Commercial Office located near Paris Asian Office in Kuala Lumpur (Malaysia) ñ WORLD-WIDE REPRESENTATION l Distributors of CRISTOPIA technology in more than 25 countries ñ LICENCE AGREEMENTS l l in Japan : Mitsubishi Corporation in South Korea : D. I. Corporation in India : Cristopia Energy Systems India Private Ltd. (Joint Venture) in China : Hangzhou CIAT Refrigeration Equipments Co. Ltd More than 500 references in 25 countries 2. 5 millions of k. Wh daily shifted 150 MWe saved

BASICS OF THERMAL ENERGY STORAGE

BASICS OF THERMAL ENERGY STORAGE

WHY STORE ENERGY ? l to size a chiller to satisfy the average load instead of the maximum load (few hours per day or even per year) ñ the chiller runs on a continuous basis l to increase plant capacity l to increase system reliability (back-up) l to increase system efficiency (no short cycle) l to protect the environment : – reduce CO 2 emissions – limit the use of CFC's or HCFC's l for energy management (off-peak electricity period) l to reduce system operating costs

WHY STORE ENERGY ? l to size a chiller to satisfy the average load instead of the maximum load (few hours per day or even per year) ñ the chiller runs on a continuous basis l to increase plant capacity l to increase system reliability (back-up) l to increase system efficiency (no short cycle) l to protect the environment : – reduce CO 2 emissions – limit the use of CFC's or HCFC's l for energy management (off-peak electricity period) l to reduce system operating costs

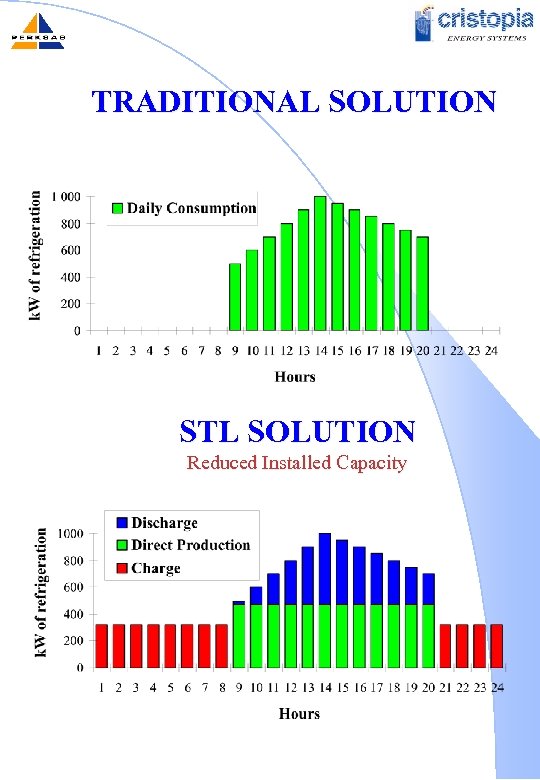

TRADITIONAL SOLUTION STL SOLUTION Reduced Installed Capacity

TRADITIONAL SOLUTION STL SOLUTION Reduced Installed Capacity

Energy management by CRISTOPIA Thermal Energy Storage l Reduce – – – – l chiller size by 30 to 70% use of refrigerant by 50 to 80% cooling tower installation space for plant maintenance running cost CO 2 emissions Increase – cooling capacity from existing chiller – plant utilization – equipment life l Additional benefits – avail yourself to a back-up system – shift cooling load from peak hours to off-peak period

Energy management by CRISTOPIA Thermal Energy Storage l Reduce – – – – l chiller size by 30 to 70% use of refrigerant by 50 to 80% cooling tower installation space for plant maintenance running cost CO 2 emissions Increase – cooling capacity from existing chiller – plant utilization – equipment life l Additional benefits – avail yourself to a back-up system – shift cooling load from peak hours to off-peak period

APPLICATION FIELDS AIR CONDITIONING l l l Office buildings Hotels Hospitals Banks Conference centres Computer rooms Airports Clean rooms Supermarkets Sports centres Theatres, cinemas, TV studios

APPLICATION FIELDS AIR CONDITIONING l l l Office buildings Hotels Hospitals Banks Conference centres Computer rooms Airports Clean rooms Supermarkets Sports centres Theatres, cinemas, TV studios

APPLICATION FIELDS INDUSTRIAL PROCESS COOLING l l l Dairy and food industries Bottling plants Slaughter houses Meat industries Cold storage Central kitchens Breweries Laboratories Pharmaceutical industries Chemical plants Refineries Computing rooms

APPLICATION FIELDS INDUSTRIAL PROCESS COOLING l l l Dairy and food industries Bottling plants Slaughter houses Meat industries Cold storage Central kitchens Breweries Laboratories Pharmaceutical industries Chemical plants Refineries Computing rooms

CRISTOPIA LATENT HEAT STORAGE STL FOR : l l AIR CONDITIONING INDUSTRIAL APPLICATIONS For a better management and use of electricity

CRISTOPIA LATENT HEAT STORAGE STL FOR : l l AIR CONDITIONING INDUSTRIAL APPLICATIONS For a better management and use of electricity

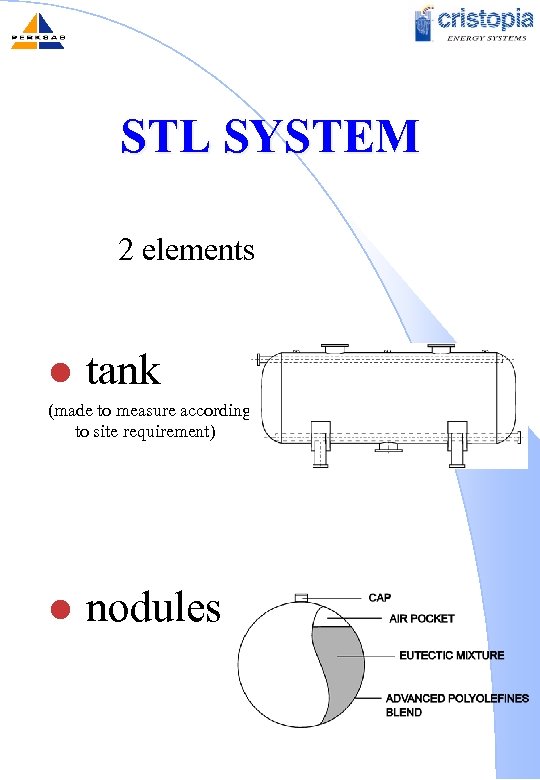

STL SYSTEM 2 elements l tank (made to measure according to site requirement) l nodules

STL SYSTEM 2 elements l tank (made to measure according to site requirement) l nodules

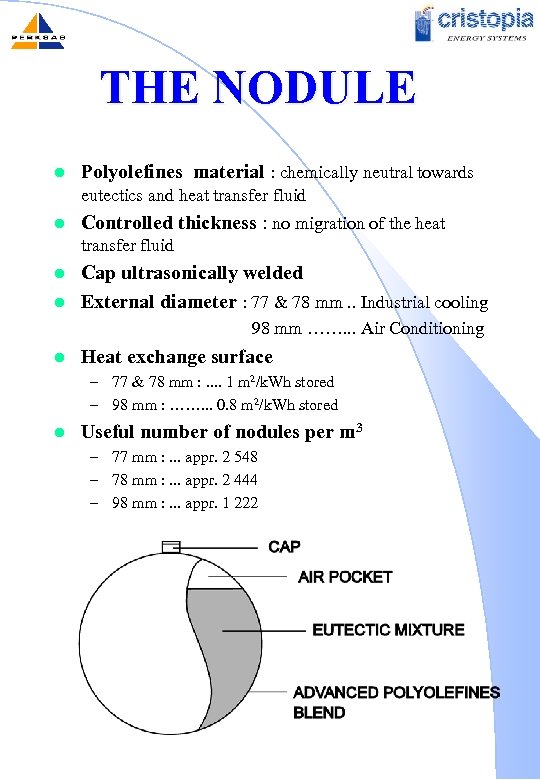

THE NODULE l Polyolefines material : chemically neutral towards eutectics and heat transfer fluid l Controlled thickness : no migration of the heat transfer fluid l l Cap ultrasonically welded External diameter : 77 & 78 mm. . Industrial cooling 98 mm ……. . . Air Conditioning l Heat exchange surface – 77 & 78 mm : . . 1 m 2/k. Wh stored – 98 mm : ……. . . 0. 8 m 2/k. Wh stored l Useful number of nodules per m 3 – 77 mm : . . . appr. 2 548 – 78 mm : . . . appr. 2 444 – 98 mm : . . . appr. 1 222

THE NODULE l Polyolefines material : chemically neutral towards eutectics and heat transfer fluid l Controlled thickness : no migration of the heat transfer fluid l l Cap ultrasonically welded External diameter : 77 & 78 mm. . Industrial cooling 98 mm ……. . . Air Conditioning l Heat exchange surface – 77 & 78 mm : . . 1 m 2/k. Wh stored – 98 mm : ……. . . 0. 8 m 2/k. Wh stored l Useful number of nodules per m 3 – 77 mm : . . . appr. 2 548 – 78 mm : . . . appr. 2 444 – 98 mm : . . . appr. 1 222

TESTS of the PRODUCT ñ CEA PCM ageing ñ ECOLE des MINES de PARIS Nodule mechanical strength ñ CETIAT STL thermal performances ñ COSTIC STL thermal performances ñ CSTB STL durability

TESTS of the PRODUCT ñ CEA PCM ageing ñ ECOLE des MINES de PARIS Nodule mechanical strength ñ CETIAT STL thermal performances ñ COSTIC STL thermal performances ñ CSTB STL durability

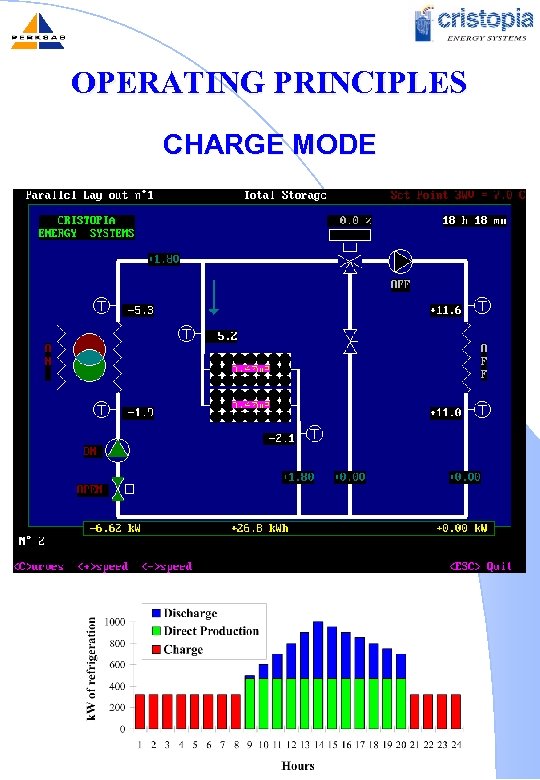

OPERATING PRINCIPLES CHARGE MODE

OPERATING PRINCIPLES CHARGE MODE

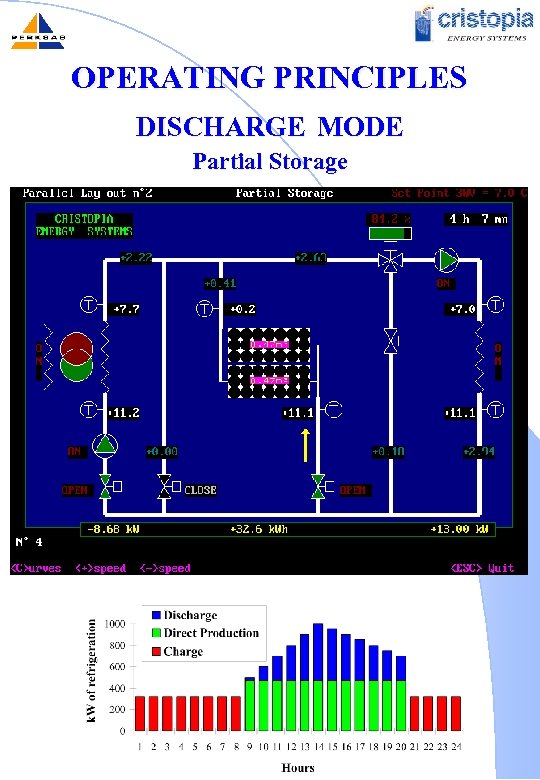

OPERATING PRINCIPLES DISCHARGE MODE Partial Storage

OPERATING PRINCIPLES DISCHARGE MODE Partial Storage

ADVANTAGES of the STL l l l Reliable system manufactured automatically with a high level quality control Storage temperatures adapted to usage (from -33°C to +27°C) Static system – maximum reliability – no risk of breakdown – no maintenance l l l Closed system with high service pressures allowed Adaptability to site Optimized time to store due to a high exchange surface High cooling capacity Eco-friendly system Large know-how based on more than 16 years of experience More than 500 references worldwide

ADVANTAGES of the STL l l l Reliable system manufactured automatically with a high level quality control Storage temperatures adapted to usage (from -33°C to +27°C) Static system – maximum reliability – no risk of breakdown – no maintenance l l l Closed system with high service pressures allowed Adaptability to site Optimized time to store due to a high exchange surface High cooling capacity Eco-friendly system Large know-how based on more than 16 years of experience More than 500 references worldwide

CRISTOPIA Energy Systems Airport, bank, hospital, office building, department store, central kitchen, computer room, food industry, dairy industry, . . .

CRISTOPIA Energy Systems Airport, bank, hospital, office building, department store, central kitchen, computer room, food industry, dairy industry, . . .

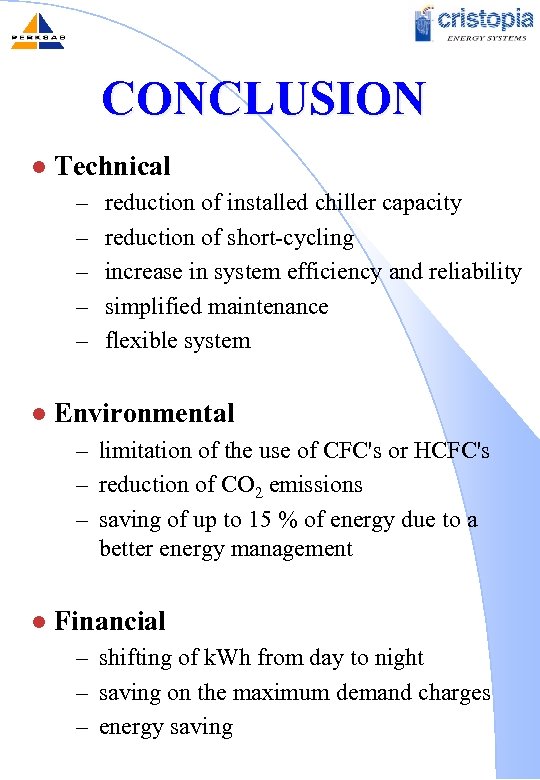

CONCLUSION l Technical – – – l reduction of installed chiller capacity reduction of short-cycling increase in system efficiency and reliability simplified maintenance flexible system Environmental – limitation of the use of CFC's or HCFC's – reduction of CO 2 emissions – saving of up to 15 % of energy due to a better energy management l Financial – shifting of k. Wh from day to night – saving on the maximum demand charges – energy saving

CONCLUSION l Technical – – – l reduction of installed chiller capacity reduction of short-cycling increase in system efficiency and reliability simplified maintenance flexible system Environmental – limitation of the use of CFC's or HCFC's – reduction of CO 2 emissions – saving of up to 15 % of energy due to a better energy management l Financial – shifting of k. Wh from day to night – saving on the maximum demand charges – energy saving

Contact us Maris Vitols Project manager l l l l Phone. : +371 7370722 Fax. : +371 7370723 Mobile. : +371 6488512 E-mail: maris. vitols@perksas. lt SAS PERKSAS Kr. Valdemara 118 - 407 Riga, LV 1013 www. perksas. lt

Contact us Maris Vitols Project manager l l l l Phone. : +371 7370722 Fax. : +371 7370723 Mobile. : +371 6488512 E-mail: maris. vitols@perksas. lt SAS PERKSAS Kr. Valdemara 118 - 407 Riga, LV 1013 www. perksas. lt